Week 7: Casting and Molding

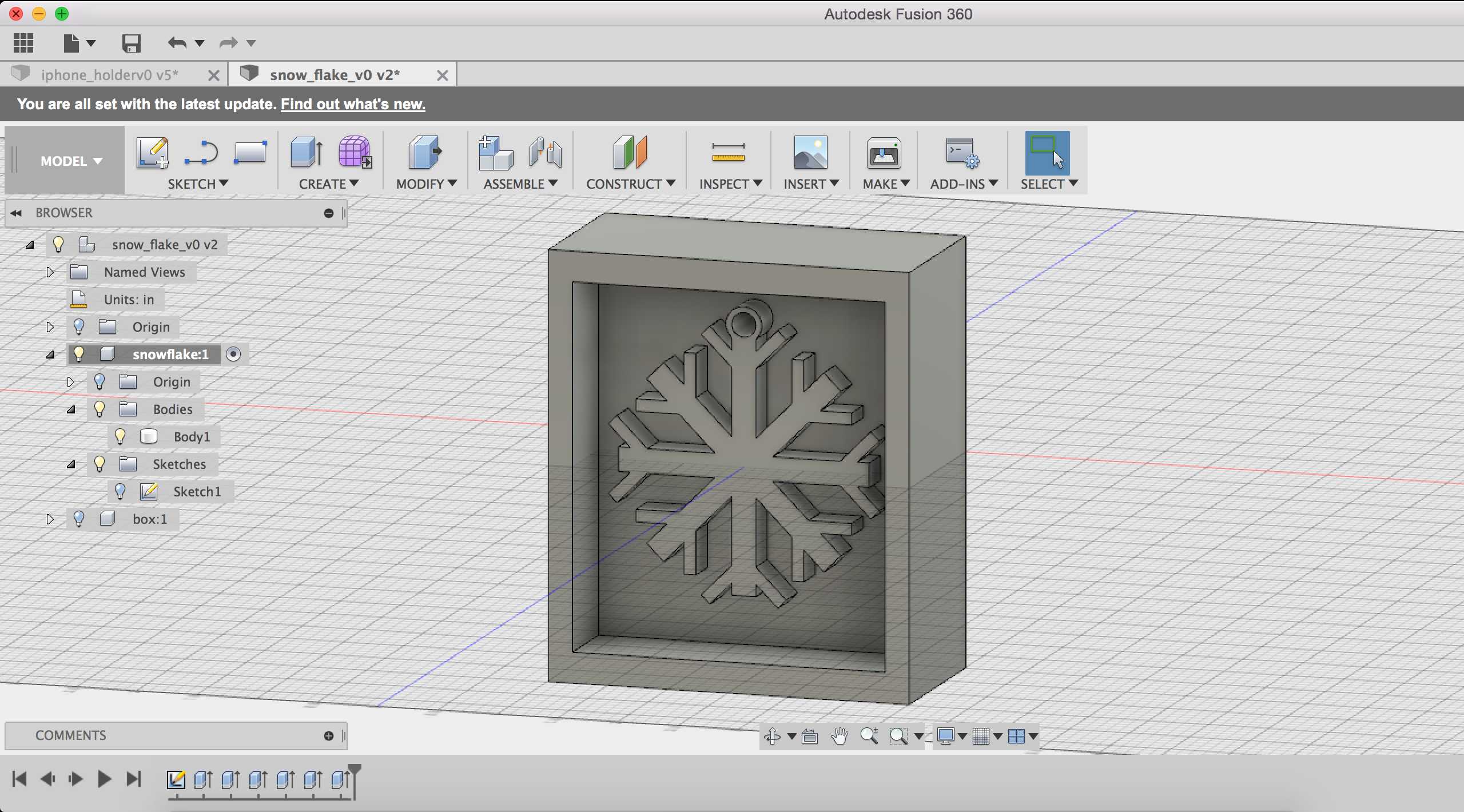

Making an iPhone Holder

Nov 2, 2016

Assignment

Design a 3D mold, machine it, and cast parts from it

Workflow

- Design a positive mold.

- Mill it on machinable wax with with either Roland SRM-20 or Othermill in EDS.

- Cast it with OOMOO to make a negative mold.

- Cast your positive object with Hydrostone, Drystone, metal, etc.

Making an iPhone Holder - No success yet!

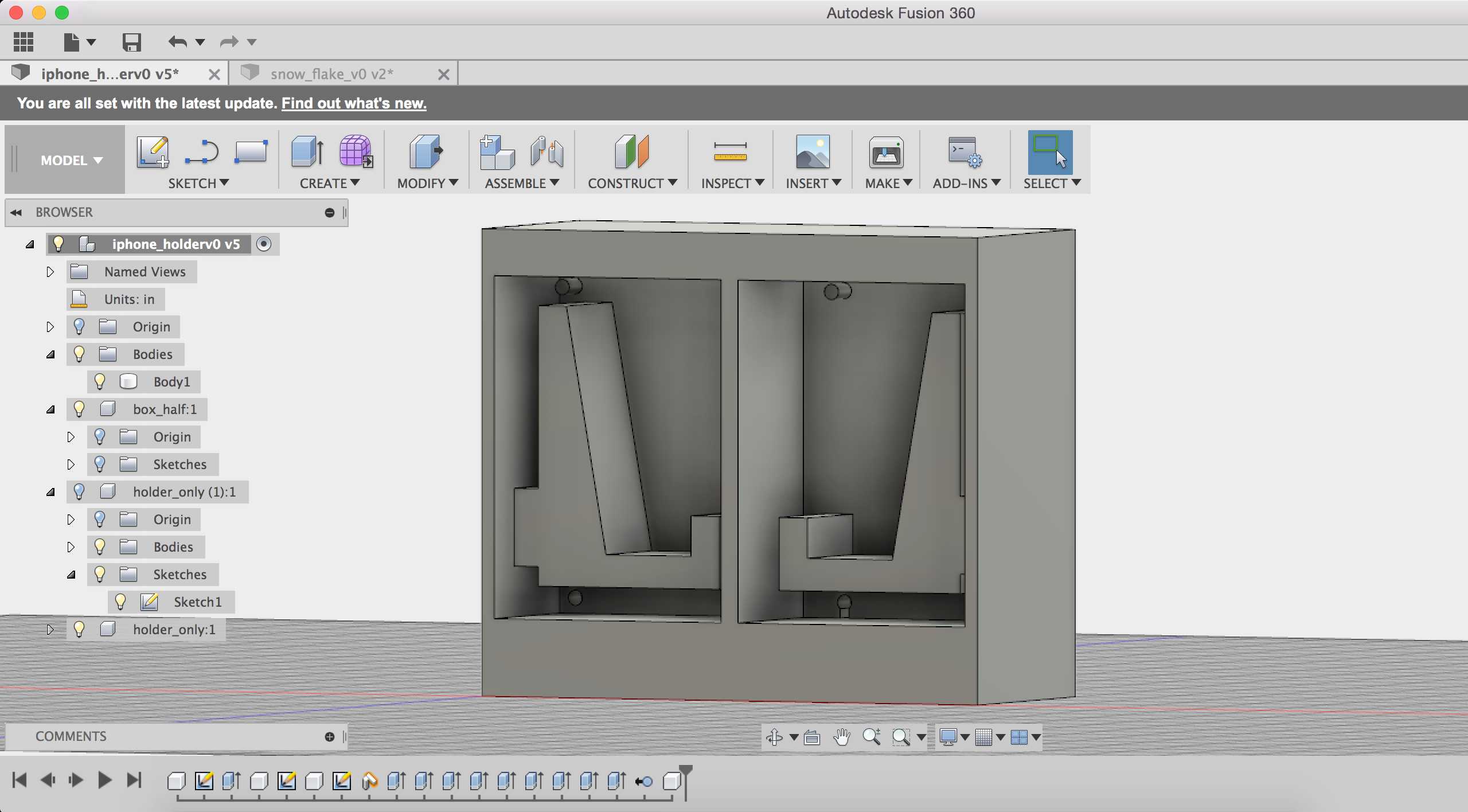

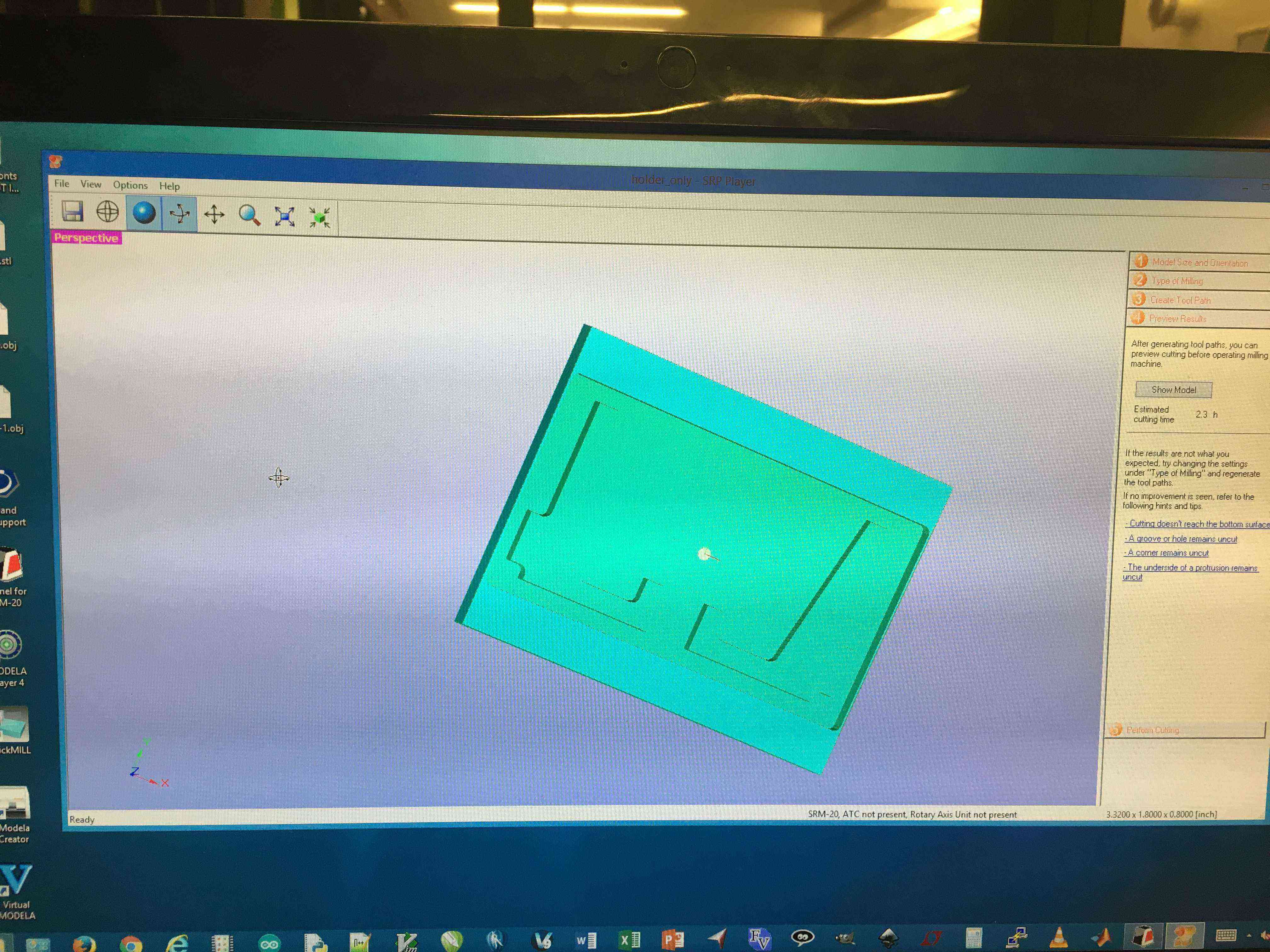

First, I wanted to make a 2-part mold for a small iphone holder on my desk. The SRM-20 in the EECS section is supposed to work with both fabmodules and Roland's sofwtare package (SRP Player, Modela). But since their software package only works on windows, I tried usign fabmodules, which turned out to be much more complicated than expected. I couldn't send any commands to the machine! I copied the send command from the new fabmodule settings for SRM-20, PCB milling and edited the server to localhost:1234. But went I hit send command, it killed the command shell. I asked other people who have used fabmodules with SRM-20 for instructions, but I couldn't figure out how to make it work.

Then Gavin decided to setup the Roland software package on a windows machine. The user-interface is more friendly, but I still had so many problems! First of all, when working with fabmodules, you your mold into the block of wax. But the Roland software only takes the mold and the dimensions of the block, and automatically creates a space for the mold in the block.

This meant that I couldn't mill a two-piece mold in one block at one go. Additionally, I'd designed an opening on my mold to pour casting material in. But the sofwtare recognizes that as another object and would try to create empty space around it, which defeats the entire purpose of the mold!

So I decided to make a one piece mold to get the work going. I sent the toolpath to the machine and started milling on air to check the toolpath, and of course, it didn't work... For some reason, the mill moved outside the boundaries of my working piece. I checked the dimensions on my piece and in the software and made sure everything was in inches. But still no sucess! I'm planning to go back to lab and try othermill.

To be continued...