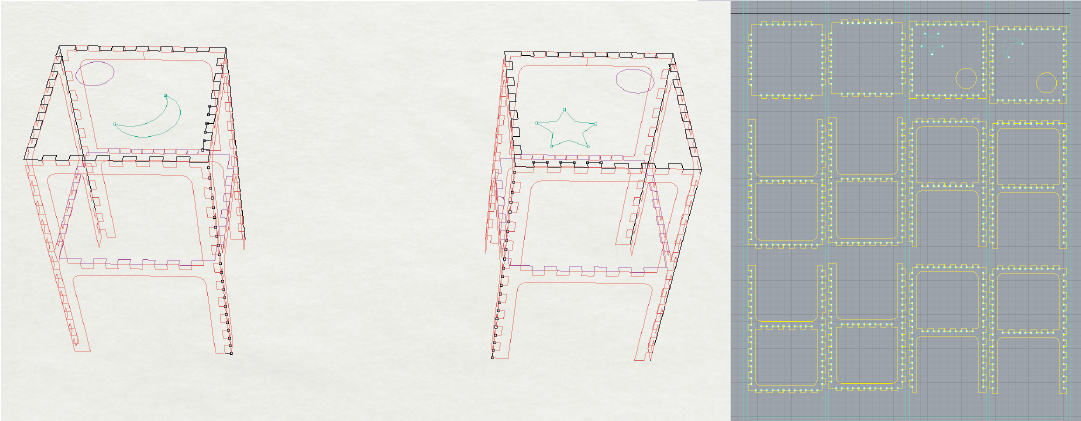

Design

For design I wanted to do furniture that would be assembled without nails or glue. Two night tables that would be made out of one sheet of plywood. The idea was to do a press-fit that would be enough detailed as to be decorative. On the table, both tables would have a cut-through holes for glasses (of water or whatever), and each table a carving of a moon/star.

Doing the press fit so detailed was challenging. For that I used a grasshopper script that generates a zip-zagging press-fit curse on the corners of the table.

Test Drive

Before milling of the full tables, risking a full sheet, did a test, trying just one corner of the press-fit corner. To do this I measured the width of wood - important to know the exact depth of the drilling and cutting.

Also placed points on inside of the “teeth” of the press-fit, to direct the drilling, to ease fitting of parts.

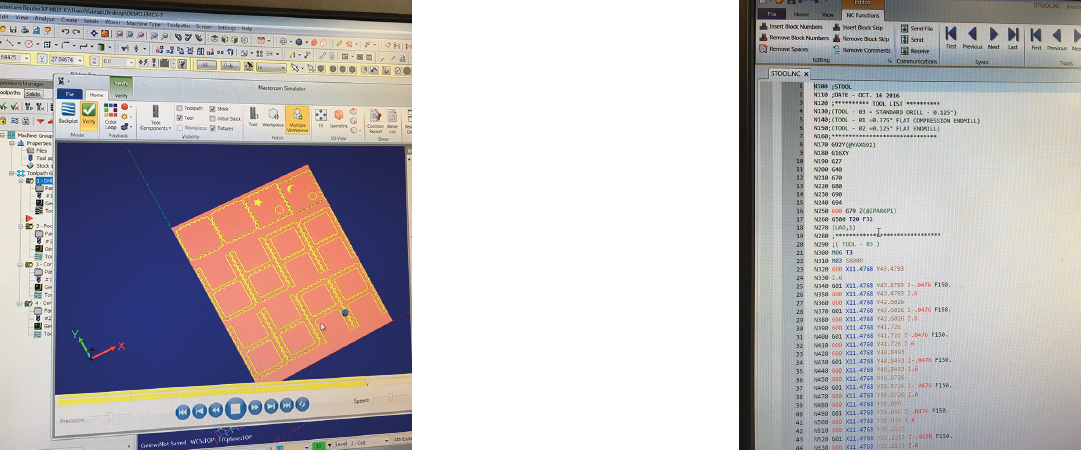

Mastercam

1. merging file into Mastercam

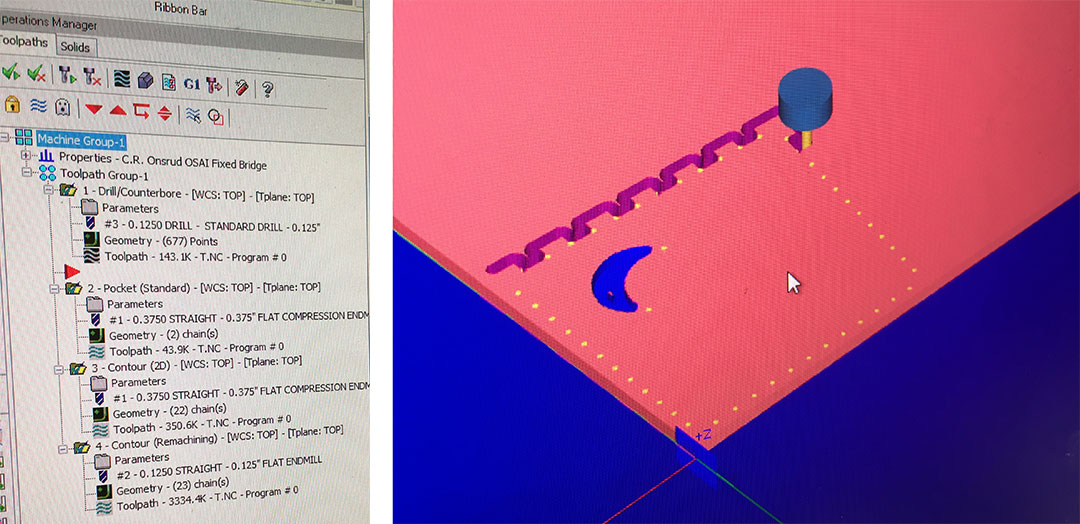

2. Creating 5 toolpaths:

(a) drilling holes;

(b) pockets - half the way through the material (0.2 inch);

(c) machining contours, half way through with 1/8” mill. Half the way to prevent mill rom breaking;

(d) Remachining of contours, almost all the way through, leaving an “onion-skin” of 0.05”.

(e) Redrilling of holes at corners of press-fit.

Chaining

The tricky part of chaining is the direction of the chain. The direction also determines the offset direction

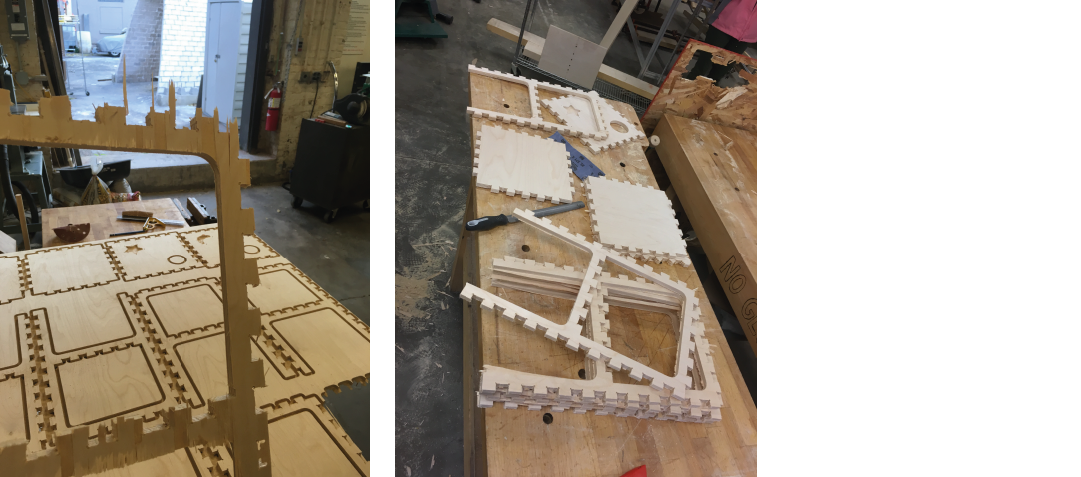

Test Milling

Tested press-fit of one corner. Turned out fine:)

Full sheet milling

"Onion-Skin” and plywood - can be messy

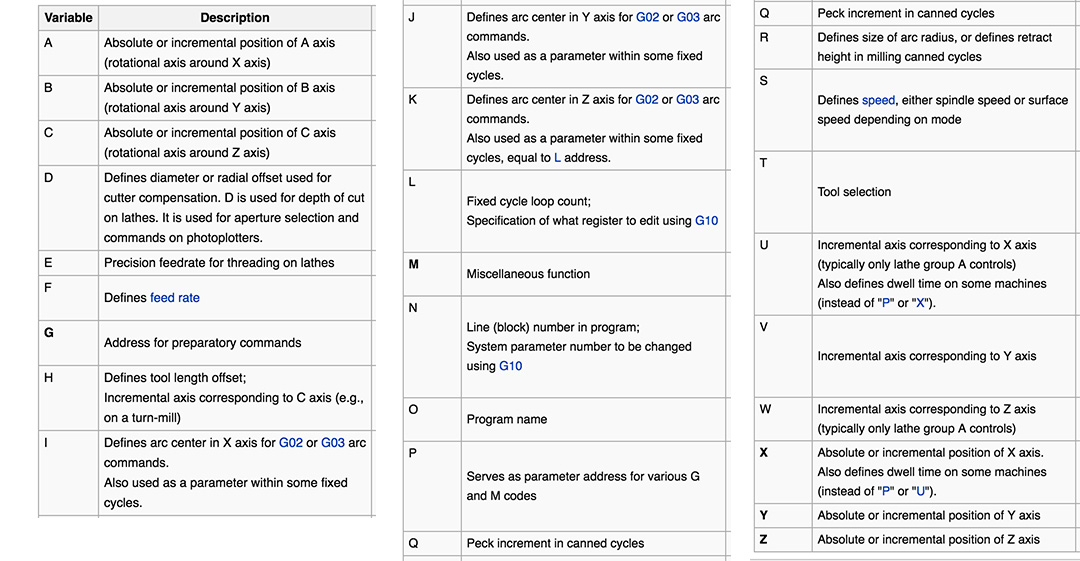

GCode

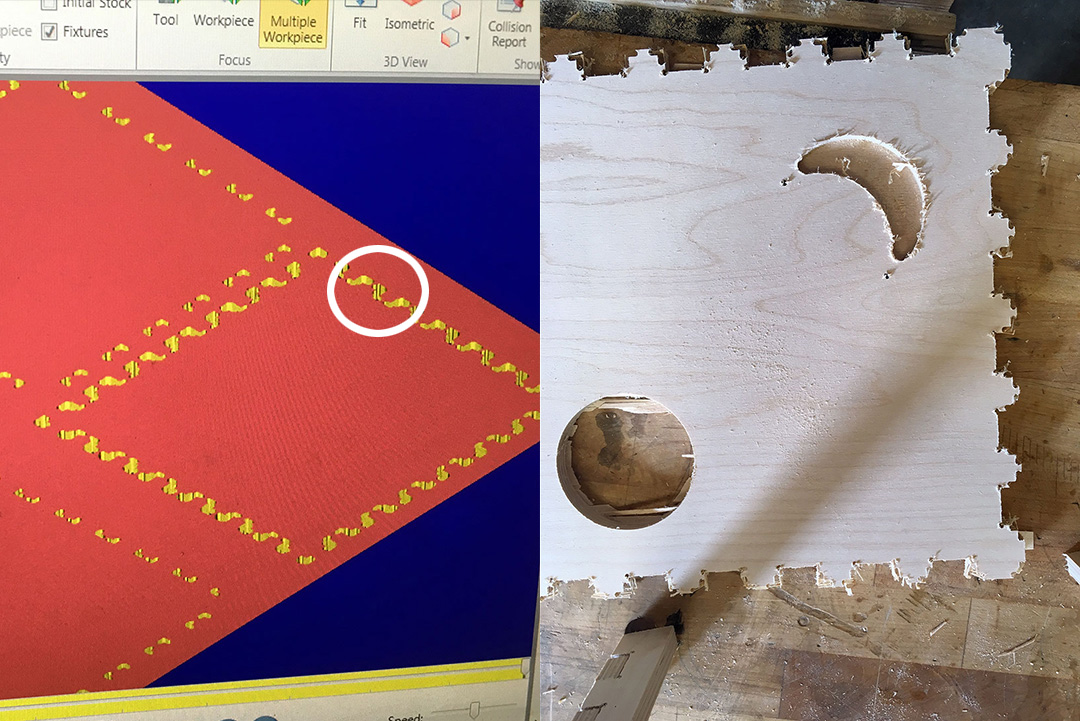

We have a problem: in re-milling, final chain was reversed

Going back to mastercam to debug, turns out that the last remachining of the contours was reversed.

Remilling last part

Press-fitting

This was way harder than fitting the test. Needed extensive filing and hammering to get it together.

WORKED OUT NONTHELESS. GOOD NIGHT!