Week 10: Composites

This week we had to do a cool process to create objects made of composites! I decided to go once more for the sphere, but using this process.

Milling the outline

Milling the outlines was just as in the molding and casting before, but on the large machine. Tom and John were truly helpful giving us the tips on how to glue the foams together to make a larger mold, and they gave us the recommended settings for the mill. We had to stick our foam mold unto the milling machine by drilling screws into the sacrificial layer.

Milling the sphere outlines

Composite Creation

I paid a ton of attention to the process. I took notes as Jasmin was giving us the recital. These were the notes that I took, and they served to guide me in the general process

-

The general process is to put the epoxy on the foam and cover it.

You will cover it with 3-5 layers of burlap that will have the resin mix. That in itself will be covered with teflon-like paper with holes and vacuumed.

- Start by putting a paper over your workplace.

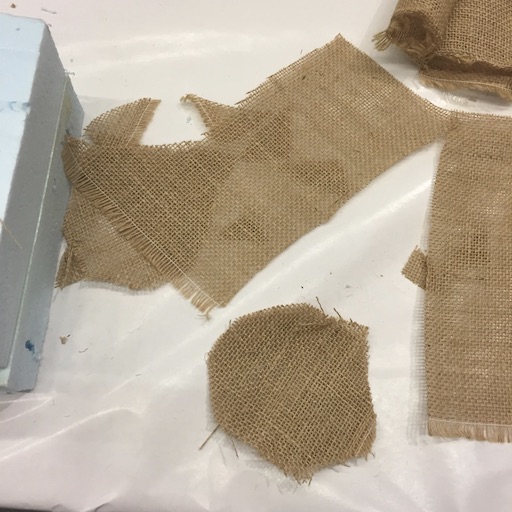

- Cut the burlap into shapes that will be able to cover your mold

Cut burlap

- Spray glue unto the foam

- Put aluminium paper where you want the resin to stick to

- Prepare to mix the resin

- Use Gloves and glasses

- You have 18 minutes to work with it after you mix it

- After this you’ll need to leave it at least 3 hours for it not to be sticky

- It takes 7 days for it to be completely dry

- Mix is composed of 2 parts epoxy, 1 part hardener

- Spread epoxy mix on burlap uniformly

- Spray the easy release on the aluminium

- Put soaked burlap on the aluminum

- Cover the burlap with the teflon-like paper. Make sure to make small holes on the teflon.

- Cover with the cotton-like material

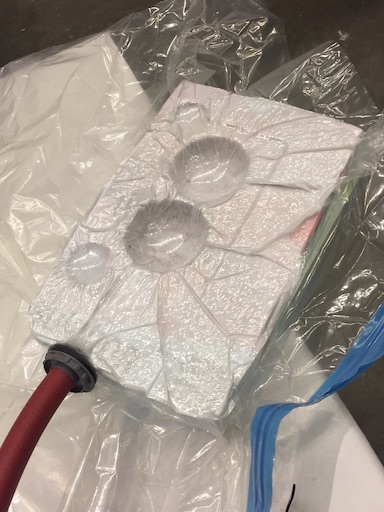

Result before putting into vacuum bag

- Open a vacuum bag and spray easy release.

- Put project in the vacuum bag

- Close vacuum bag

- Vacuum out the air for 30 minutes

Vacuumed bag

- Close the bag completely

- Leave for 3 hours (ideally with the vacuum connected)

- Profit

Final Result

The final result was not as pretty/precise as I wouldve liked it to be. However, it was a good attempt, and I'm sure that with a better mold and more caution, it will be better!

Split sphere

"Sphere"

Files

Here are the files that I used for the models.