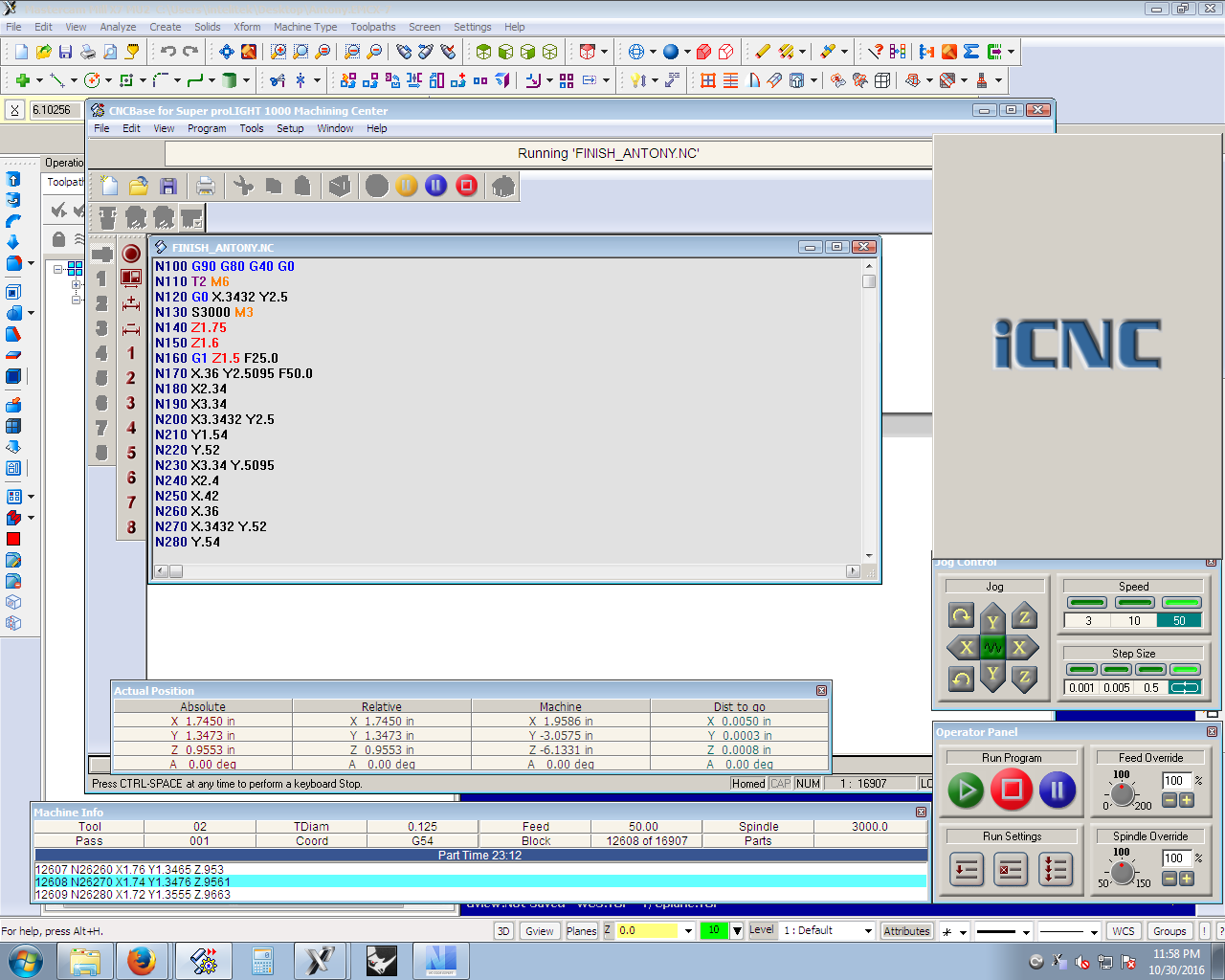

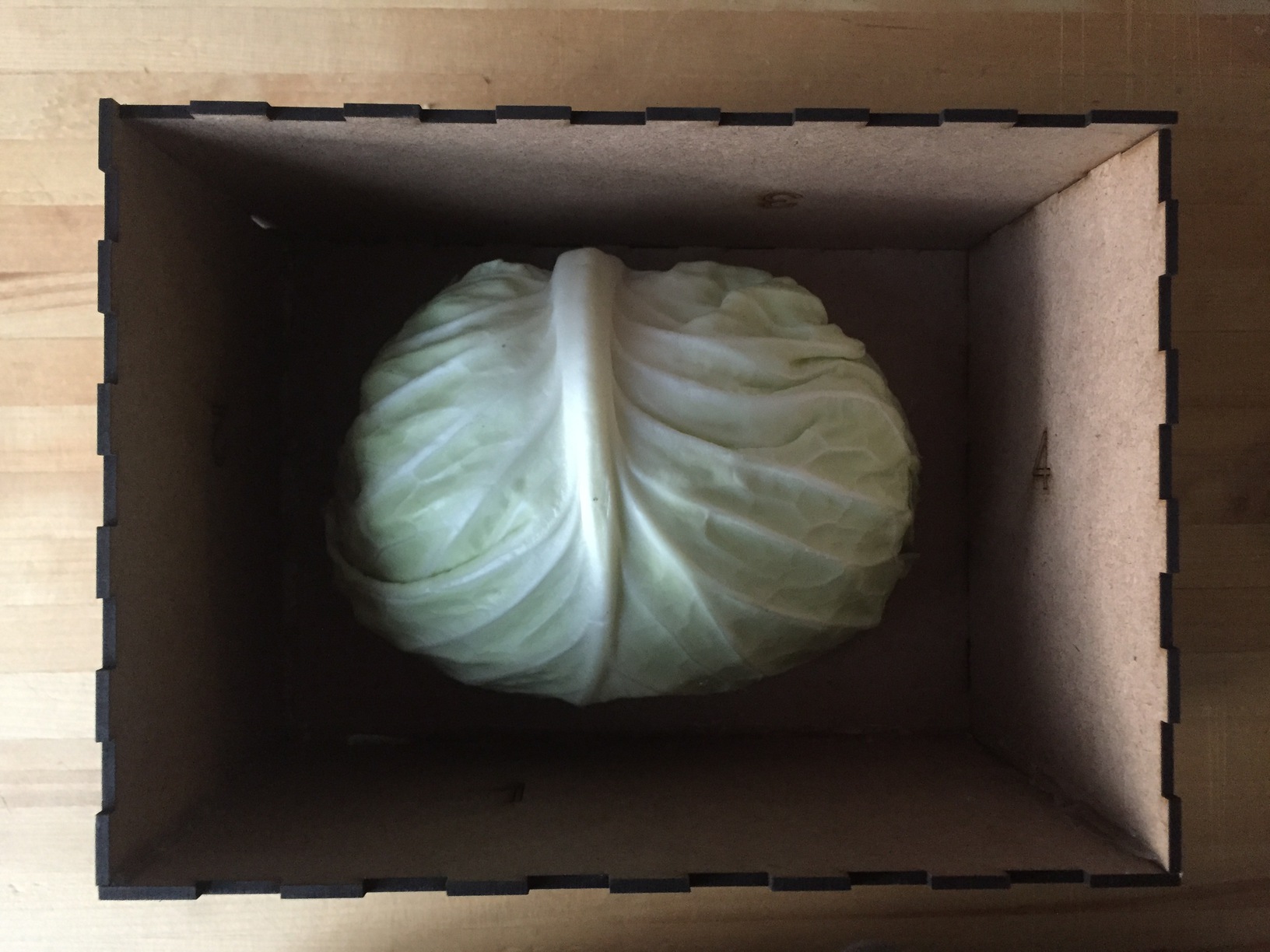

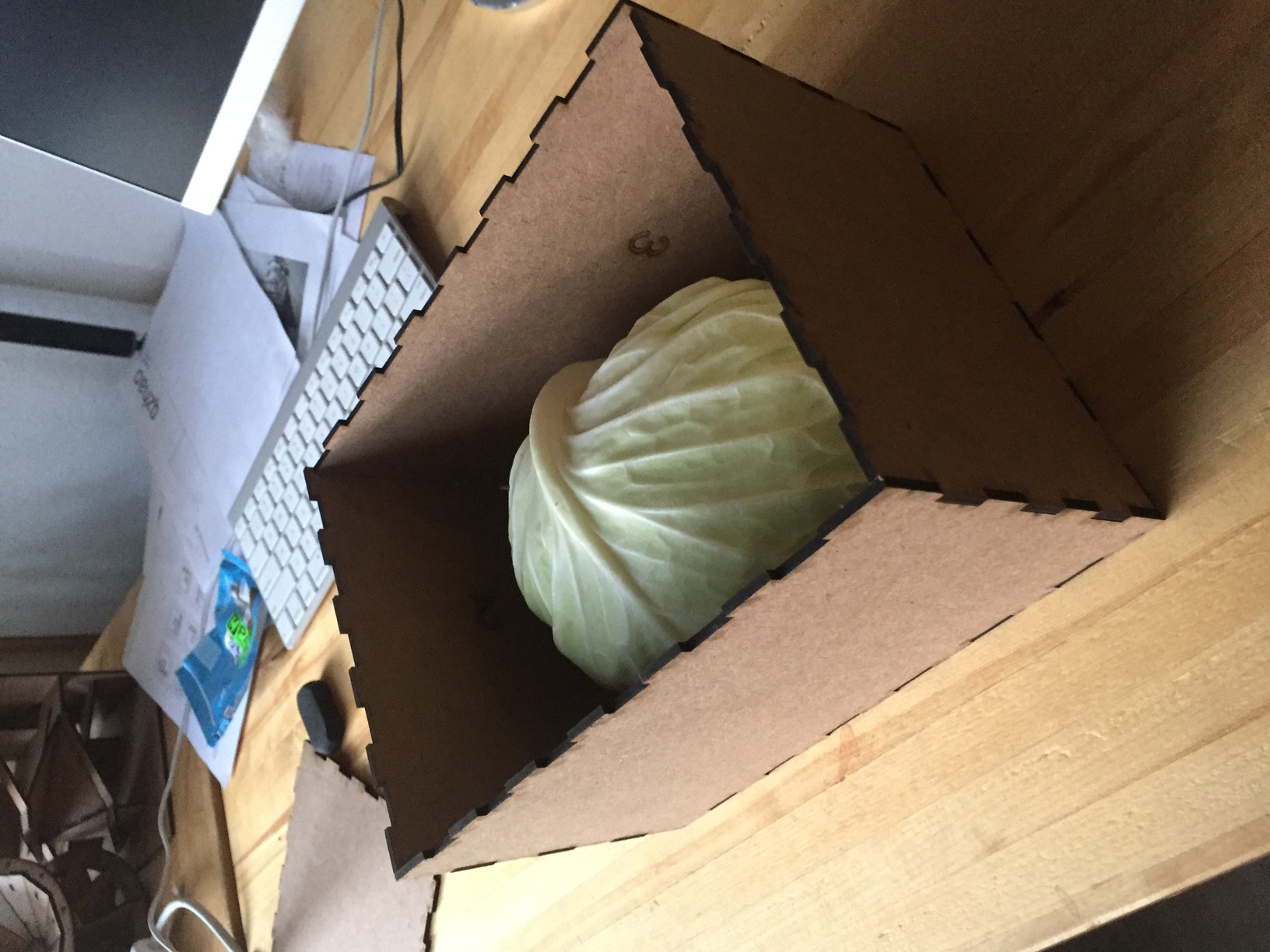

After getting down the workflow, I start to look for challenges. Then, I found a handsome looking cabbage.

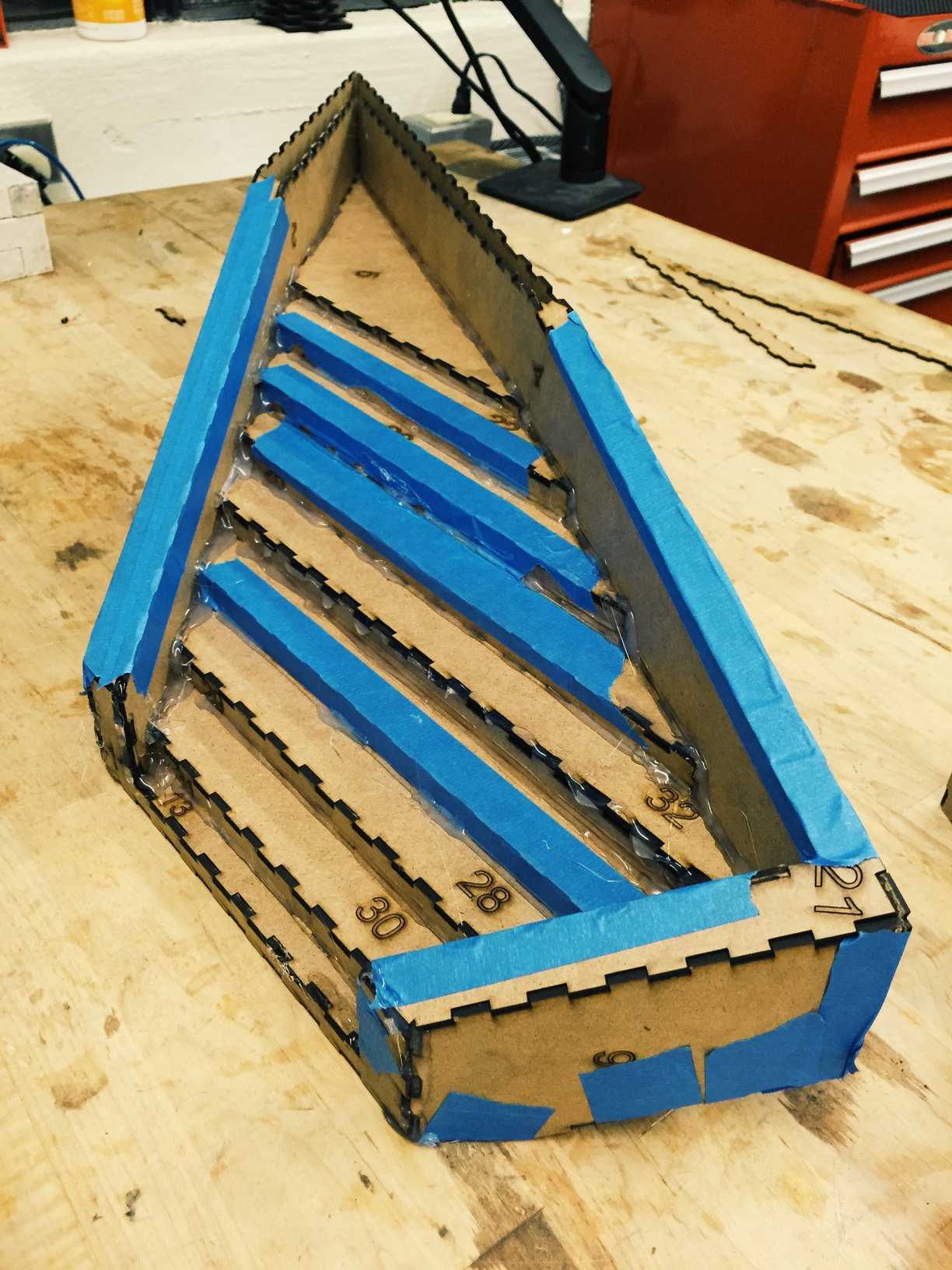

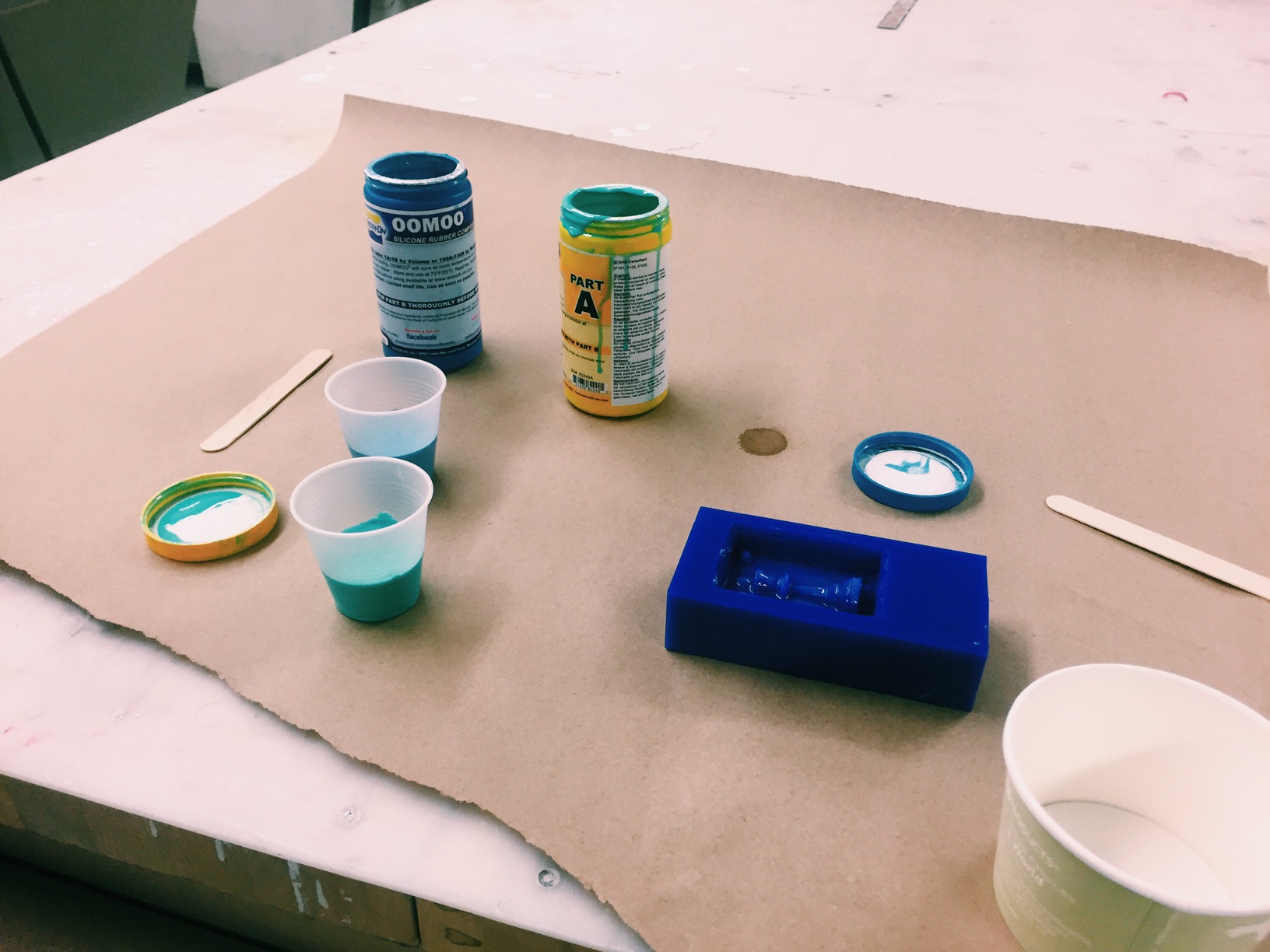

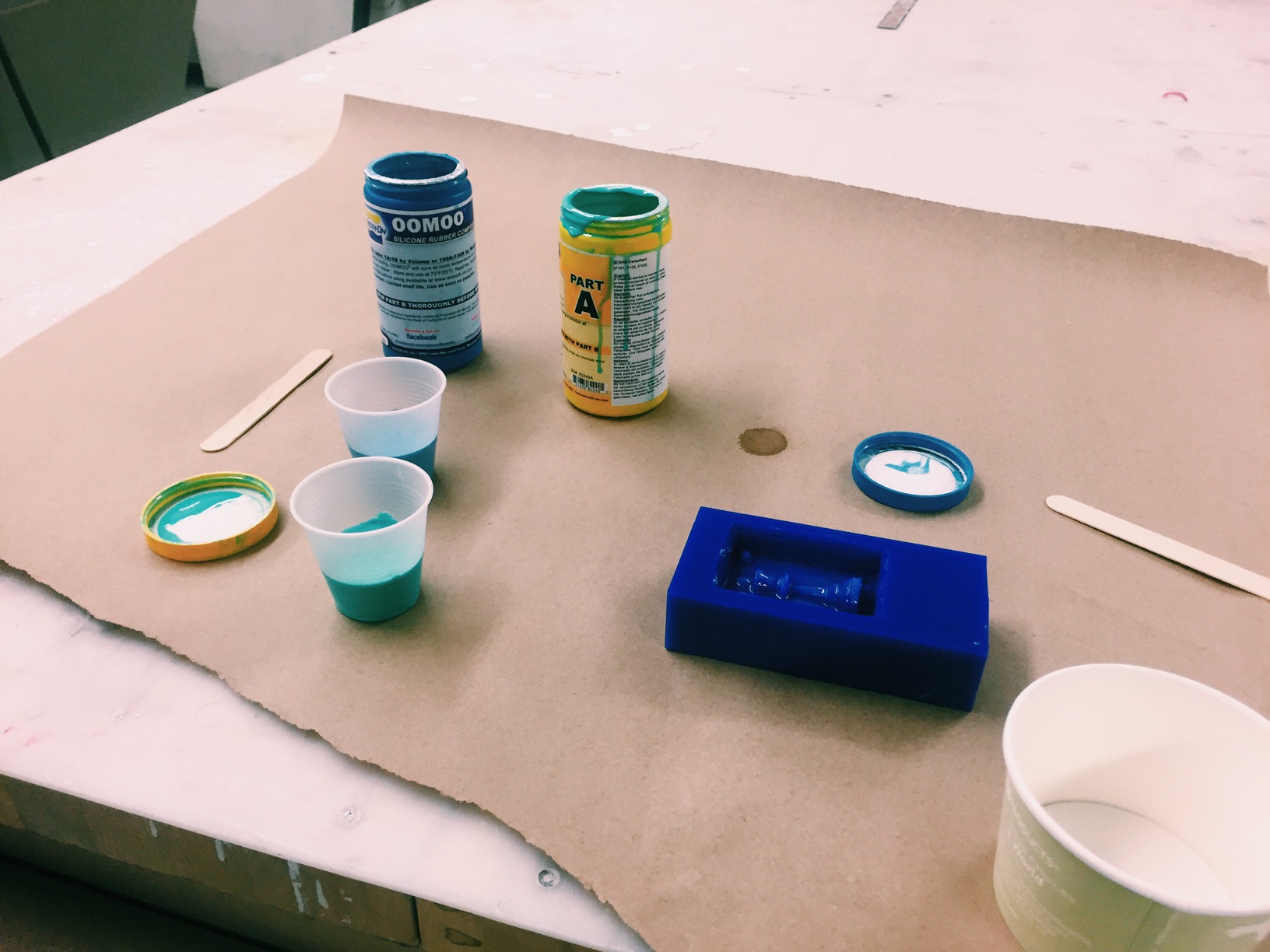

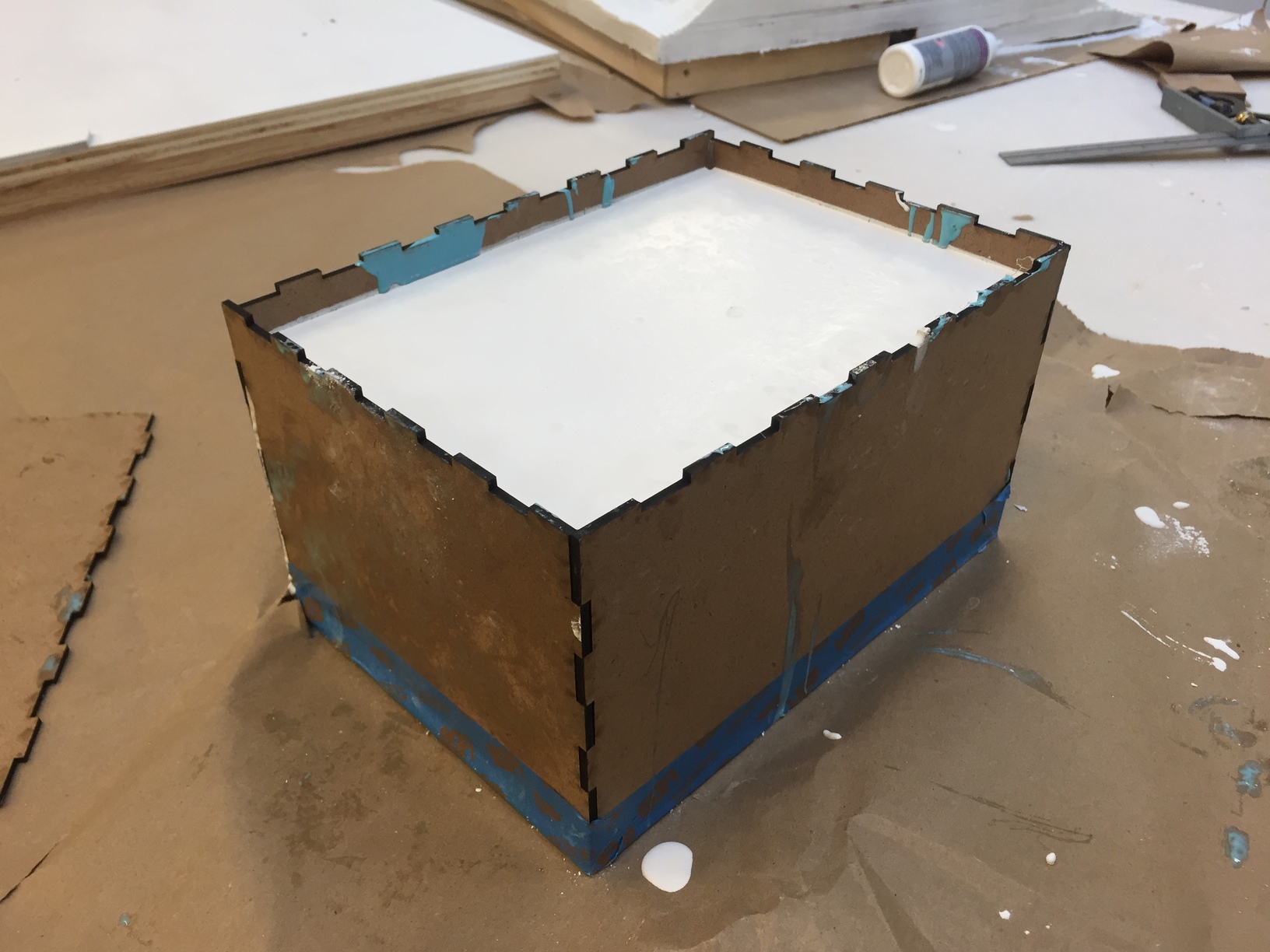

I used a cabbage for making the mold for making the cabbage. I tossed the cabbage into the container which I lasercut with masonite. A batch and a hald of OOMOO 25 was used in filling three quarters of the container, and it was not enough to cover the whole cabbage but a thin shell of rubber was formed on the surface. So to reduce the cost (OOMOO is expensive), I casted the rest with rystone.

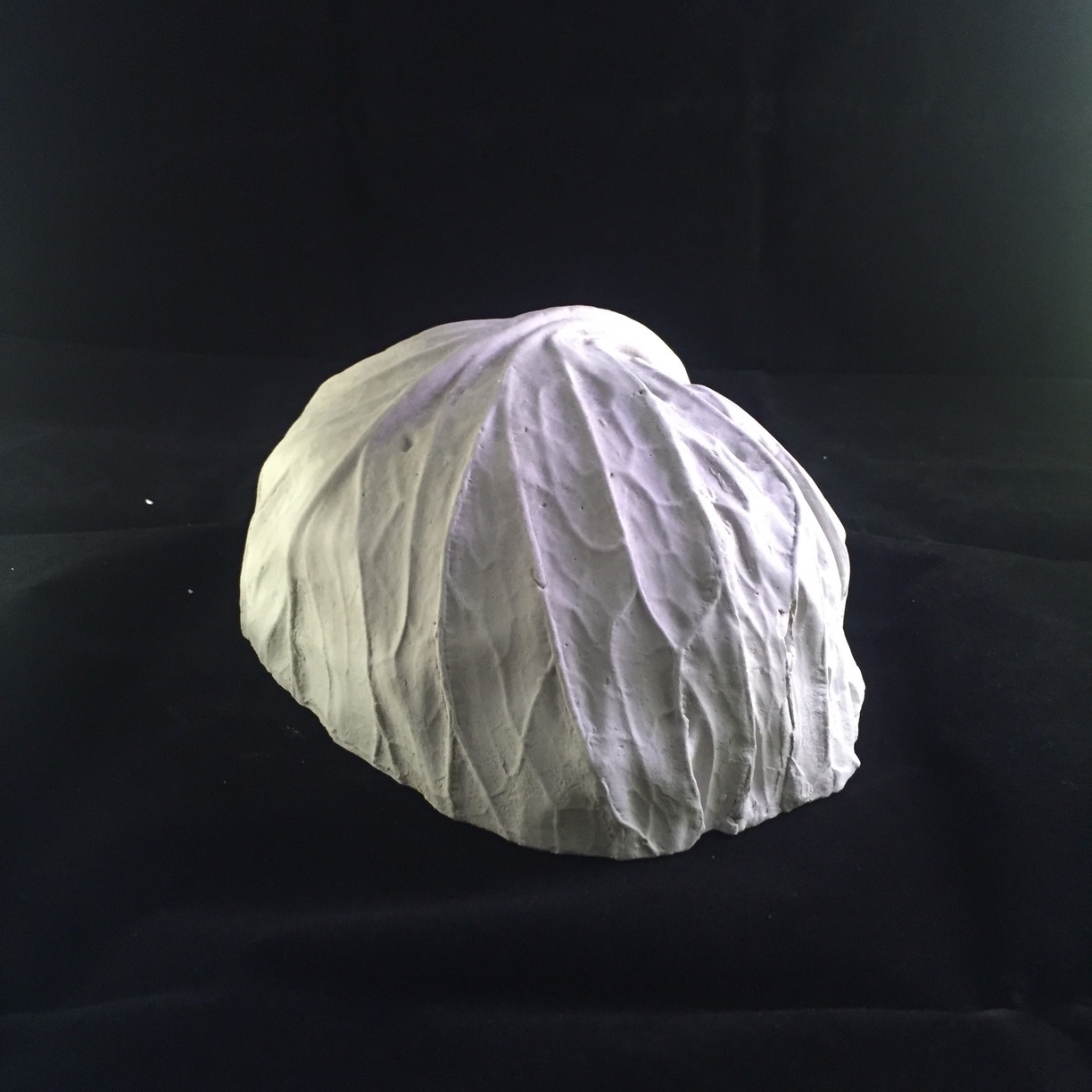

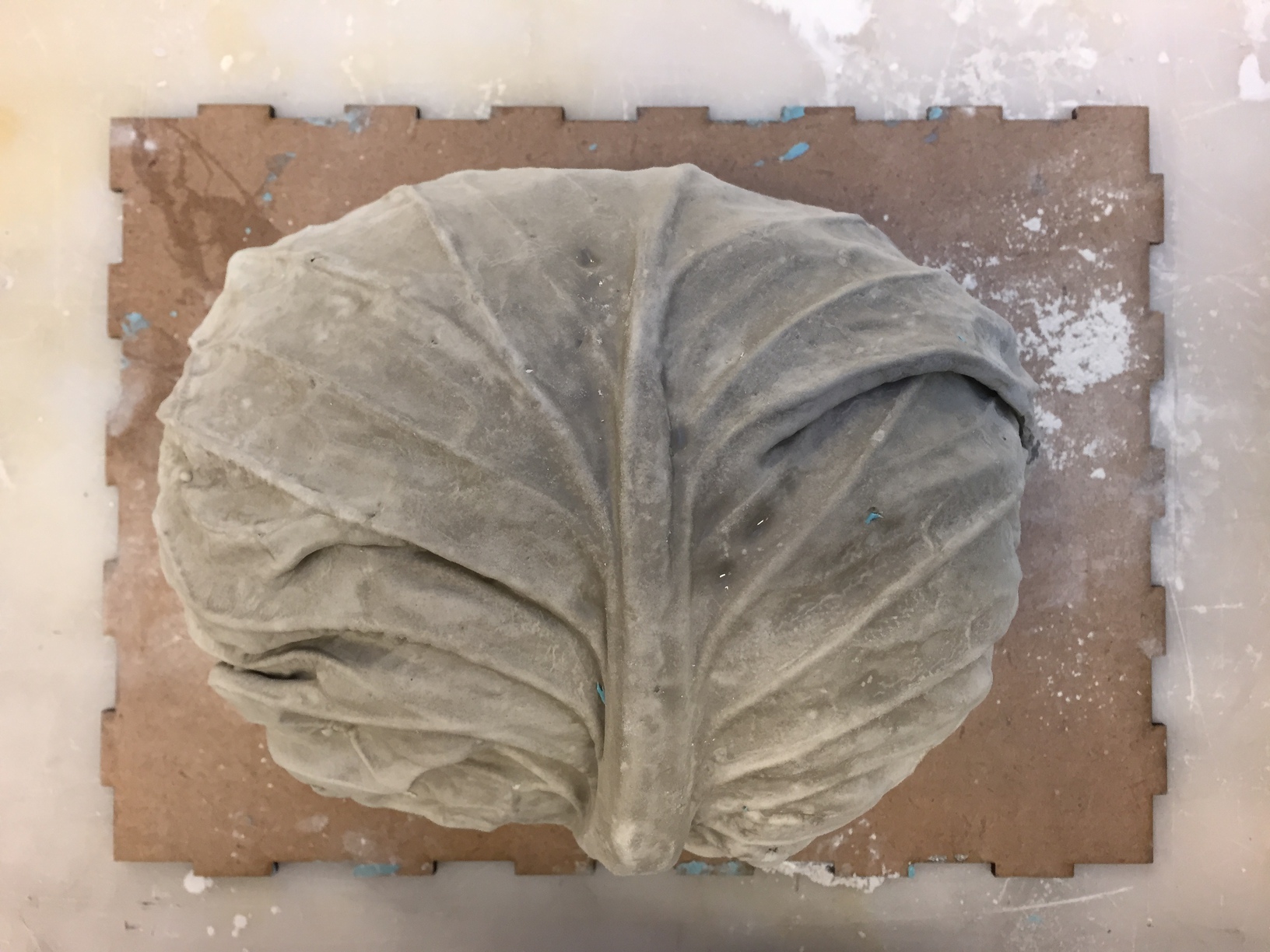

The mold itself turned out to be an art piece -- an frantic encounter of hard and soft.

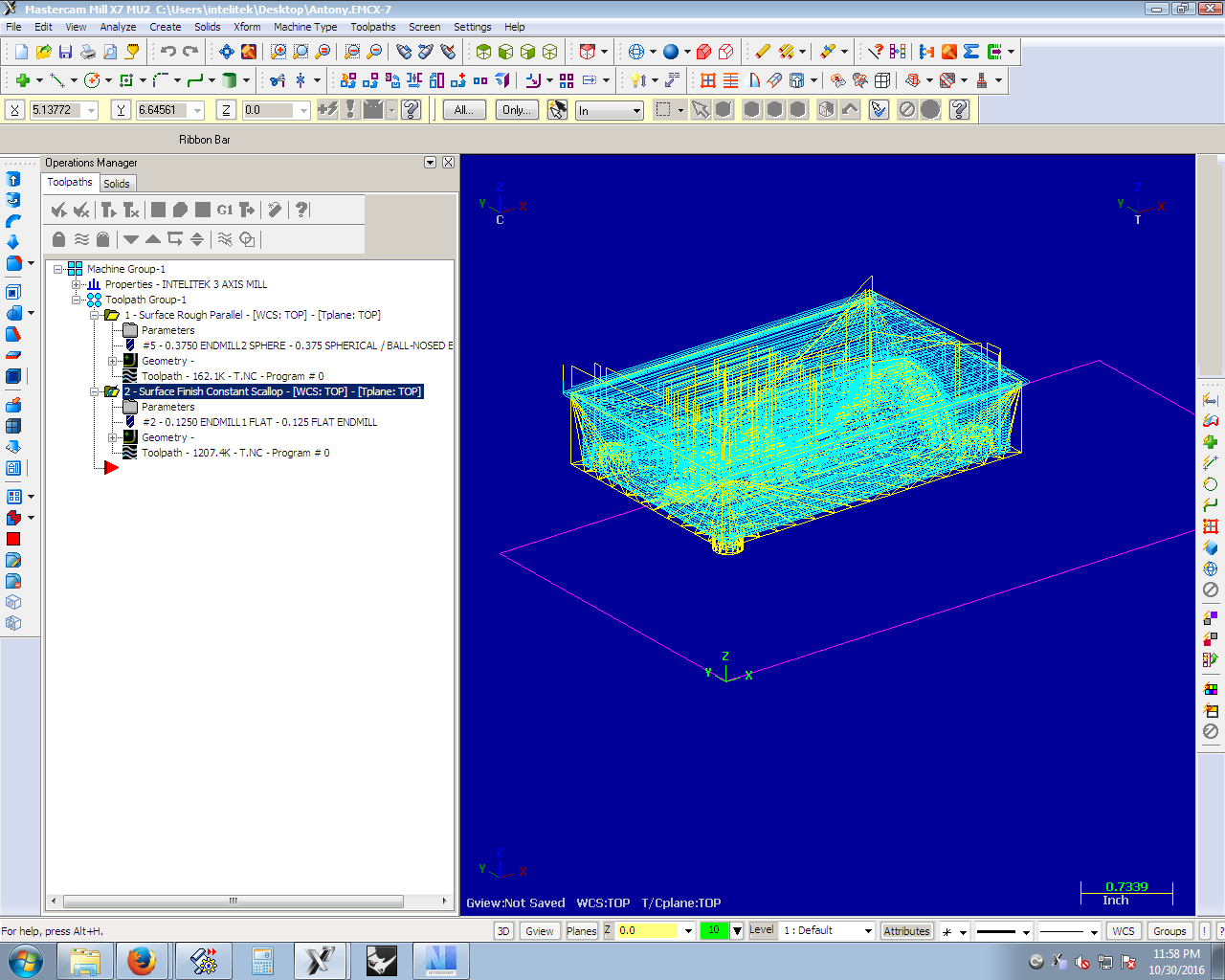

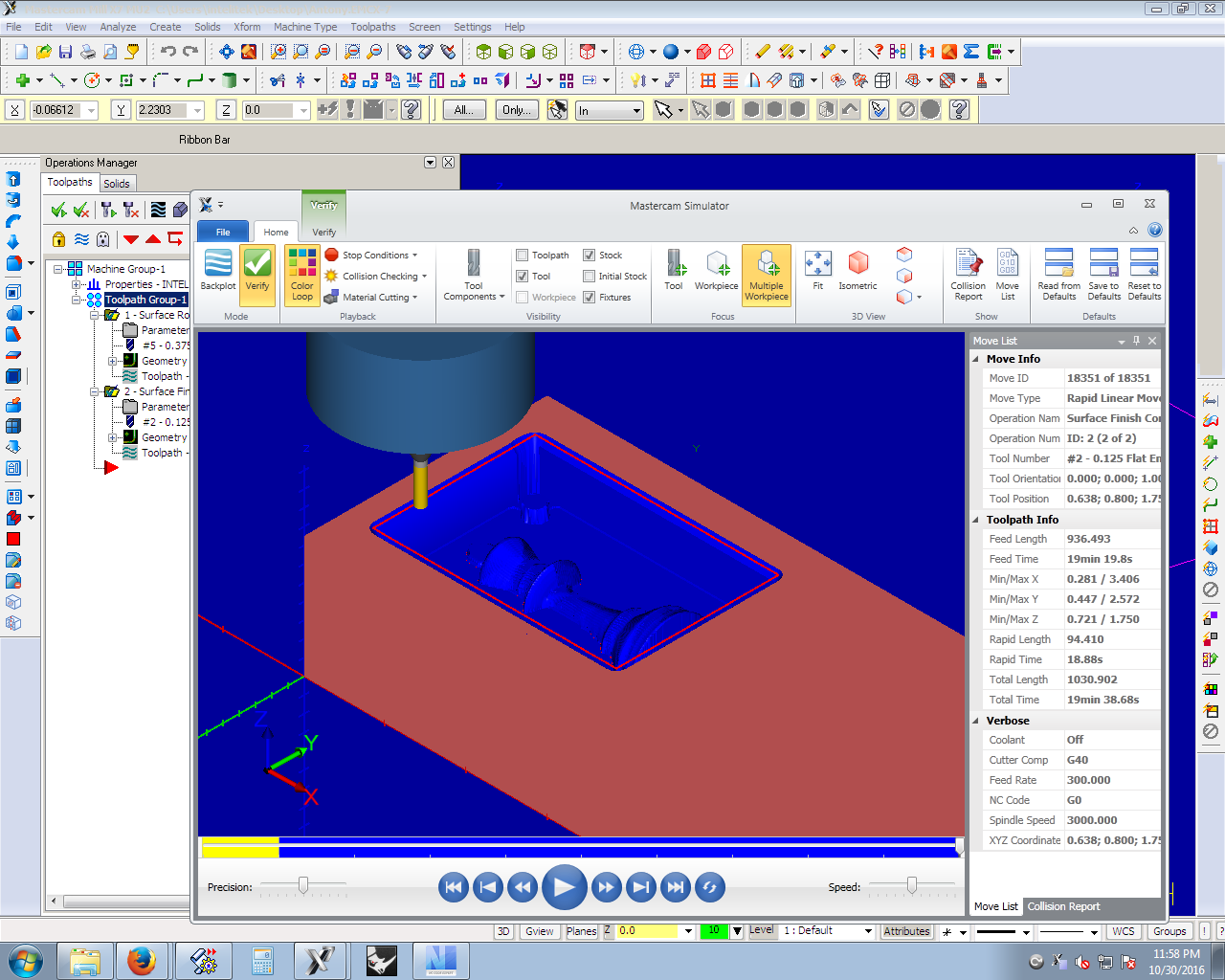

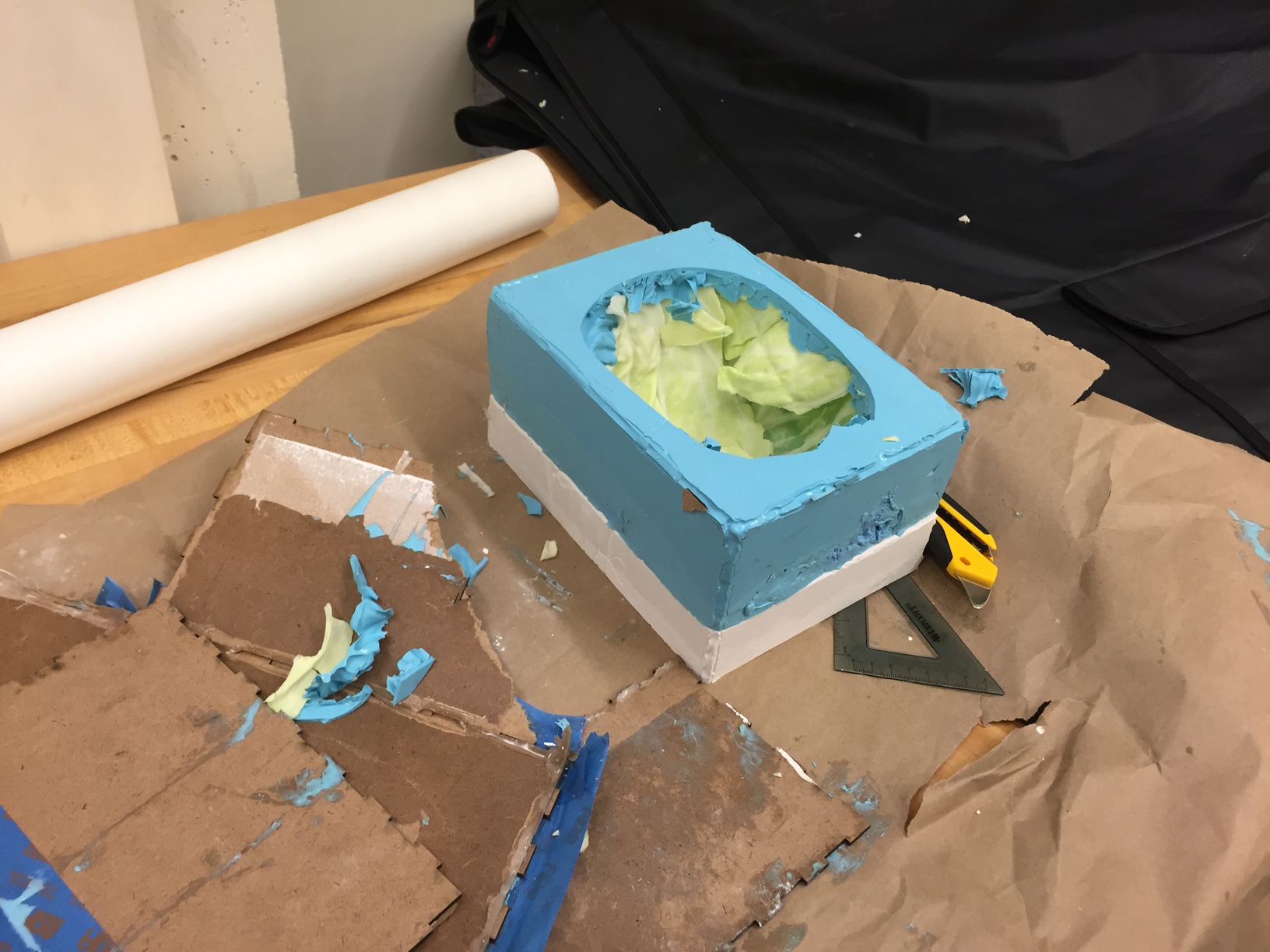

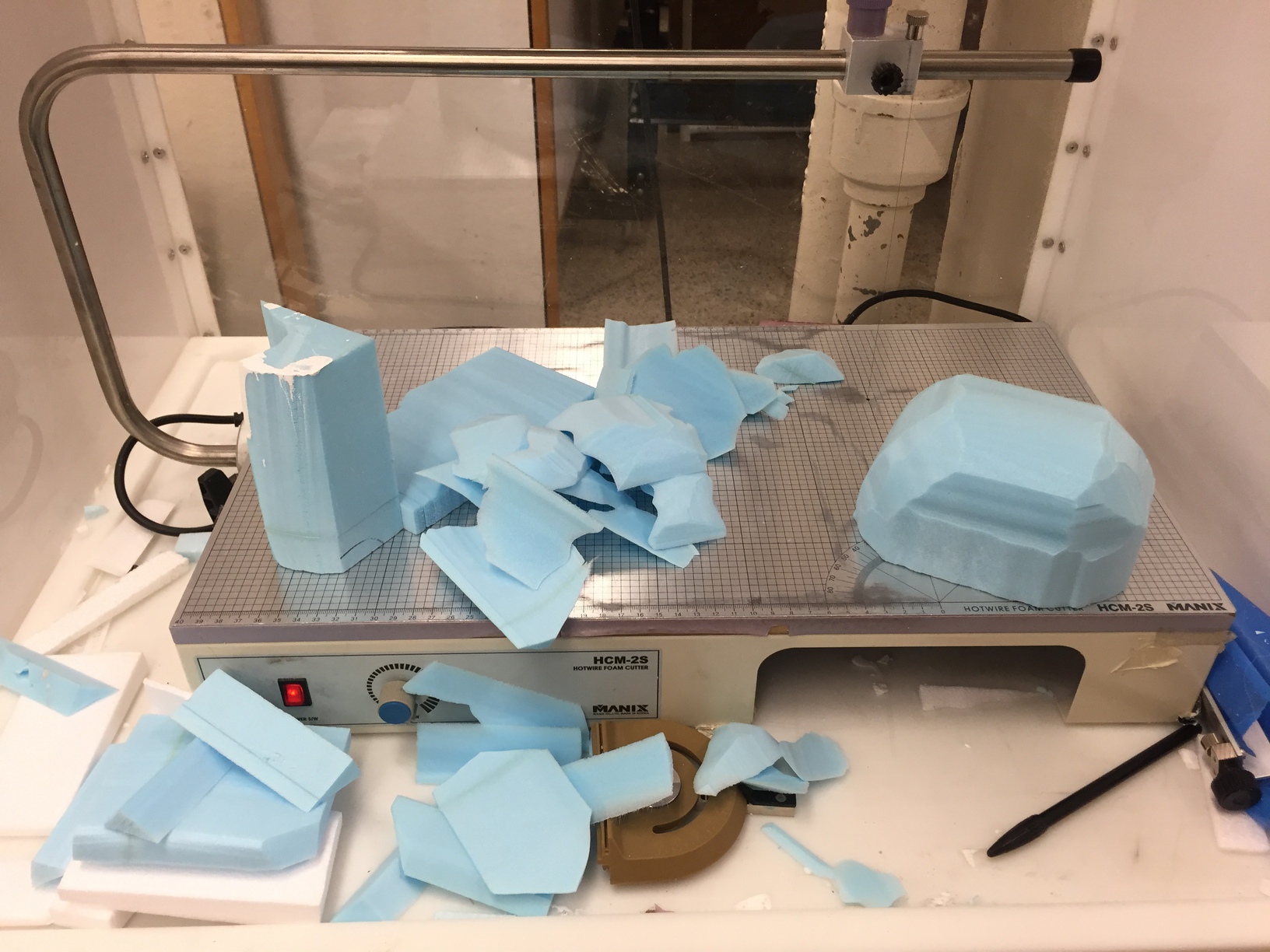

Proceeding into casting the positive, I first cut a piece of foam down into roughly the shape I want for the cavity of the planter, sanded down the corners and edges, put on 5 layers of gesso, sanded the surface again, and finally sealed the primer with varnish as I want to reuse this cavity mold for more production in the future.

This time I used Hydrostone. A layer of release agent was applied prior to casting.

The result is amazing.