Week 5: Electronics Design

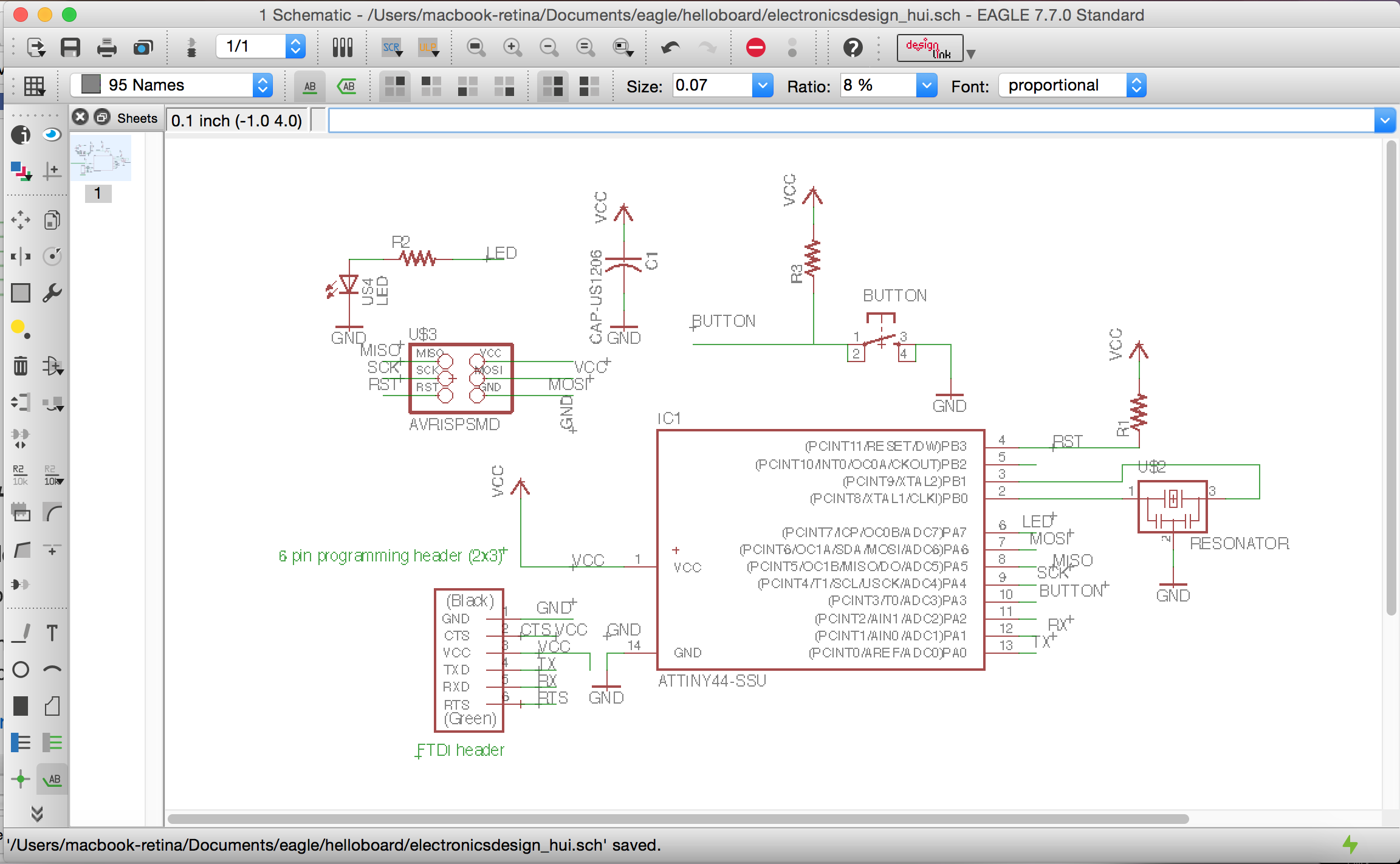

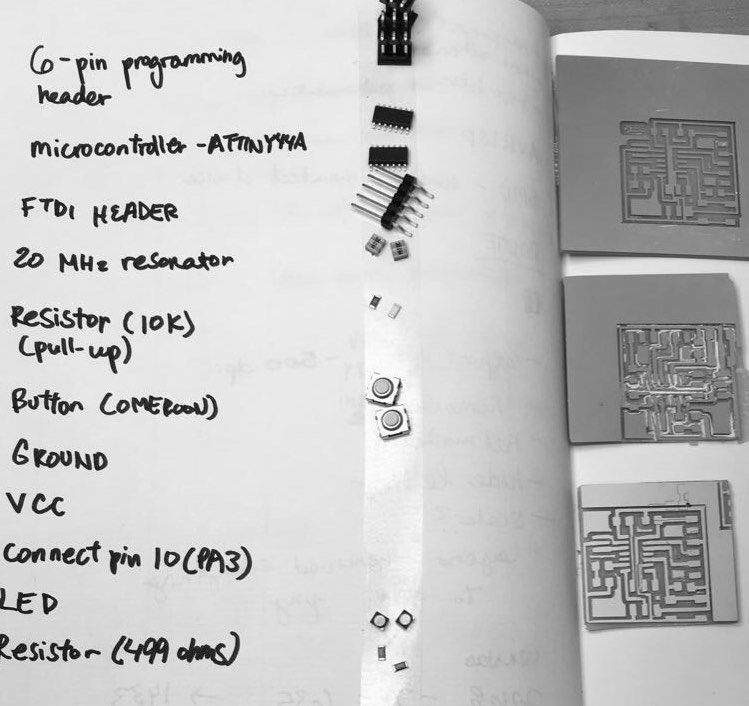

This week we were tasked with designing an electronics board from scratch using Eagle circuit design software, adding a LED and button to the existing Hello Echo schematic. Connecting schematic design to fabrication was a beginning educational process in relating computer design with hardware.

I started off with importing the fab.lbr into Eagle alongside the control panel, and adding our parts via the "Add" command one by one. Once all the parts were in, I began connecting them in the schematic view. Eagle by no means is a user friendly software; there is no easy intuition to navigate editing buttons. I constantly had to side click or go to the upper tool bar in order to make edits. The grid snaps in places that would make the routes too close to each other or intersect. The way I adjusted for this was to change the grid size to a finer grid to increase flexibility.

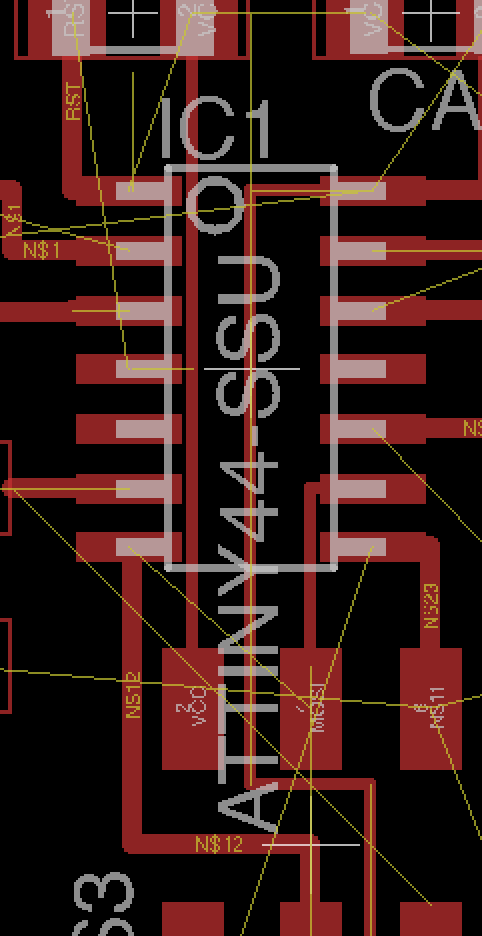

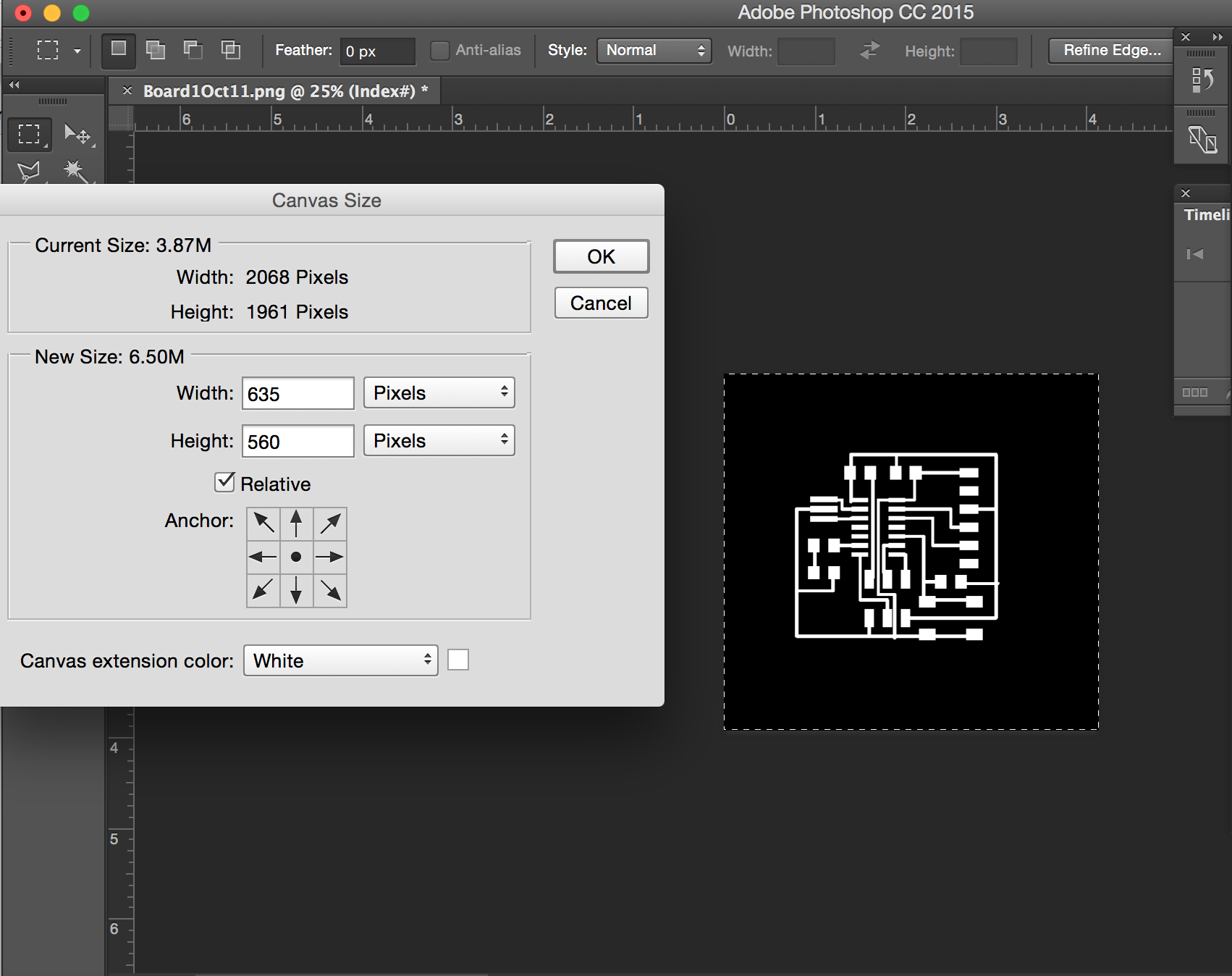

Once the routing is completed, I unticked all of the layers except for the top layer and exported it into photoshop. There were a number of routes I had to clean up. Moreover, there was a retina exporting issue with Macbook that required me to double the dpi (from 500 to 1000 dpi) in the mods in order for the schematic to scale down by half so it would fit the 2 inch constraint on the milling board.

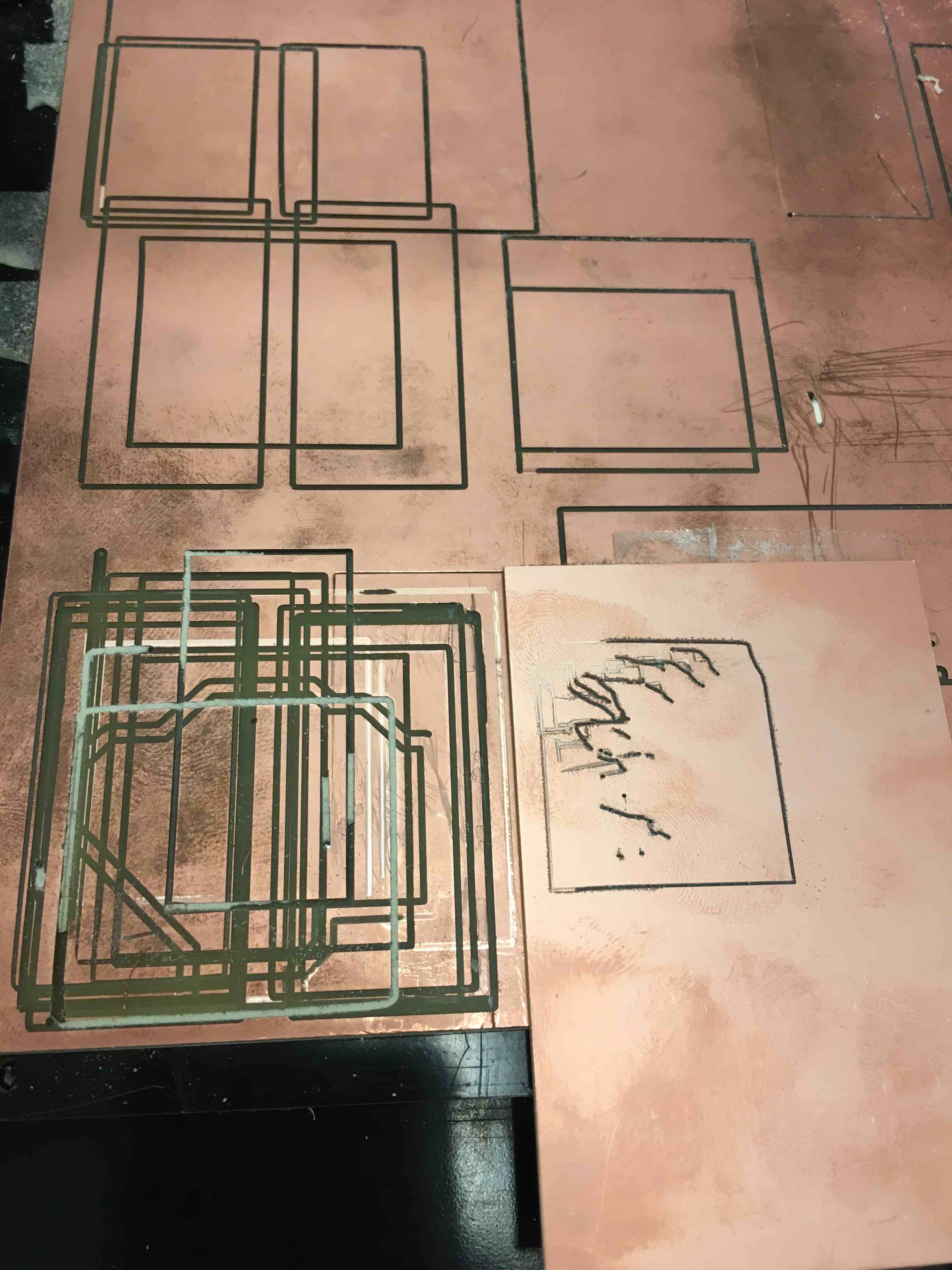

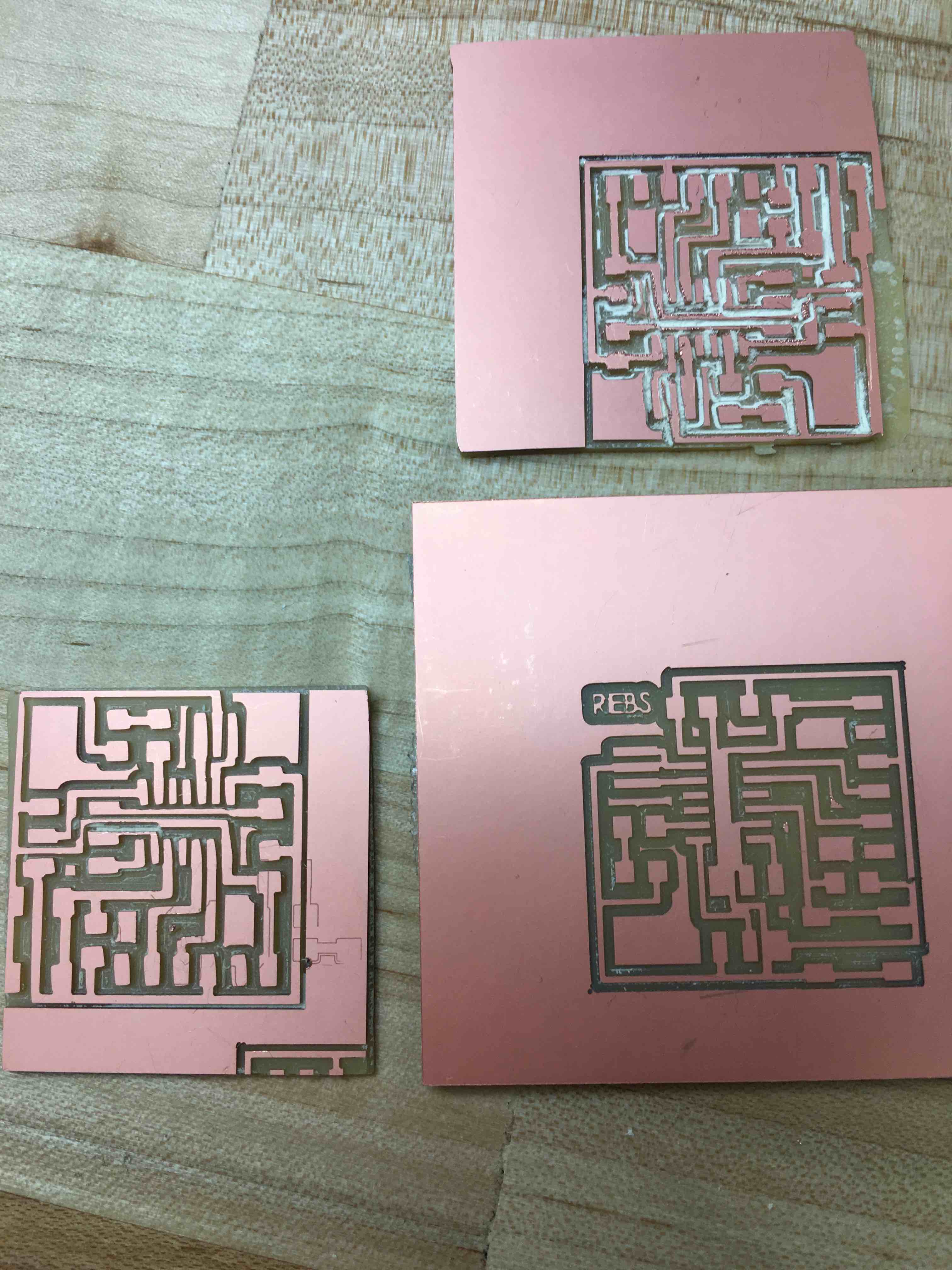

I had a rough day milling for a variety of reasons. Firstly, the bed of the mill had been milled into and no amount or precision of tape could stop the top pieces from moving. Second, there was a lot of dust on the mill. Third, the 1/64" end mill was dull, created jagged ends during the drilling process. The machine all together was also not very user friendly. I had to restart mods and terminal several times, and there was much delay between the mods and the server.

There was a lot of room for improvement on my boards. On one hand, some of the routes were not cut through. I over compensated for this by drilling the mill in pretty deeply, making very deep cuts on a second cut. Then, my third board looks drunk because the board kept moving during drilling. The board would not sit still because there were so many previous cuts already on the board.

I had a rough day milling for a variety of reasons. Firstly, the bed of the mill was totally milled into and no amount of tape could stop the top pieces from moving. Second, there was a lot of dust on the mill. Third, the 1/64" end mill was dull, created jagged ends during the drilling process. The machine all together was also not very user friendly. I had to restart mods and terminal several times, and there was much delay between the mods and the server.

Then I soldered the board following the schematic, adding a button and LED light.

Could have been better, but most of my energy had been exhausted trying to get the board right. At last, it should work, and I have to call it a night.