Chika Makes Things 2016

Week 6: Computer-Controlled Machining

Goal: Design and make something with a CNC Mill.

Process: I chose to make a laptop desk, taking inspiration from the image below.

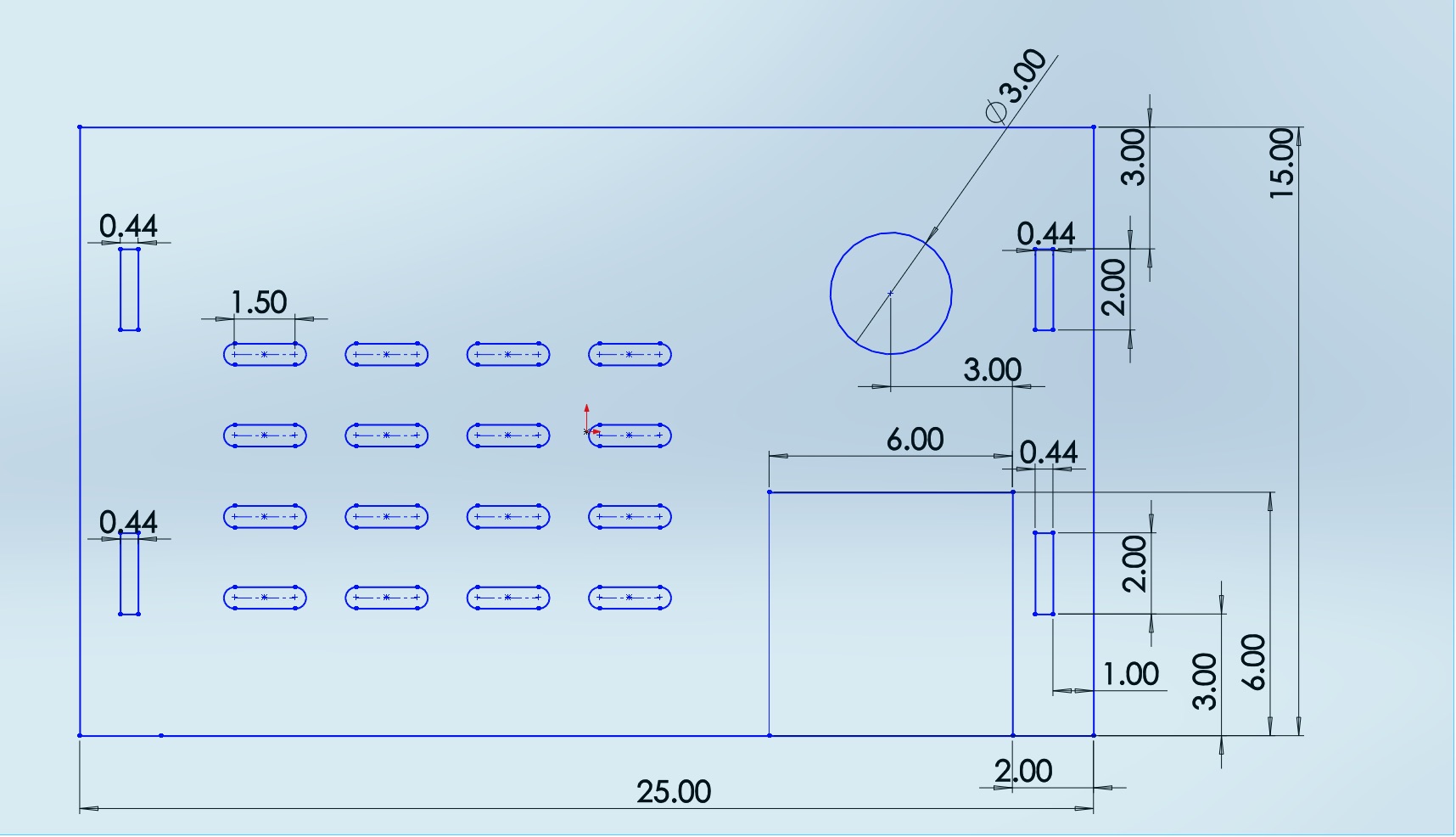

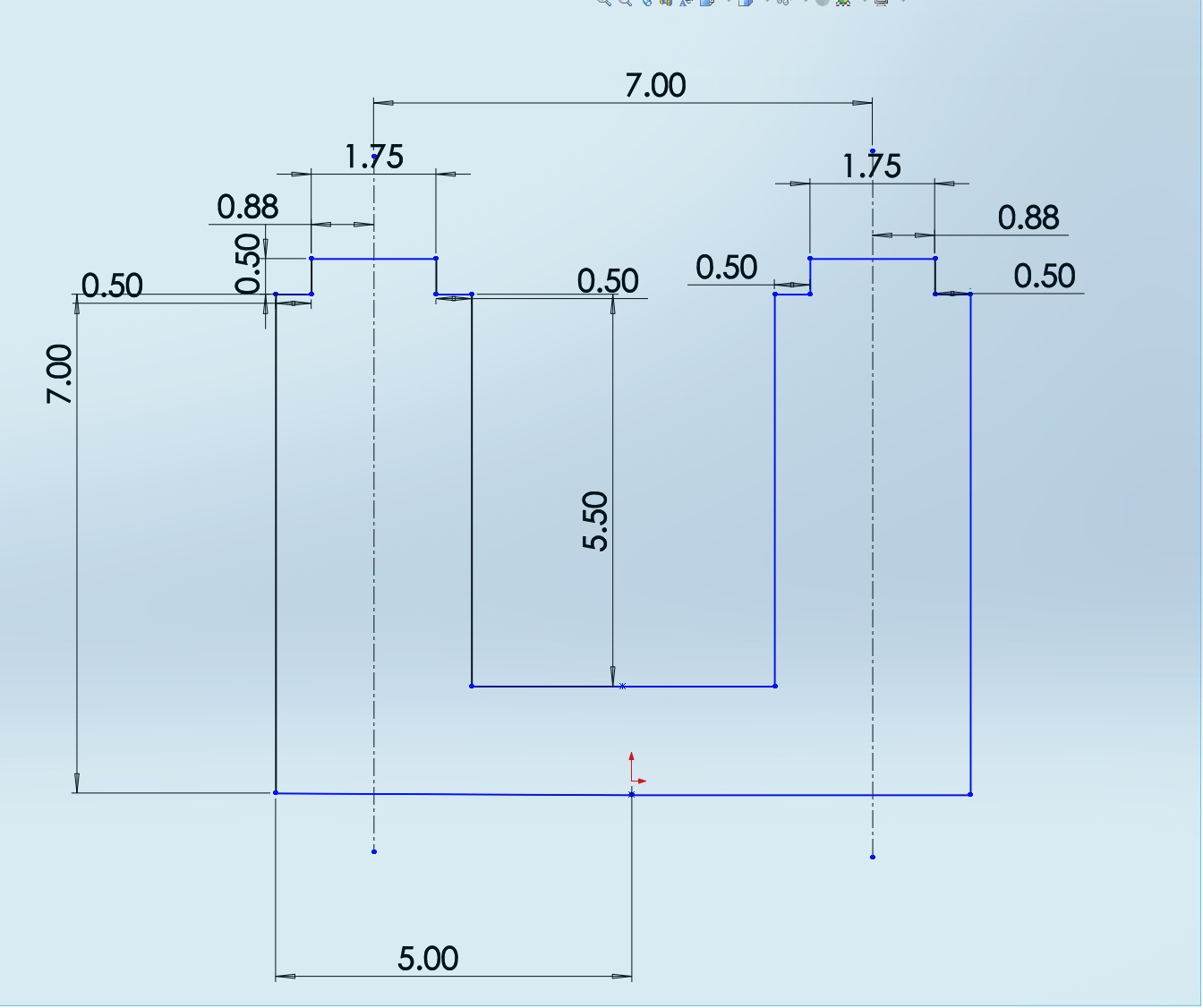

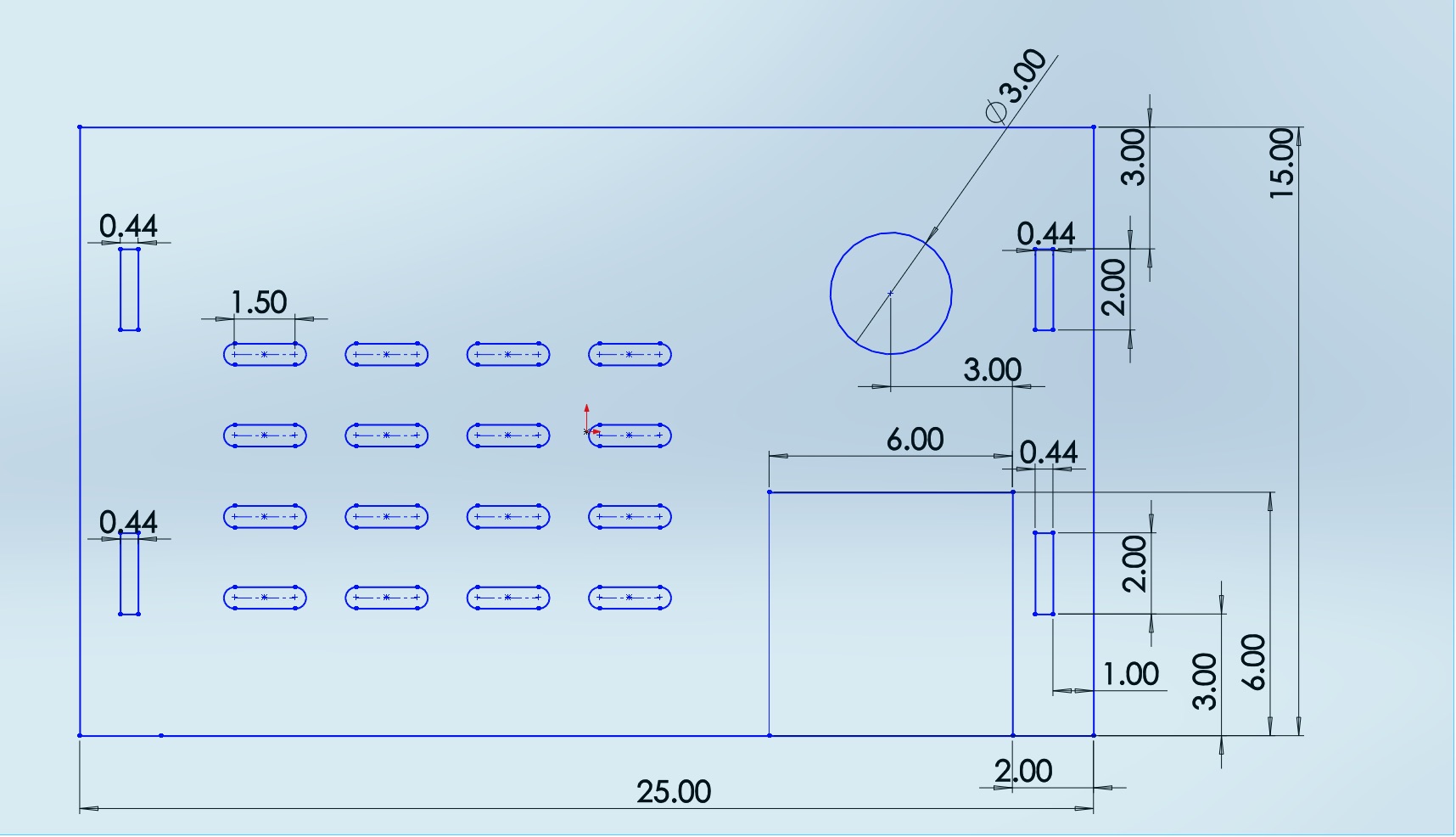

My design included holes to allow the heat from the laptop to escape, a pocket for mouse placement, a cup holder, and legs to hold the desk up at a more comfortable working level (similar to a stand up tray for eating breakfast in bed). I created a 2D sketch in Solidworks with dimensions that were catered to the size of my laptop and the width of my bed.

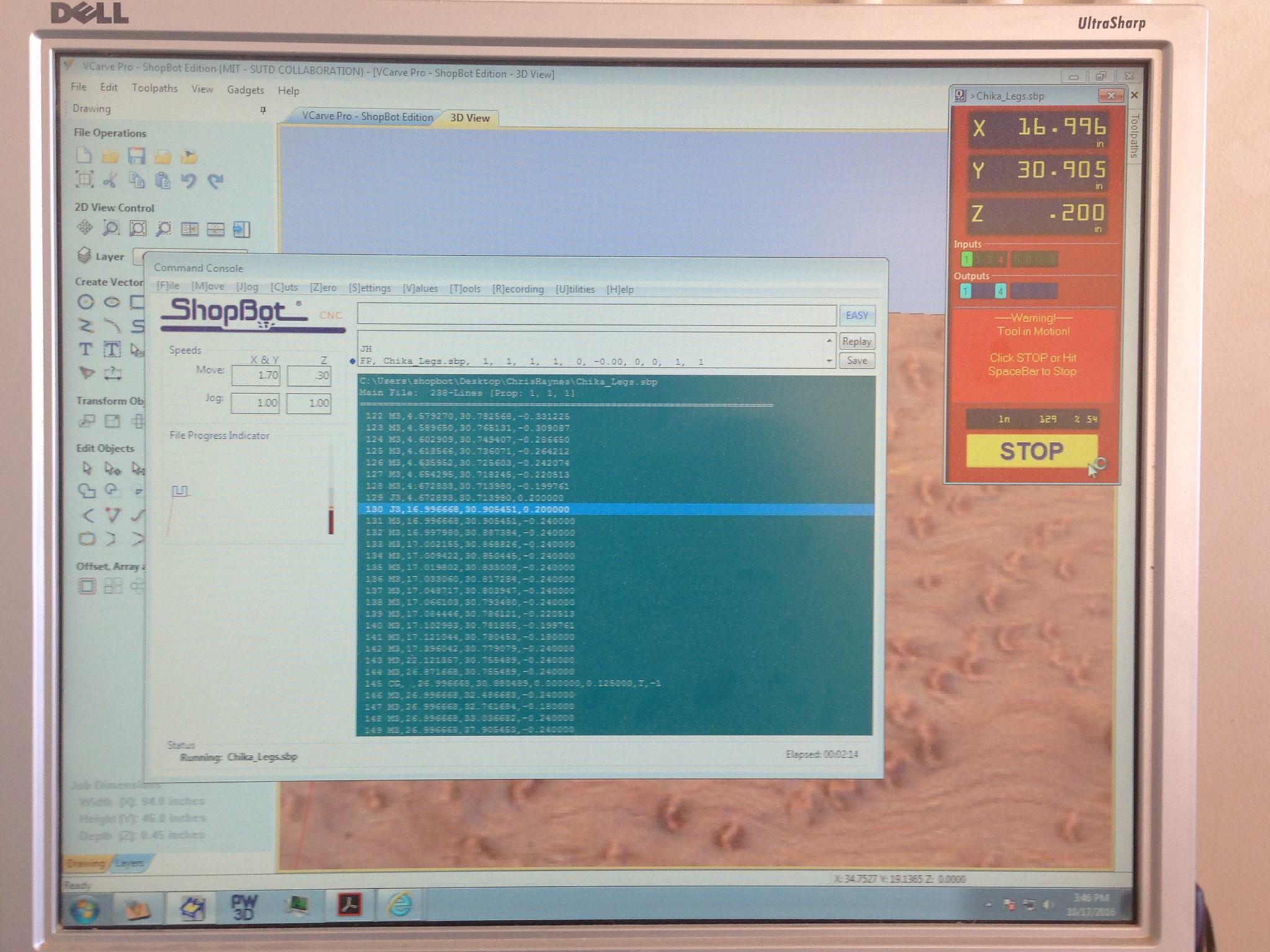

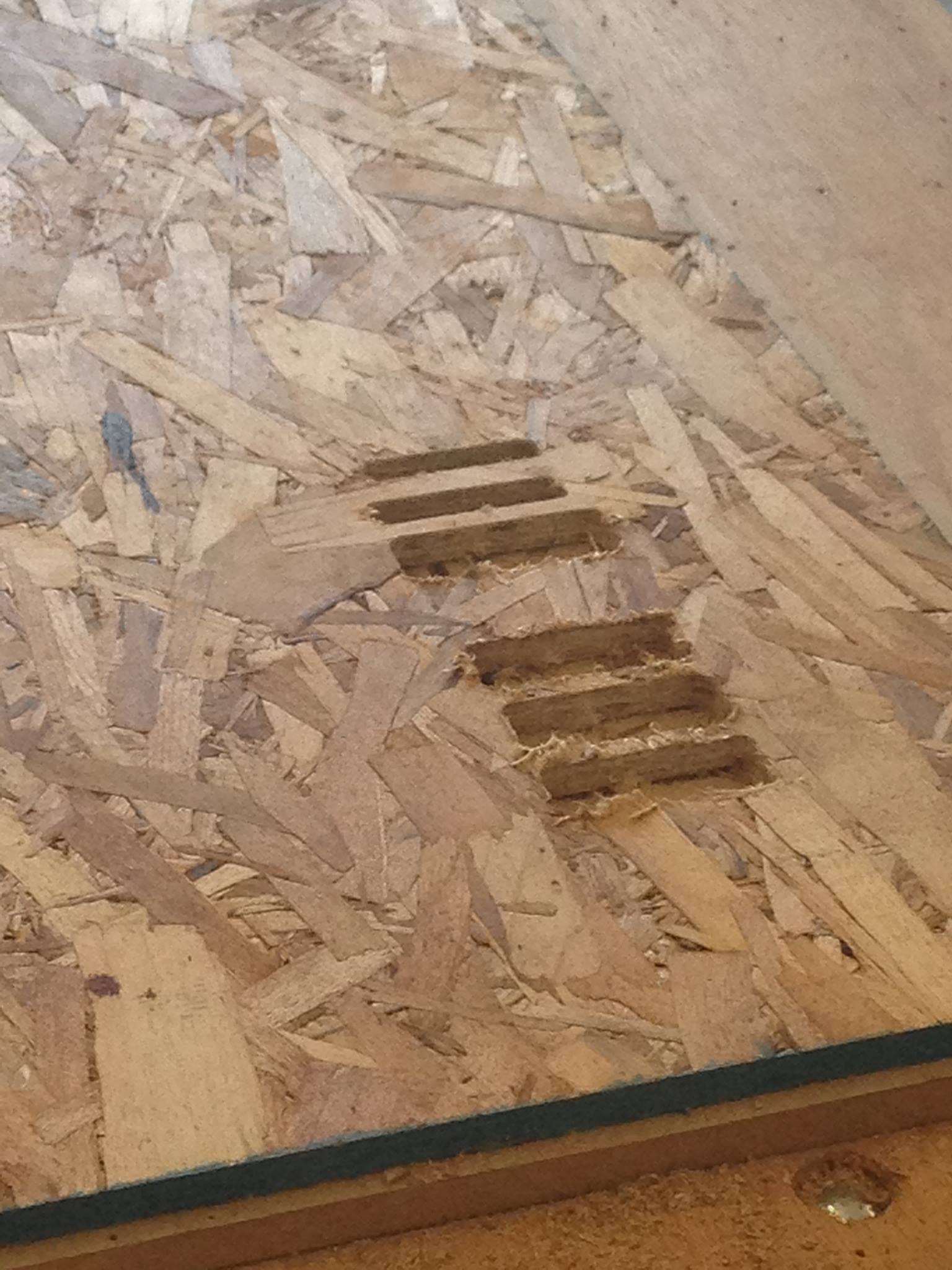

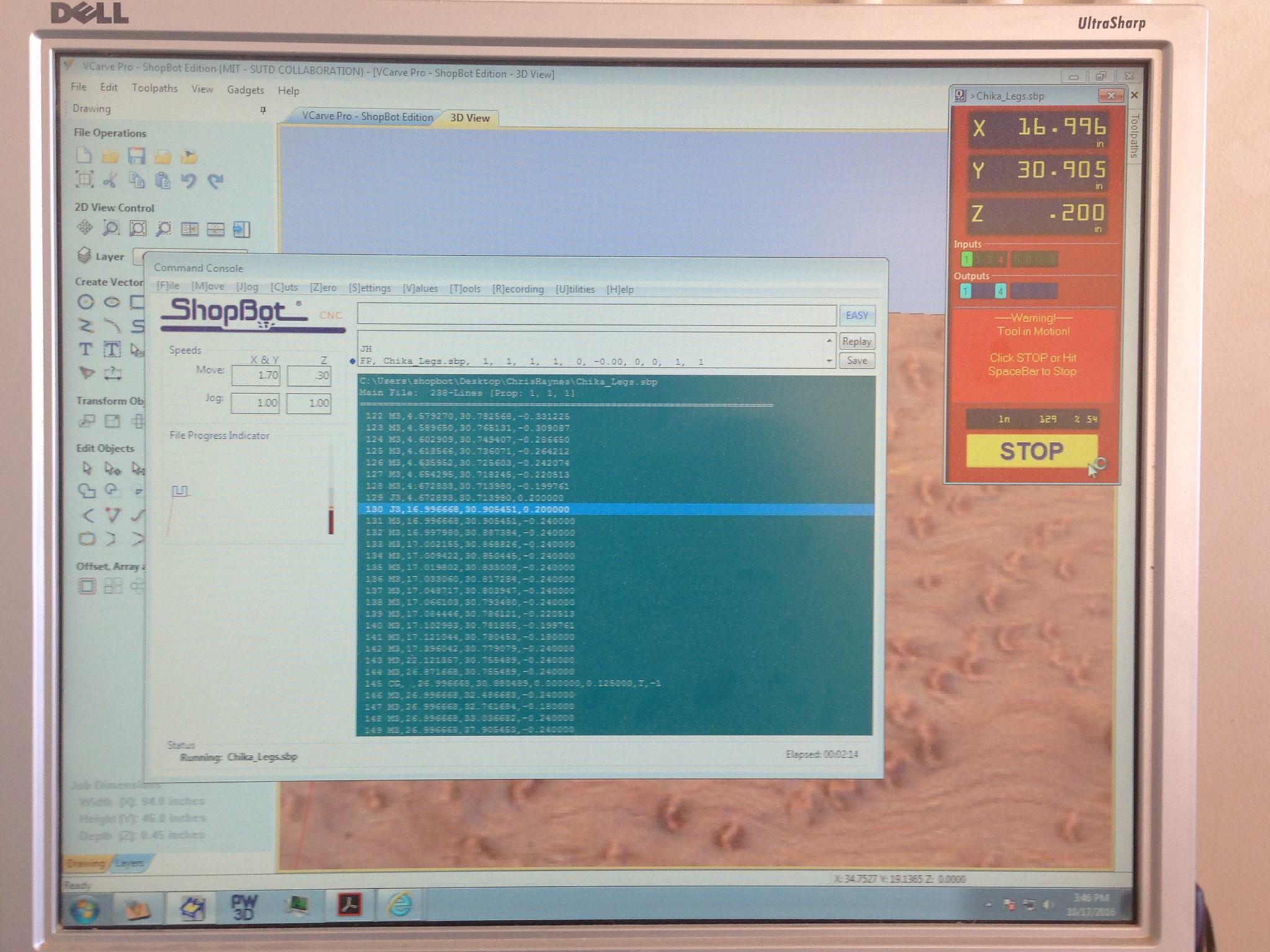

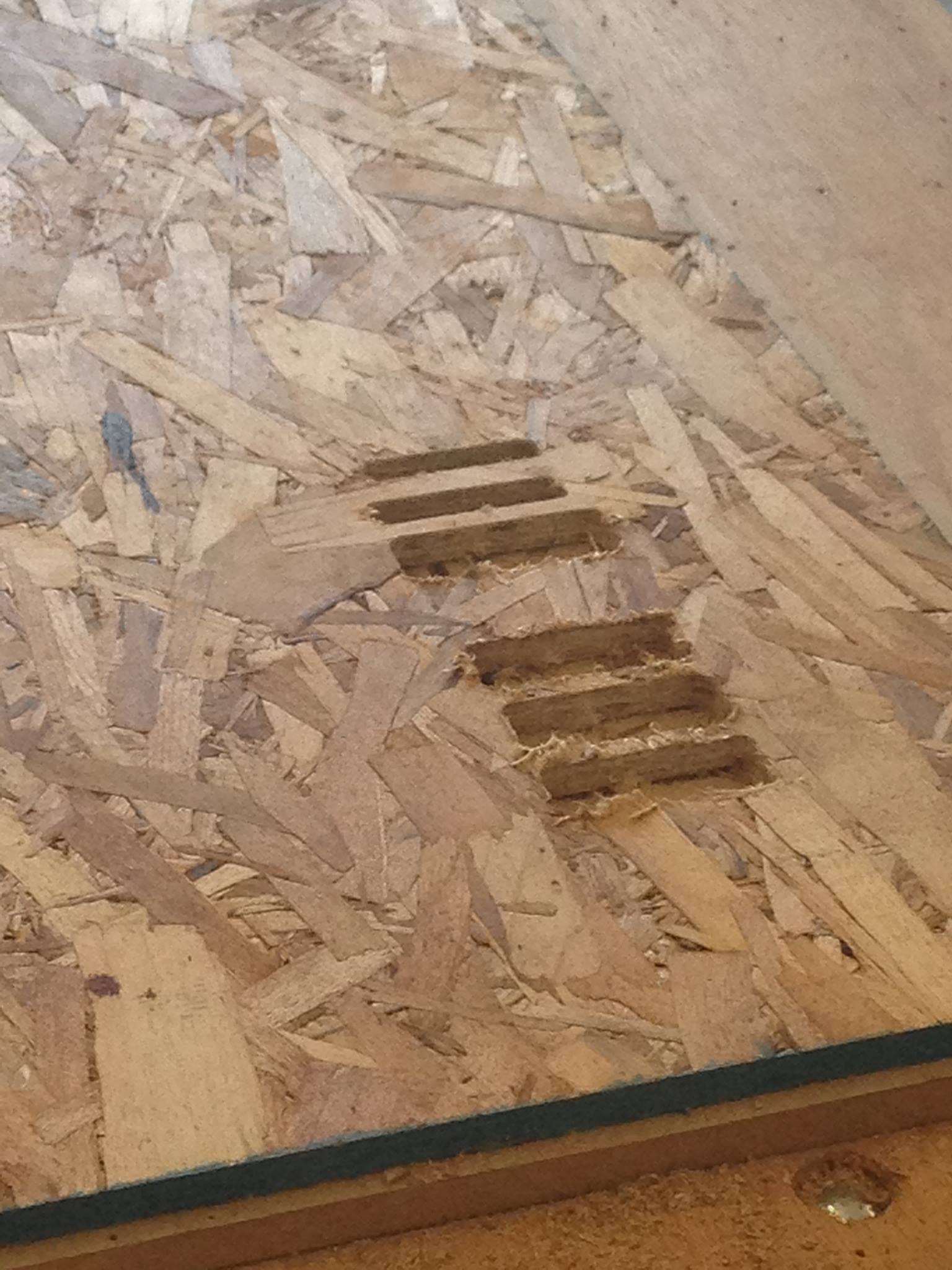

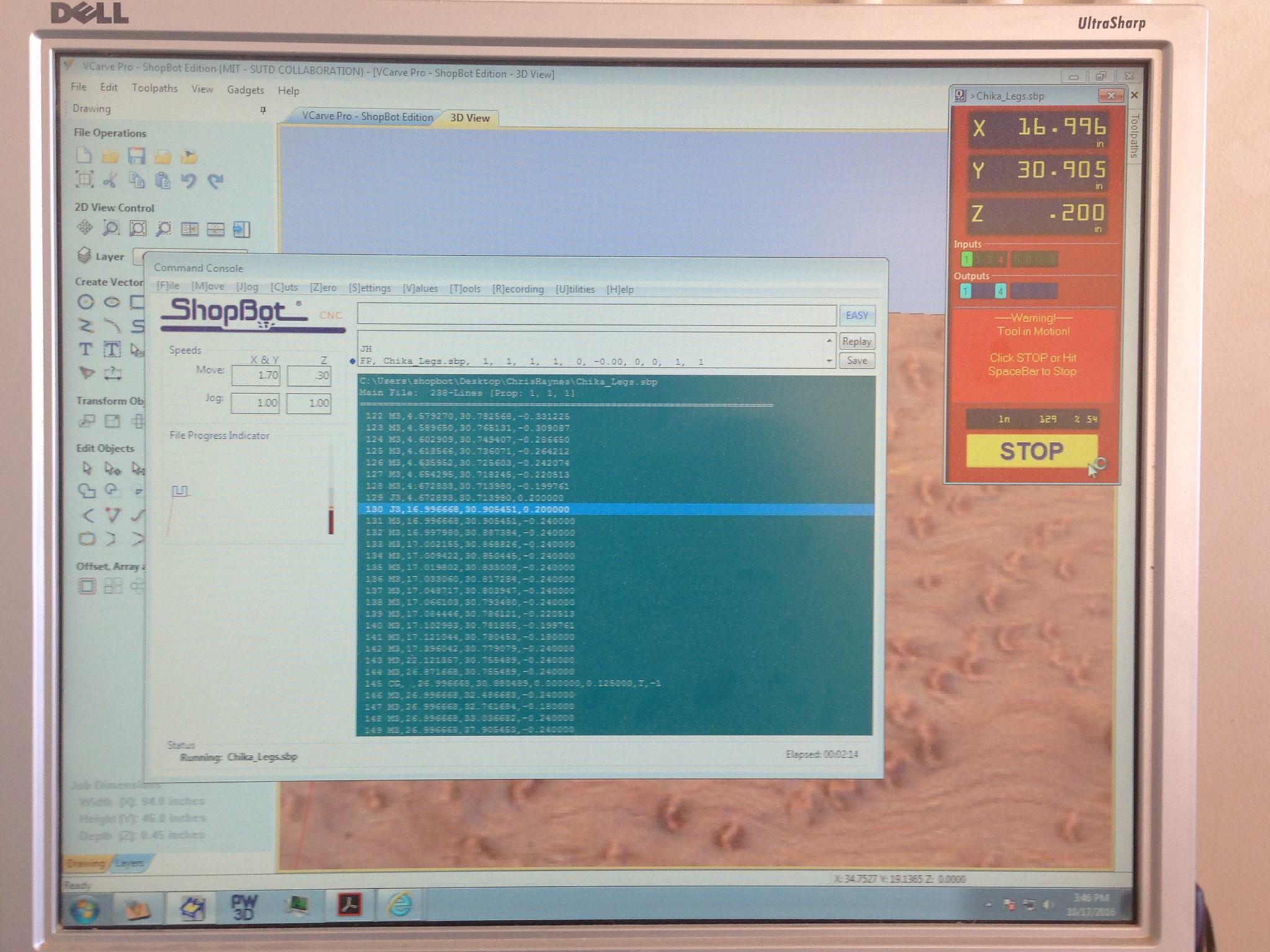

Challenges: I ran into a couple of issues when it came to actually milling the piece. The first was that not all of my vectors in Solidworks were closed. This caused the mill to produce edges that were not straight. Although I received an alert when reviewing toolpaths before starting the job, the misalignments were so small that I didn't catch them and clicked proceed. I also noticed that the bit had trouble cutting the radii of the slots in my sketch, resulting in jagged holes. Future work will involve more careful dimensioning to suit the tool size.

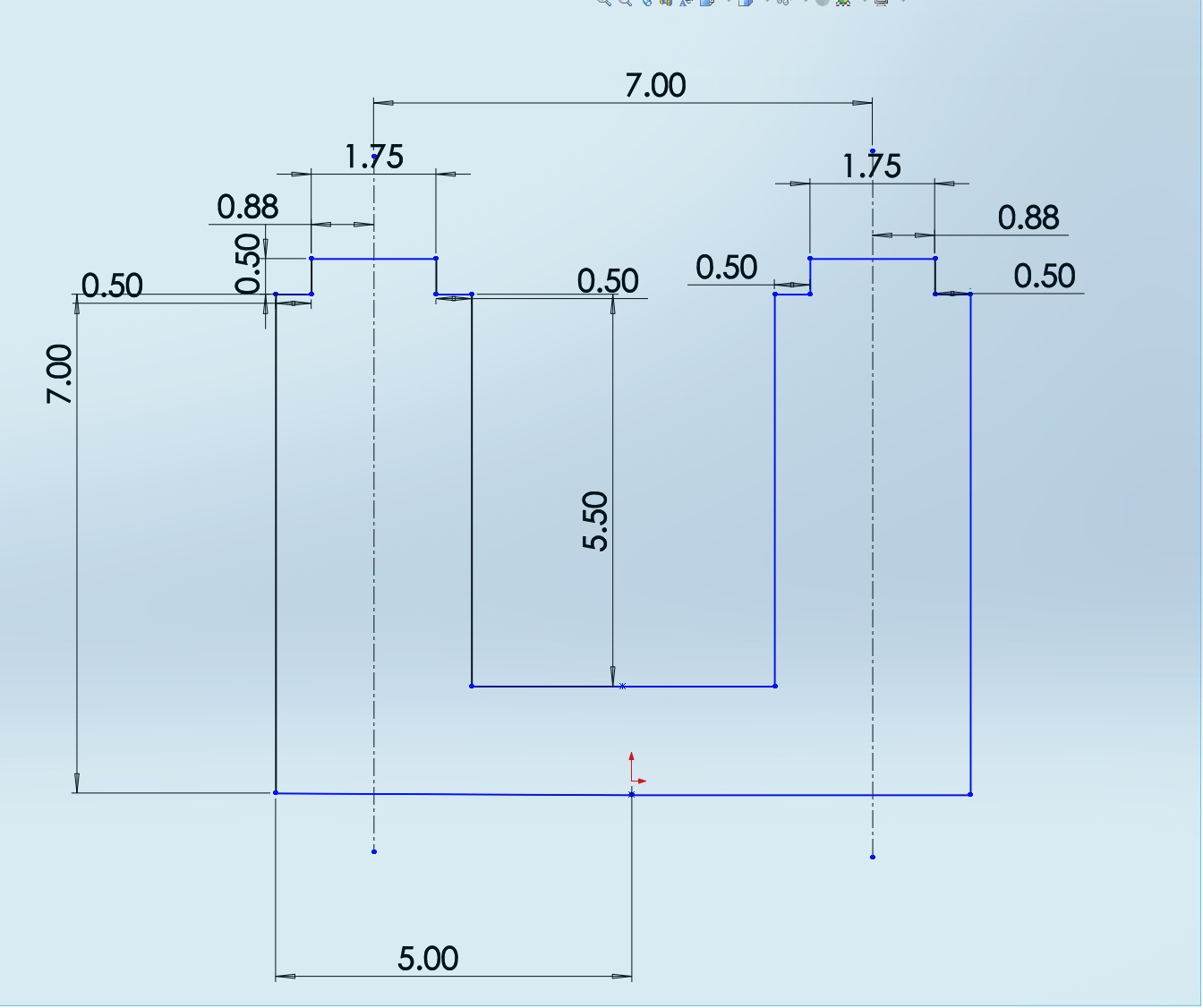

Another challenge was gettin the press-fit design of the legs exactly right. Before making the final piece I cut out a few test slots to determine (1) how thick the slots on the edges of the table top needed to be for a snug fit and (2) how long the rectangular tabs on the legs should be to fit in the curved radii of the slots. I started out with a design for rectangular slots and quickly realized that these were not possible on the mill due to the circular bit.

Unfortunately, after spending so much time figuring out the perfect slot and tab dimensions, I accidently chose the setting to cut on the outside of the slot path rather than the inside. The resulting slot on the table top was too large for a press-fit and the legs can not currently hold up the top. I ran out of shop time before I was able to try again. I am, however, able to use the desk comfortably without the legs.