Press-fit Mickey Mouse

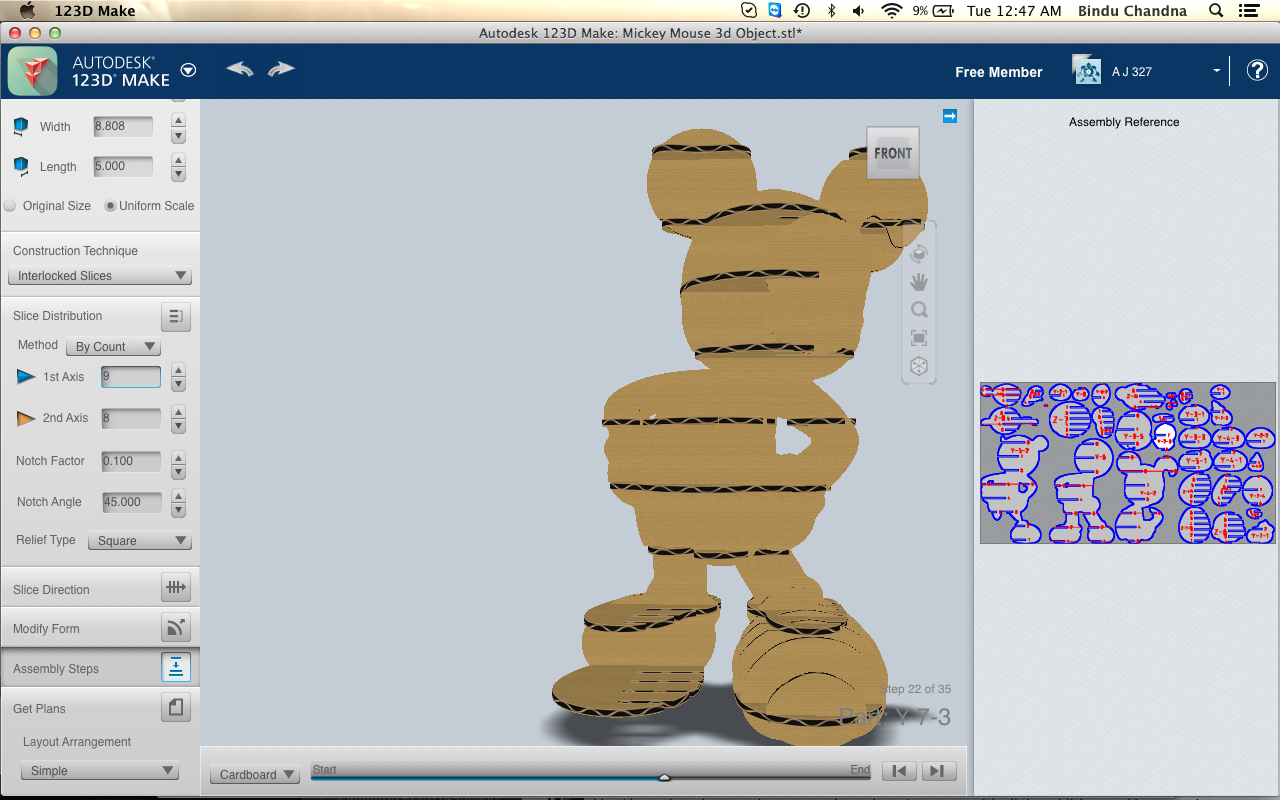

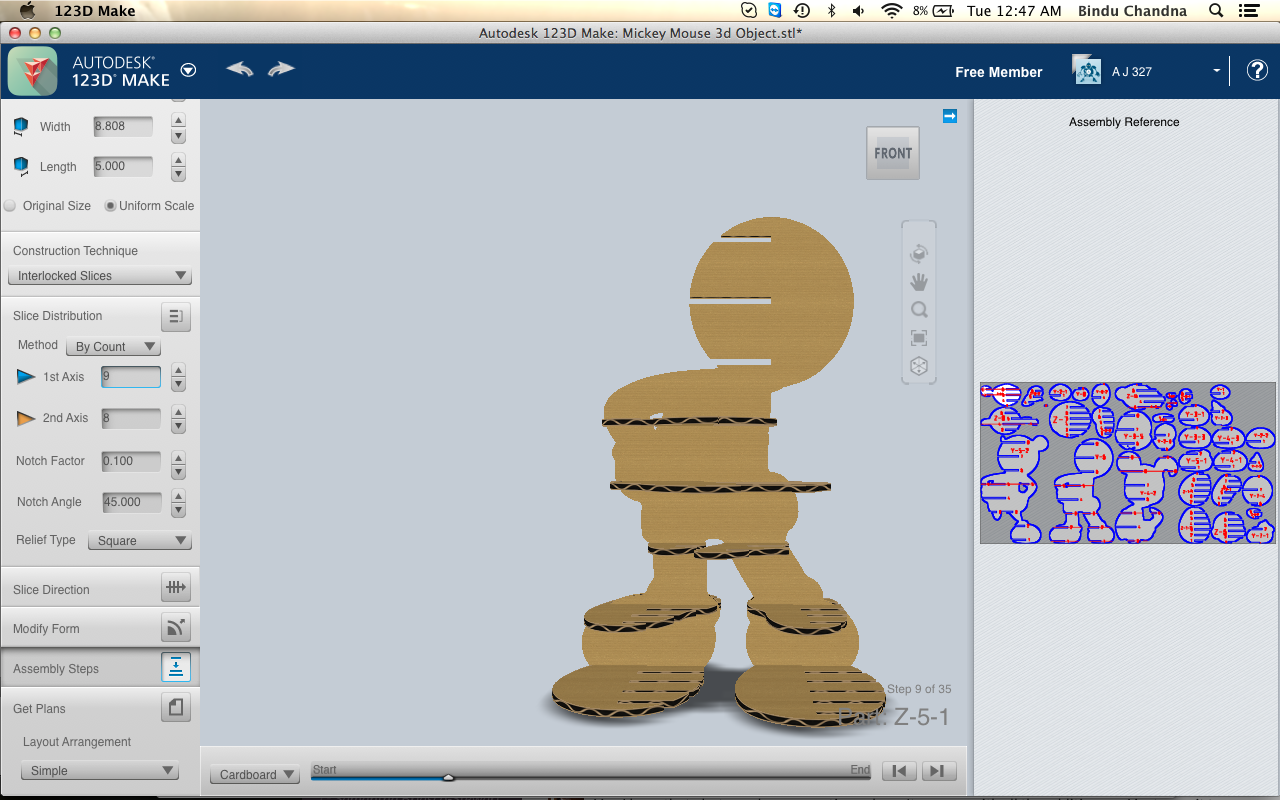

At first, I struggled with coming up with an idea. I wasn't 100% sure what I wanted to make, because I wanted it to be unique but also be able to make different things with it. I started experimenting with multiple different pieces of software, as were presented on the class, and remembered this video I had seen from Glowforge (a new laser cutter) that had a full size globe lamp made out of laser cut cardboard. This inspired me to want to make something that meant a lot to me - which reminded me of Camp Kesem, a camp for kids whose parents have cancer run by MIT students, that I had been part of for the last 4 years. My camp name was Mickey, and so I thought it'd be really cool to make a Mickey Mouse out of cardboard. Using Autodesk's 123D Design and 123D Make, one can import a 3D design and then be able to get a construction kit for it through Make.

123D Make also gives you steps as to how to put the pieces together.

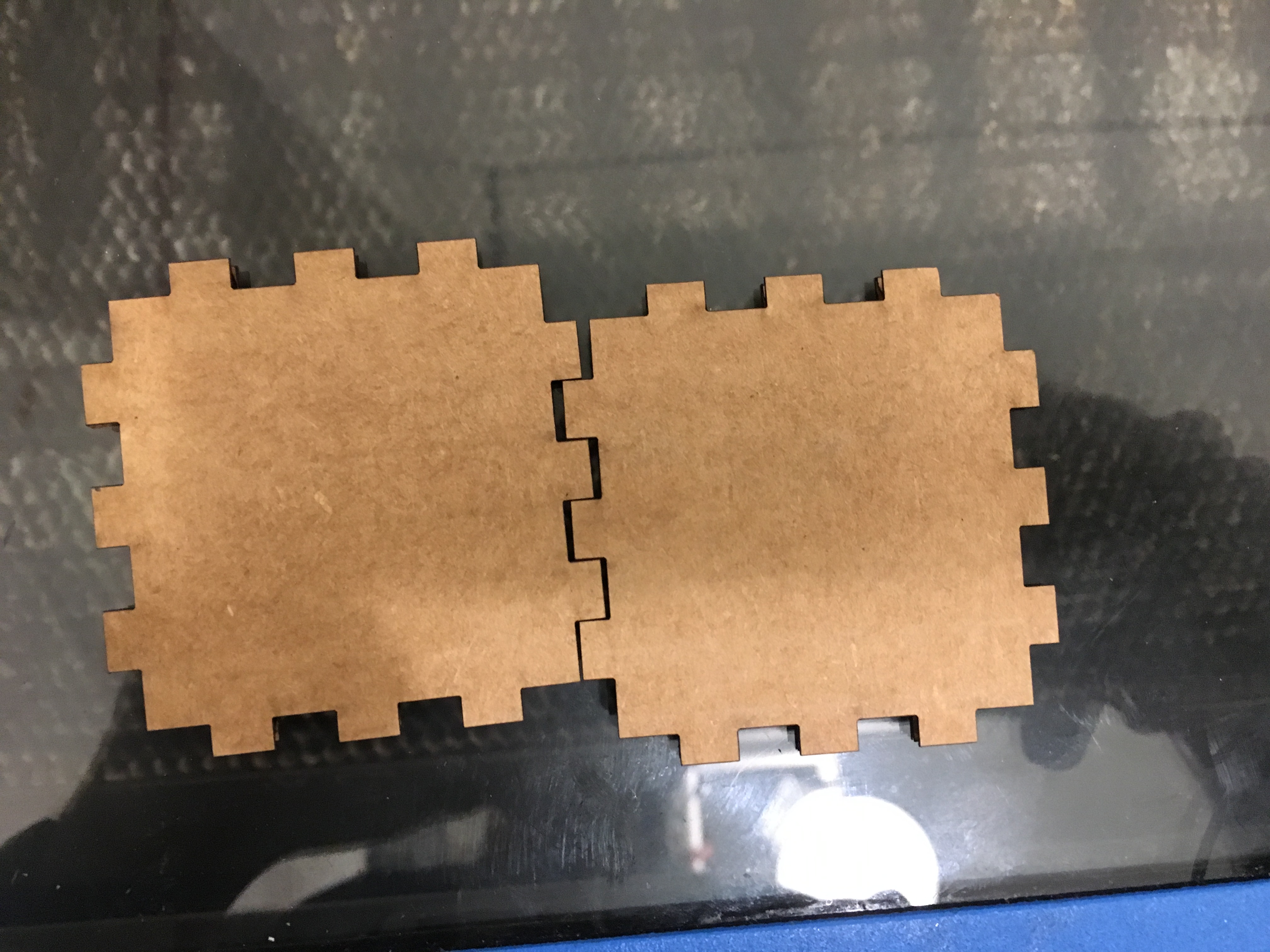

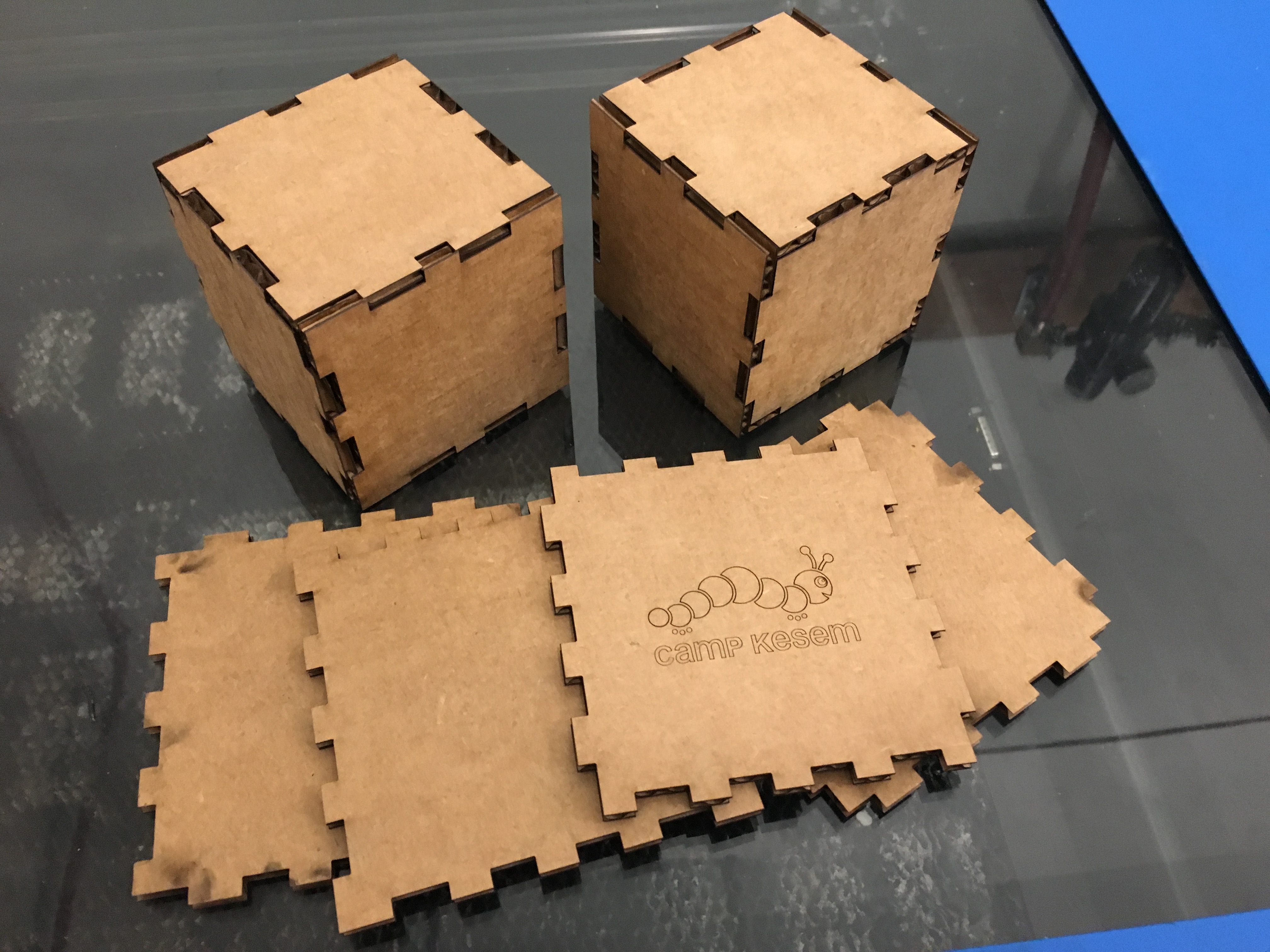

Although this was really cool, I wanted to also practice trying to make other press fit kits that I had to make myself. The first attempt I did at this, I made the joint too loose because of the kerf (how much cardboard is burned off by the laser beam width) and thus had pieces that didn't fit together well.

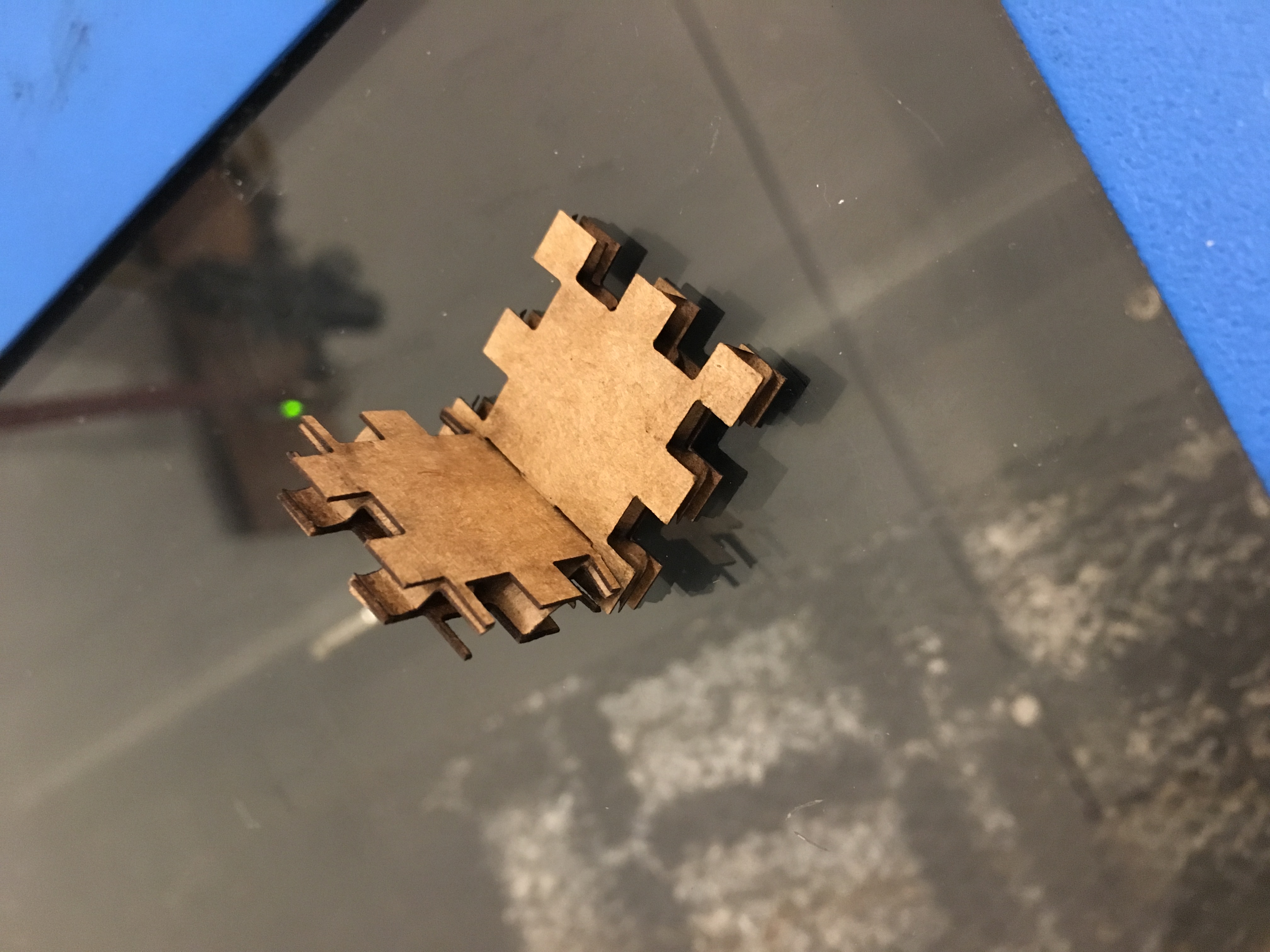

However, after a few more tries, I was able to get a good point.

With this, I was able to make a few different simple squares boxes and also tried out scoring logos into the cardboard.

This was definitely exciting to work on the laser cutter and I look forward to taking these skills for prototyping in the future!