PPE tips for working with corrosives and skin sensitizers

It is prudent when working with strong corrosives and/or skin sensitizers, to take extra precautions to ensure that you do not get these materials on exposed skin or clothing. The Entropy Resins Super Sap ONF hardener used in the composites assignment is both a category 1A chemical for skin corrosion and a category 1 skin sensitizer (more information on what this means is available in the How to read a Safety Data Sheet, for beginners tutorial). Since the composites assignment involves handling and placing large pieces of burlap or other fiber, wetted with epoxy, a single pair of lab gloves often not enough to keep you from getting epoxy on your skin and clothing. The simple PPE suggestions in this guide should go a long ways towards ensuring that you can work safely with these materials throughout your career.

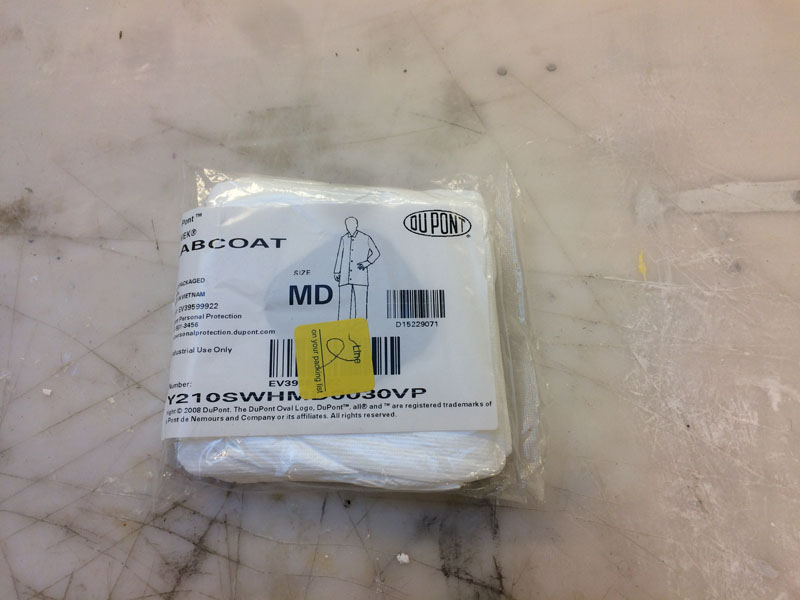

The first step is to obtain a Tyvek lab coat. If your project is quite large, and a coat is not sufficient, a pair of Tyvek coveralls costs just a little bit more. If your lab does not have these in stock, ask your lab manager to order some.

Tyvek clothing is tends to follow the latest trends and use the most stylish cuts. Feel free to embellish your coat with additional information such as your name.

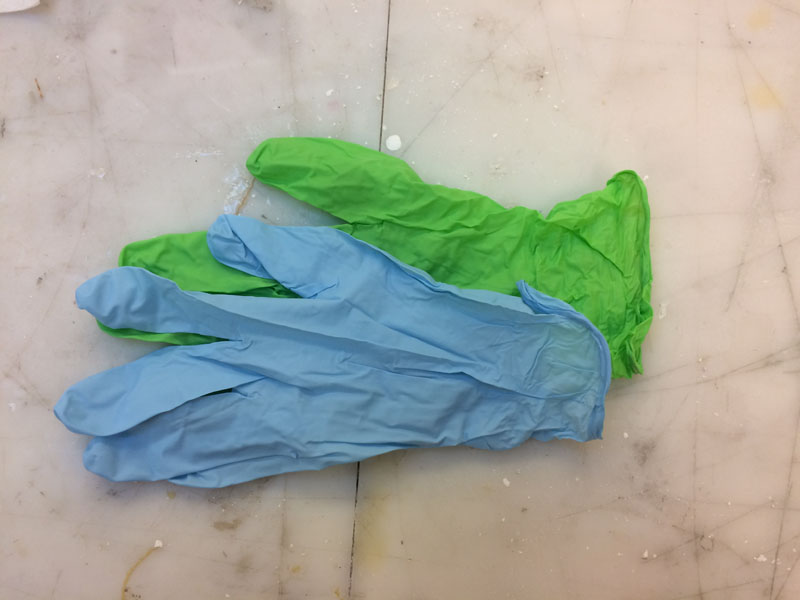

It is very helpful to wear two pairs of gloves when working with epoxy. The uncured material is so slippery, it's usually impossible to get a wet pair of gloves off without reaching inside the cuff. The second pair of gloves keeps the material off of your wrist. Better yet is to have a box of gloves with a longer cuff (green) that you put on first, and gloves with a standard cuff (blue) that you wear over them. This can be a helpful strategy for doing small-scale work, that may not necessitate a lab coat, while protecting your wrists from exposure during glove changes.

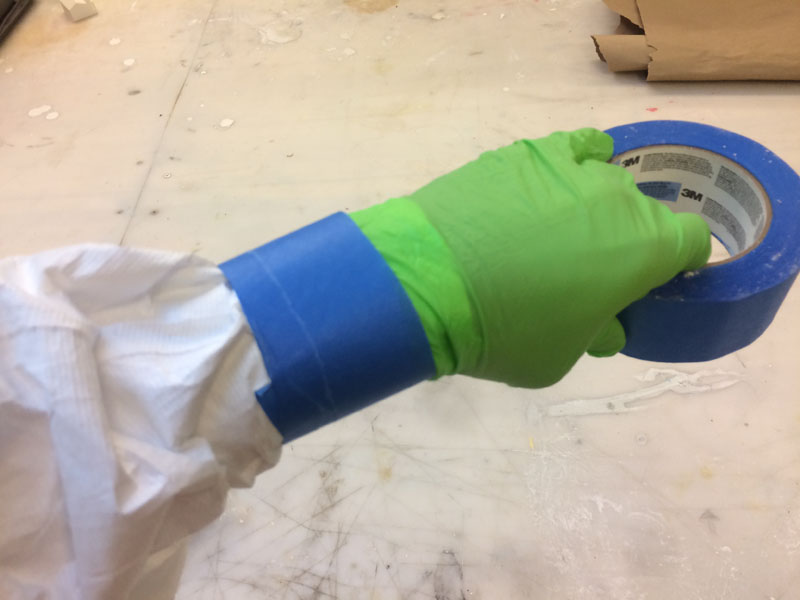

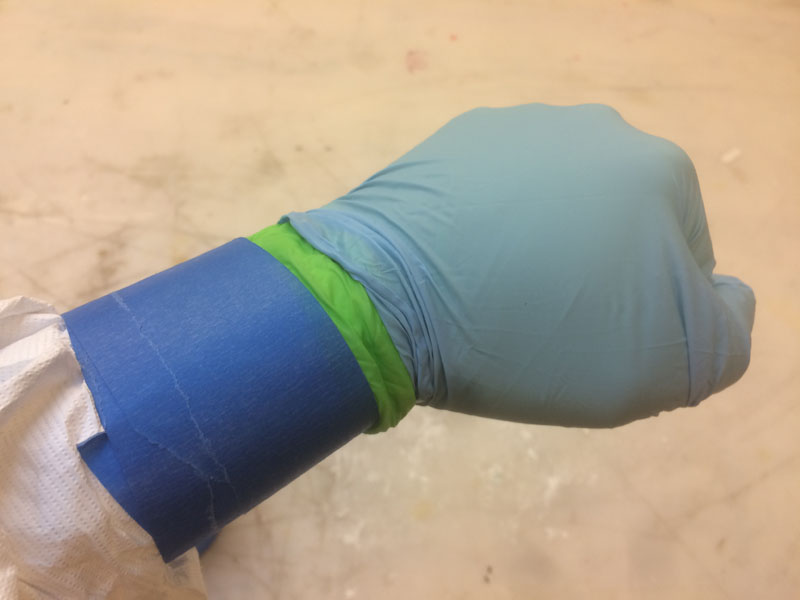

Once your Tyvek protective garment and your long-cuff glove are on, it's nice to tuck the jacket cuff into the glove cuff. If this is tricky to do on your own, ask your shop buddy for help.

Once the cuff is neatly tucked into the glove, a few wraps of tape can help keep it in place.

Now, you put put on your second pair of gloves, get them dirty and swap for a new pair, and repeat as often as necessary, without worrying about getting epoxy on your forearms or clothing.

Remember that it's just as important to work neatly and protect others who will be using the shop after you from accidental exposure by remembering not to touch door handles, pick up tools, or touch anything else besides your mixing cup and laminates with dirty gloves. Most of the exposure in the shop comes from secondary contact, when people accidentally leave traces of material around the room on things they touch with wet gloves, that get on them or others later. Change gloves frequently.

Not covered in this tutorial are safety glasses, which are mandatory at all times. Prescription glasses do not count as safety glasses, so grab a pair of safety glasses or goggles designed to fit over your glasses, or get a pair of prescription safety glasses from the MIT Optical Shop. If you are working with low viscosity (flow easily, like water) corrosives that might splash, it's highly recommended to also wear a face shield. Epoxy hardeners tend to be lower viscosity than the resins, and are also more corrosive. This is even more true with infusion epoxies. The MEKP initiator used with polyester resins can cause severe eye damage or blindness instantly. A face shield is highly recommended when dispensing and mixing resins.

Finally, be aware that all the PPE listed here, from the Tyvek suits to the gloves, is not permanently impervious to penetration from corrosives. The gloves will have a specific time rating for specific materials, which will also be based on the glove material and thickness. If you are working on large parts for several hours, it's a good idea to change your base gloves every hour or two. If you're getting resin onto your jacket, change that out eventually. If it stays clean, take it home in a trashbag and use it again on your next job!