Modeling for Intelitek CNC Moulding:

Tried a few models, before I got the limitation of the machine..

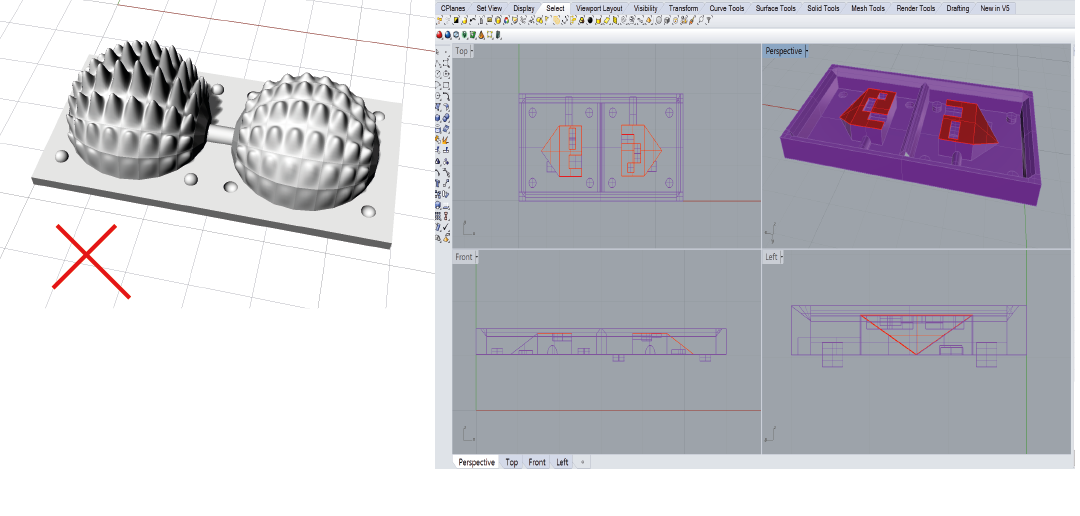

The first one was a parametric spherical candle. But soon after I did the model I realized it is way too detailed for the Intelitek CNC with the tools at hand.

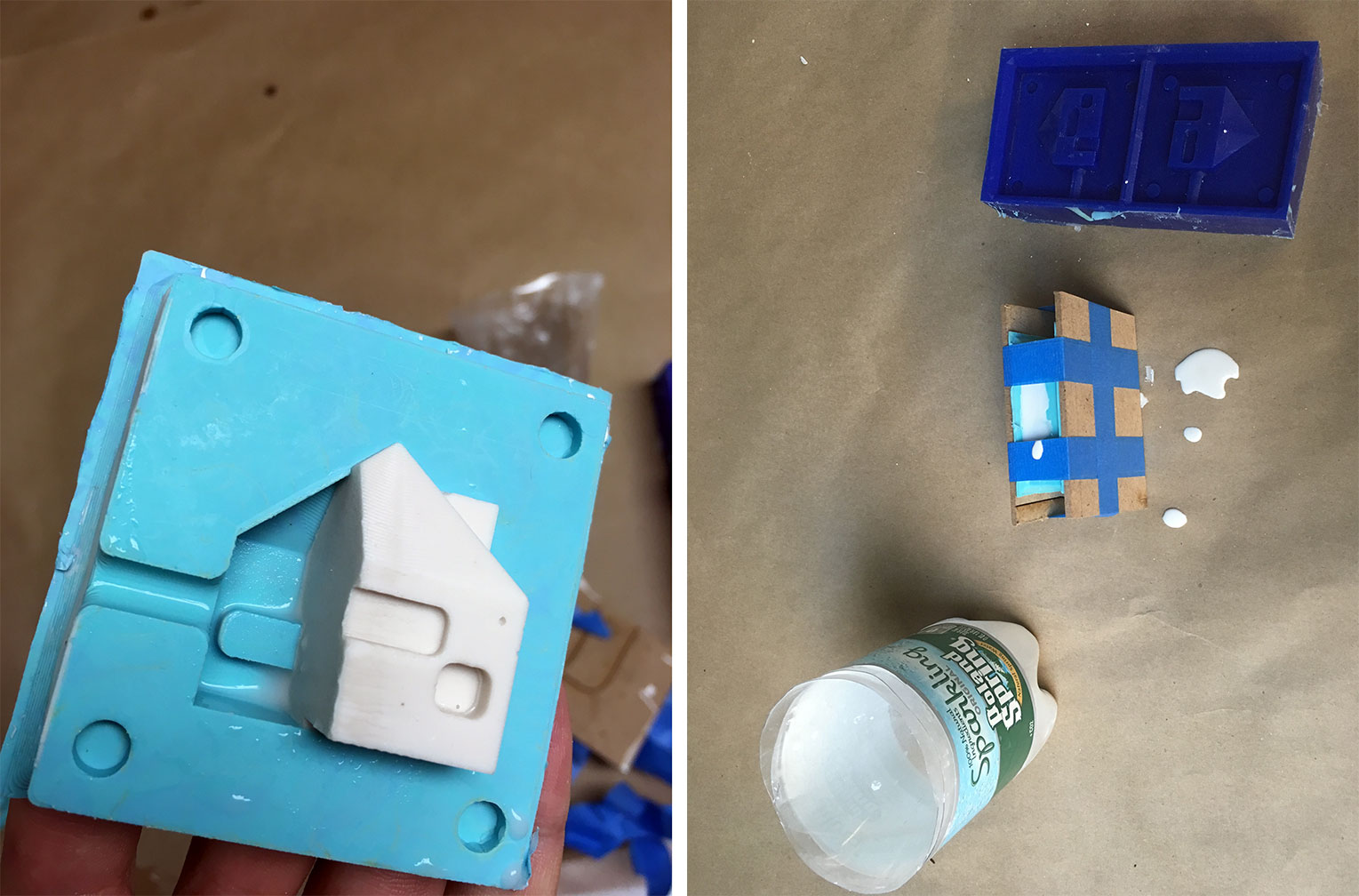

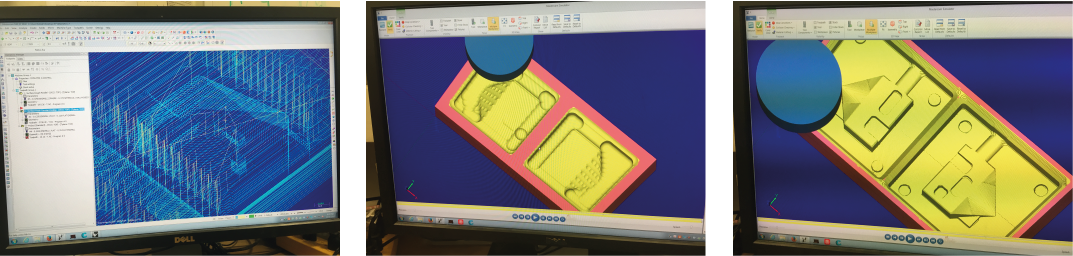

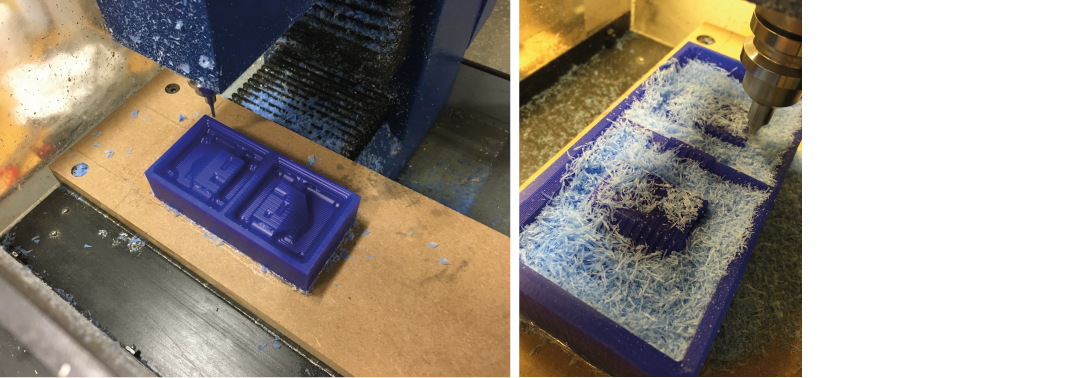

From that I went to a simple model of a house, double sided mould.

Rules for modeling and importing into Mastercam:

- No over-hangs.

- No need to import any vertical surfaces.

- Export only face of model

- Recommended to chamfer walls of wax to refrain from colissions.

- Keep model clean, minimize unnecassary surfaces and curves.

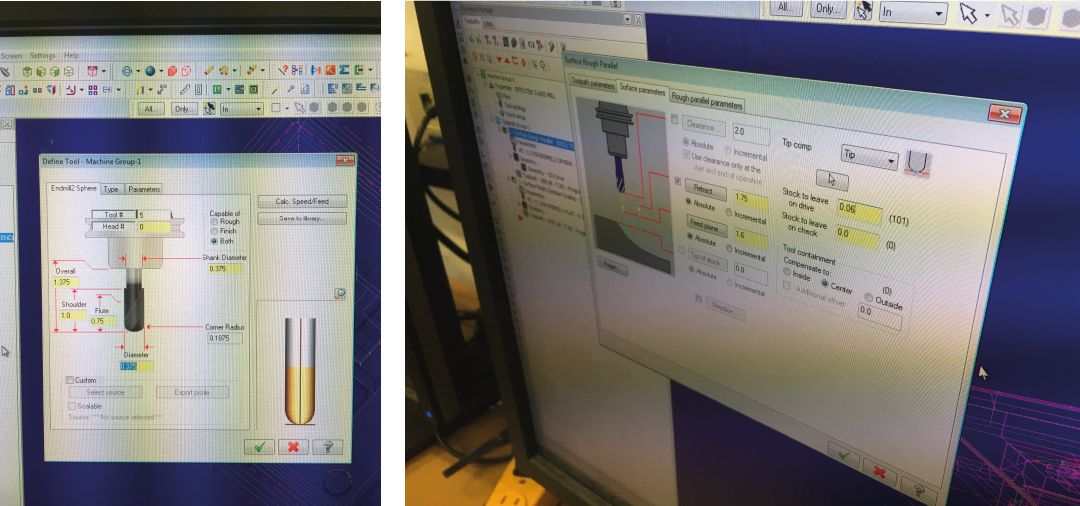

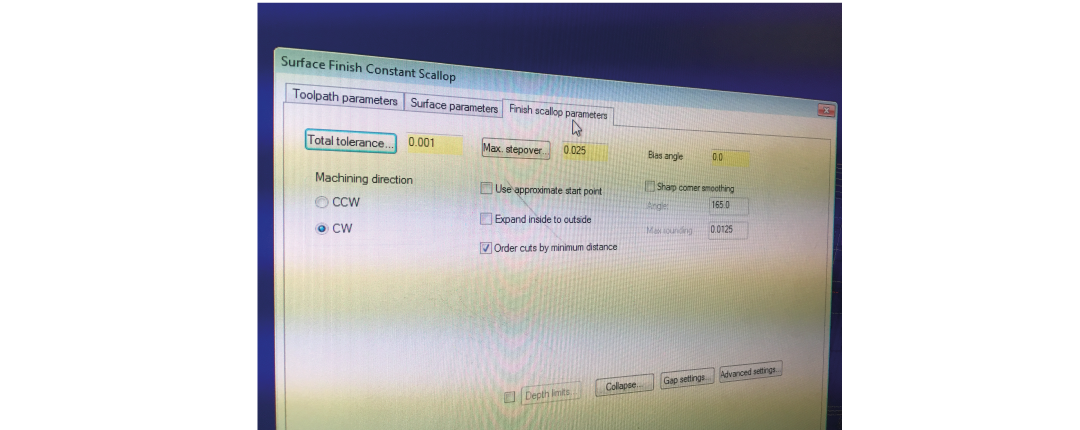

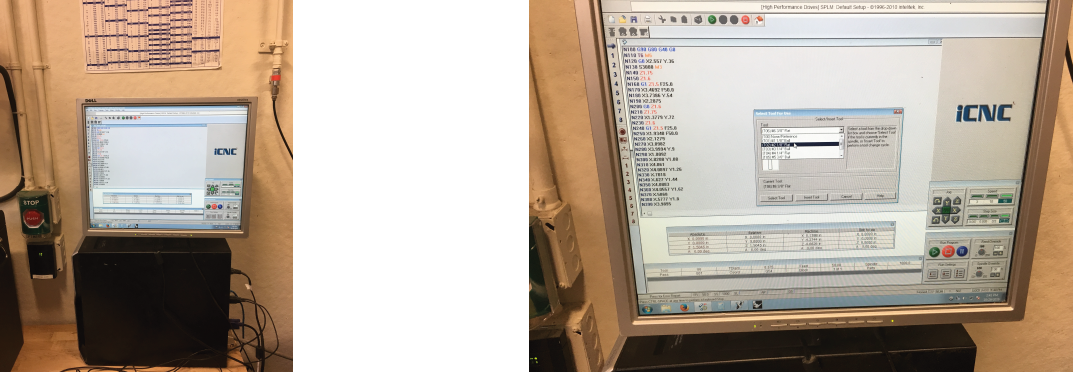

Mastercam Definitions

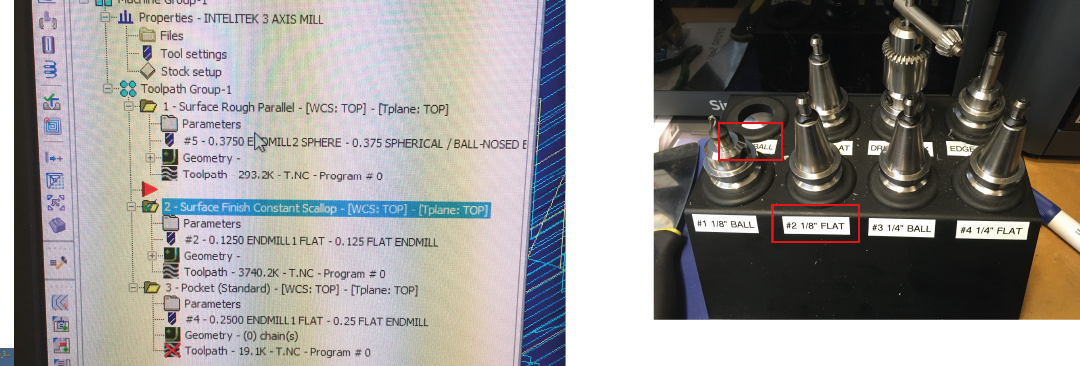

Intelitek Tools Library:

There are 6 tools offered:

#1 - 1/8 Ball

#2 - 1/8 Flat

#3 - 1/4 Ball

#4 - 1/4 Flat

#5 - 3/8 Ball

#6 - 3/8 Flat

and then there’s the Edge Finder

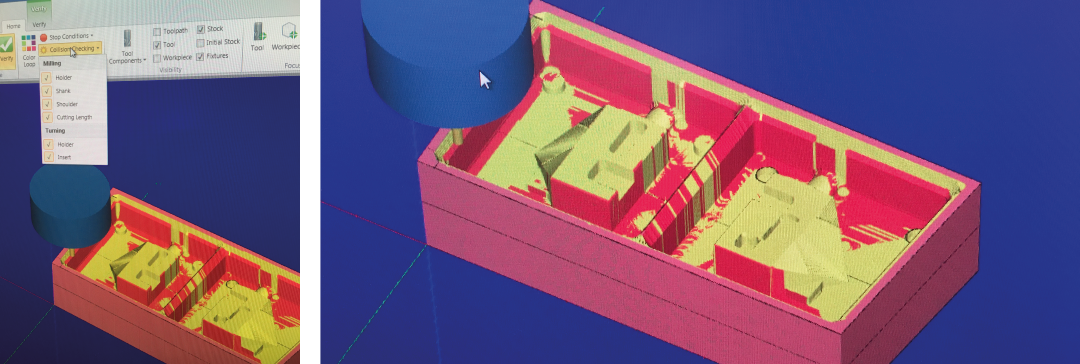

Collisions!!

Solving the collision

Setting the Intelitek software and machine

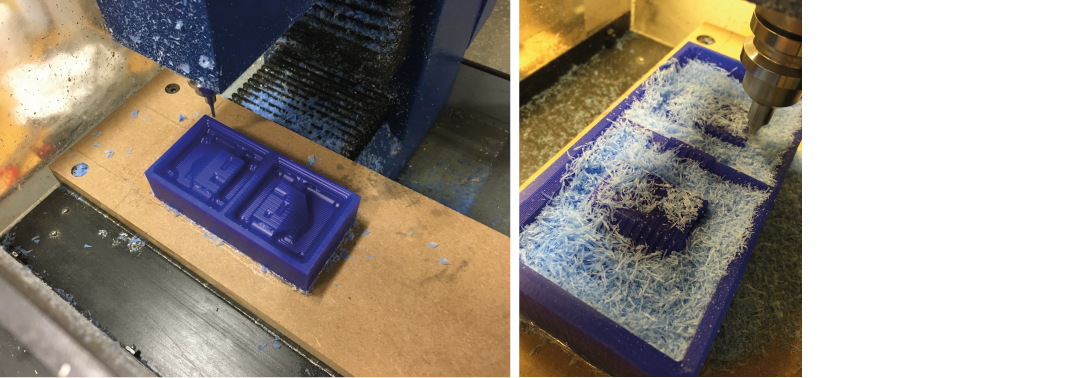

Milling

Casting the positive - to make negative mould

Spray with lubricant with Smooth-On Oomoo product (https://www.smooth-on.com/products/). Oomo 25 take about an hour. (3

I0 6 hours.

Ratio 1:1

Stir before pouring. Use gloves. Put paper on table.

Combine is bowl. Tap down air bubbles. Pour from high slowly.