WEEK 7: _ design a 3D mold, machine it, cast parts from it

Creating a Wax Mold

Molding and casting gives another weird combination of freedom and constraint - like other fabrication methods, one must consider details of the process which may make a certain shape very well suited, tricky, or completely impossible for fabrication. For molding and casting we get to consider the ShopBot's 3-axis milling 'reach' as well as where all the goop of mold and cast material goes (positive and negative shapes). What an interesting assignment....

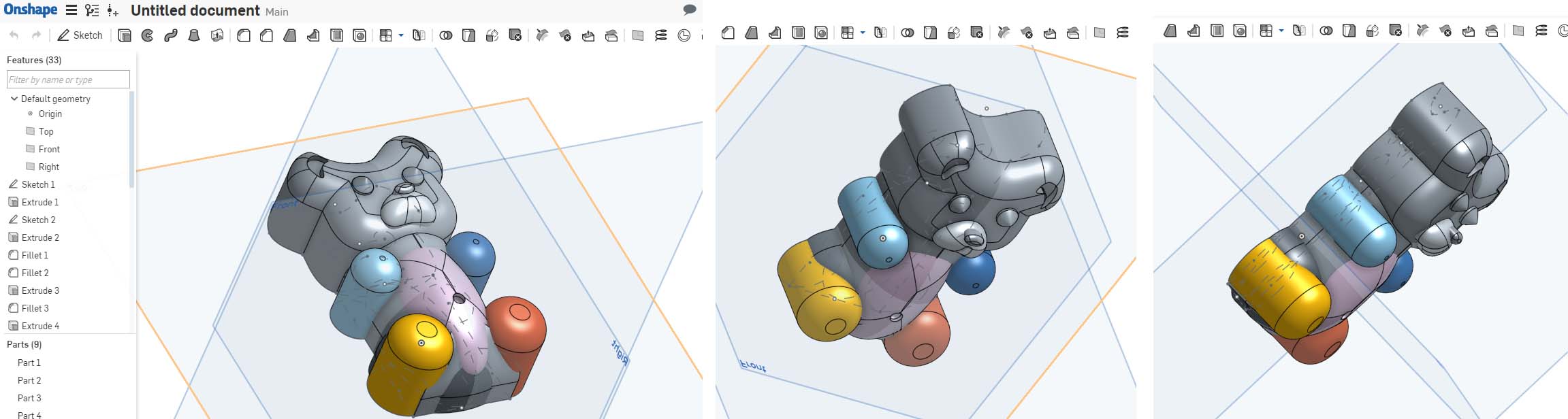

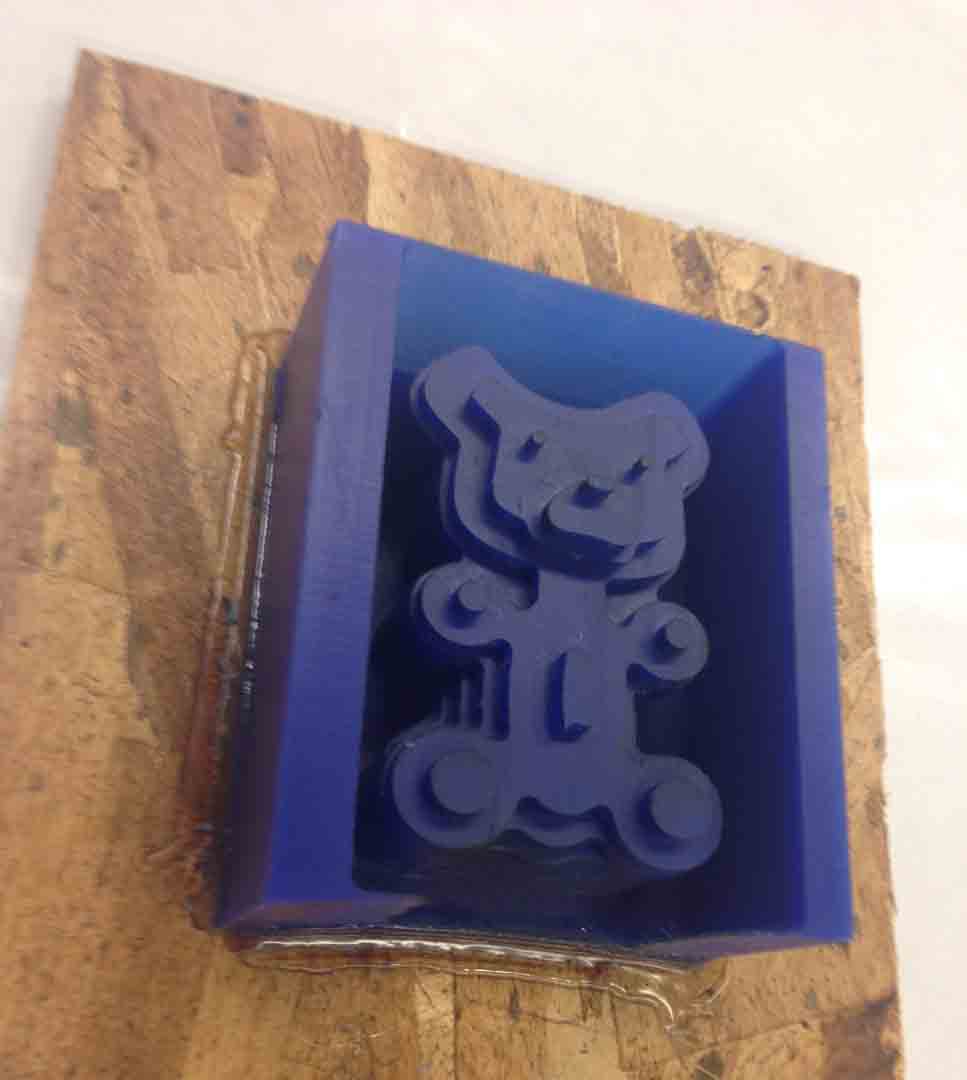

I was enthused to try my luck making everything from barnacles out of gypsum wet stone or modular stackable plant pots. But soon realized it is much more zen to start with your method at hand and let it tell you what it is good at making. From 'experience' consuming Gummi Bears, one of my favorite stress foods, I can vouch for how successfully they can be fabricated via a mold and cast process. Good place to start. Here is the rendition of a Gummi Bear which I sketched up in OnShape.

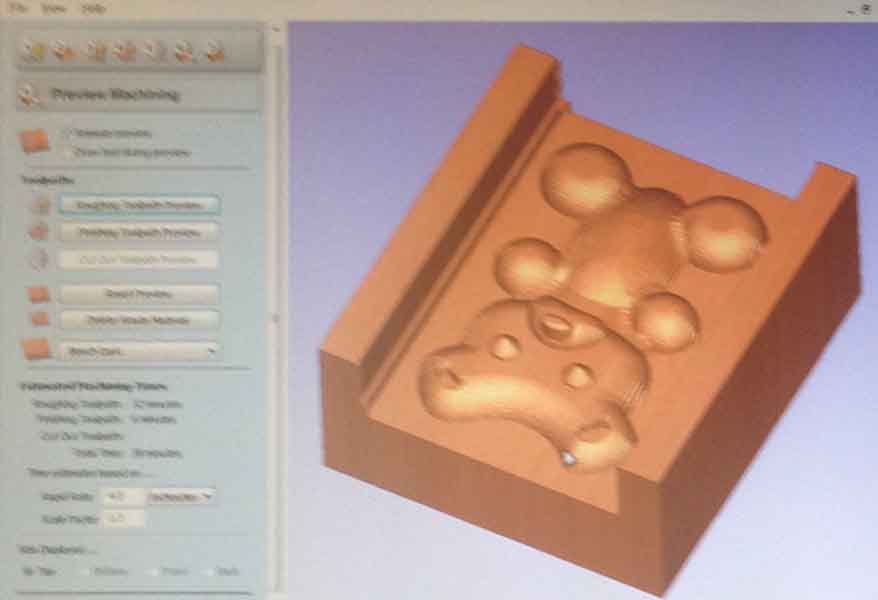

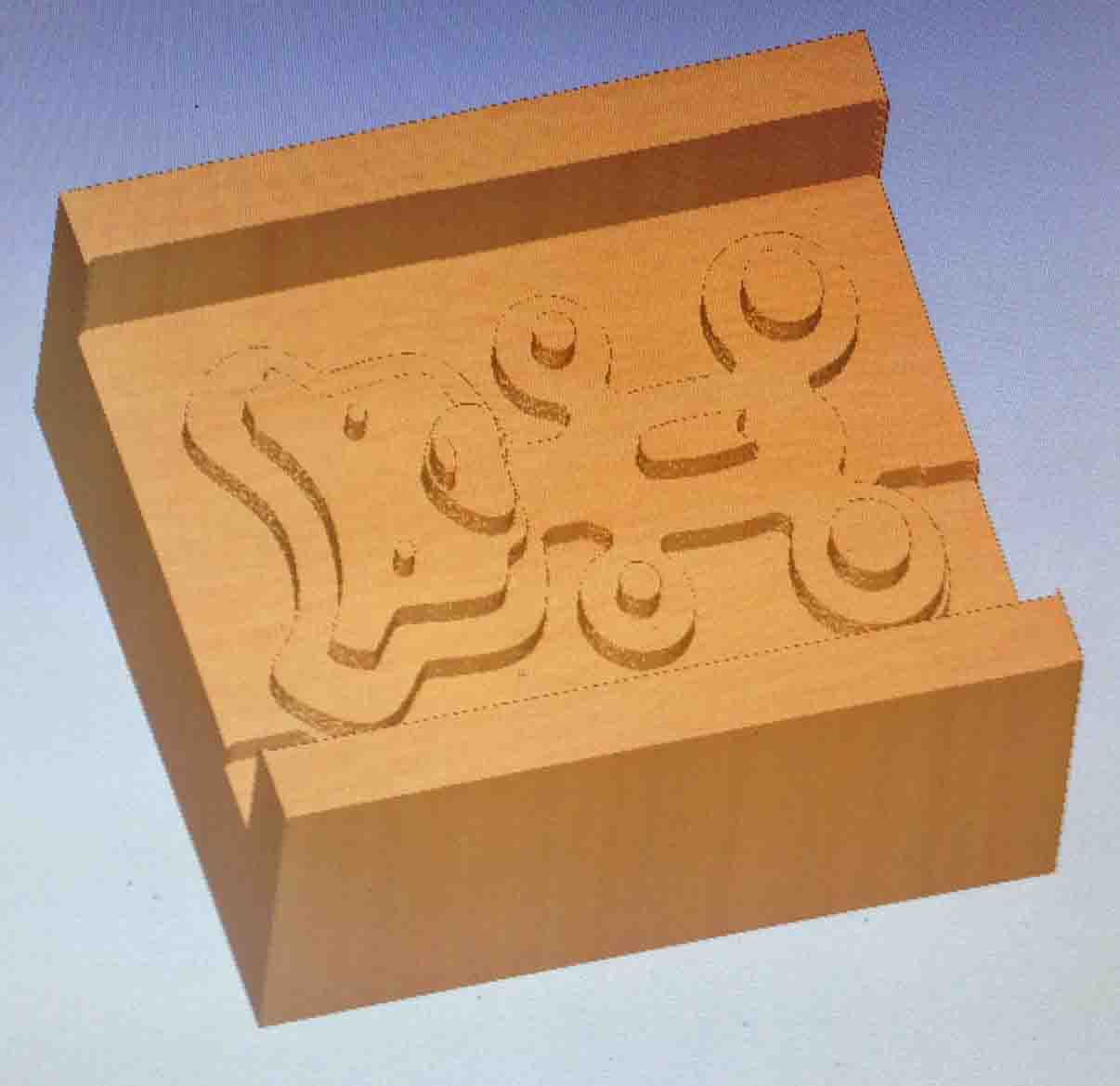

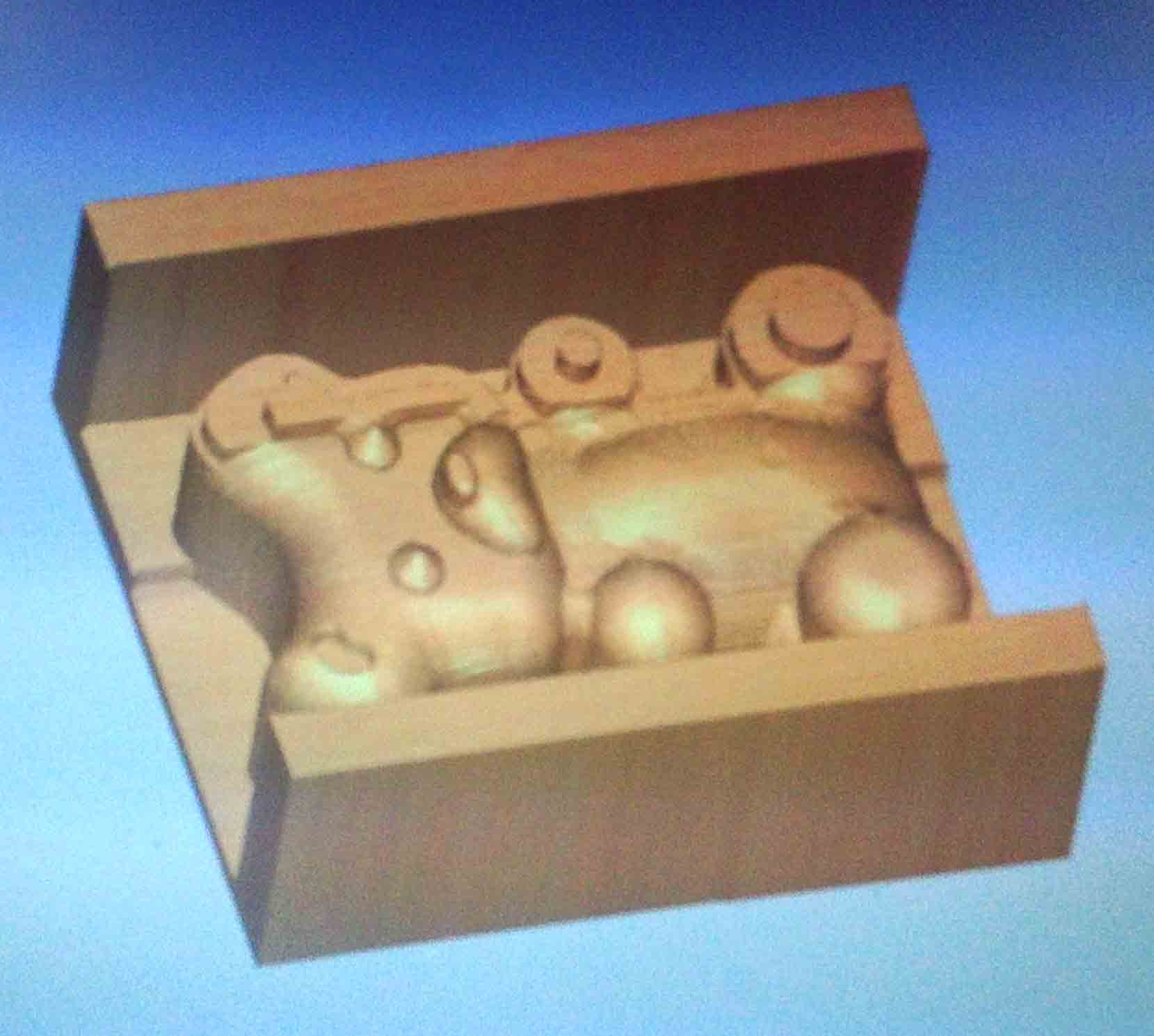

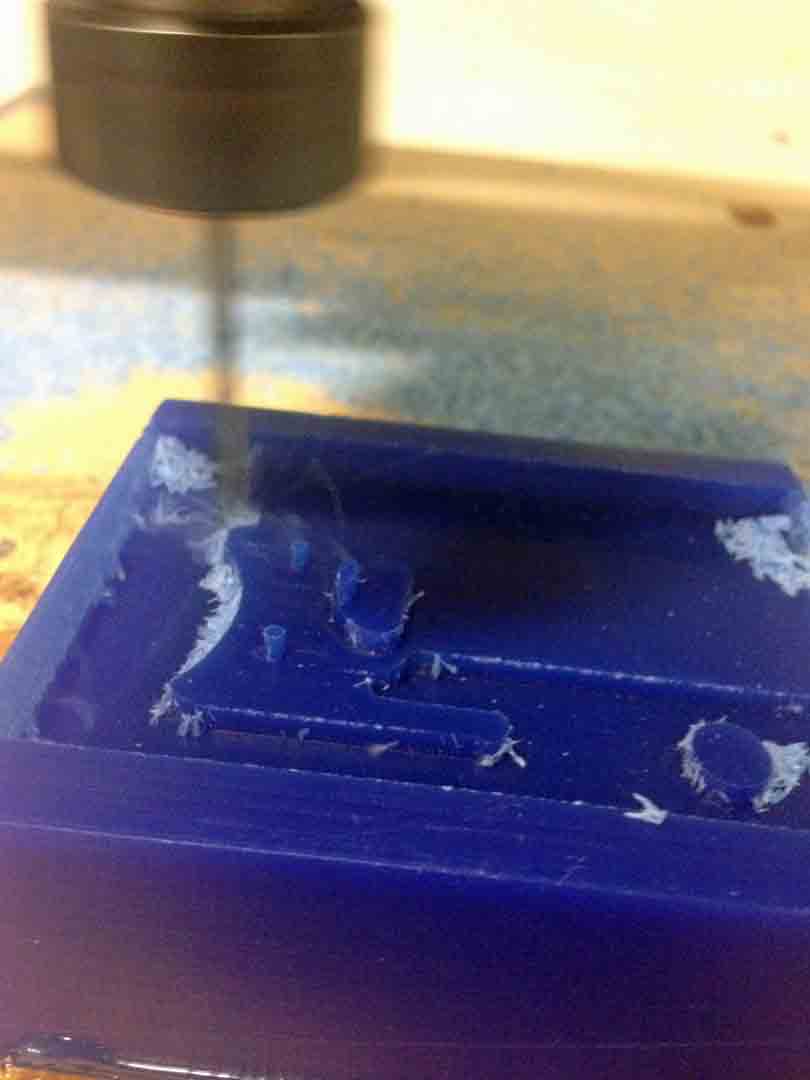

Tool paths!! Created in PartWorks. To review we are making the positive shape inside a containing cube. This will be a breakable mold that will form the shape of the soft, flexible mold material that we cast in it. The milling is split into a 'Rough' and a 'Final' cut, and the parameters involved can be fiddled with to create a tool path of optimized cutting time.

Here it goes. Milling wax is fun. I liked the gummi bear so much after the rough z axis tool path, I did not continue. I present to you, techno gummi.

Fabing a Rubber Mold (from a wax mold)

Brush your wax mold completely clean of any dust or wax residue. The oomoo comes out in ridiculous precision, and will pick up and of these little lumps and bumps.

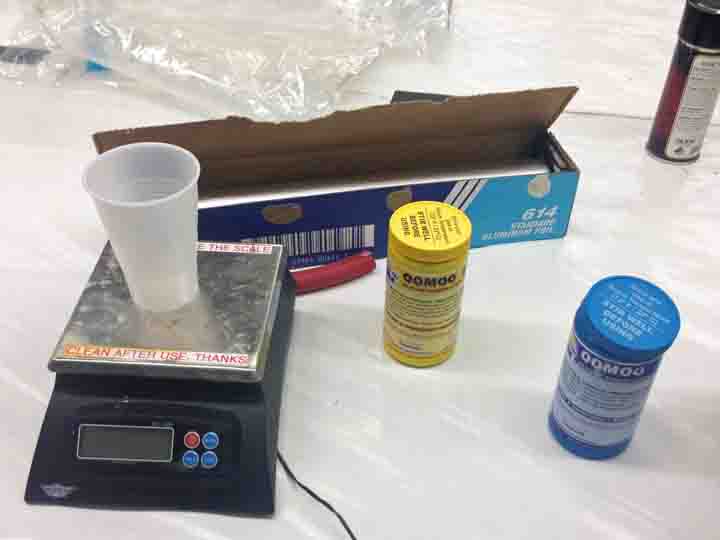

We are using a silicone rubber called Oomoo to make the perminent mold. It comes in two parts, which must be mixed 100:130 by weight.

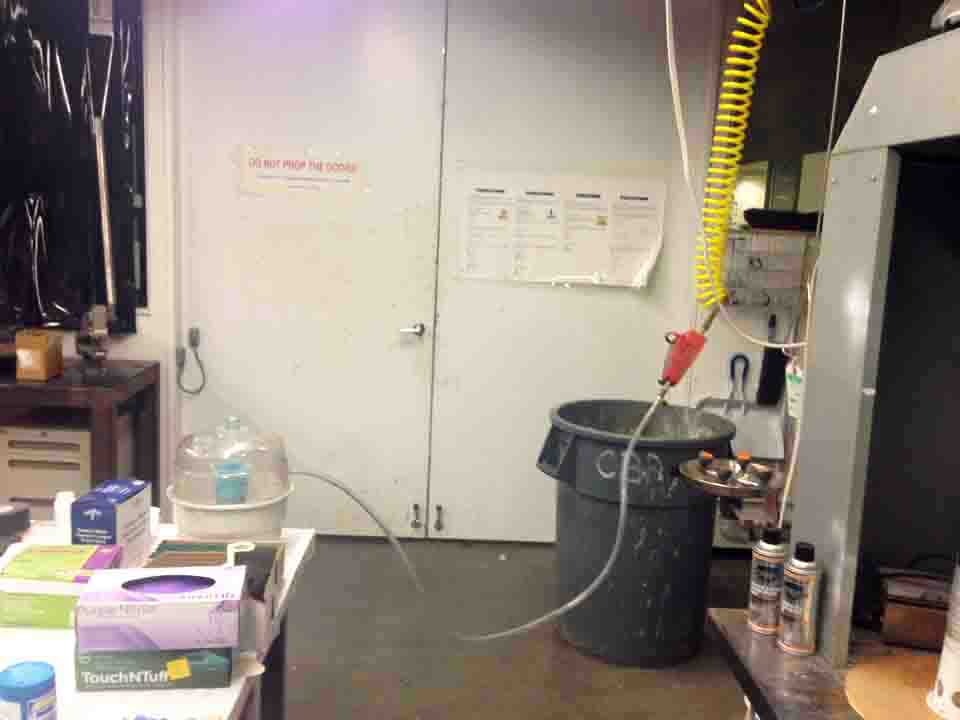

Once it is mixed thoroughly, I put it in the vacuum chamber for 5 minutes. It makes a BIG difference, so don't skip this step. It will remove all the bubbles from the rubber. Pour it in! Optionally, put the whole wax piece filled with oomoo back in the vacuum for another spin.

Casting Things with a Rubber Mold (first attempt...)

The plan is to make a homemade fluorescent 'smooth on' cast with embedded LEDs to excite the fluorescent molecules. I am using a fluor-acrylide, which is made to bond with acrylic plastics. This isn't acrylic, but we can give it a try. Here are all the materials.

Uh oh - unintended unexpected exothermic frothing reaction - most likely because of adding water.

Well... the mess-up still yielded and interesting gummi bear. It is opaque white in color like marble, and I managed to get two LEDs in before it hardened completely. I hooked the bear up to a power supply for a little show.

Casting cool things x Infinity...

One more try. This time I will be using a highly concentrated food dye called Bengal Red. It turns hot pink, and I think the plastic accepted it this time!

It's gummi bear time..