In lab, we tested the design constraints for our 3D printers. For design constraints, our group printed a model of Shrodinger's cat: A sitting cat was placed in a box with three flaps. This design enabled us to test the machine's capabilities for hollowness, wall thinness, and overhangs.

As for the printing process, we learned a few tips:

- Before printing, put base material on the bottom of the machine surface. This will prevent damages to the object when scraping it off with a spatula.

- Depending on the object, place it in the container next to the Stratasys so that the material can solidify. This will prevent breakage.

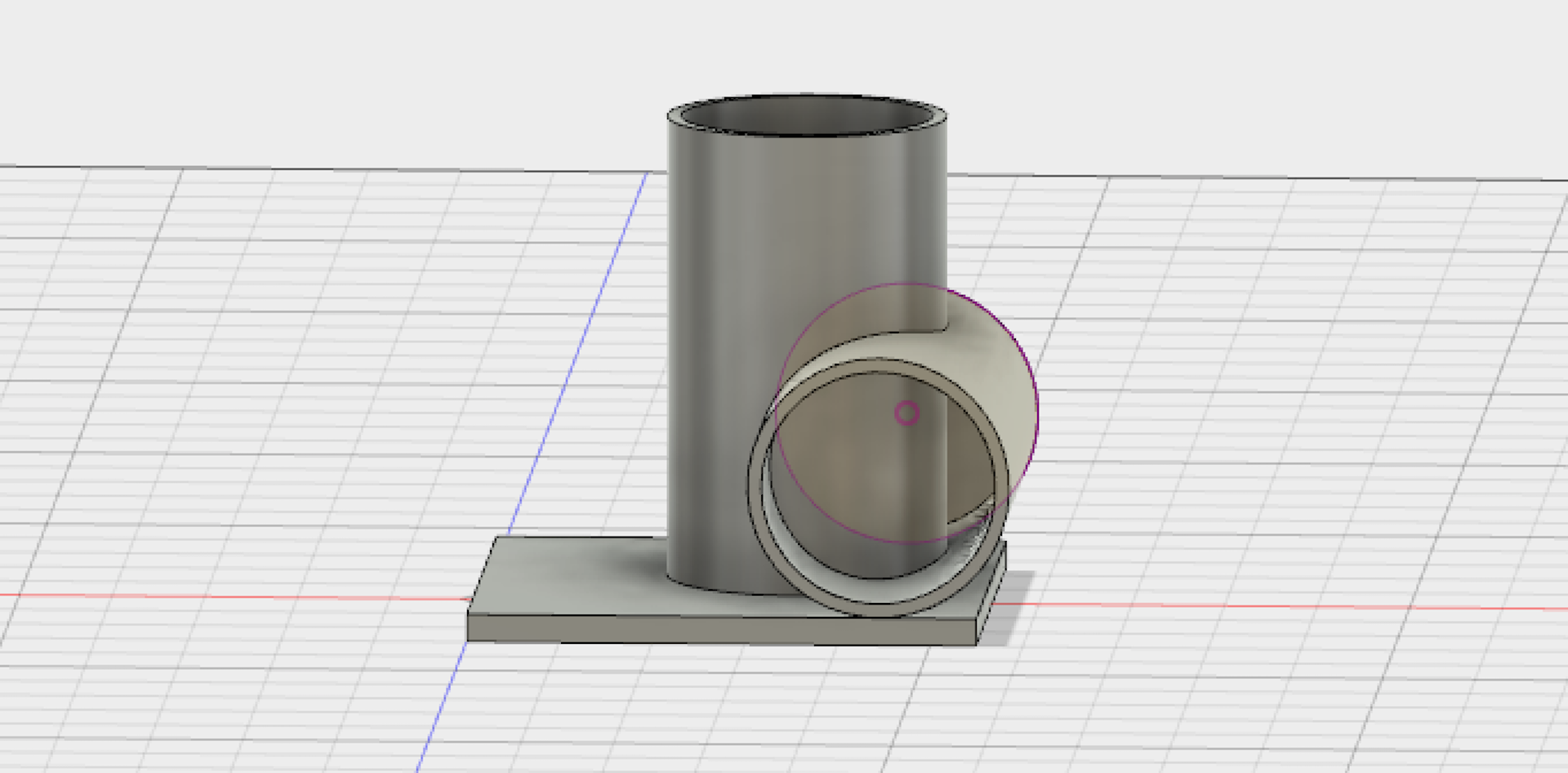

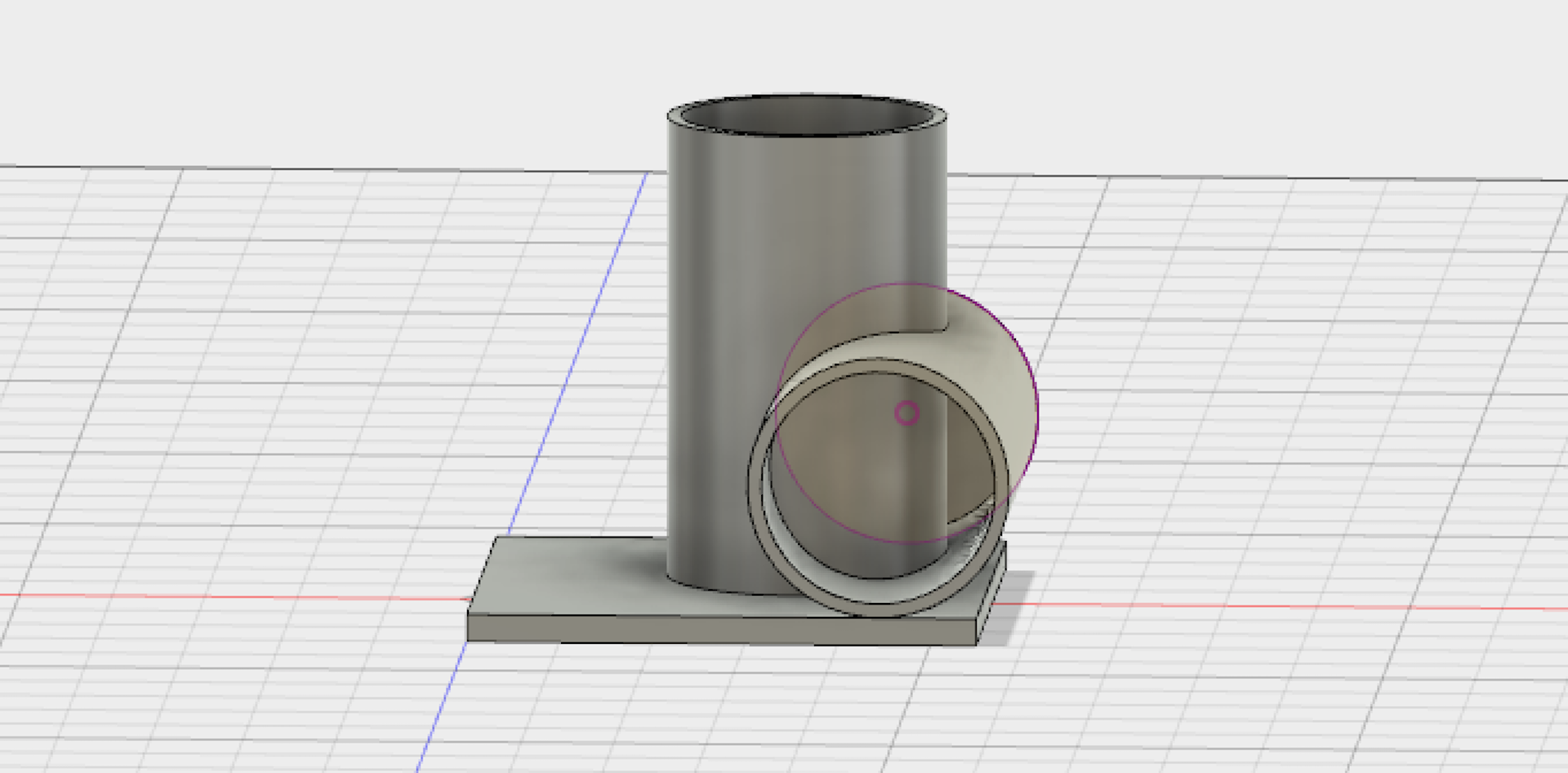

Developing a concept for an additive 3D print challenged my creativity, as my goal is to build artistic, yet functional products with each fabrication method. My initial idea was to create a musical note inscribed within a diamond-shaped pendant. However, I was severely limited by my lack of experience with CAD. So, I went back to the drawing board, brainstorming different combinations of geometic shapes and their potential practicality. I ended up with a micro-protoype of a desk organizer, where I can stuff pencils and trinkets.

After a frustrating date with Fusion 360, I designed my object: 2 perpendicular cylinders on a square surface. I hollowed out the cylinders for an inside thickness of 1.5mm. After saving the design as an .STL file on a USB, I inserted the device into the U Print, loaded my file into the print queue, and initiated the print job: ETA ~ 3 Hours.

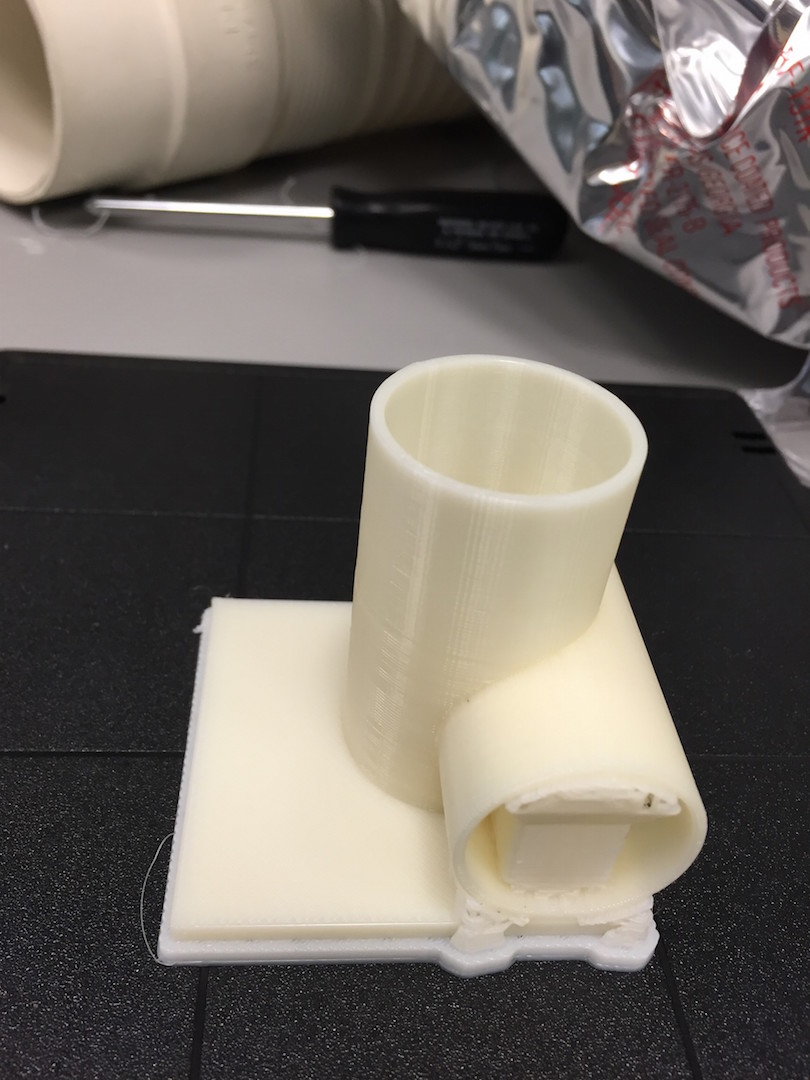

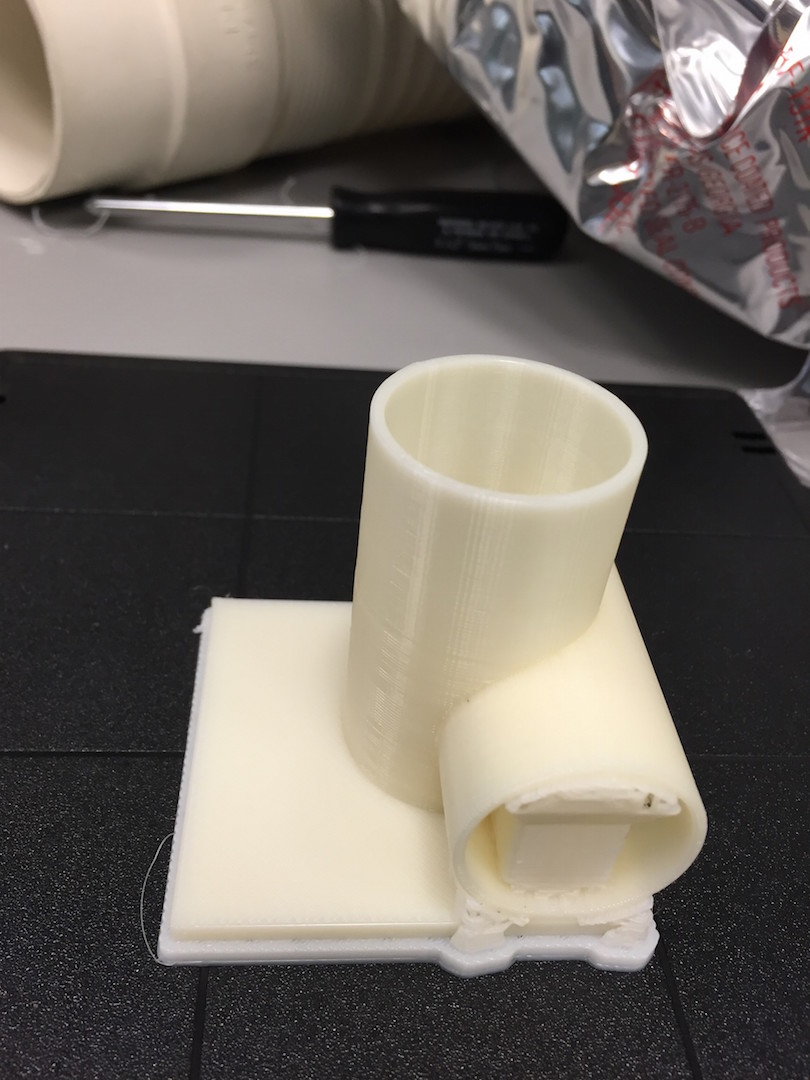

Three hours later, my object printed true to form - there was just excess material in the horizontal cylinder and a support base. However, I learned that the U Print, or Stratasys, differs from the other 3D printers in that it uses two materials. Therefore, objects must be cured in an adjacent container to dissolve the inessential material.

So, I put on the fat rubber gloves, opened the container, and initiated the curing process: I placed my object inside a silver cage and immersed it in the hot liquid, waiting another 2 hours to shed the excess materials.

The final product, sans support base and excess materials in the cylinders:

Overall, it was pretty rad learning additive manufacturing through a 3D printer. In addition to learning about the design parameters, machines, and process, I gained exposure to CAD software and will familiarize with the functionalities to become a more proficient designer.