Week 2: Electronics Production

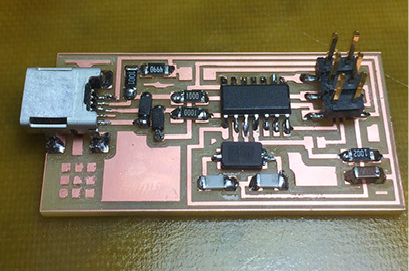

This weeks project involved the milling of a PCB which is then populated with surface components to create a programmer for micro-controllers. Effectively I'll be programming a programmer to program programmers and maybe a few turtles along the way. It is my first time doing all of this so it should be an adventure.

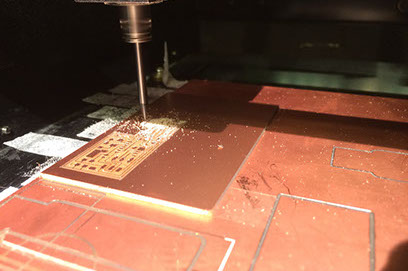

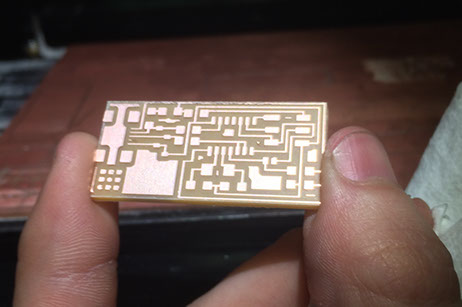

Milling worked beautifully. I needed to grab a new bit from the stock because the one available was broken. It was very hard to remove the board however so I had to use Methanol to dissolve some of the adhesive. In the future I think It makes sense to do a layout of duplicates in the same file as to waste less material

I tried both five and six paths and found that the PCBs are much more attractive with more passes.

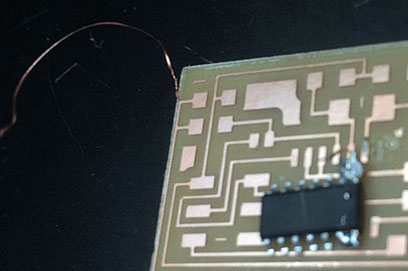

Once the circuit board was milled I brought it down for soldering. On my first try I used a soldering iron and a solder filament that was too big. This resulted in a fused connection between multiple contacts. In trying to remove the part I ended up ripping up a trace.

After milling a new board I tried again with a nicer Iron and smaller solder. Whereas I failed on the first solder last time, this time I succeeded on the first try for everything with the new tool.

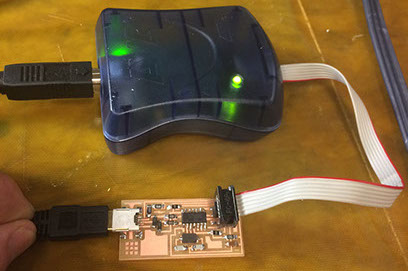

I tested all my solders using a multimeter and everything checked out. Programming also worked on the first try. I removed the jumpers afterwards to prevent reprogramming.