Week 1: Laser Cutting

& Pressfit Kit

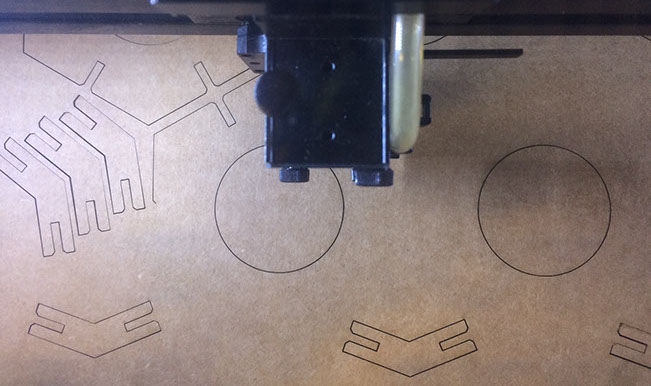

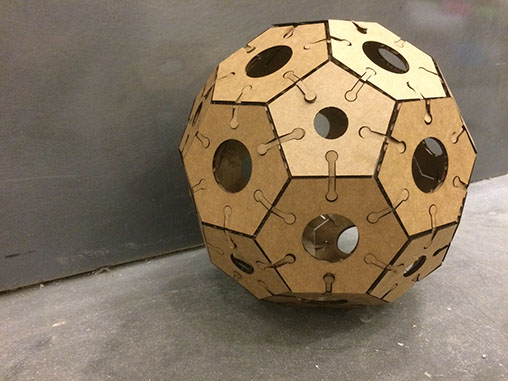

This week the goal is to learn how to use the laser cutter and make a construction kit. I'm not sure how to work this into my final project so I intend to make a buckyball assembly kit. I had already learned to use a laser cutter so getting to work was very straight forward. I made parametric parts in Fusion 360 and outputted dxf files to feed the print drivers via Correl Draw.

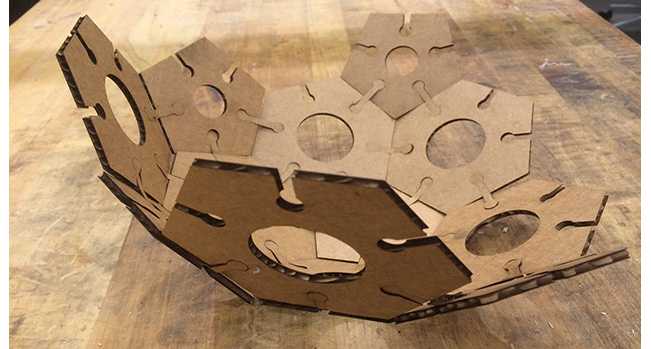

My first design was made to have hexagonal and pentagonal parts with in plane joints to create a continuous surface in order to make a buckyball. I was able to make partial cuts in the joiners allowing for them to join both the hexagons and pentagons which have slightly different angles between them. While this design was very attractive it lacked structural integrity due to the poor joining of corrugated areas in the cardboard.

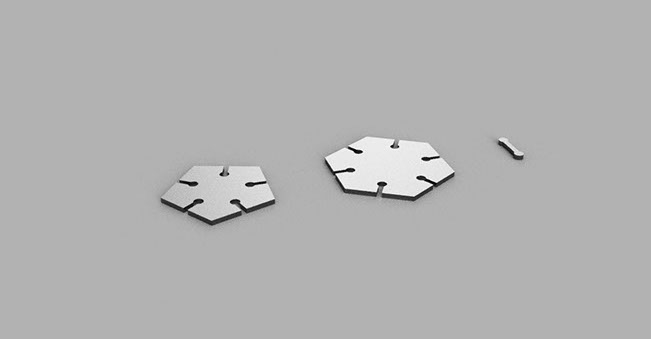

To address this issue I created a second design that uses orthogonal joints which take advantage of the springy corrugation of the cardboard. In order to maintain simplicity I chose to only make hexagons and joints for the hexagon-hexagon angles in the buckyball. Another perk of this design is that i would allow the assembly of assemblies of buckyballs. If I made enough parts I could even make a buckyball out of buckyballs... but maybe thats excessive.