Week Ten

CompositesThis week we were asked to make a composite based off of something else we made, like a 3D cad design or a two-part mold. I decided to use this week in preparation for my final project. I wanted to create the back support to fit my body perfectky so wouldn't need straps or anything of the like that wrraps around my body for the wings. That way they are not only easy to take off and put on, but they are also comfortable and light.

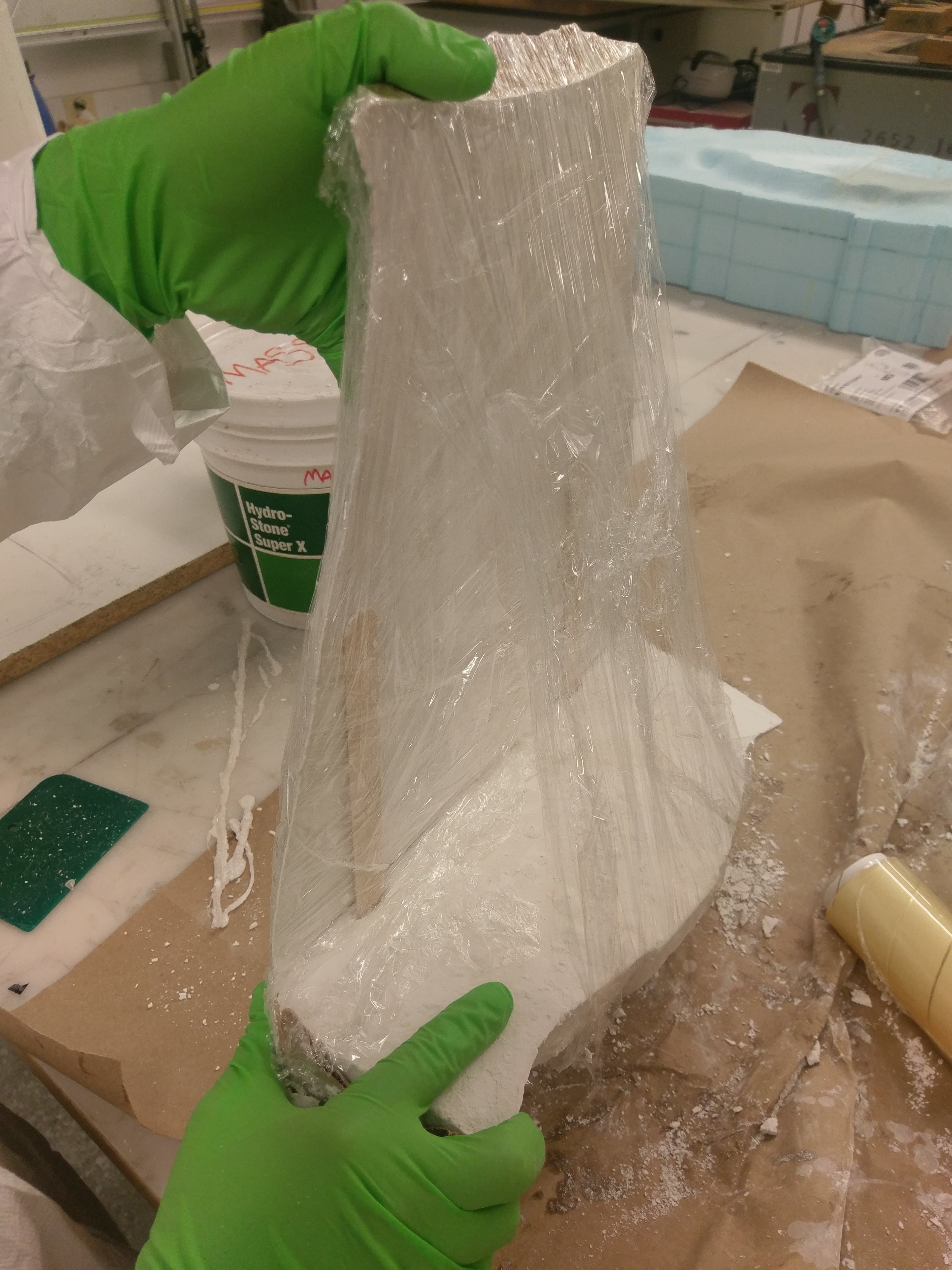

I got plaster gauze from the nearby art store for relatively cheap and decide to make a negative of my back and shoulders.Plaster Gauze is basically gauze with powdered plaster in it so when you dip it in water and lay it down it can hardn in different shapes. It, itself, works in a way that is very similar to epoxy composites. I had my friend John halp me cover myself in plaster strips.I t felt so weird and slimey. I also couldn't move for a good 30 minutes or so until it dried to be rigid.

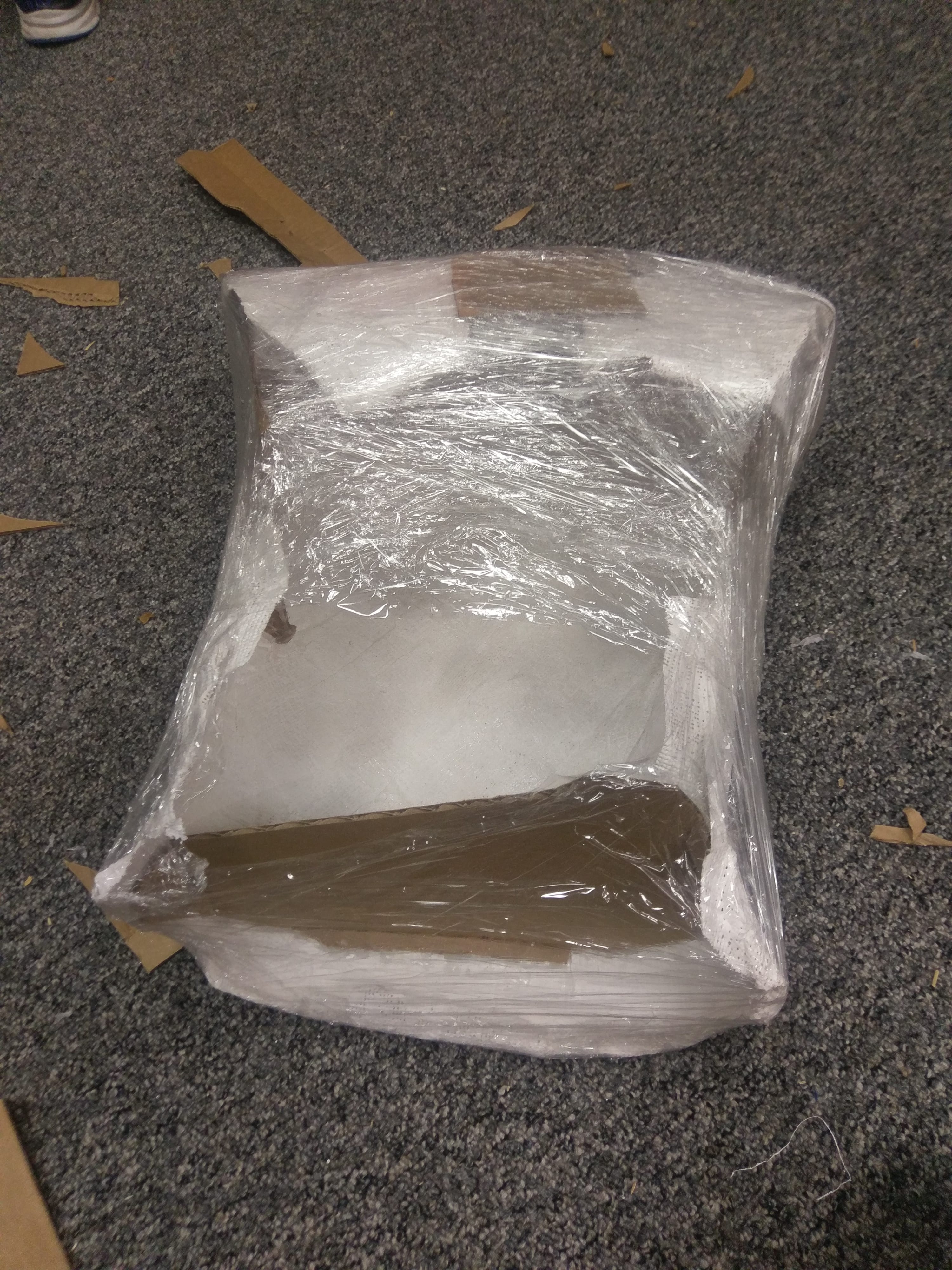

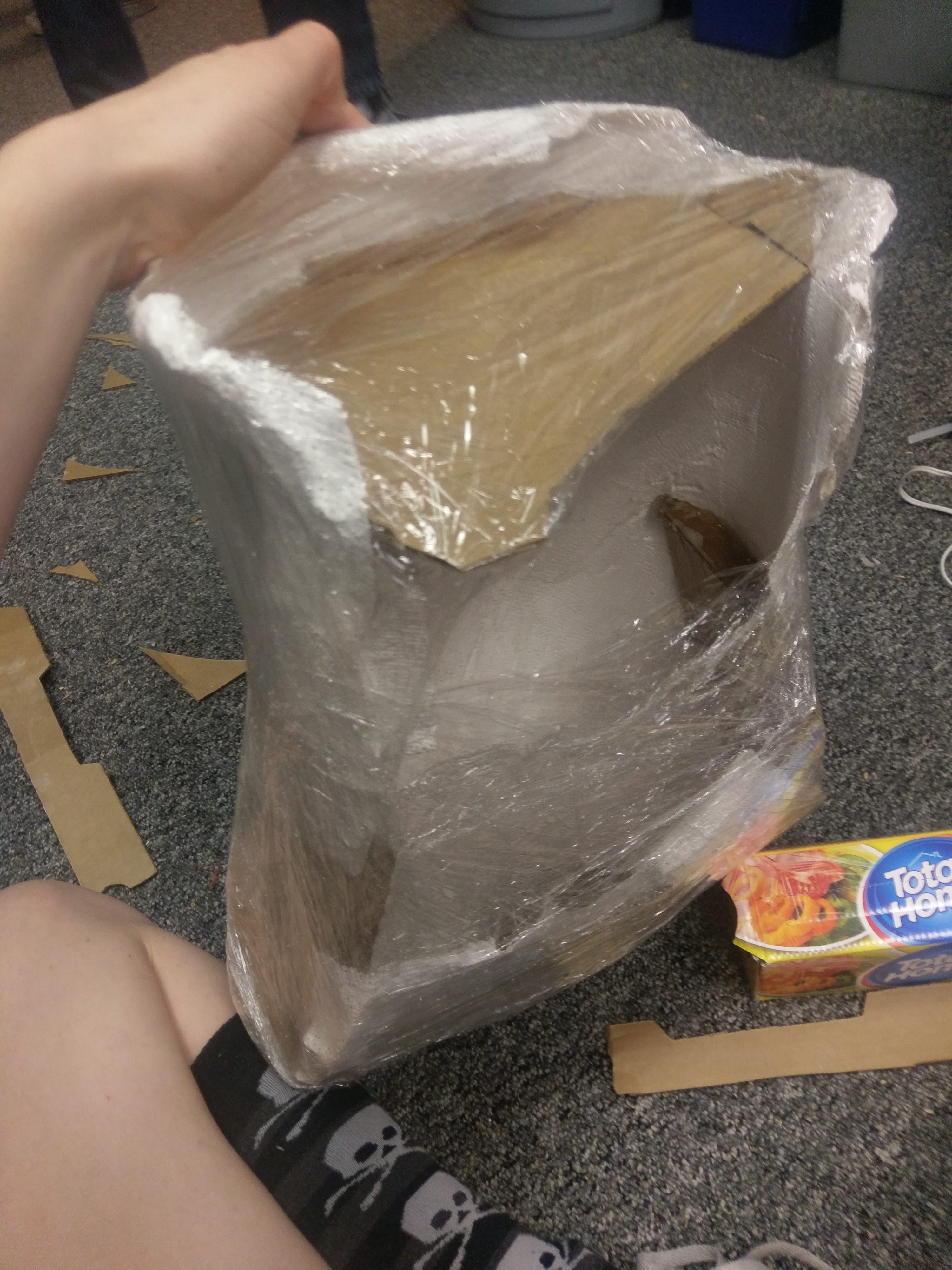

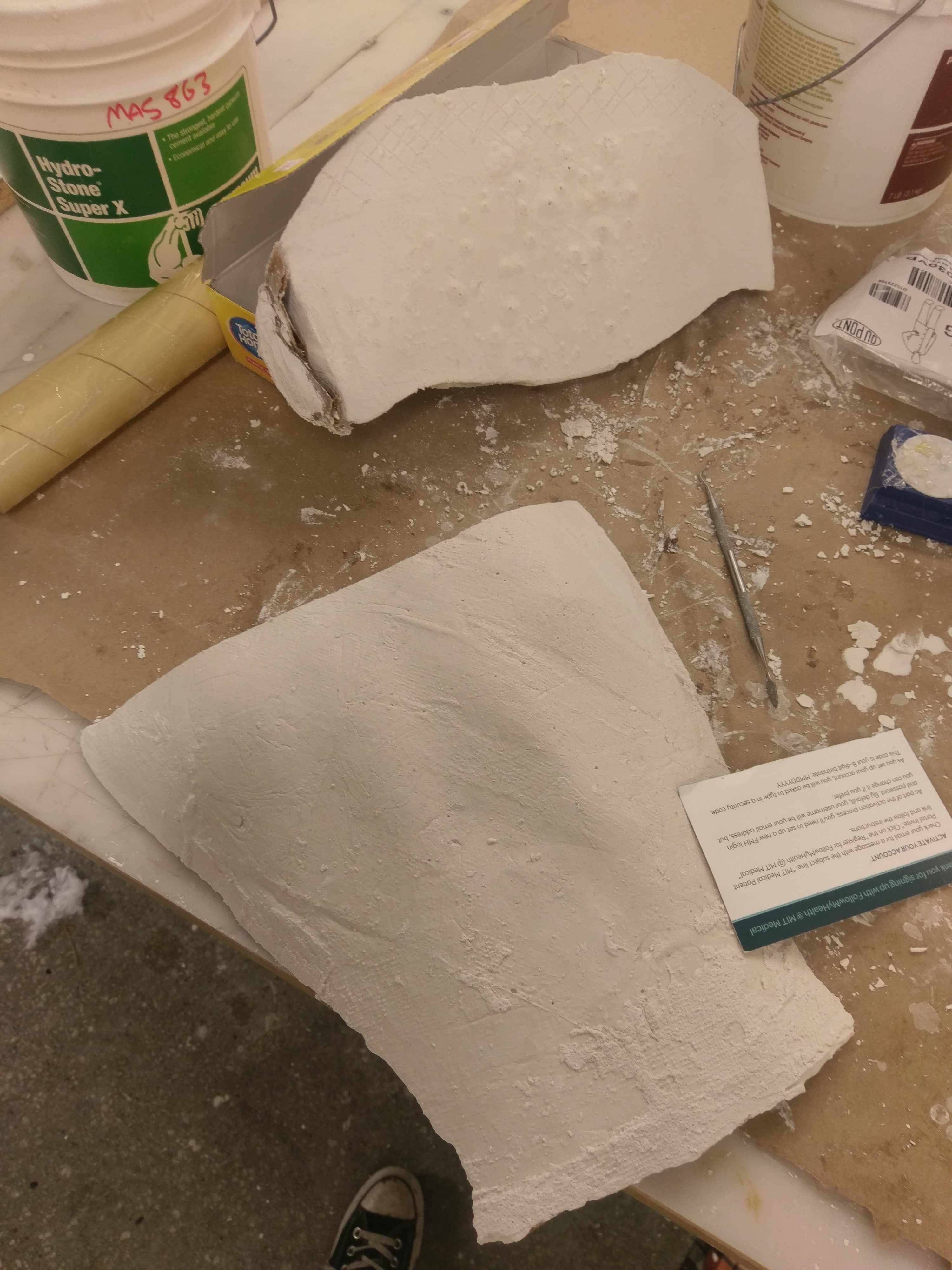

The next step was to turn this negative into a mold. I cut cardboard to fill holes, coated the inside with plastic wrap and then vaseline so the plaster wouldn't stick.

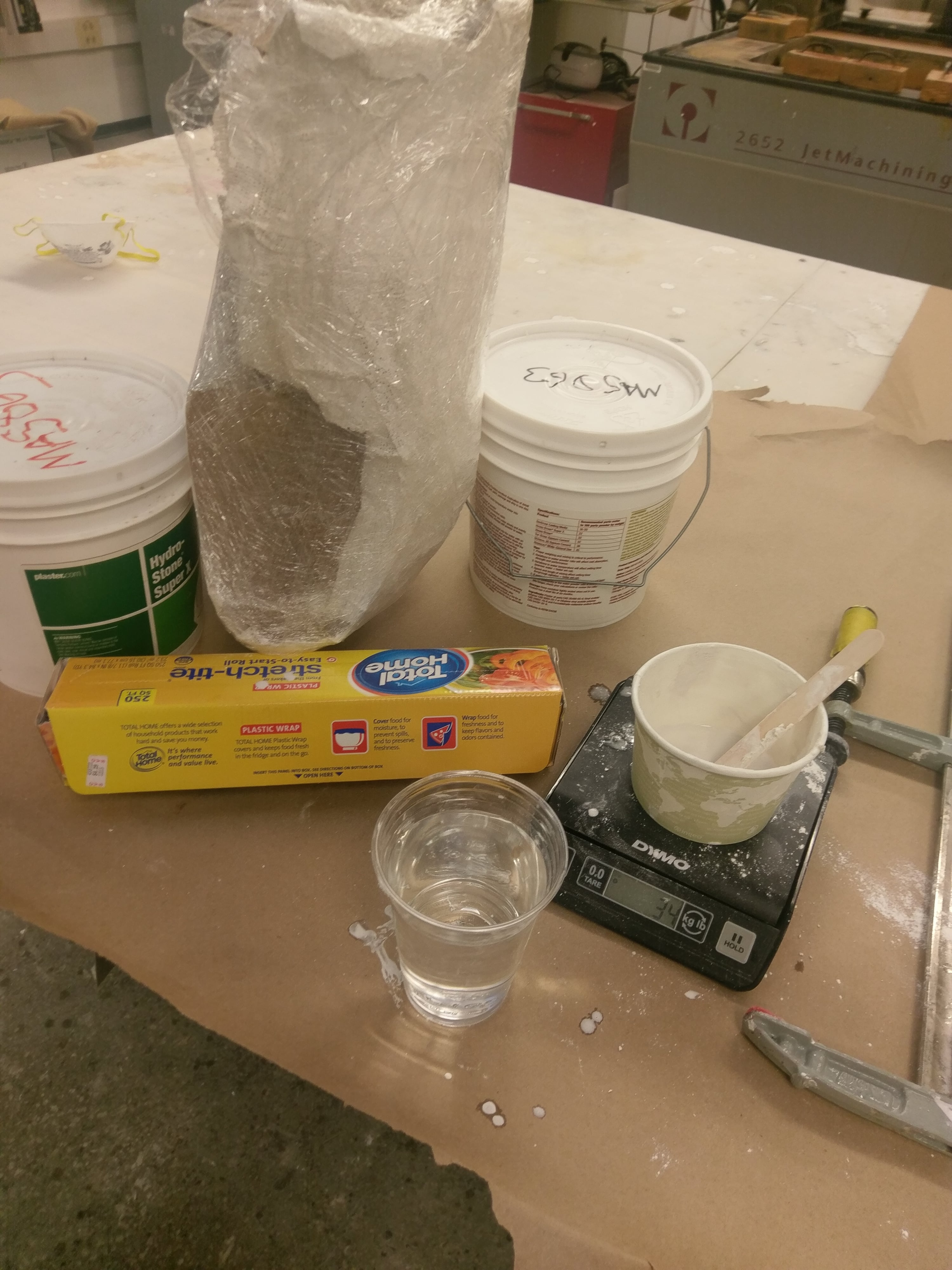

I had to rest the mold up on the plaster containers in orer for it to not flal over and mix more plaster together than I initially expected. In order to get the shoulders and the back I had to build the mold at two different angles (to limit the amount of plaster I had to use).

The two plasters didn't set together well and they came out as two separate parts. I tried gluing them together but they refused to stick together.

I started trying to stick the pieces together by digging holes into the plaster and putting sticks in to hold it up. I tried hot glue but it didn't stick so I ended up just propping it nicely together before putting the composites on.

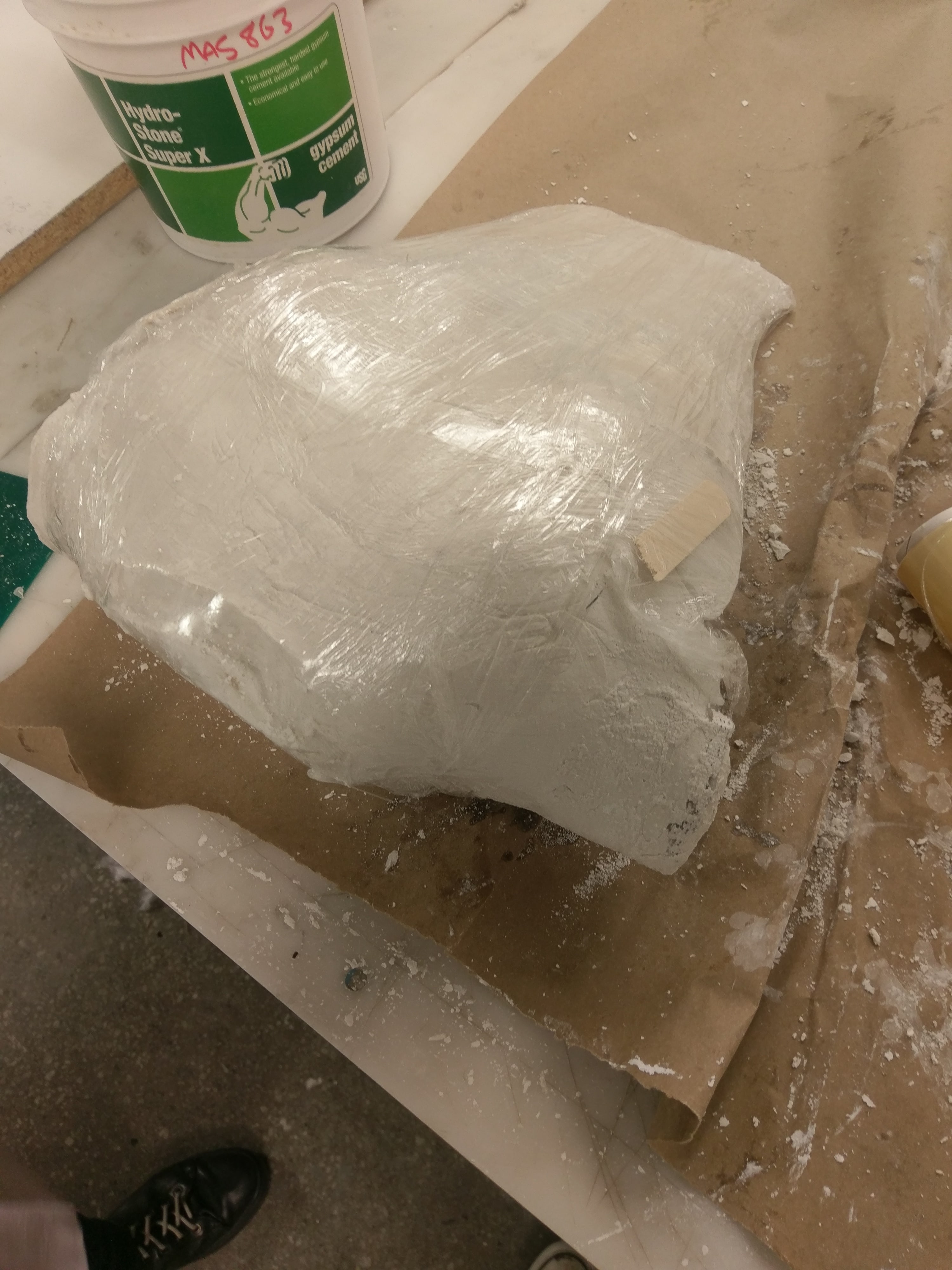

Here's a picture of the mold sitting up together.

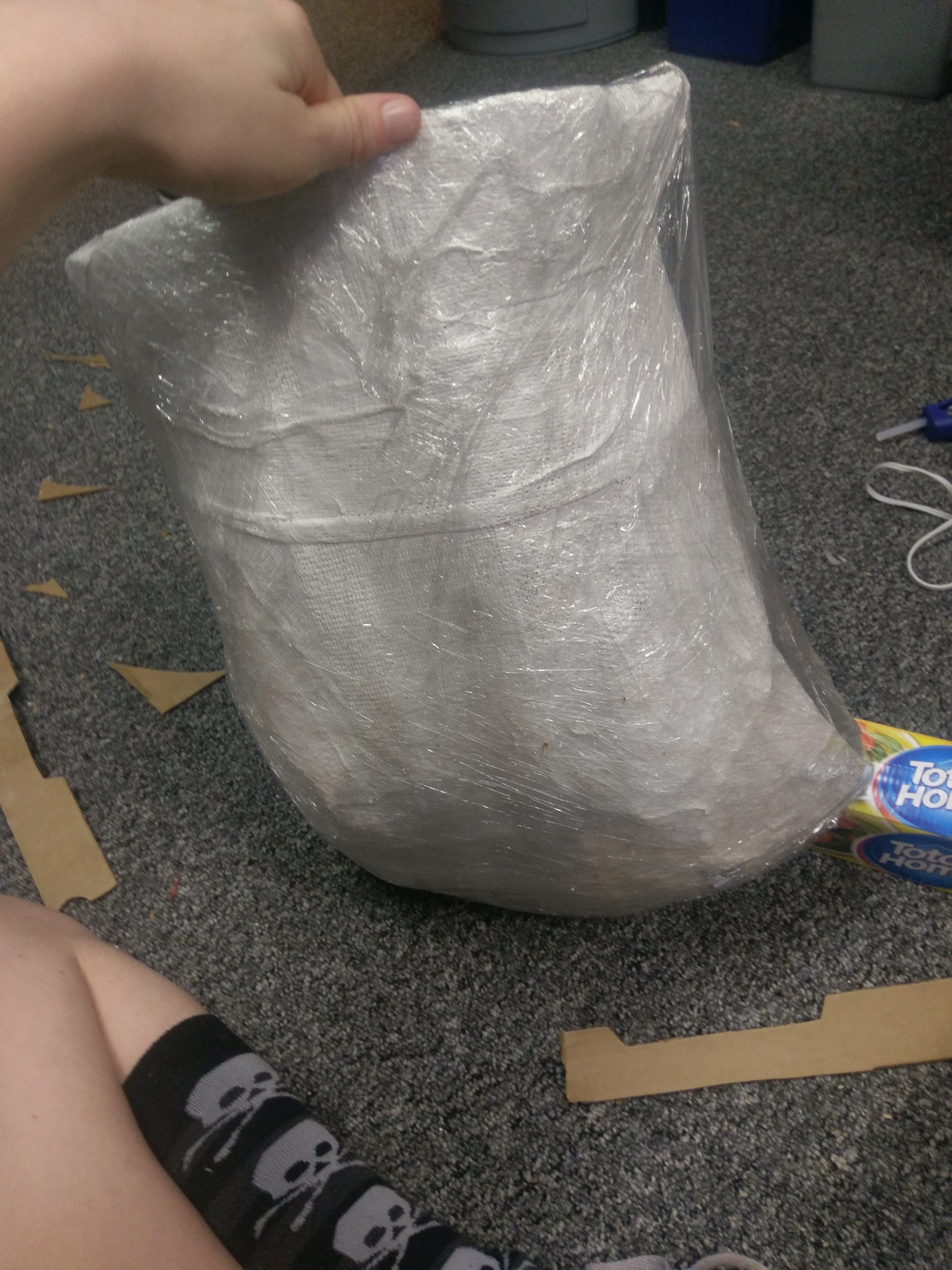

I had to coat the plaster with the plastic wrap and the different absorption papers to prevent the composites from sticking to the positive.

I cut out 3 layers of the burlap to coat in epoxy.It seemed like that would be stiff enouh to work for my back support.

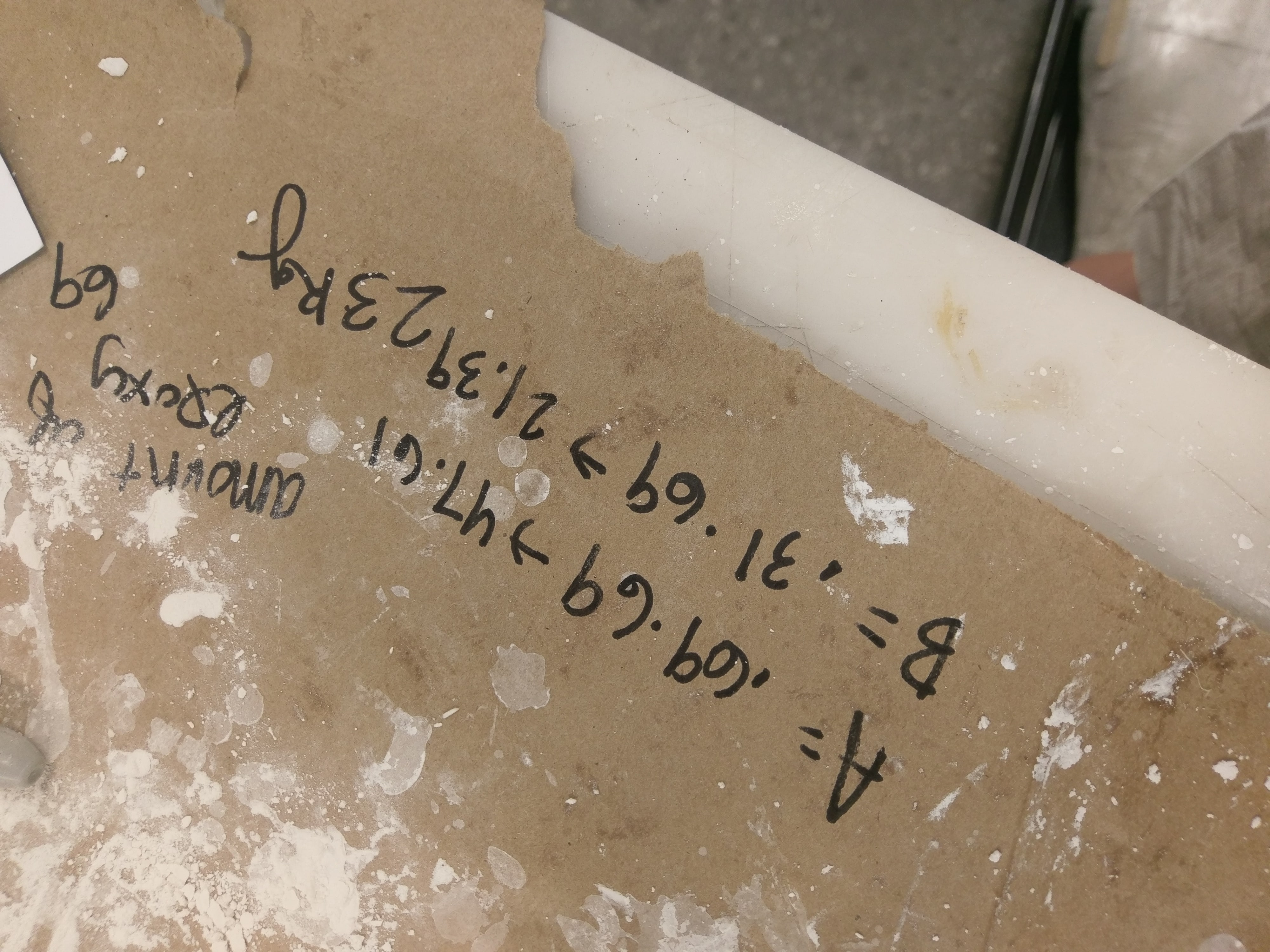

I did the calculations on a stray piece of paper and figured out how much epoxy I needed for the bburlap and how much of part Aand part B I needed to mix.

I used the Hydrostatic method that Neil suggested. I filled a large bag with water and placed it on top of the composites.This works very similarly to a vacuum bag but with less pressure. It works really well.

It came out very nicely and fits on me as well as I had hoped.