HOW TO MAKE [ALMOST] ANYTHING_MAS.863

Week 03 - 3D Scanning & Printing

This weeks assignment was design and 3D print a small object that could not be made subtractively. Additionally, we learned to 3D scan objects. I've done quite a bit of 3d printing over the years, so I decided to have a bit of fun with this assignment.

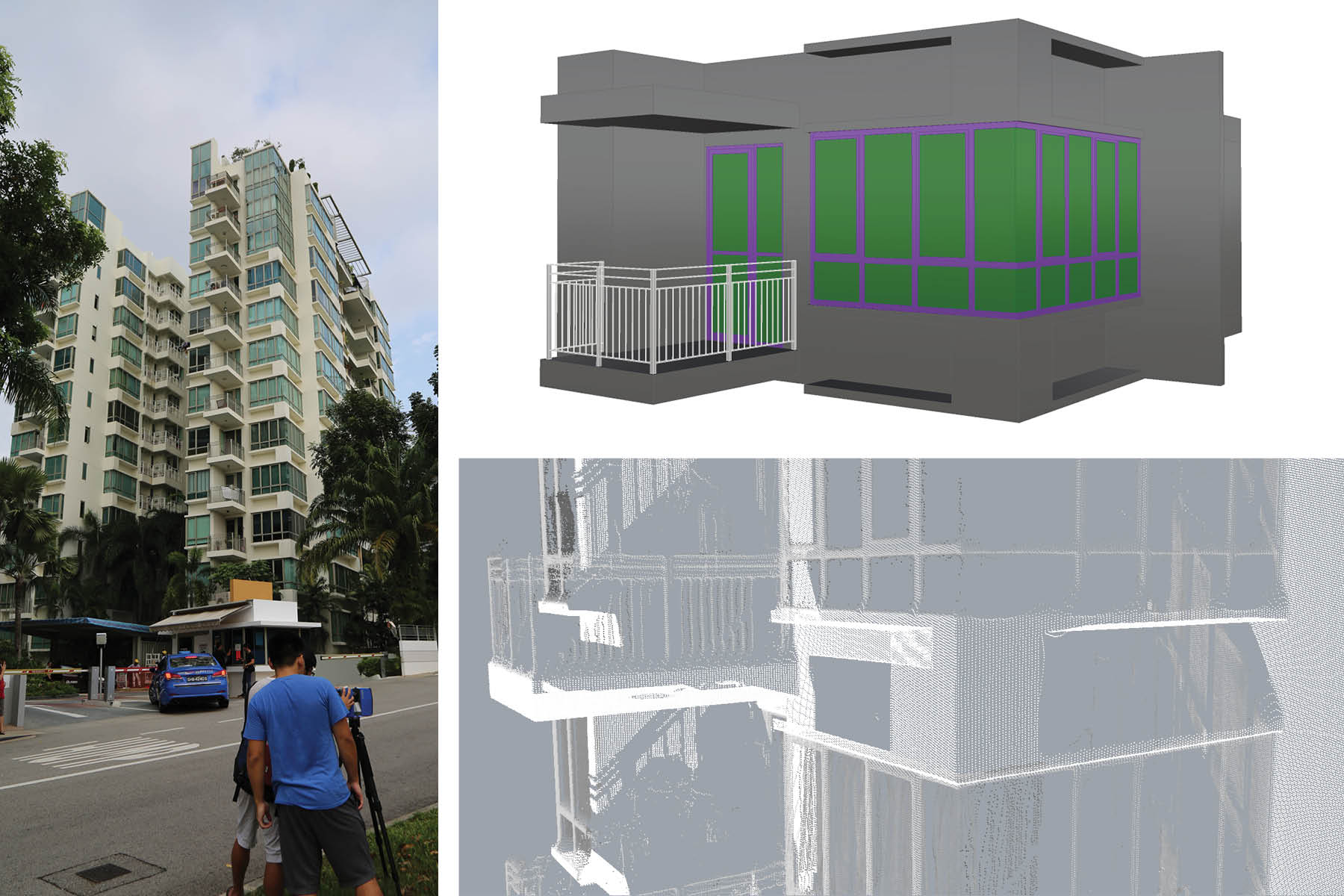

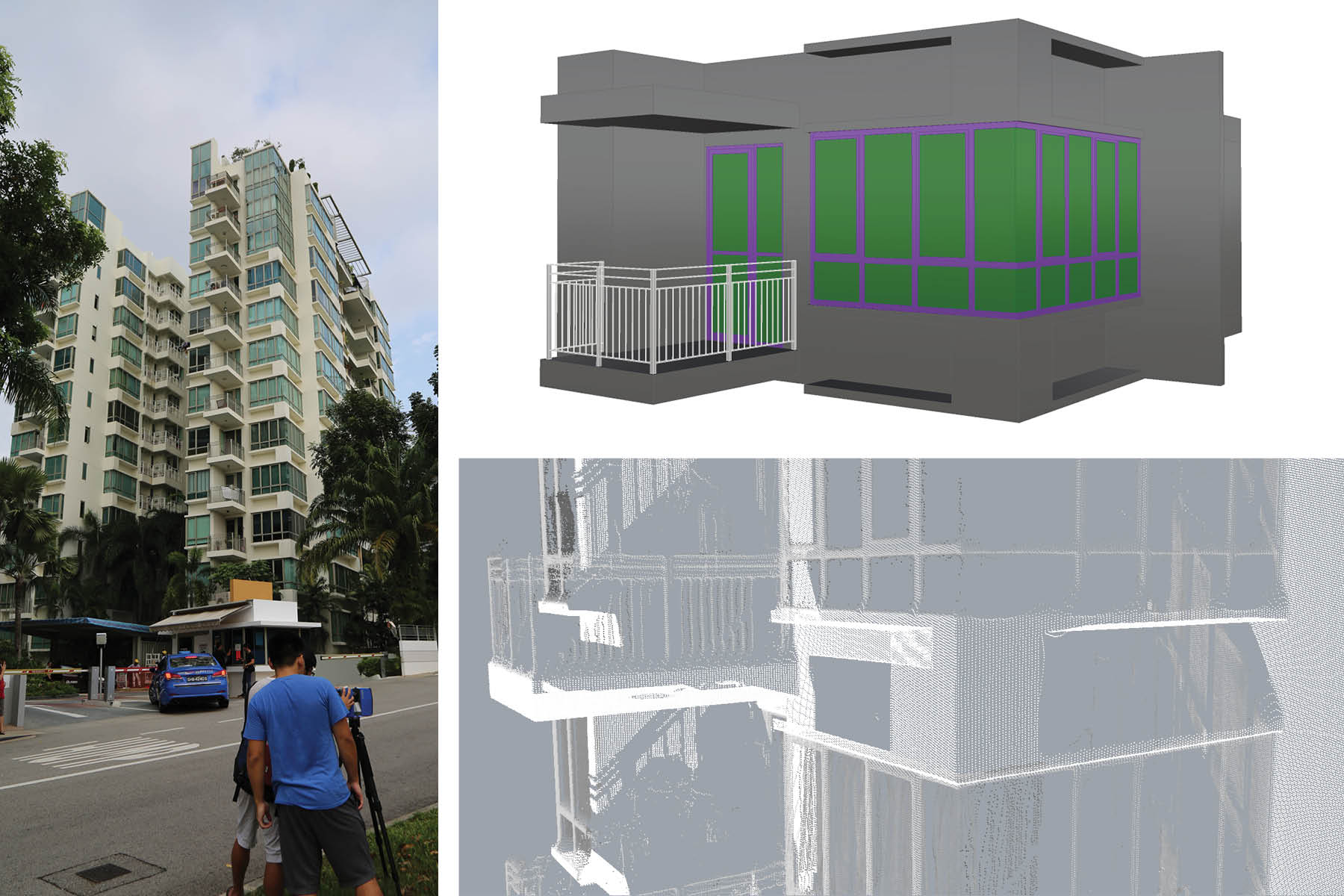

Scanning - Buildings & Objects

Over the summer, I worked on a research project at SUTD in Singapore where we 3D scanned 10 buildings. We used this information to accurately model the building facades for daylight, ventilation and energy simulations. We used a Faro Solutions scanner, which uses LiDAR technology. The images come back as point clouds (bottom right above) which are a little tough to work with. We used the point clouds to take accurate dimensions and model the facade elements (top right above).

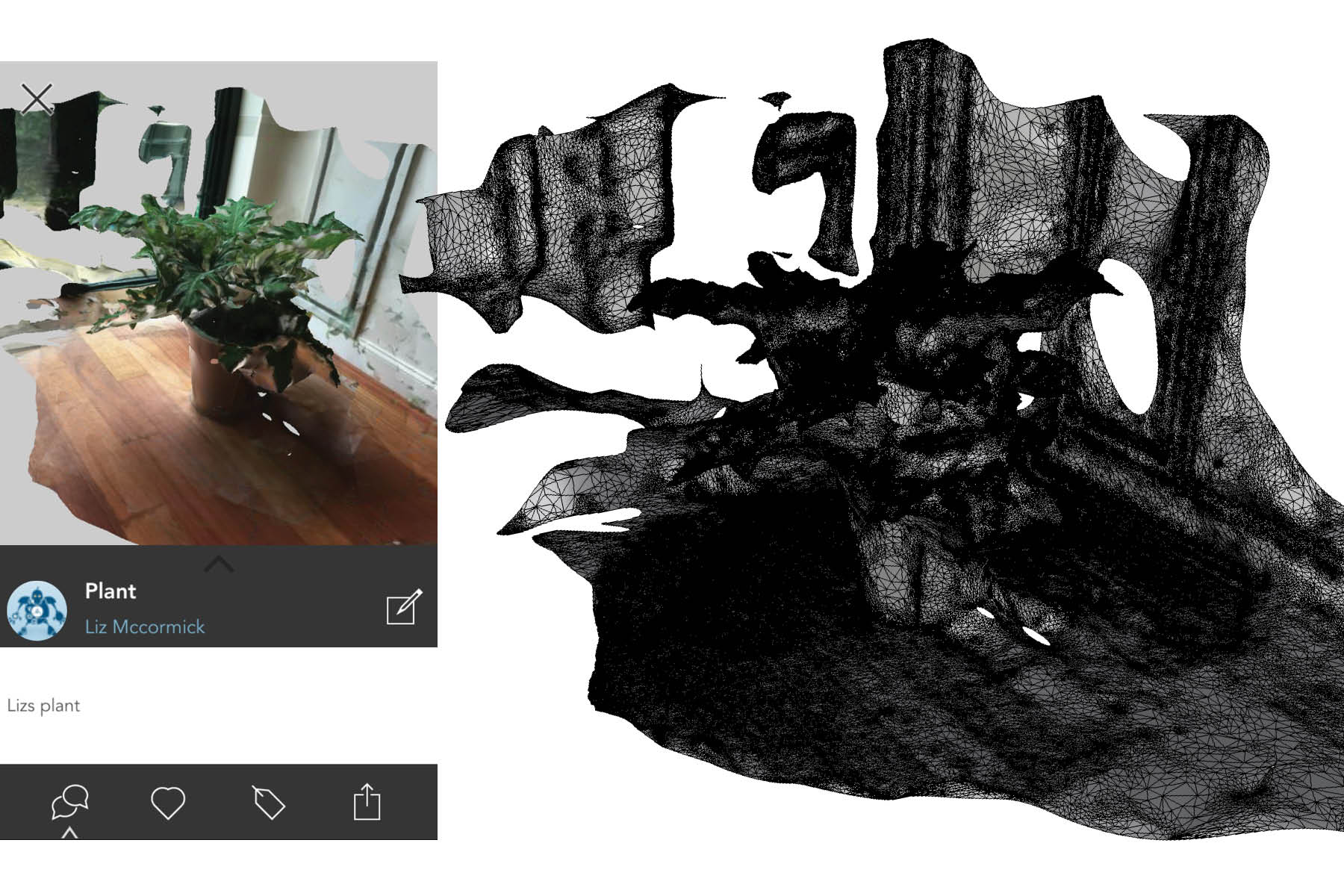

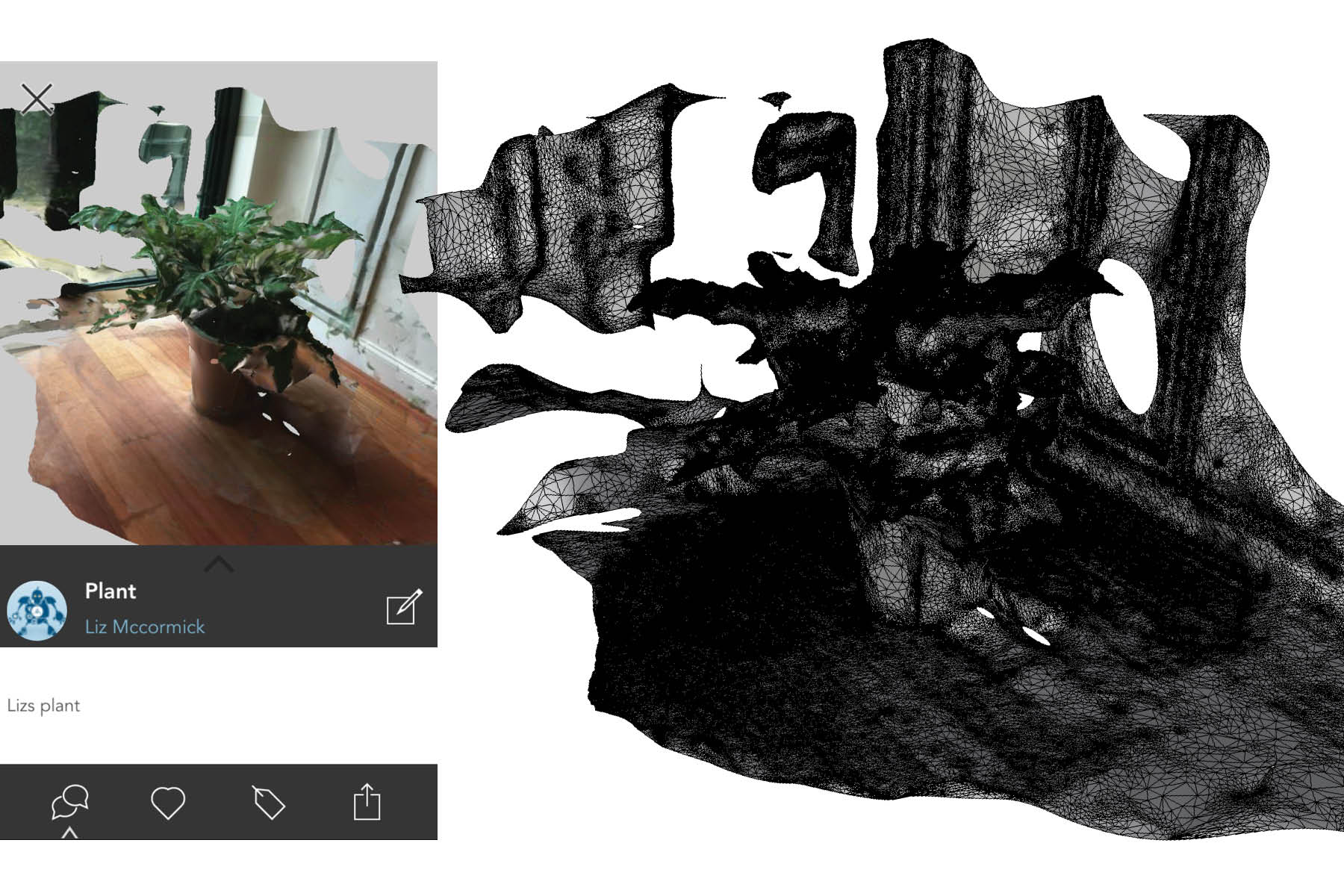

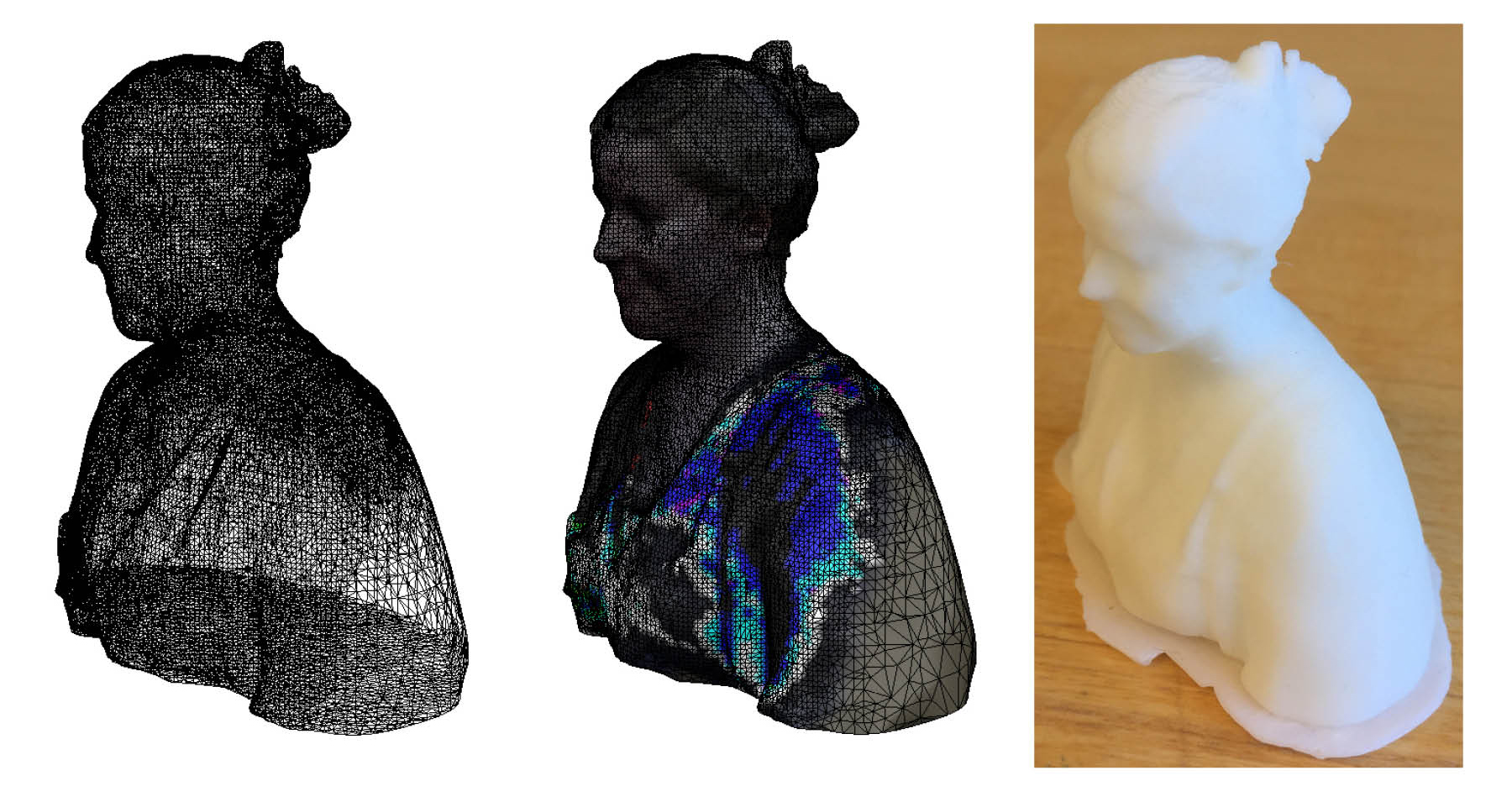

I downloaded 123D catch onto my iphone 6 to test how accurately it would work. It's a free software and I was pleasantly surprised with the results. The scan required a lot of light and works from between 20 and 40 pictures. There were a lot of missing holes in the model, but I was still impressed. Once you publish your scan to the website, you can download a 3d file in .stl, .obj, or .3dp. I downloaded the .stl and opened it in rhino (right). It would take a bit of work to get to be a closed object for printing, but it was an interesting study.

You can take look and spin around for yourself here

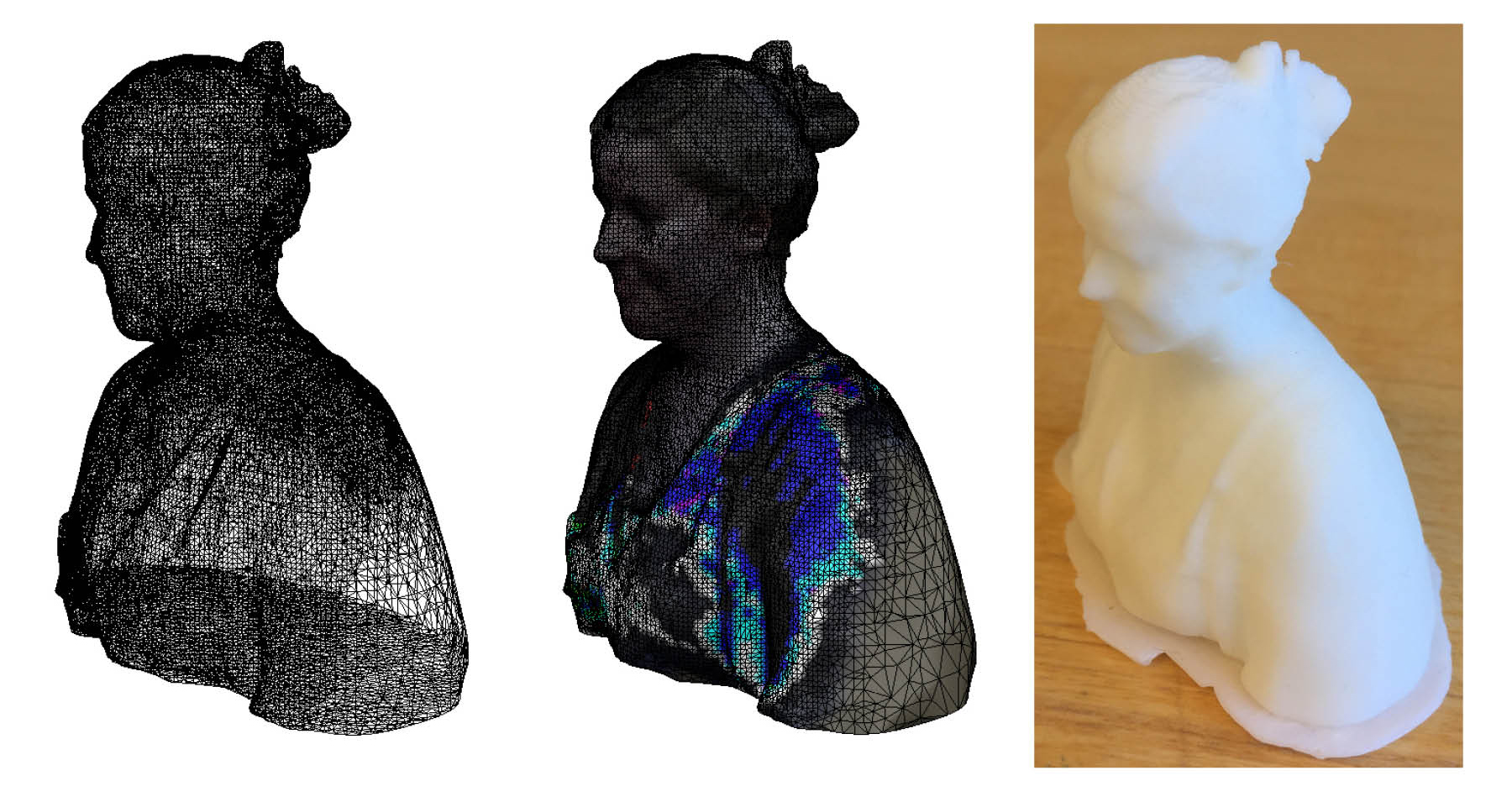

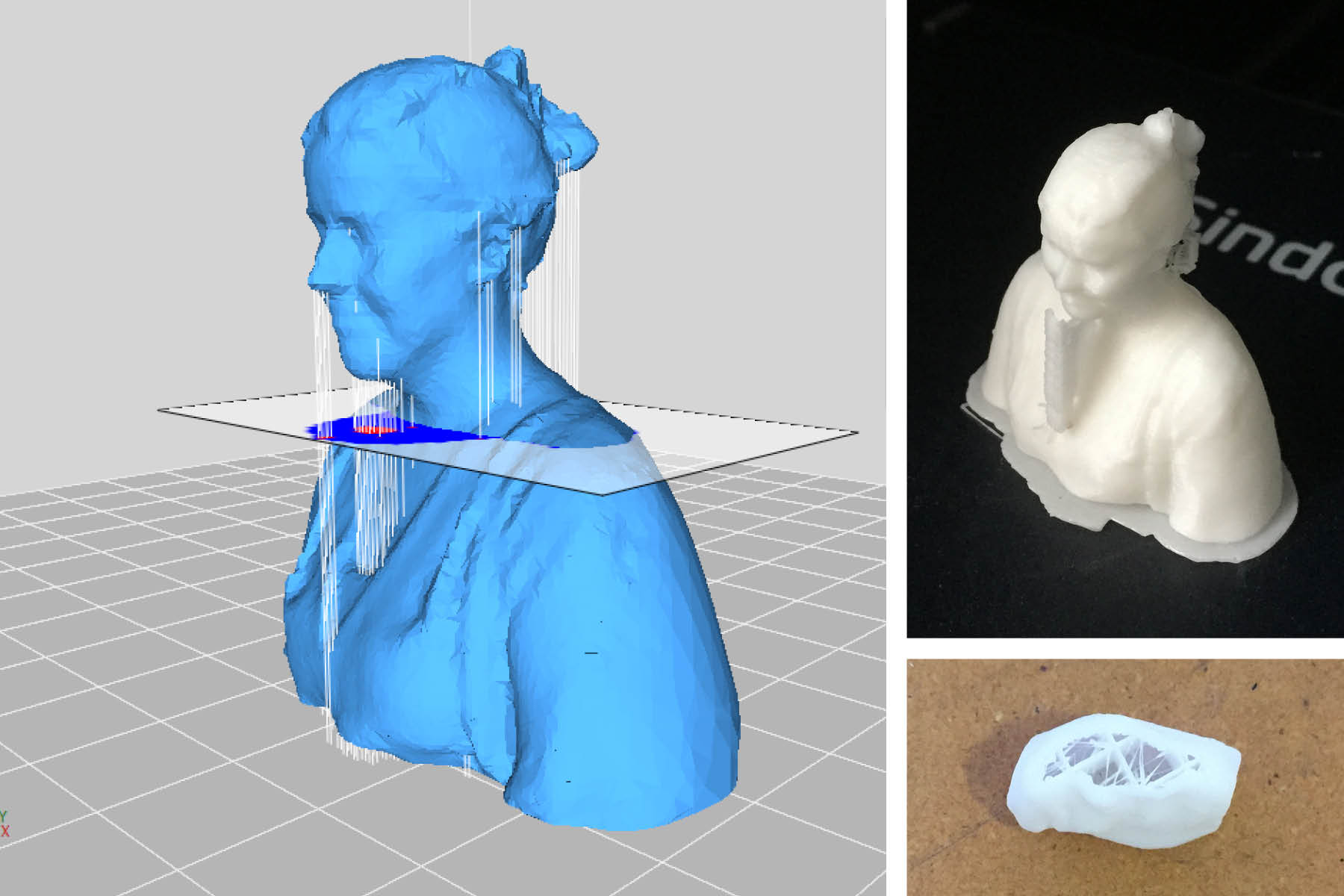

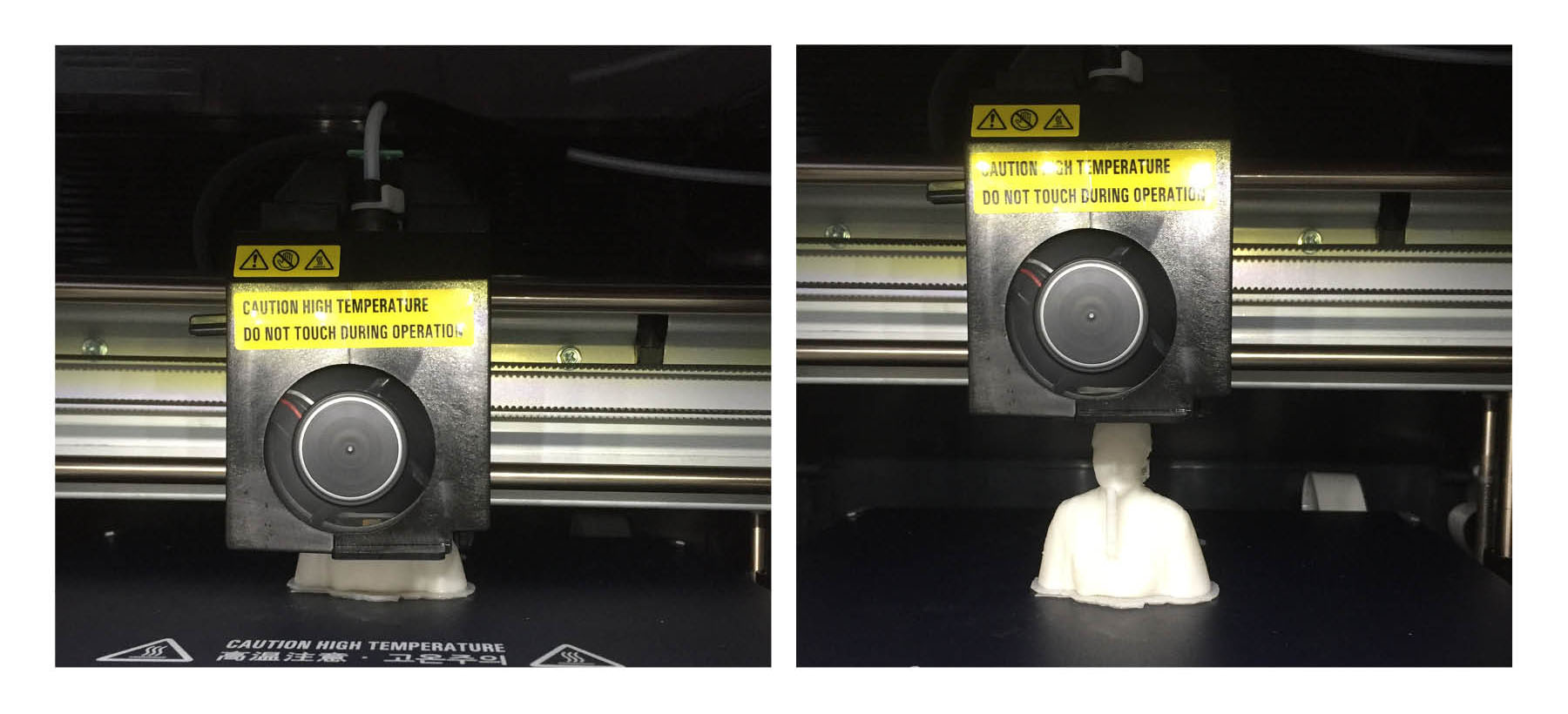

Next, I used the architecture shop to use the Sense Scanner. This is a relatively inexpensive piece of equipment that was incredibly easy to use. Once you scan the camera entirely around the head (slowly), it builds a series of surfaces. In the software, you simply clean up the unwanted elements and hit "solidify". Then it is ready to print - no modeling required. Just export as a .stl and send to the printer.

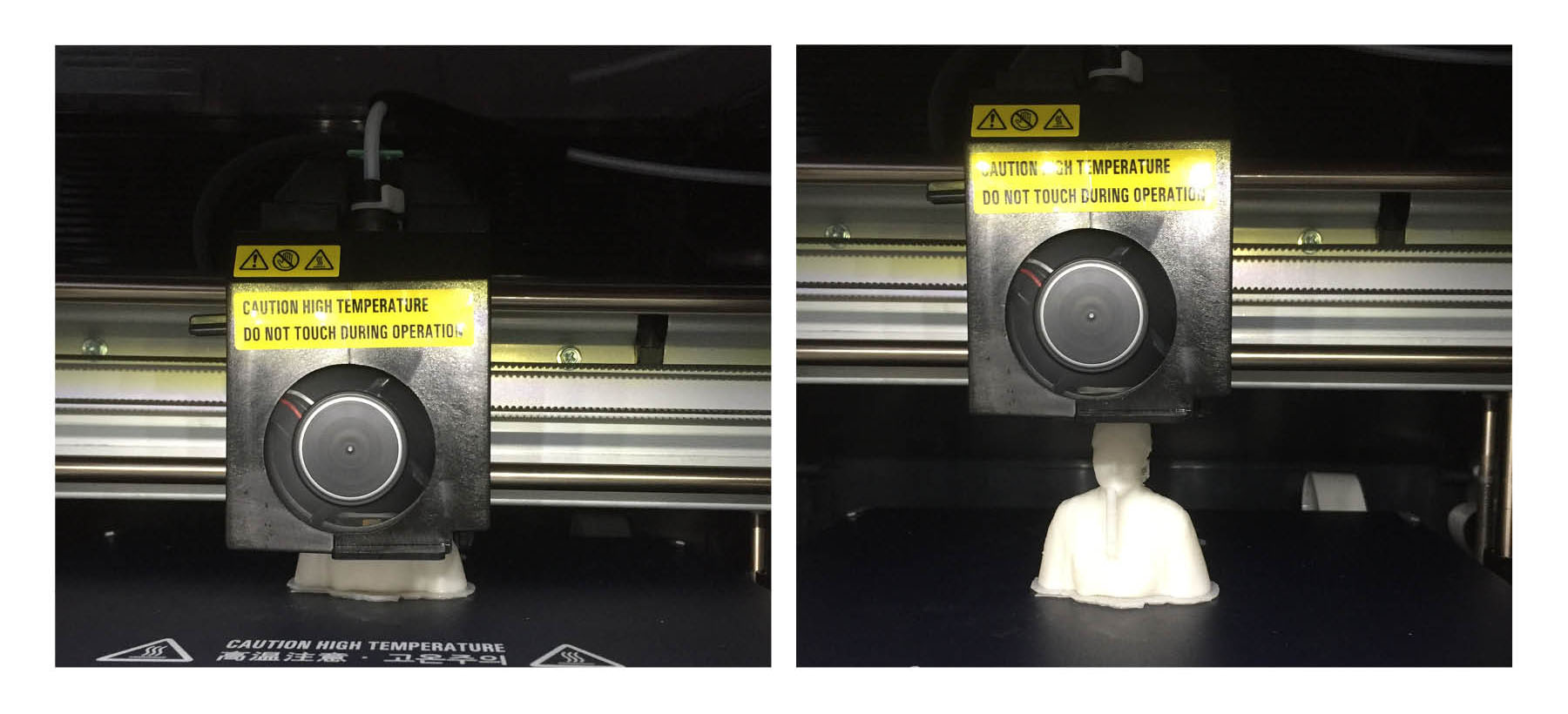

a .stl file (Stereo Lithography) is a series of traingulated meshes - essentialyl a wire frame. Above are two image from rhino - wire frame on left and shaded in the center. On the right is the actual 3d print which took one hour 11 minutes to print out of PLA plastic. It is just over two inches tall.

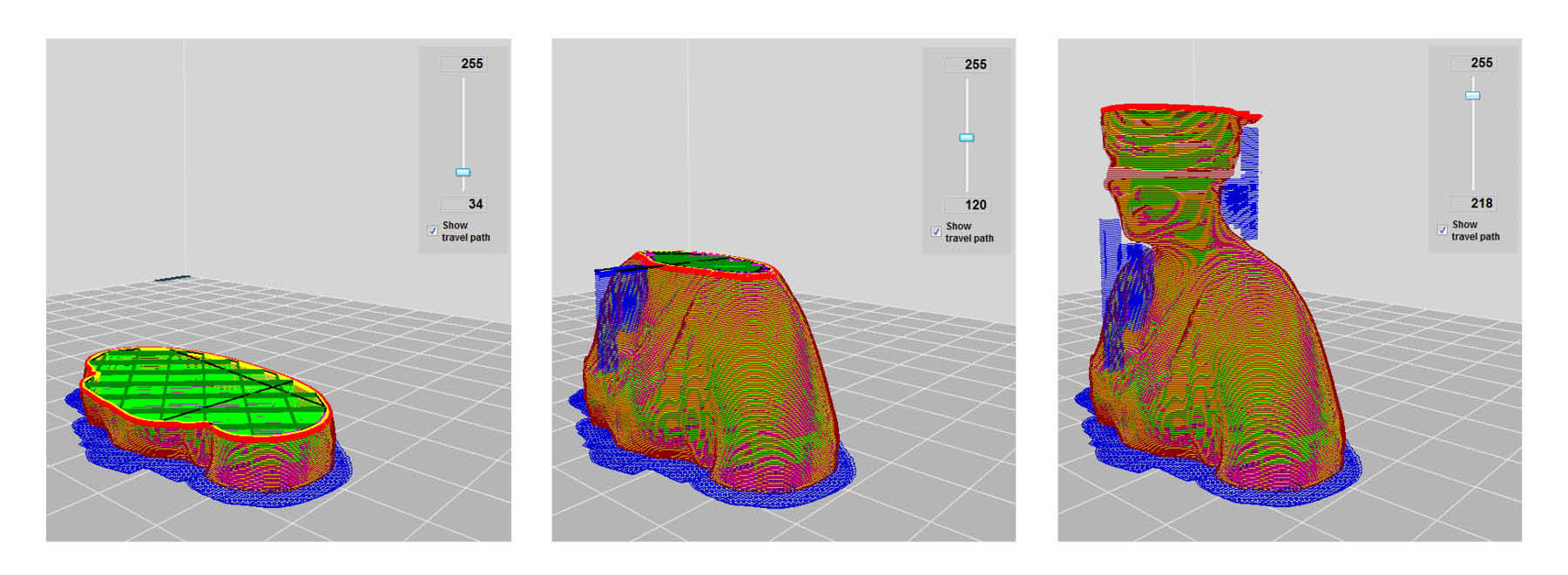

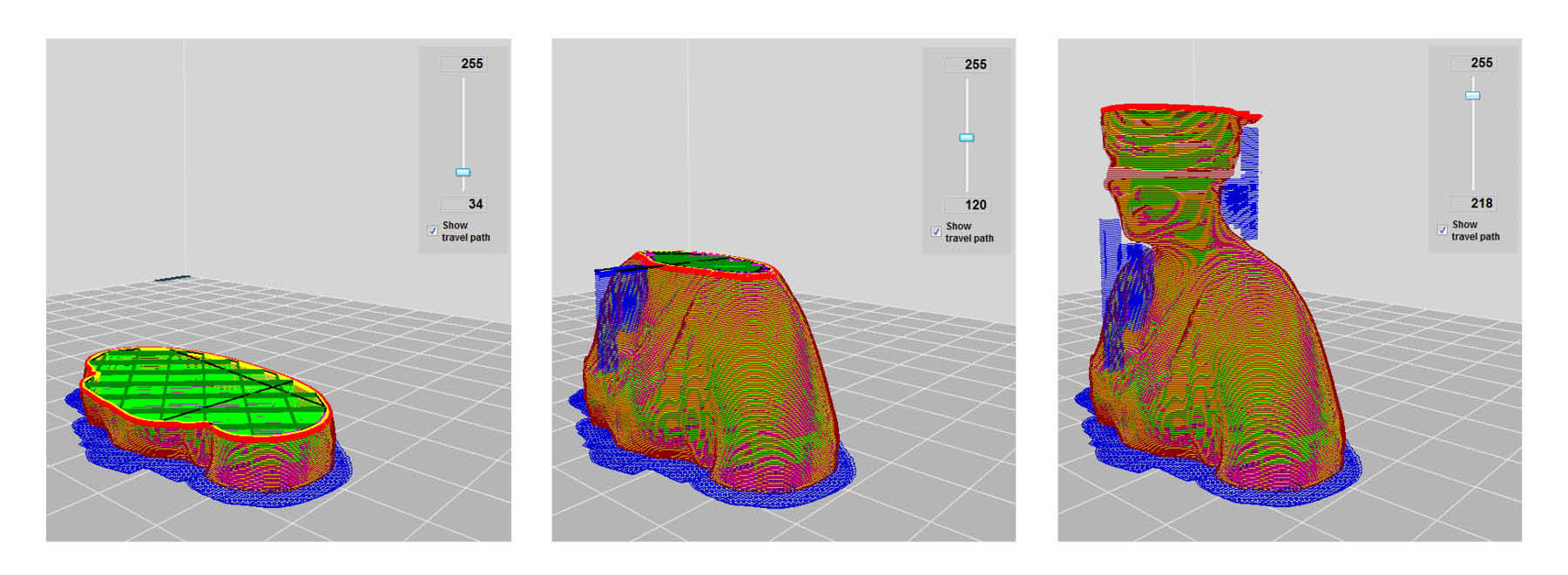

The 3d printer prints layer by layer. Here you can see the different cuts through the model. The inside is filled with a much less dense plastic. The blue color indicates the support material.

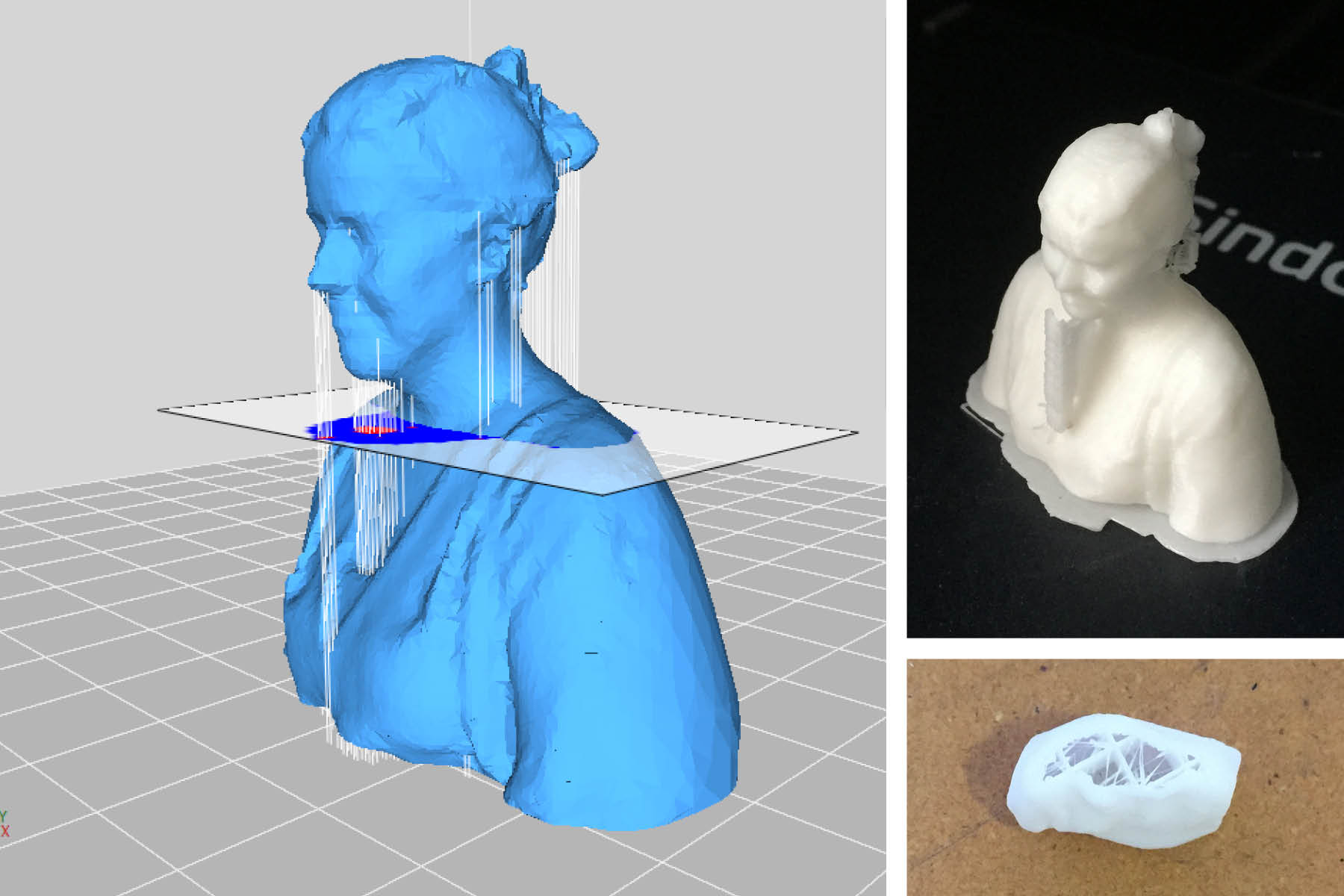

Here you can see the support material - the first print had a few issues, especially under the chin and behind the head where material extends further out than the layer below it. So for the second print, I turned the supports on. Once printed, they break right off. I used a nail file to sand down some of the edges where they did not break cleanly.

Now I just have to market these on etsy as wedding cake toppers...