Rhino Strikes Again

As I have been running late on preparing my final project, I decided to use the week to create a prototype of the final touchtable.

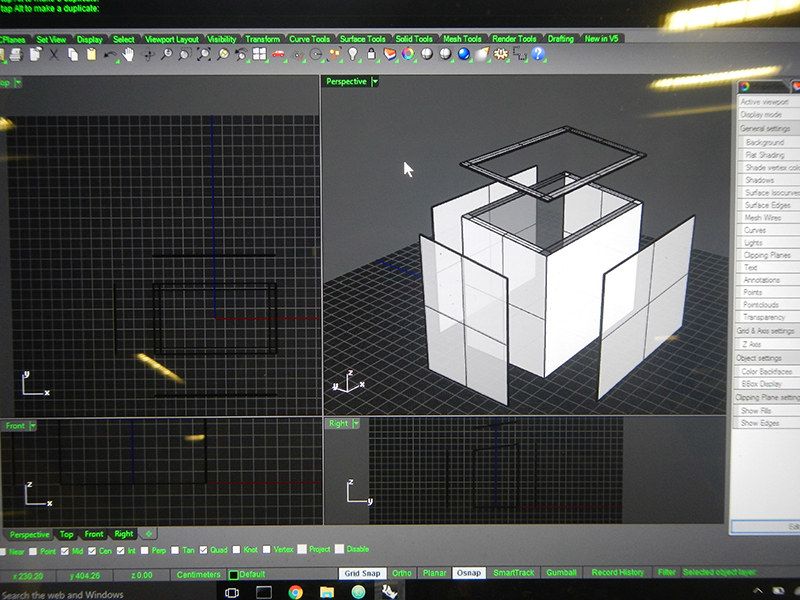

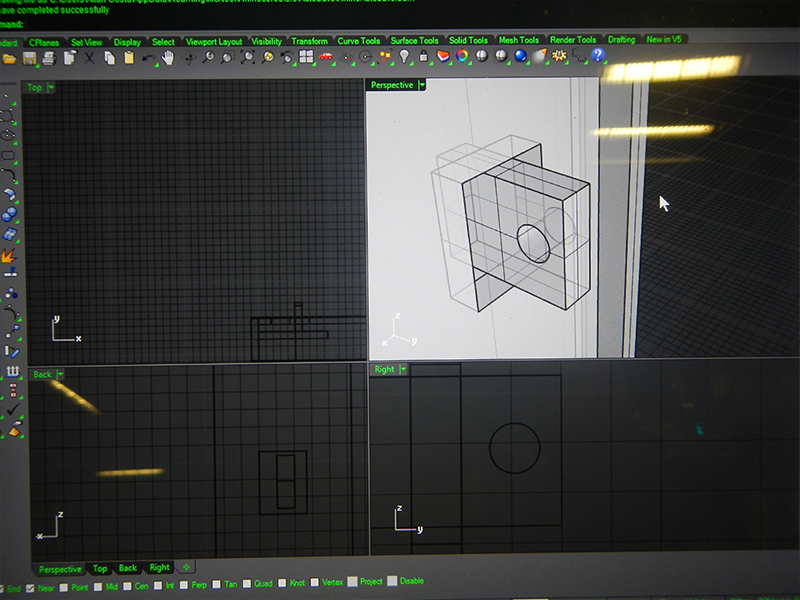

since I've been mostly using Rhino these weeks, I'll keep using it for the end of the semester and for the final project. The challenge for this week is designing the basis structure for a 3D table even if the model itself will have to be 2D cut.

The table will have a small, locked door on its back side to allow for technical things to happen (from prototyping and building the electronics to technical problems that will emerge).

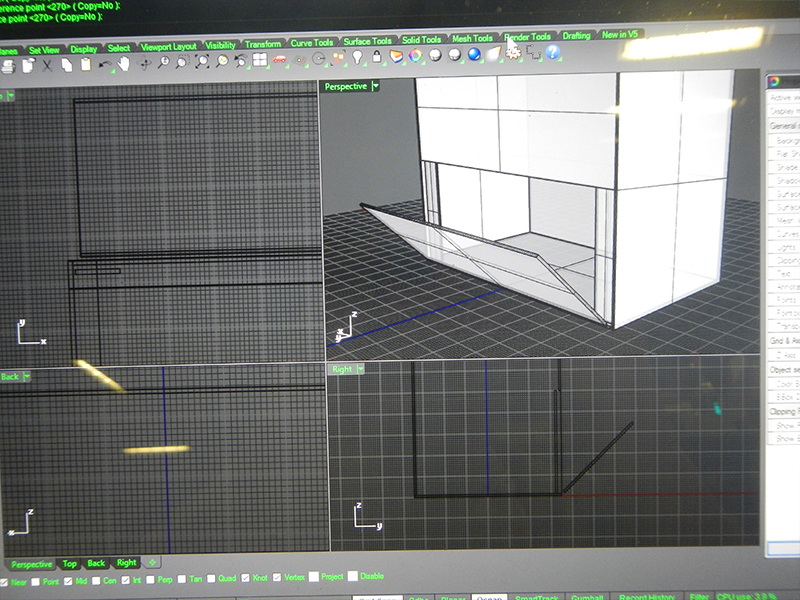

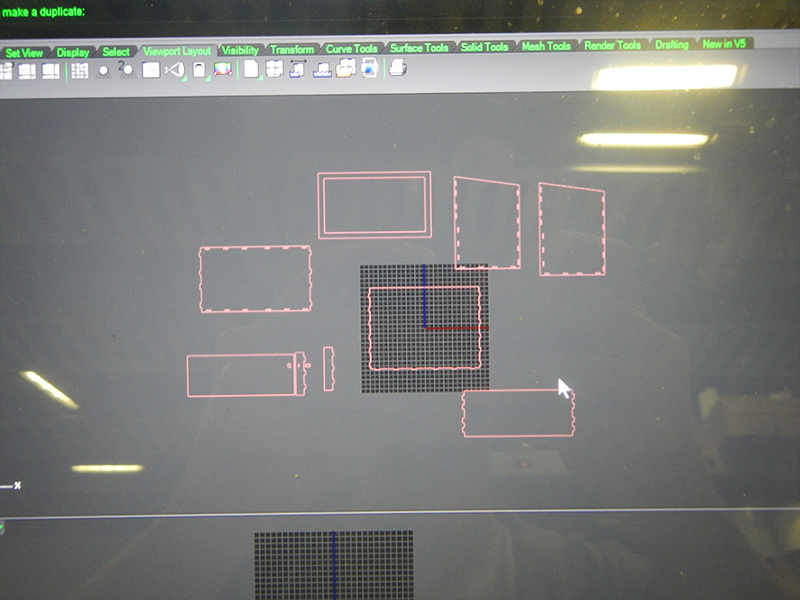

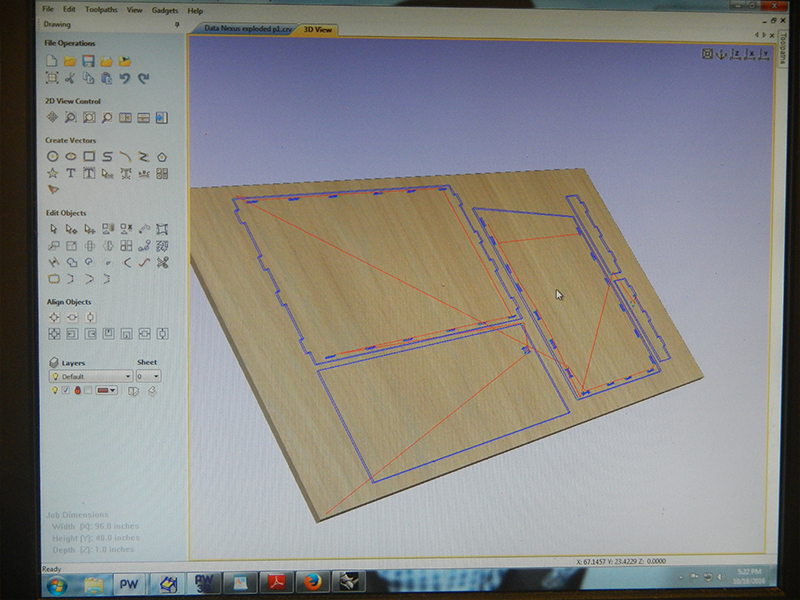

I exploded my 2d surfaces to a cuttable model, projecting all of them in the xy plane of Rhino, which is already enough for a .dxf file to be generated and processed processed for machining

Machining

Maching was much more straightforward than the design itself. One key thing that I didn't do and that would have made my life much easier was to try to organize the components already considering the size of the sheet and its position.

One problem that eventually emerged was that at that point, for whatever reason, I though we were not limited to a single piece of wood: my design was to be printed in three of them. I had to solve this by slightly resizing the 2d model for it to fit in the two pieces that I was limited to using. Because the line for using the shopbot this week is huge, I had no other option but to resize my model. Including the joints.

Don't do this.

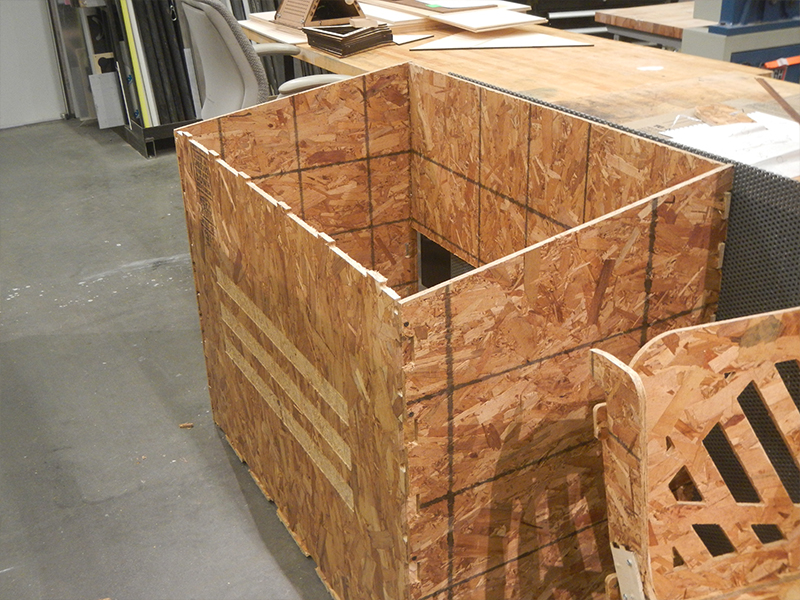

and some pieces already cut

Building...?

Of course, the resizing cause the whole joint system to fail: when I resized, I was considering the cut being made in a slightly bigger way due to the diameter of the tool; later I came to realize the tool would cut "from the outside," already accounting for its diameter in such a way that the joints would be precisely cut - and, no surprise, resizing a little bit was sufficient to make one of the pieces not fit (some other pieces would still fit, but a single face of the table by itself was able to mess up all of the project).

And here's the elegant solution to the joint size problem: destroying joints, leaving gaps and using a ton of screws. Sophistication.

Here's the final version of the table when it wasn't fitting quite well

and another one that fits ... slightly better

I will be directly working with this prototype for the final project in the coming weeks