For this week, we worked in teams to make machines over a period of 2 hours. This was a crazy frantic timeframe and I really disliked it. By having only 2 hours to make the whole machine (milling boards, stuffing them, laser cutting cardboard for the motors, gluing the pieces together, writing the software, and putting it all together), everyone seemed to be stressed but also unaware of what we were supposed to be doing which was very stressful.

I joined the electronics team to get more familiarity as to how the signals were going to propagate and control the motors. It also seemed to be the smallest team so I thought I could get to participate more. However, I was mistaken, it was hard to be able to work together since we were all stressed with getting the project done.

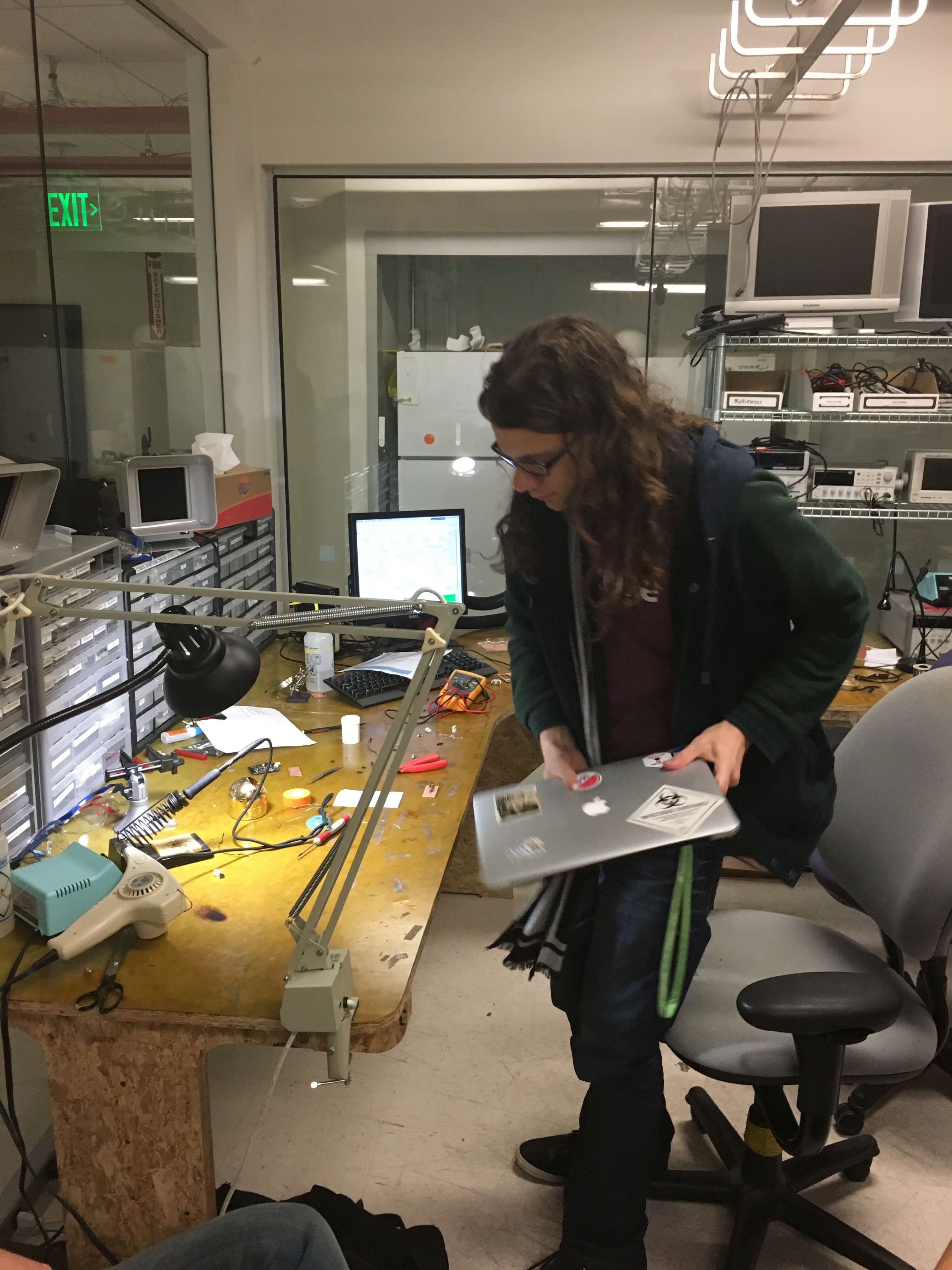

Here’s us in the CBA electronics shop

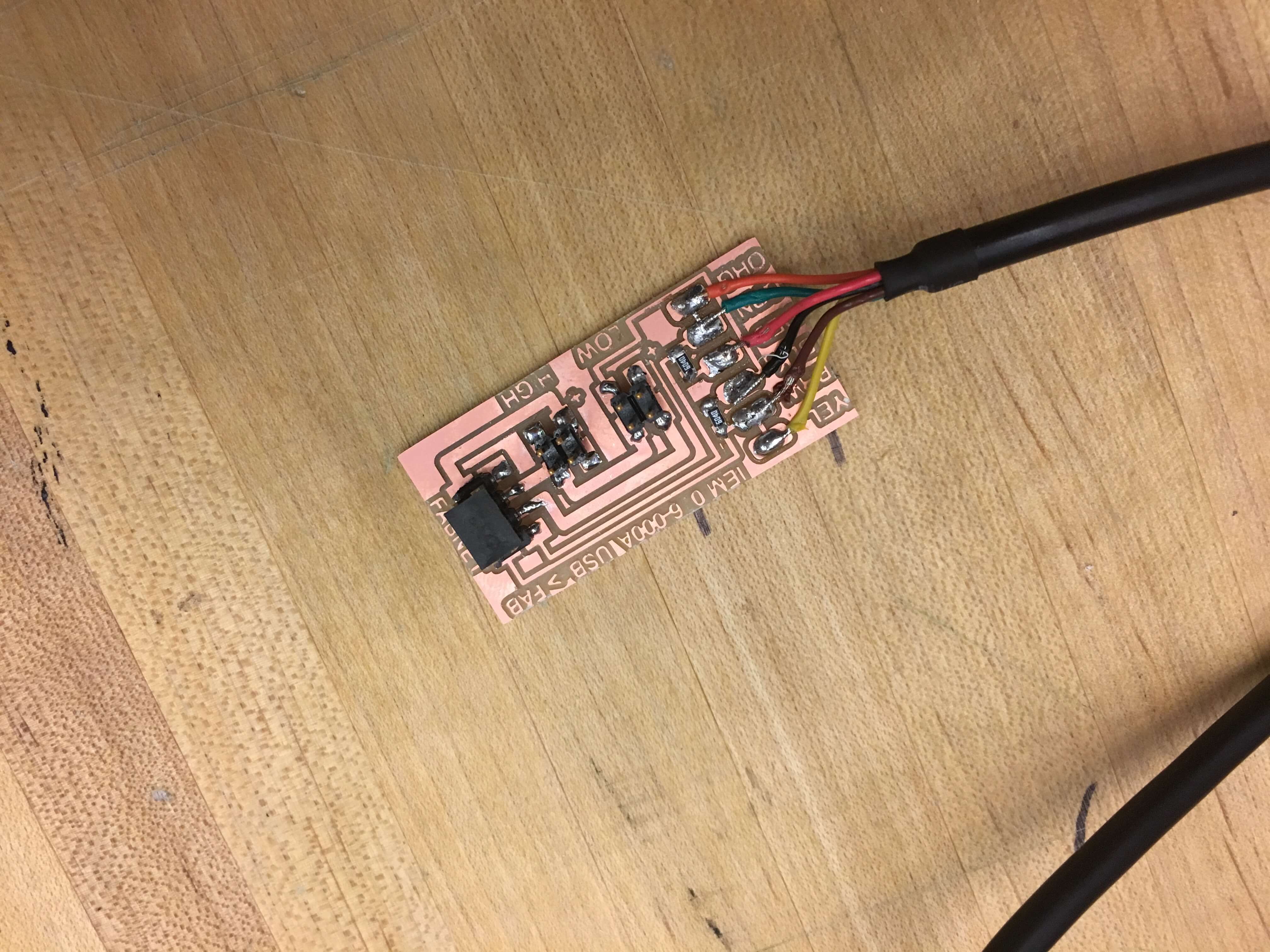

We were able to successfully get our board milled after an incorrect first attempt, however there was a short in the cable provided to us so that caused a lot of issues with being able to use our board.

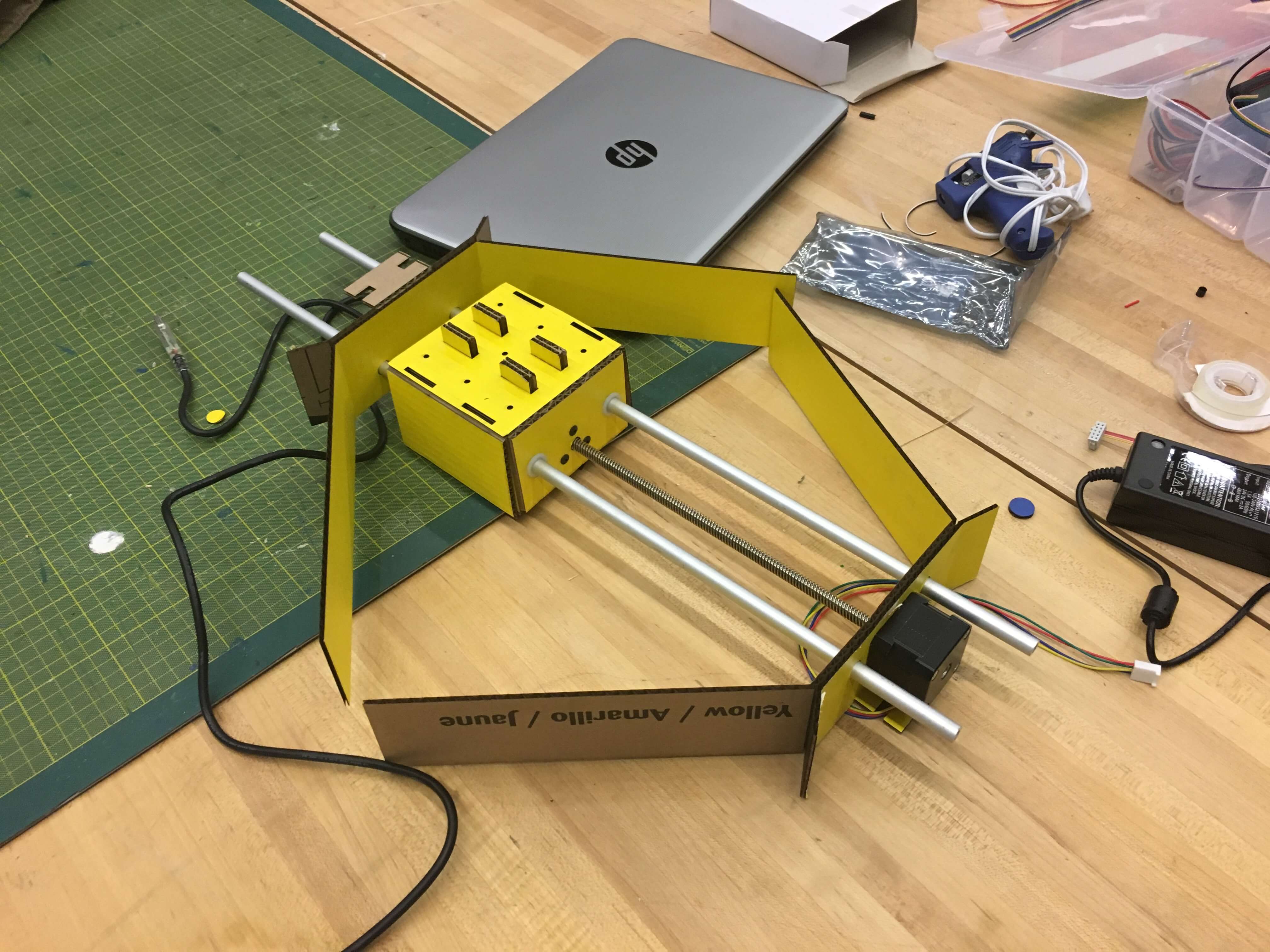

Next, a lot of us started to help with the motor assemblies and the machine axis.

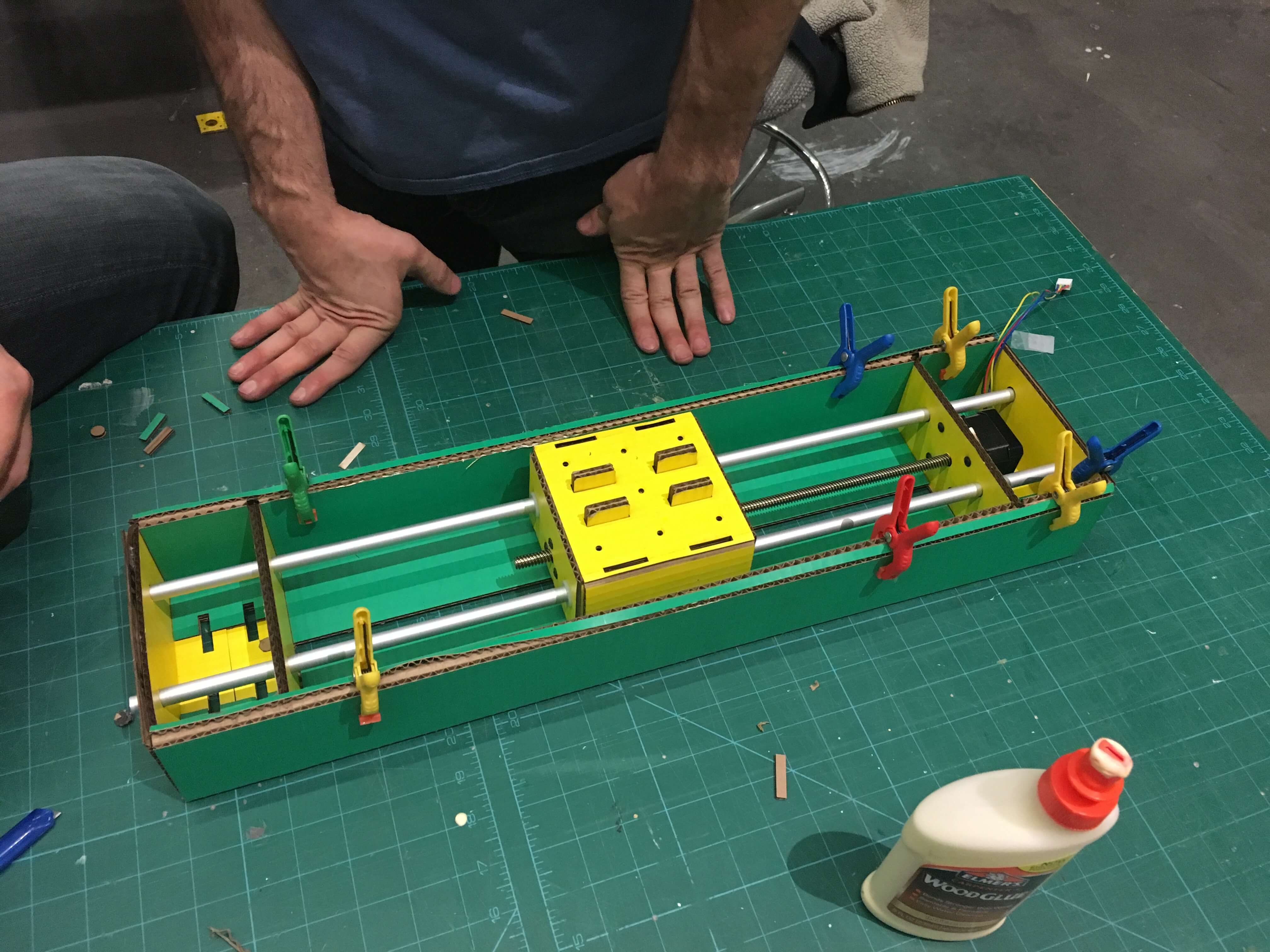

The finished motor assembly looked pretty cool:

We ended up working together pretty well in this section because it was easy to see what all had to get done :)

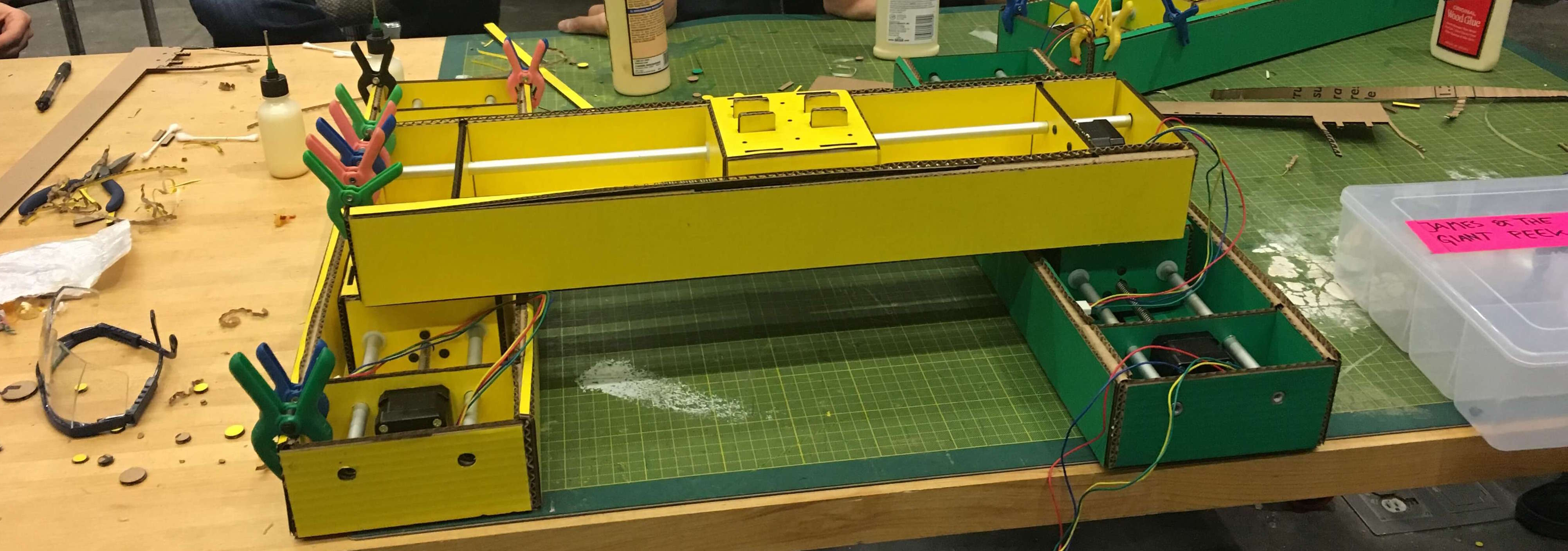

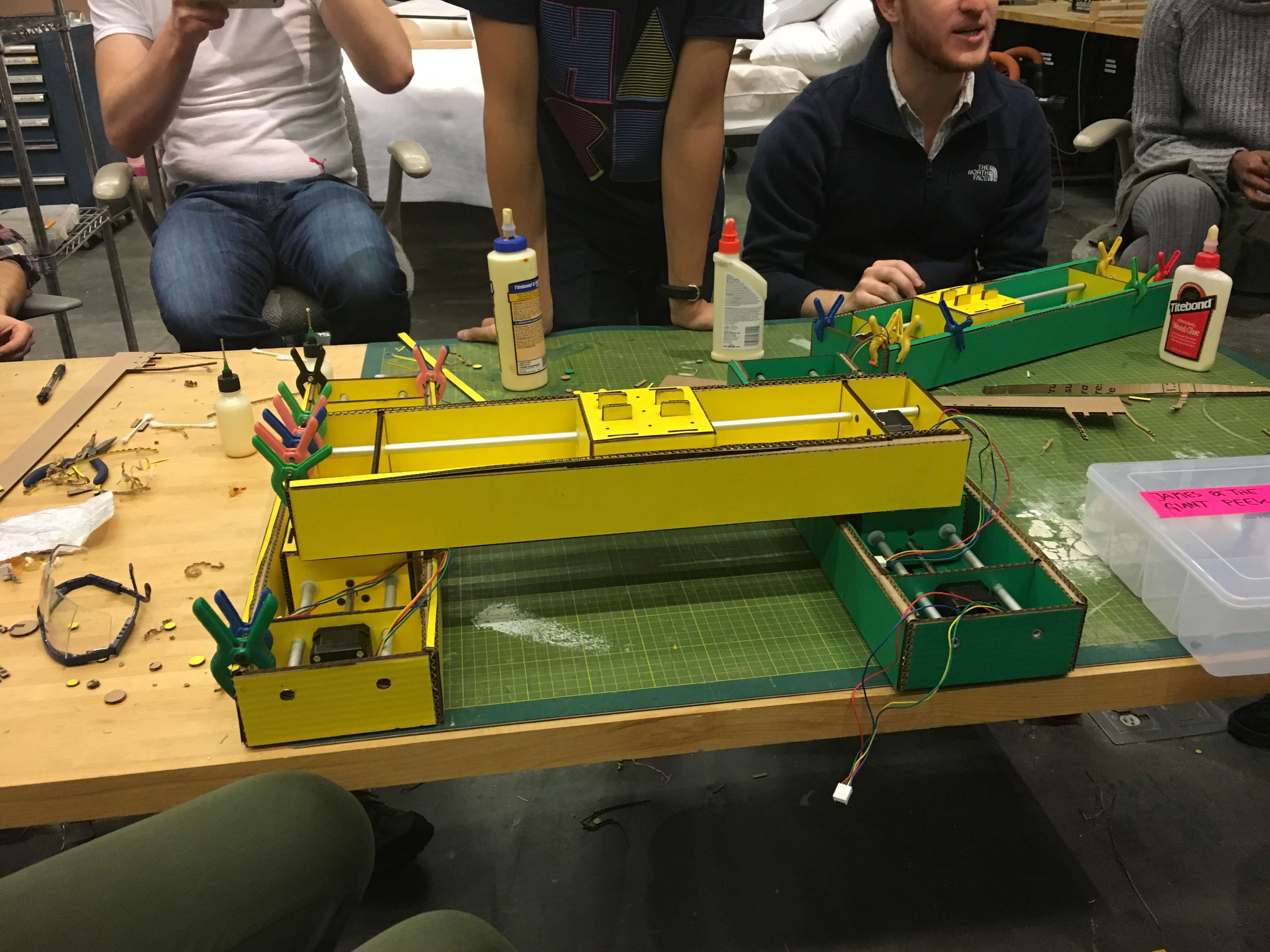

Here’s our finished machine:

We thought about adding a pen to the bottom of the middle axis so that we could use it to draw on a piece of paper once we had the electronics working :)