According to these specifications of the SRM-20, the software resolution is 10 microns/step with the RML-1 control command set, and 1 micron/step with NC code control command set. The mechanical resolution is 0.99 microns/step.

I would like to test the smallest features that I can make using the SRM-20. In particular, I would like to cast microfluidic channels in PDMS that are tens of microns wide and deep, and would also like to cast lenses as smooth as possible.

According to this FR1 molds at 48.9 to 82.2 C, which seemed a bit low, since it is advantageous to cast PDMS at least 65 C, and even possible to cast PDMS above 100 C for faster cure times. This gives some great advice how to machine PTFE. Before I give it a shot, I emailed Will to check with him, and also check which mill would be the appropriate one.

For now I will test with 10 micron steps, since the machine code should be easy to edit. In future it would be interesting to check out the NC code.

Neil's hello world is an 8-bit png and the default settings in Fab modules are

I started to investigate writing my own paths in RML-1 code command sets in order to control the motion of the machine at the resolution of the machine. By looking at the JavaScript module in mods as well as the data sent from mods to the SRM-20, I inferred 1 unit corresponds to 10 microns. Therefore an endmill with diameter 1/32 inches is 0.79375 mm which is about 79 units. With the origin set to [0, 0] mm (so [1000, 1000] units) the start position is 3537, 14111. Possible code would look something like this

X1: origin of X

Y1: origin of Y

∆: length of path

Z1: depth of full cut

M: thickness of endmill

H: height of feature

D: thickness of feature

F: stepover factor, in other words the distance is M * F

Z X1+M/2,Y1,Z-H

Z X1,Y1,Z1

Z X1,Y1+∆,Z1

Z X1+M+D,Y1+∆,Z1

Z X1+M+D,Y1,Z1

There is a deep literature on optical lens design such as this and this.

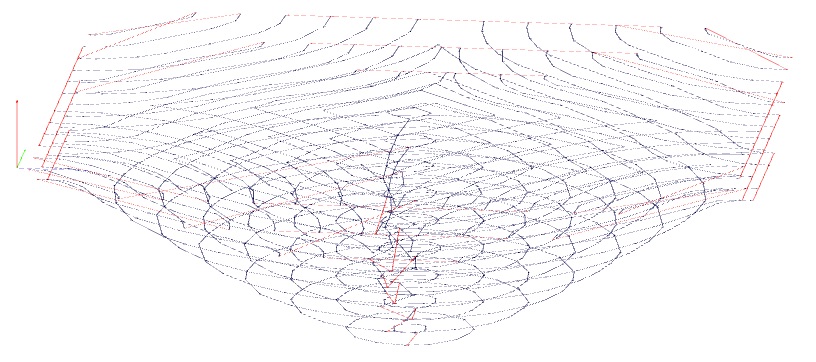

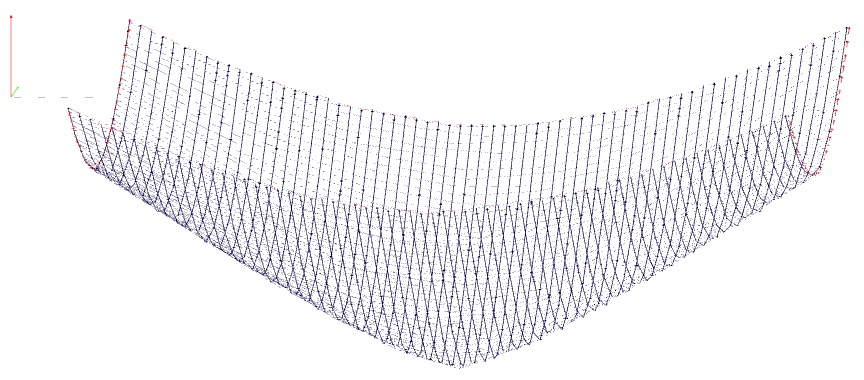

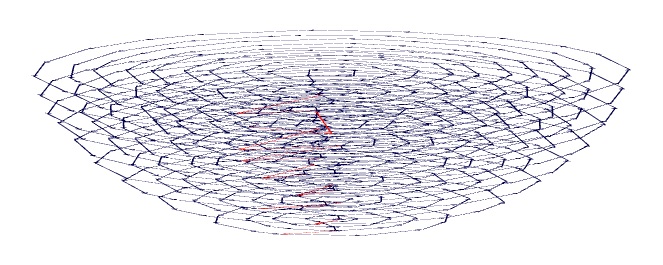

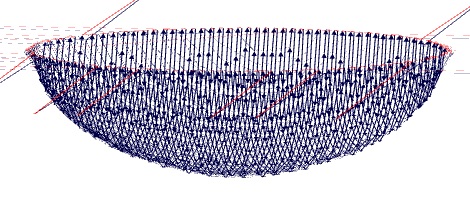

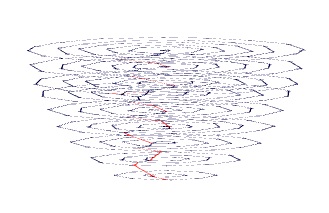

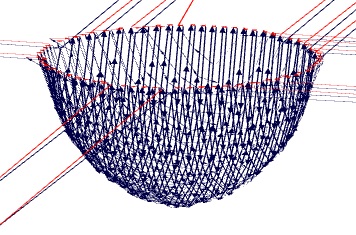

I wrote a script in Matlab to compute heightmaps of aspheric lenses and export them as png, so I can input them in Fabmodules to generate rough and finish toolpaths for the SRM-20.

Hyperbolic lens

Spherical lens

Elliptical lens

Here is some cool information on different types of lenses. Spherical shape is not ideal due to spherical aberration as described here Wikipedia page and this part of the page describes the lensmaker's equation.

According to this it might be hard to get below 0.5 microns due to the porosity of the material. To polish the plastic, could use toothpaste a gentle abrasive or liquid metal polish. Here is some advice on polishing acrylic. According to this acrylic and polycarbonate are good materials for lenses. Also possible to cast vs extrude acrylic. Here is some information on acrylate resin casting.

The form of aspheric lenses is described here