To make something big, I am making a standing desk for a computer. The desk has surfaces for a monitor, the keyboard and mouse, and for the computer so it is off the floor. 52 inches is a good height for the monitor, and 42 inches is a good height for the keyboard and mouse, and about 6 inches is a good height for the computer. 30 inches by 12 inches is a good size for the keyboard and mouse surface, and about 7 degrees downward slope is comfortable. The base for the computer will be the same width, but 24 inches deep to have a stable base. I have a wide enough base to add wheels with casters. I want to have hexagonal lattice on the side pieces, to decrease the weight and to allude to carbon nanotubes. The drawback of using Illustrator for this purpose, is Illustrator is not parametric to my knowledge. Perhaps I can export curves from Illustrator into software that allows parametric design.

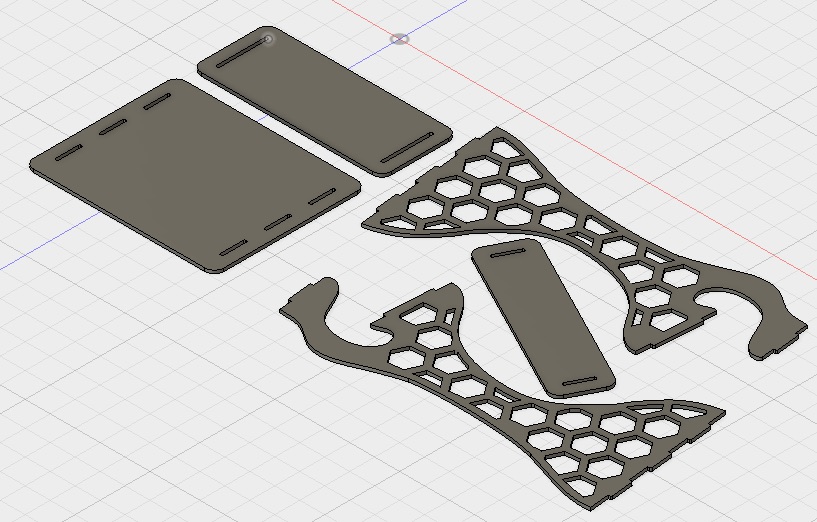

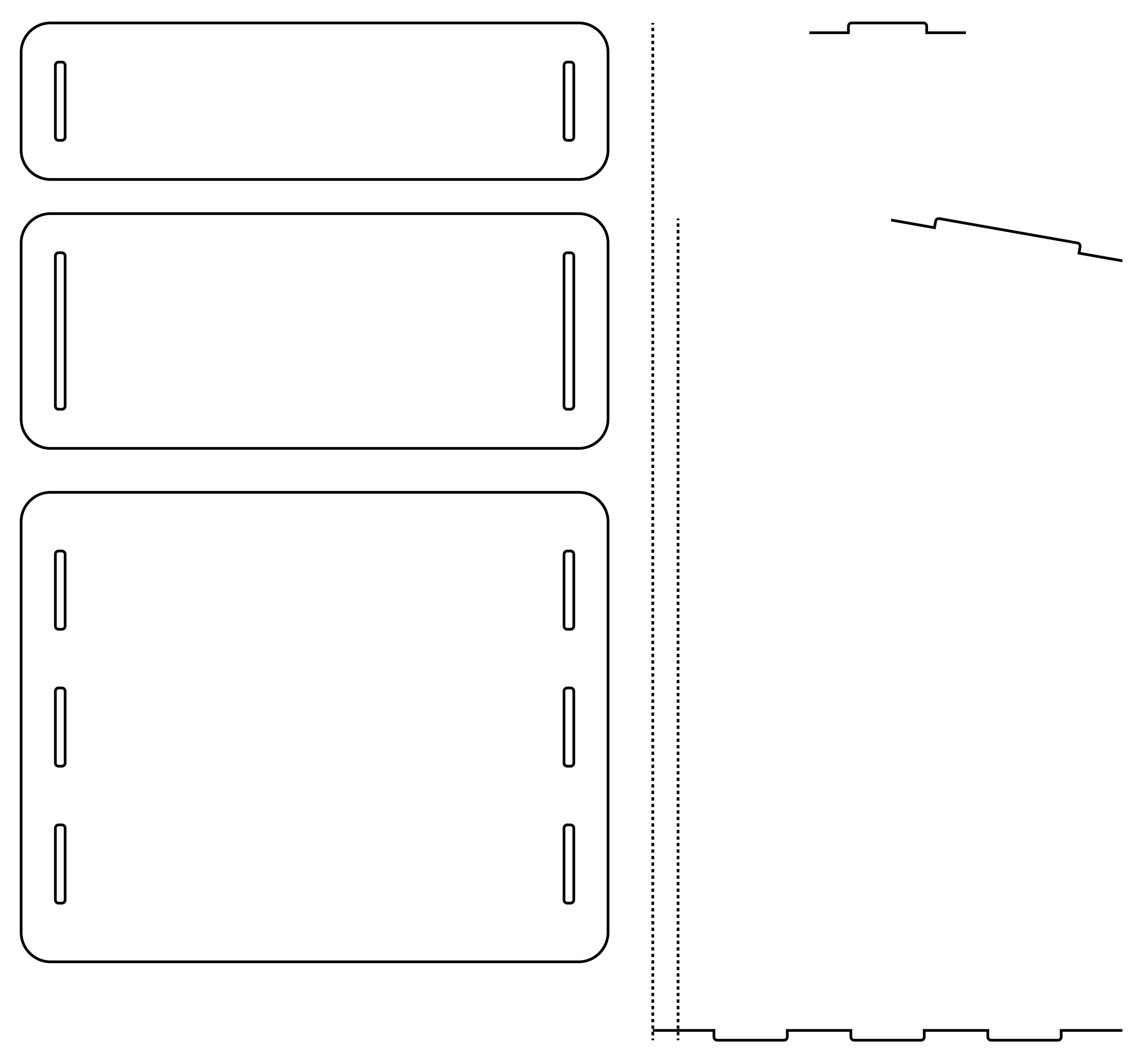

I designed the surfaces in Illustrator so the sides could have interesting contours but I could use the quantitative aspects and export a vector svg that I could then convert into an appropriate format. Here is the design without sides, just with the features located. I left 0.5 inches of distance between the ends of the tabs and the reliefs on the surfaces.

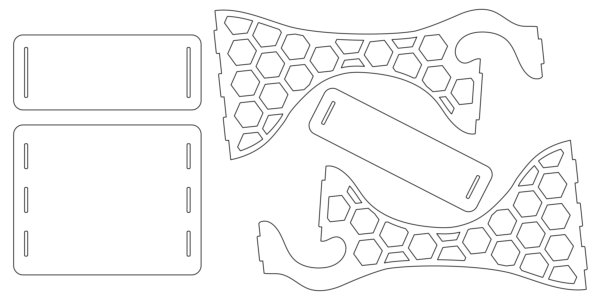

And here is the design with the parts rotated in order to fit on the 4 x 8 foot sheet.

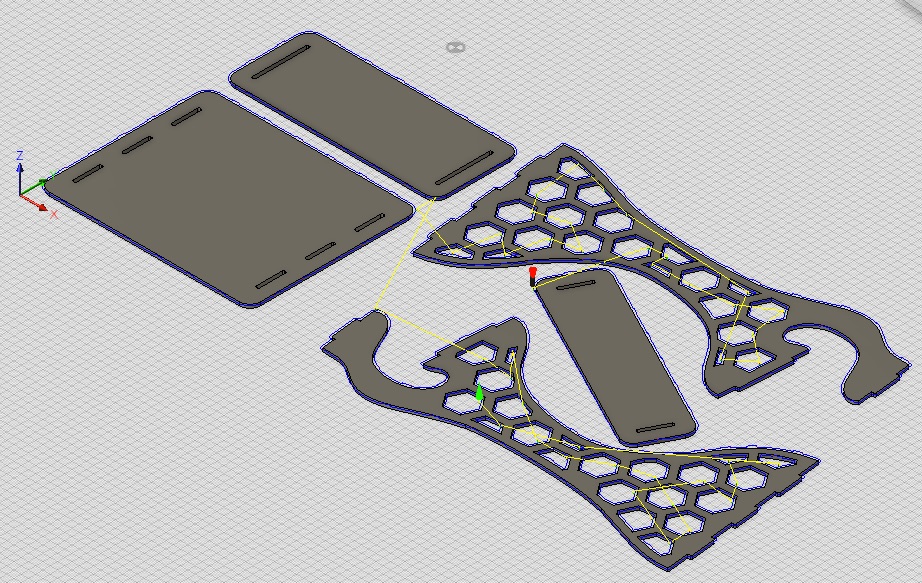

Next, for the CAM, I planned to use PartWorks, but then Sam noted that he does most of his CAD in Fusion 360 these days, so I decided to give Fusion 360 a shot. Here is a CAM toolpath in Fusion 360. I will mill these as soon as possible.