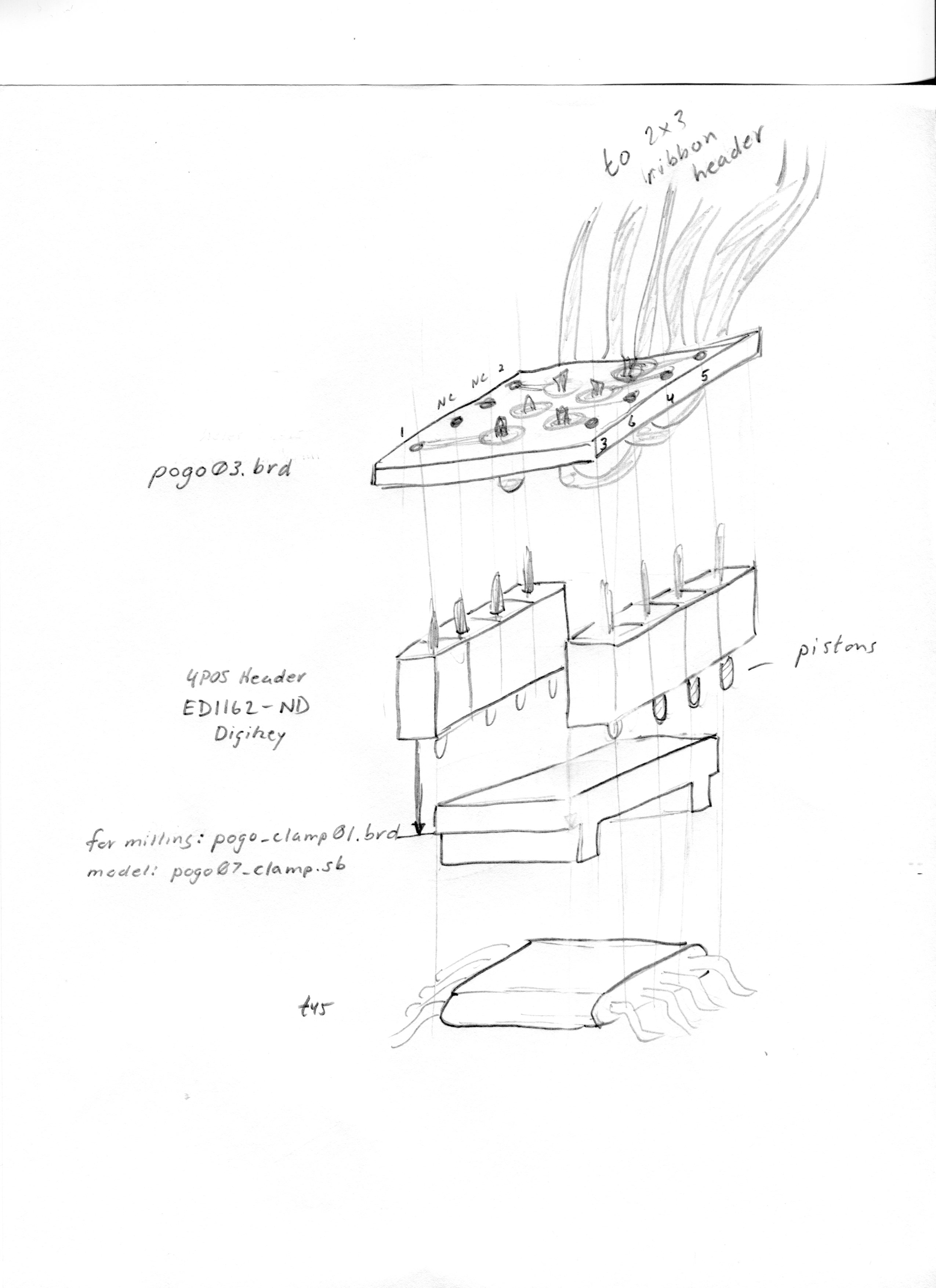

Connector using "pogo" pins to contact legs of tiny45 (and tiny44 in modified design) so that ISP 2x3 header is not required.

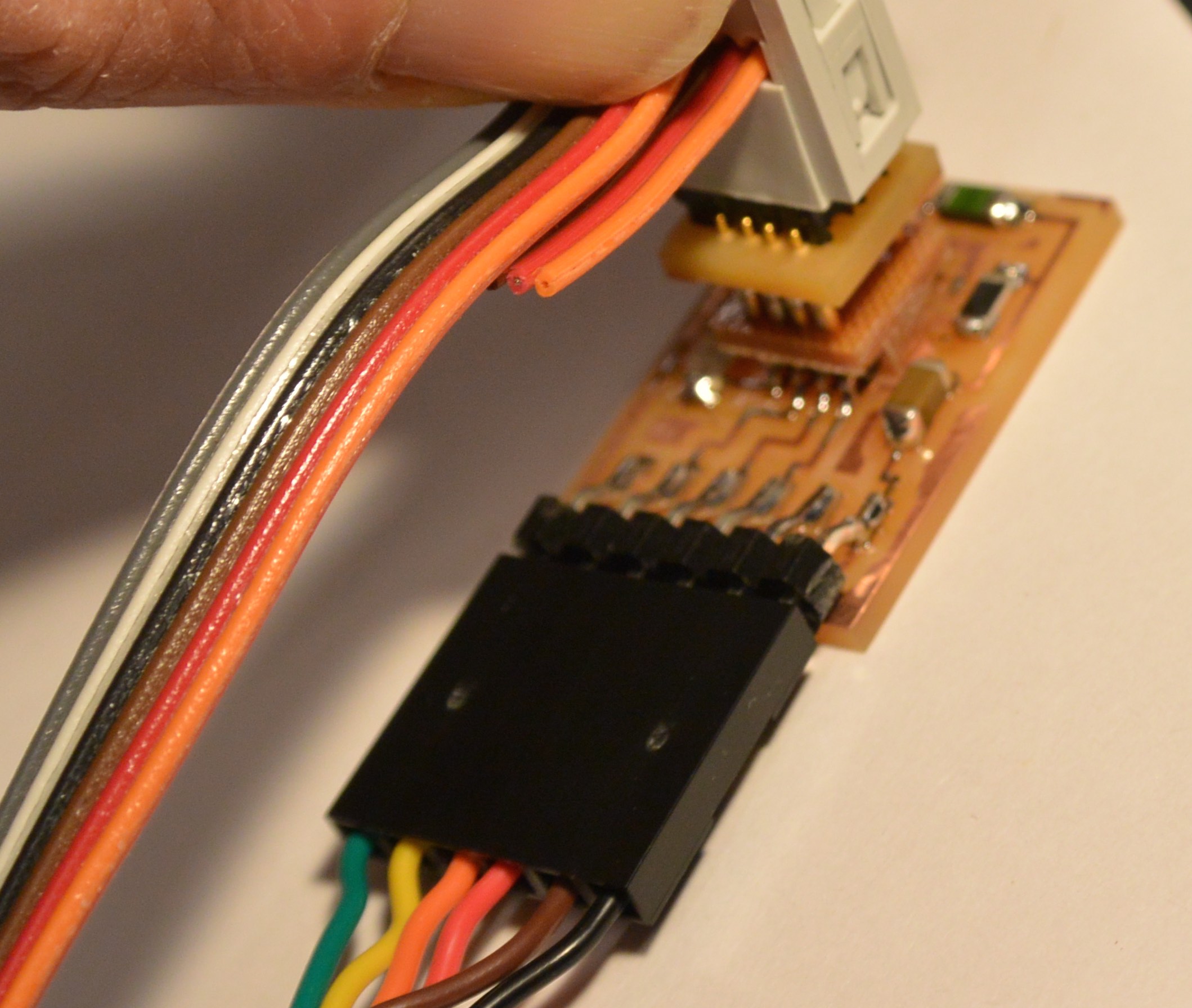

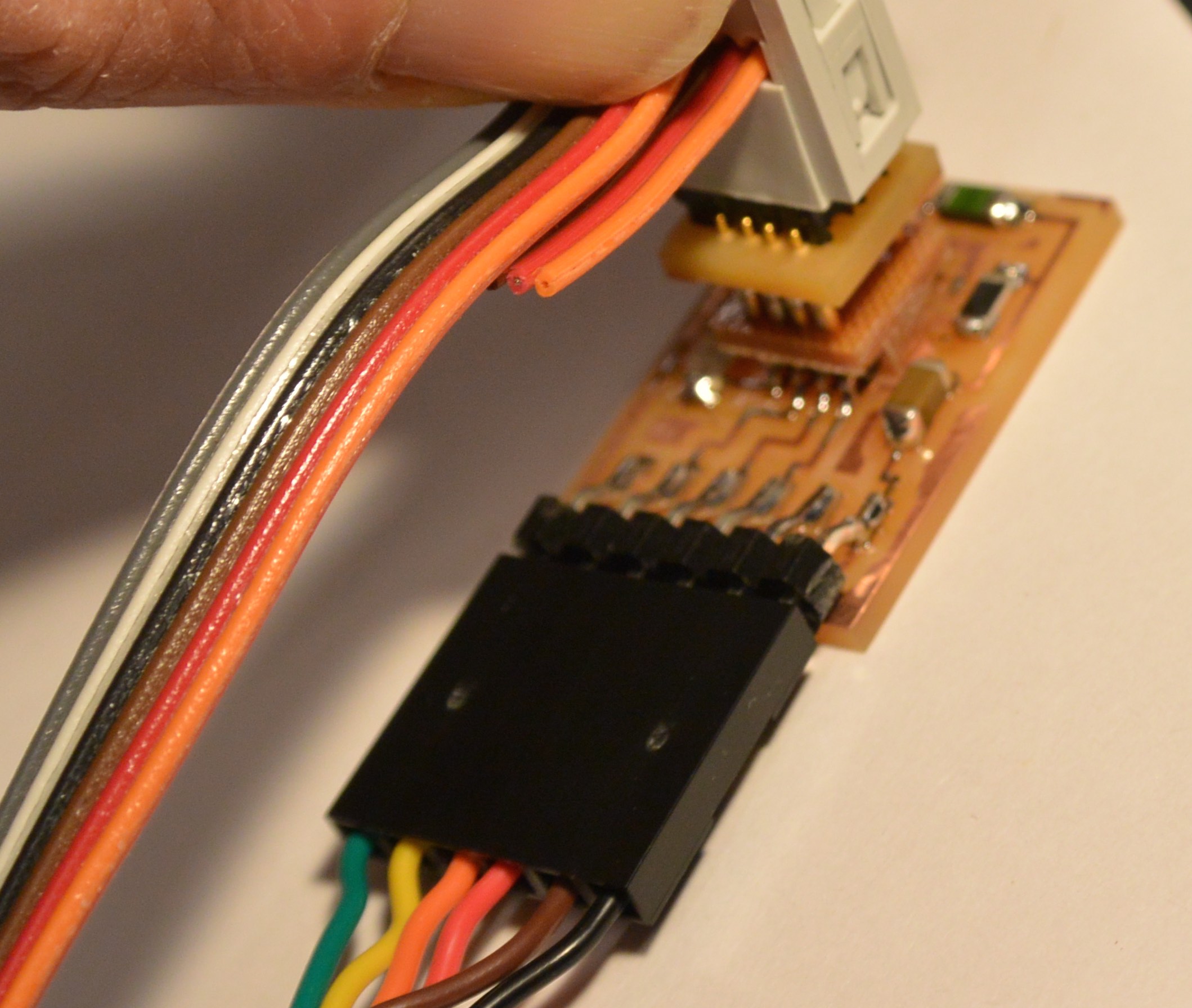

Below is the first iteration, in which premade four-pin headers are used for the pin contacts, and ribbon cable wires are soldered individually into holes in an upper circuit board. This design works well, but presents many problems in contruction, since ribbon wires are difficult to solder onto the board. Drawings and files are below for this iteration.

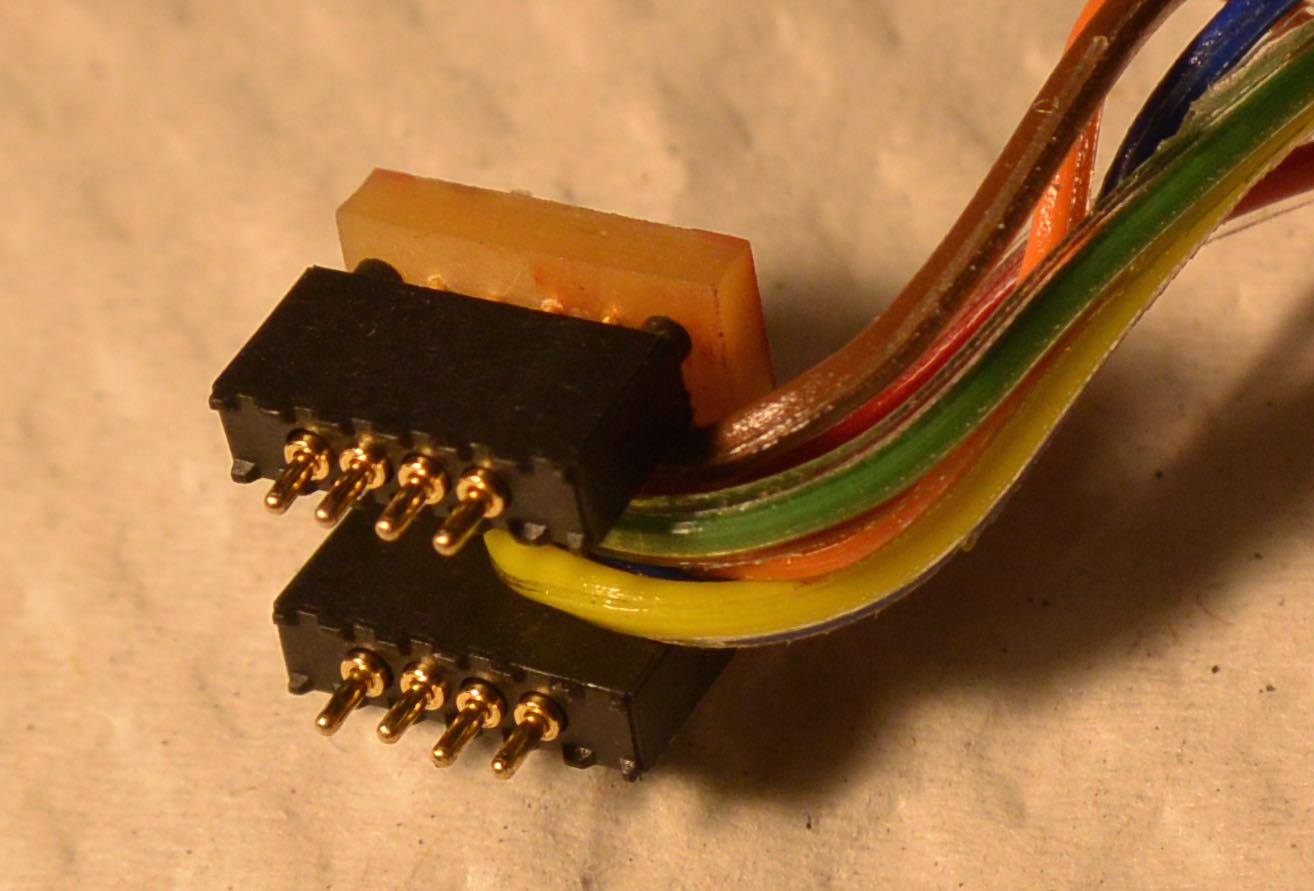

This is the top board and attached headers. Clamp is not shown, but will be glued between the headers.

This connector works for programming the tiny45. It takes some care to locate, and needs to be held in place while programming. It may need an extender to make it easier to push onto board.