Chika Makes Things 2016

Week 8: Molding and Casting..aka The week of unfortunate events

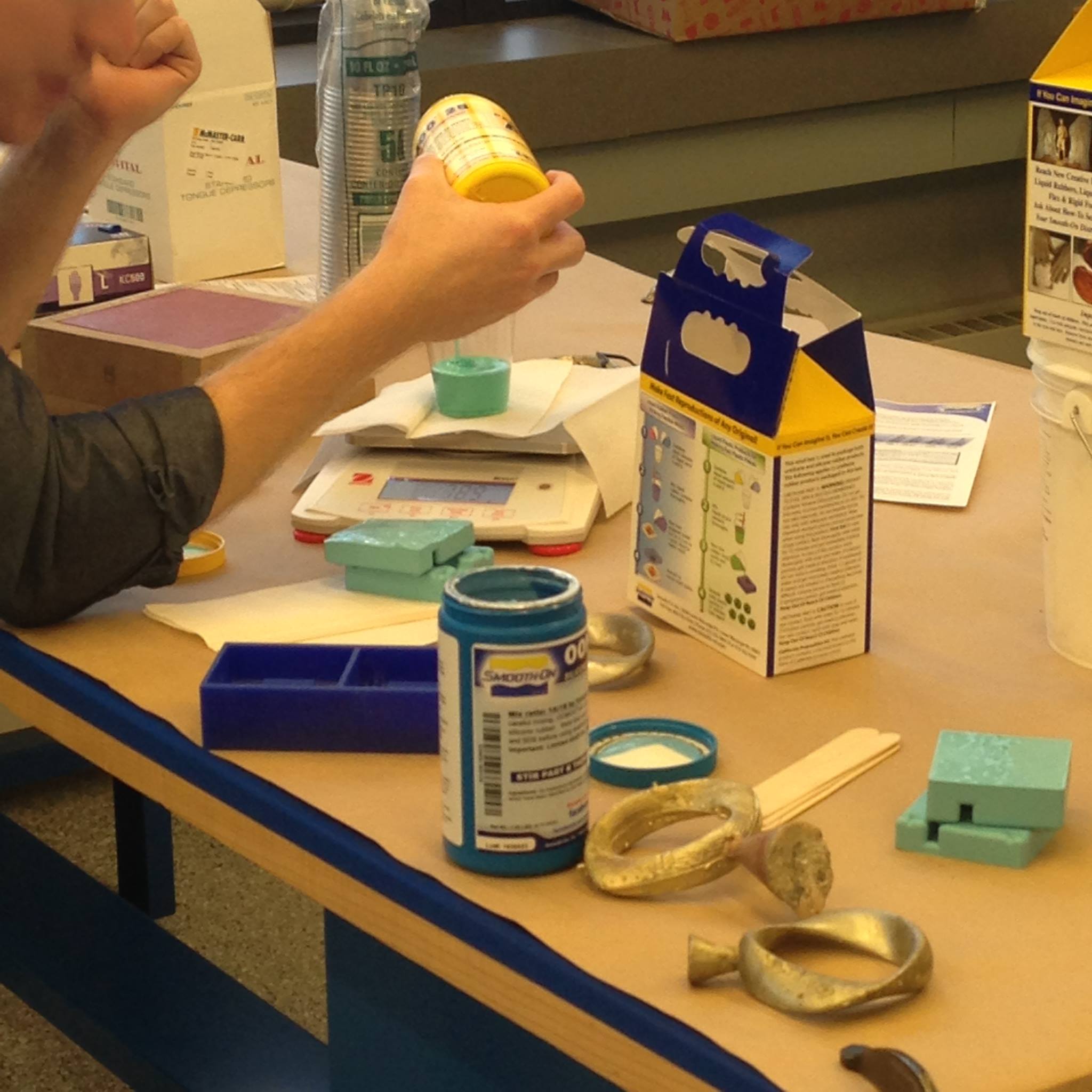

Goal: design a 3D mold, machine it, and cast parts from it.

Accomplishments:

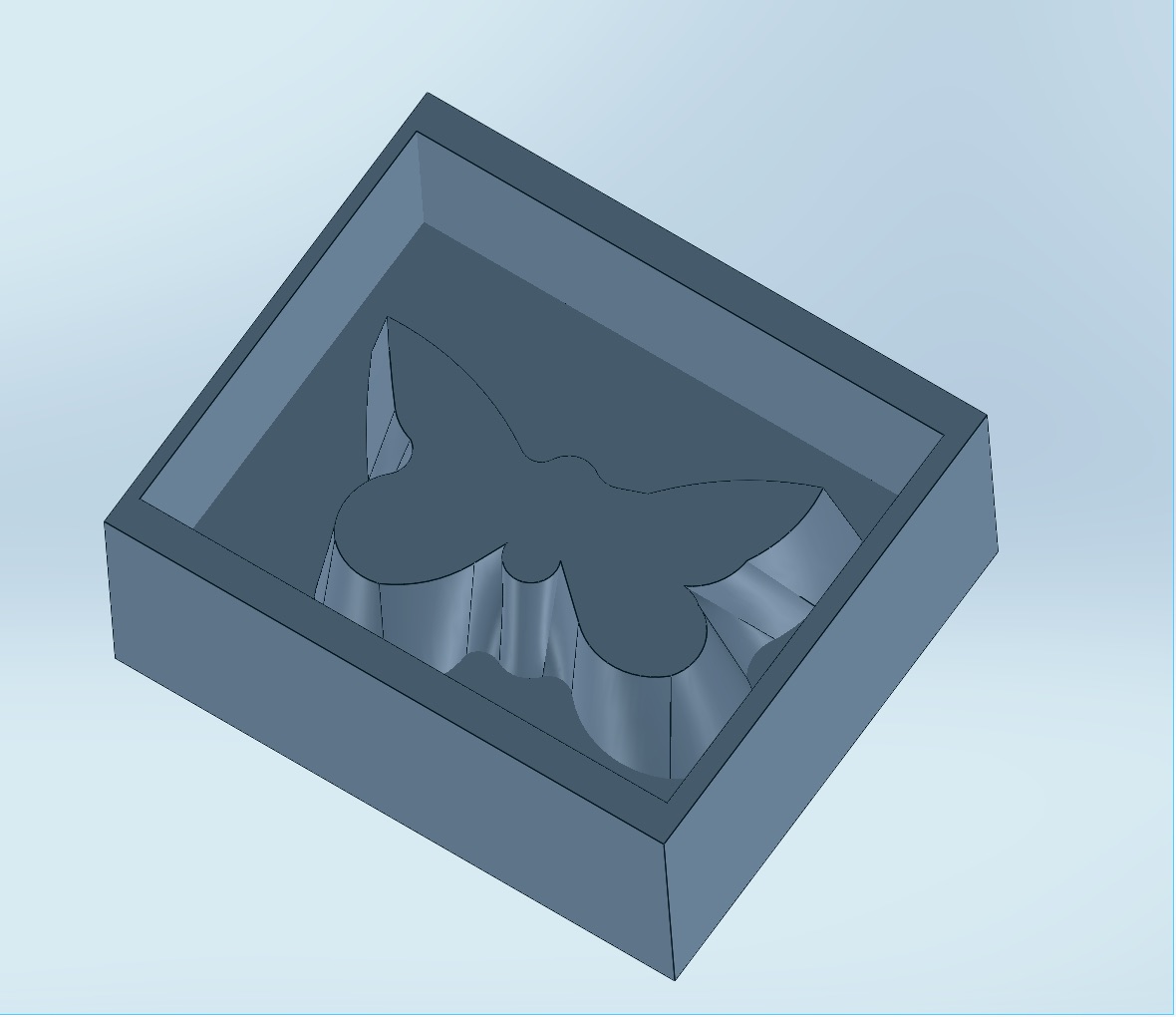

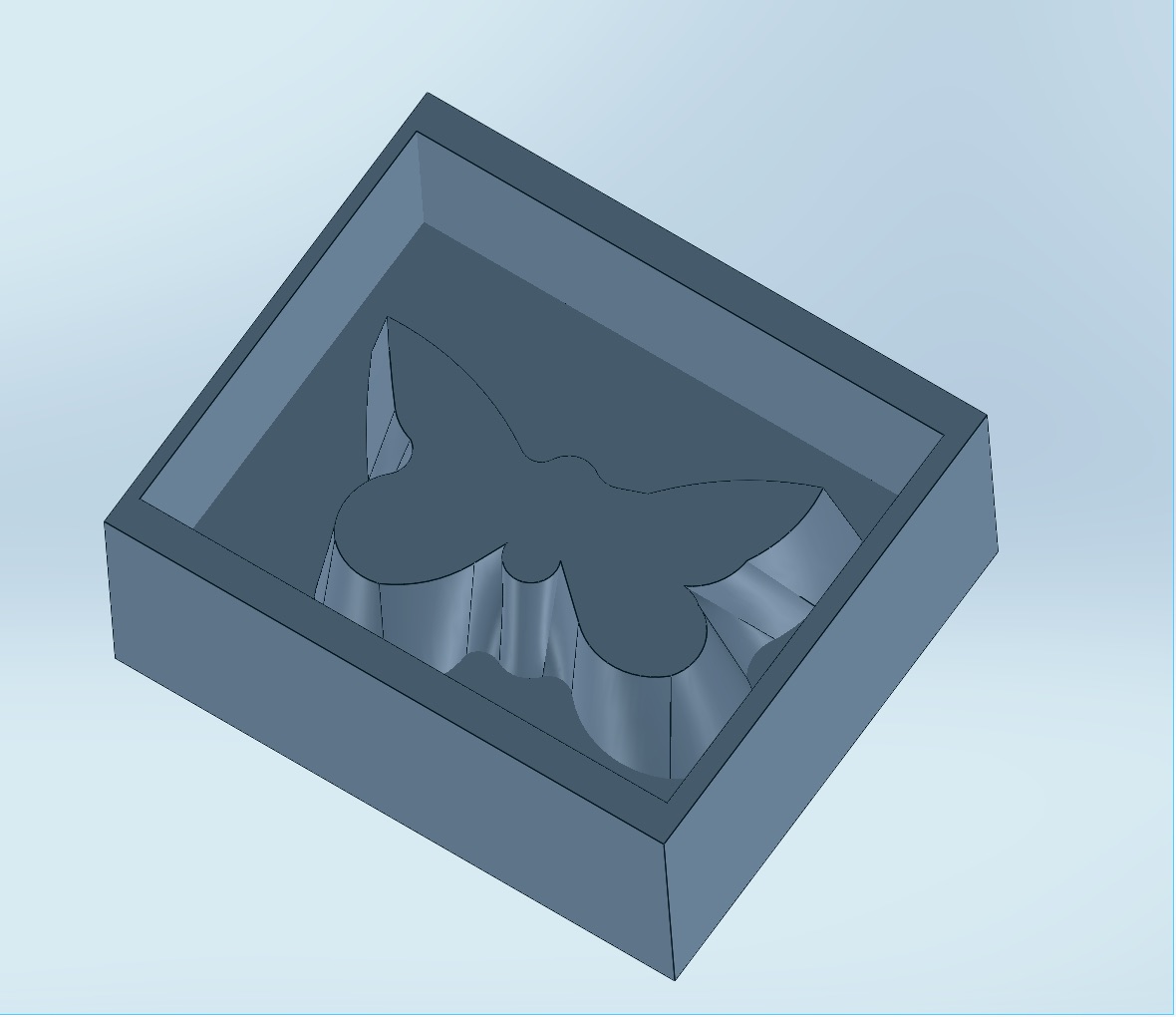

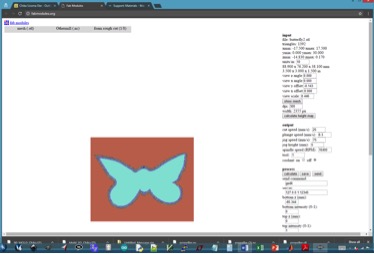

1. Designed 3D mold

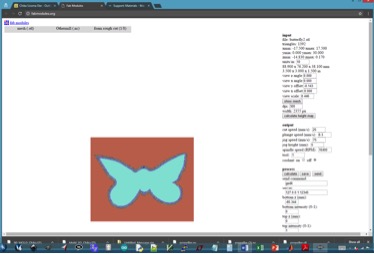

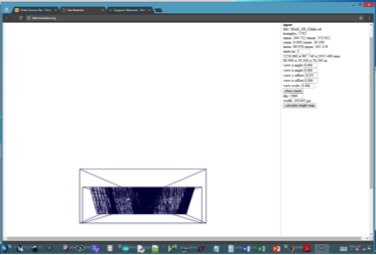

2. Generated tool paths

2. Generated tool paths

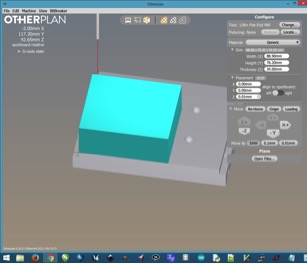

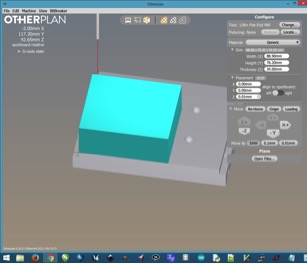

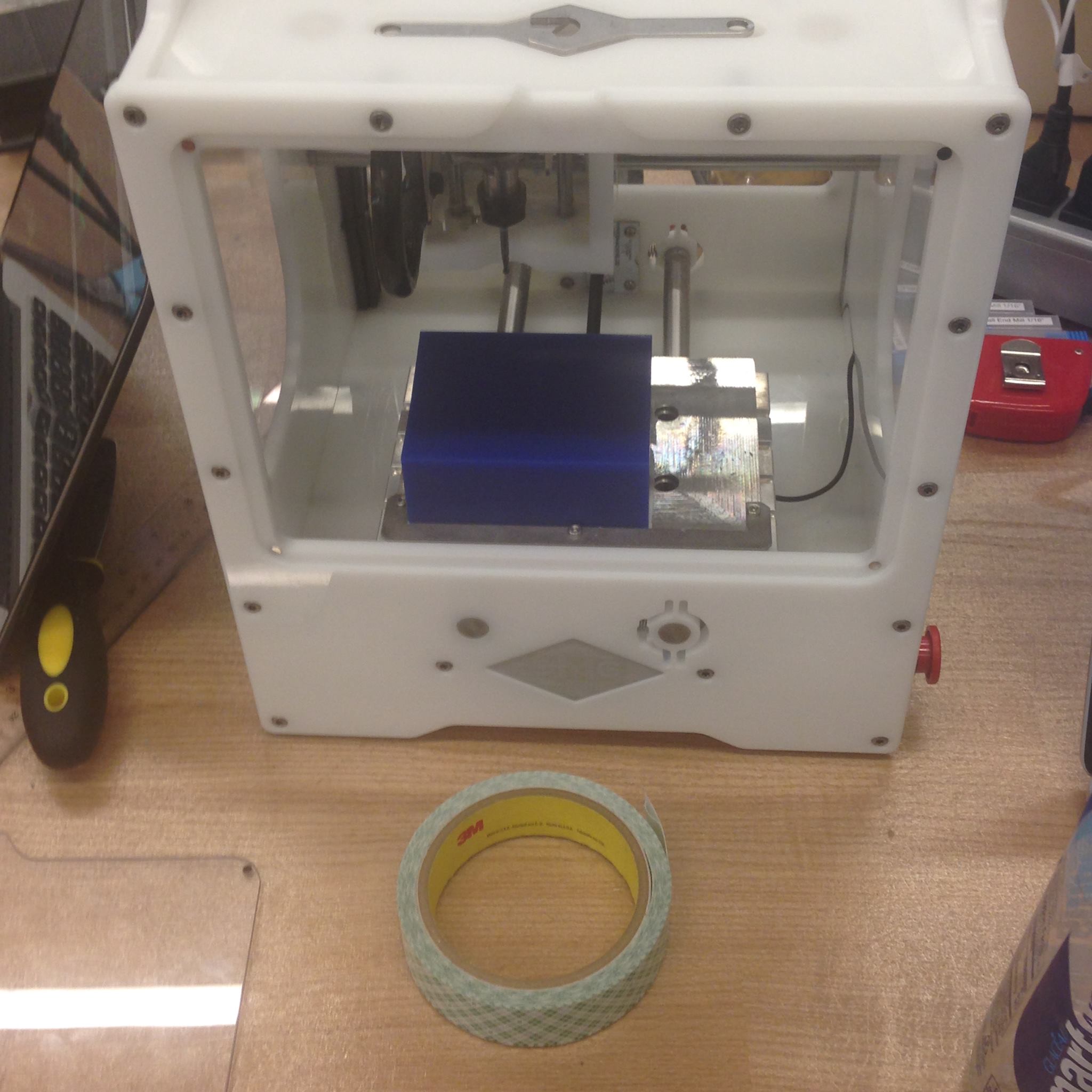

3. Prepped for machining using Otherplan Software

3. Prepped for machining using Otherplan Software

Challenges:

0. Was not able to start until Monday night due to travel for a conference.

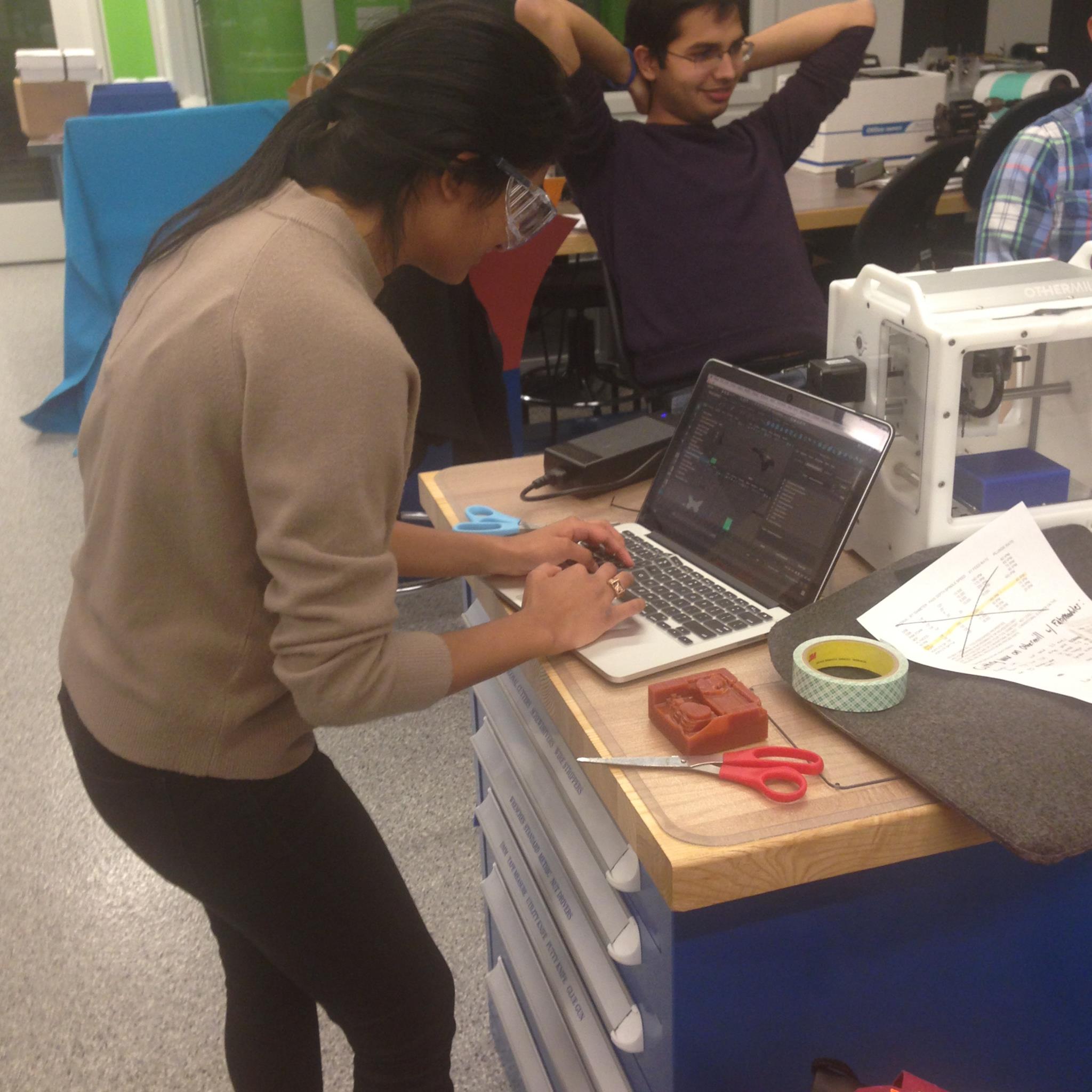

1. Needed to rotate mold for processing in fabmodules and this was not straightforward in Solidworks. Shout out to Kiran for basically remaking the part in another software just so that it could be loaded properly as a .stl!

What I learned:

1. .STL must be changed to .stl to be processed

2. Can change orientation of part by editing the original axes used for the solidworks part

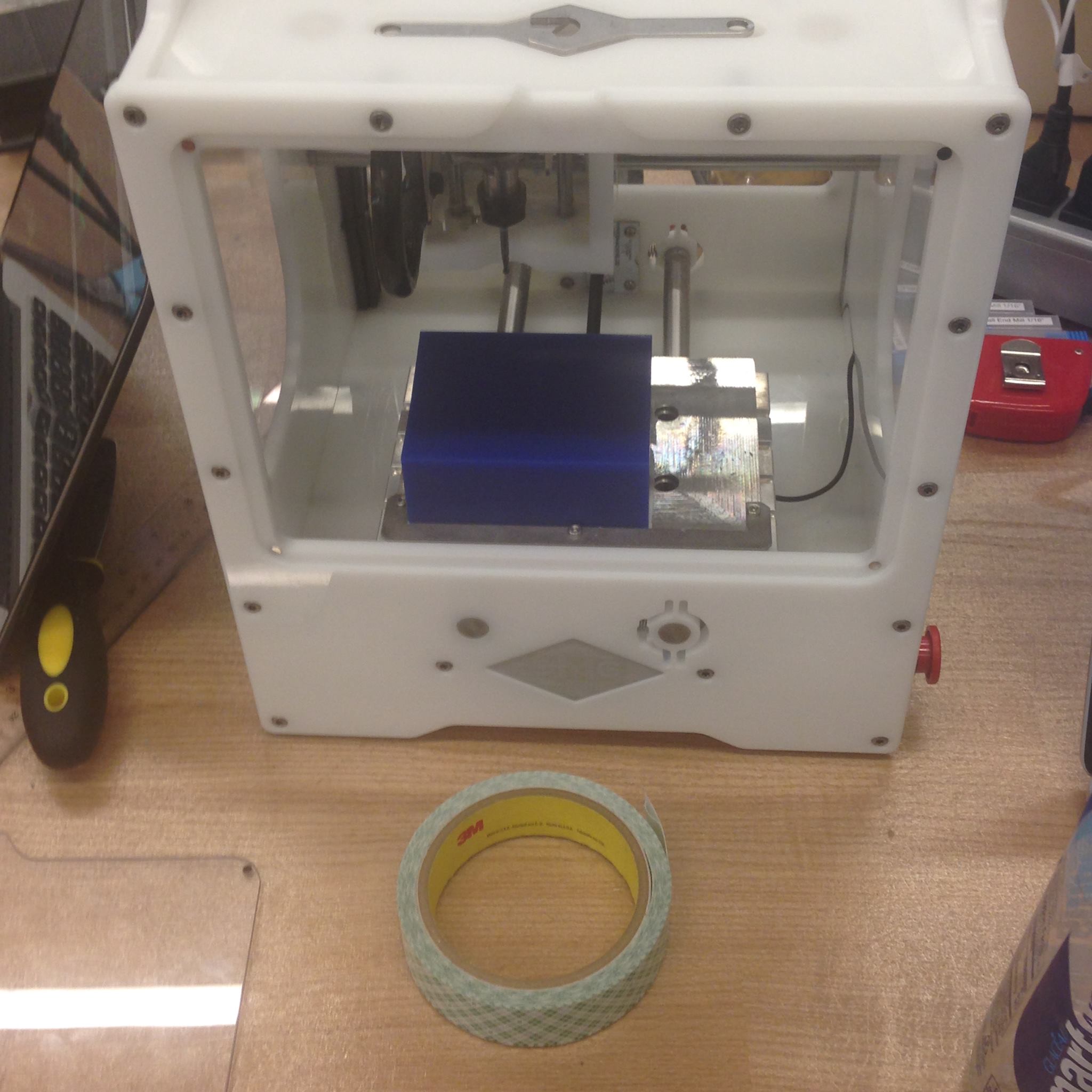

3. How to use the manual mill to shave down the part for the Othermill

4. Always use your laptop to generate tool paths!

5. General steps involved in molding and casting though I didn't get to try out every step

Questions:

Could not figure out how to align the origin of the tool in the Otherplan GUI with the origin location for the tool in the actual machine. This was not a problem for the person who used the machine before me for some reason.

The dream: