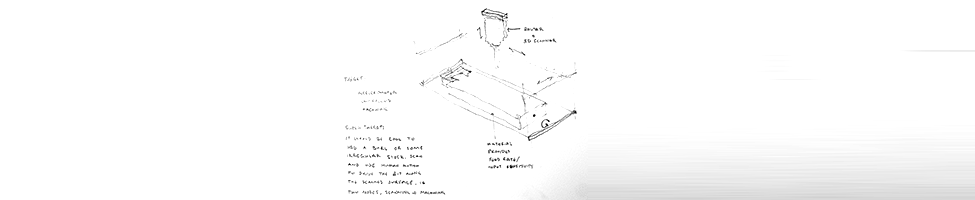

1. The final project is a 3 axis machine that moves according to motion detected by an accelerometer, a hand controlled 3 axis machine.

2. This idea is derivative of a SMArchS Computation Thesis I saw a few years ago in which a student used sensors to control the motion of a hot wire cutter.

3. The master and slave boards, assembly of the slides, and 3D printed fixtures were designed, much of the project was developed and designed.

4. The only products of significance that were bought were the stepper motors, threaded rod, rails, and bolts. The materials used were baltic birch ply, PLA filament, and mechanical fasteners.

5. Most of the material came from a hardware store called True Value Economy Hardware on Mass Ave. The nuts and bolts from Pill Hardware further away.

6. In total, the stepper motors cost $40, the wood, rods, and bolts were around $60.

7. The I2C communication system was made, the boards designed, routed, stuffed, and programmed. The slides were designed, so the hardware in the system was also fabricated.

8. CNC Pressfit, 3D printing, Electronic Design, Production, Input and Output devices, Networking and Communications, Machine Building.

9. Most of the term I struggled with electronics, in this final project I learned enough that I could continue this project confidently. The design of the slides is a non trivial undertaking, and an appreciation of the critical conditions in an assembly like this is lost if using the cardboard slides of machine building week. A deeper understanding of slide assembly was appreciated.

10. The project is incomplete, there are a few points of weekness specifically fixturing the stepper motors correctly which will solve much of the instability of the system. The second thing to fix is the accelerometer values, which haven't yet been converted to absolute positions. Having the machine respond to serial inputs when the master is plugged into the computer, will be the first test in evaluating the slide assembly.

11. Architecture students might be able to design their own fabrication tools is one implication. The other is the possibility of augmenting the hand as a tool. This project postulates a hand controlled device where the end effector makes something happen a person could not normally achieve by hand.

Here are the 3d Print files I've developed: