Assignment 9

composites: make materials stronger than they are on their own

This week, we worked on composites. Basically, what this means is forming a strong solid out of a combination of mutiple materials that fortify each other around some sort of mold. I used a 3D printed model of a shoe with burlap, woven linen and resin to make flats this week.

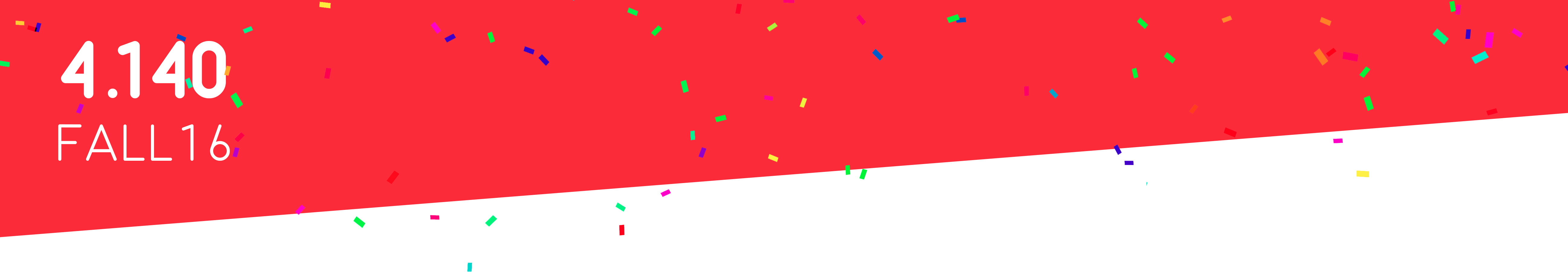

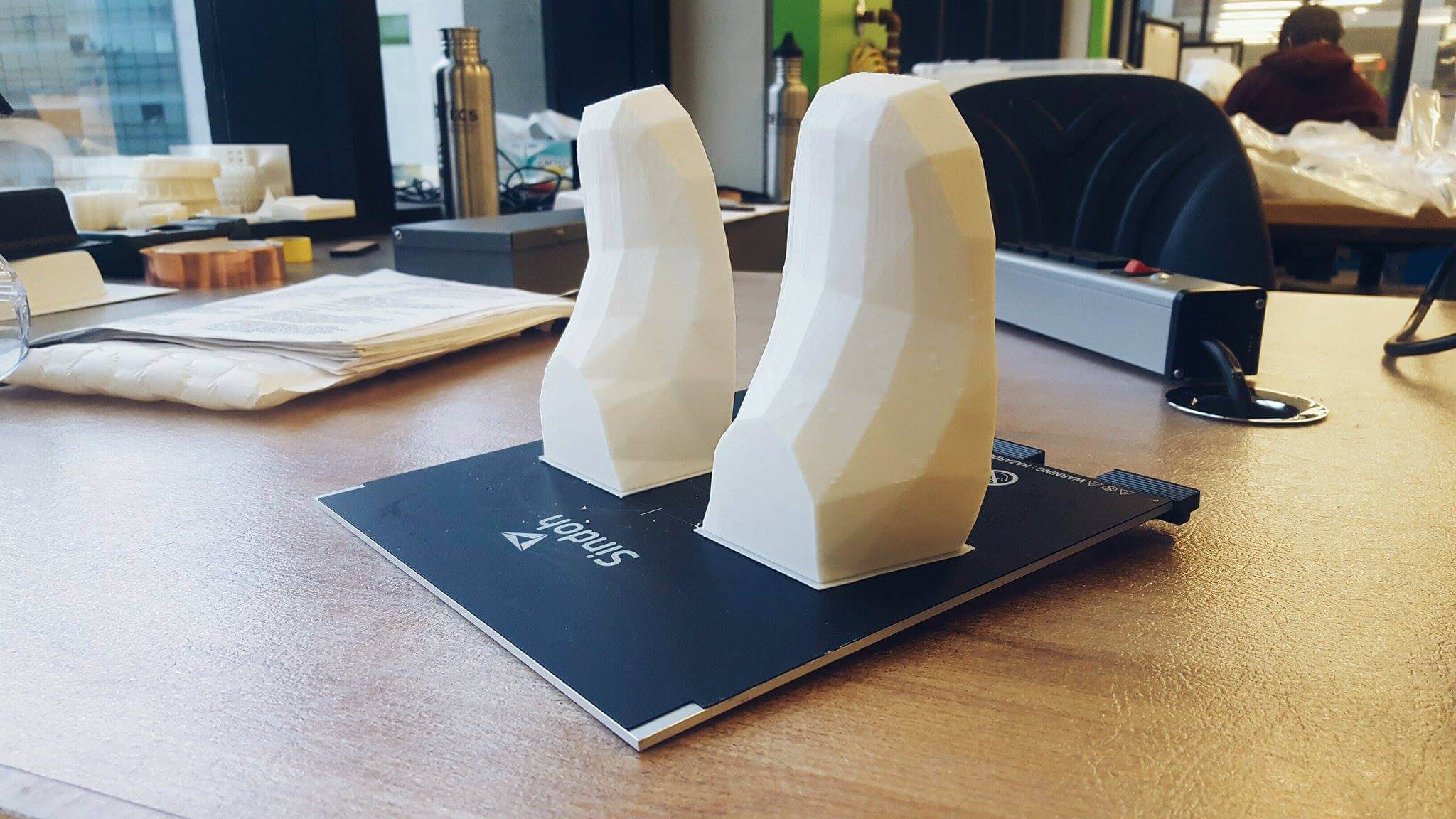

First, I 3D printed the part of the shoes I needed for forming the fabrics.

Next, I laser cut the fabric I wanted to use for the flats I had designed. I used a comination of burlap and linen layers.

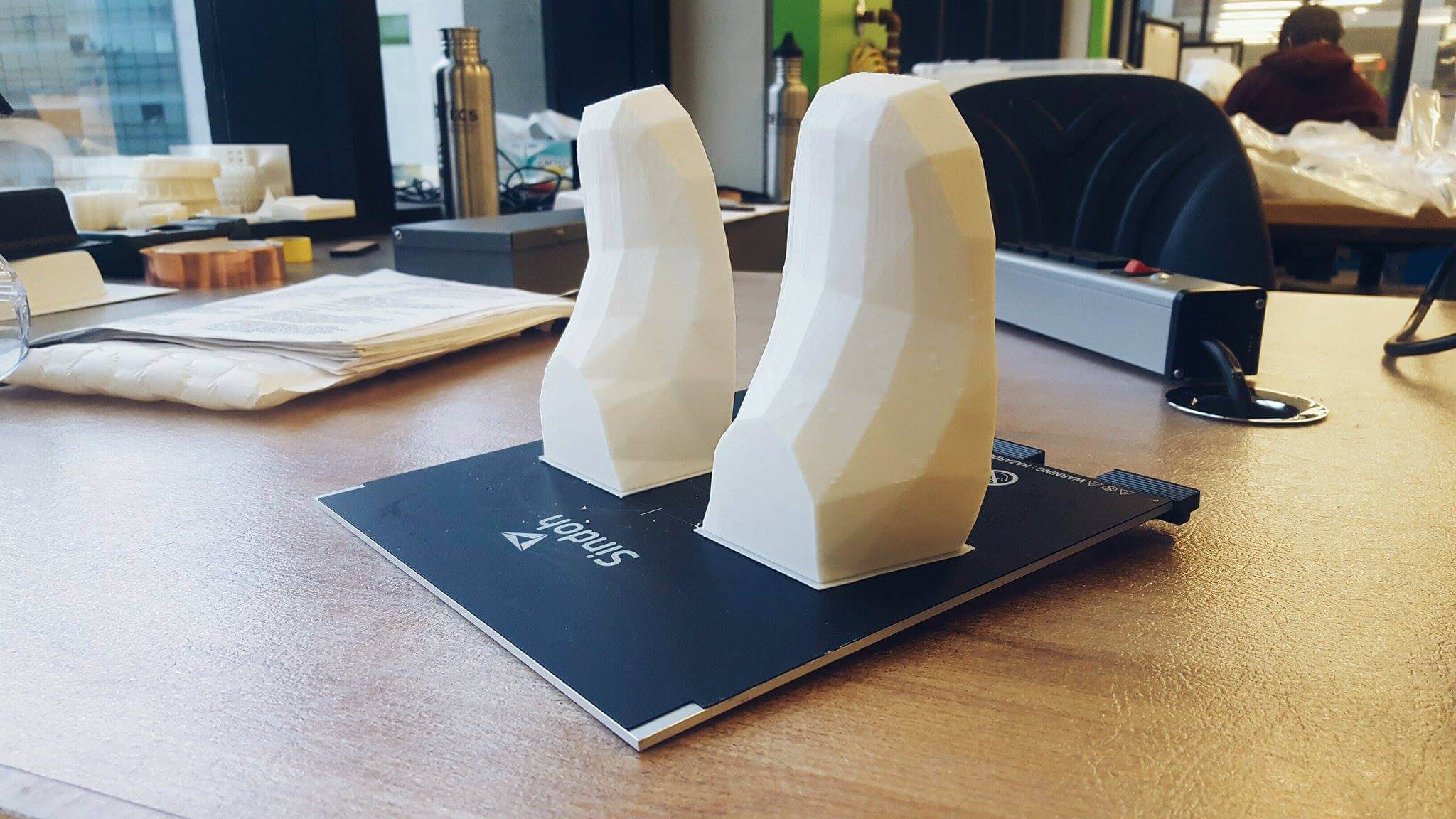

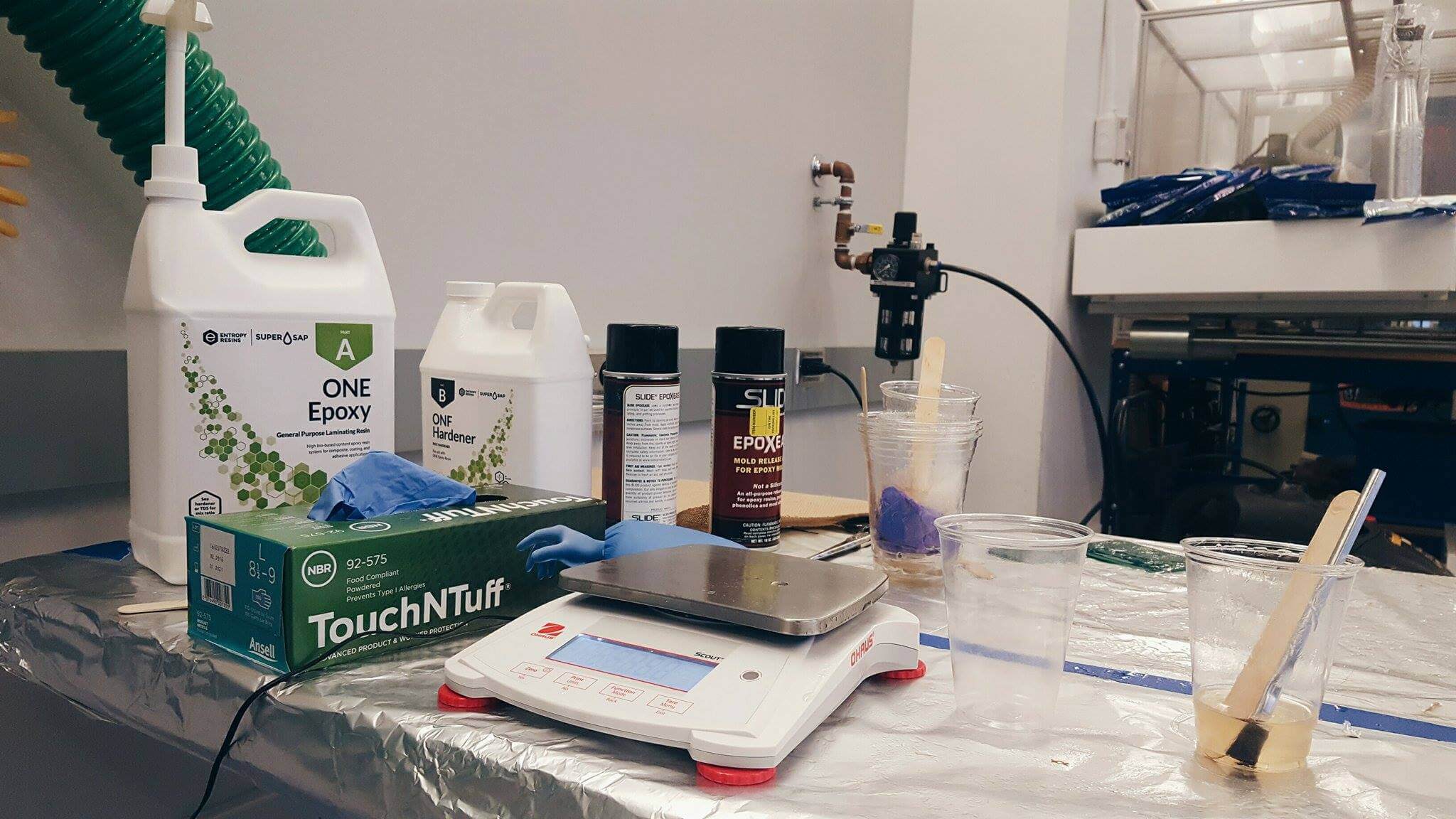

Here's the general set up for composites - a scale, cups and tongue depressors for mixing, expoxy, gloves and mold release.

Here are my shoes as they set around my model with bleeder and breather in a vacuum bag.

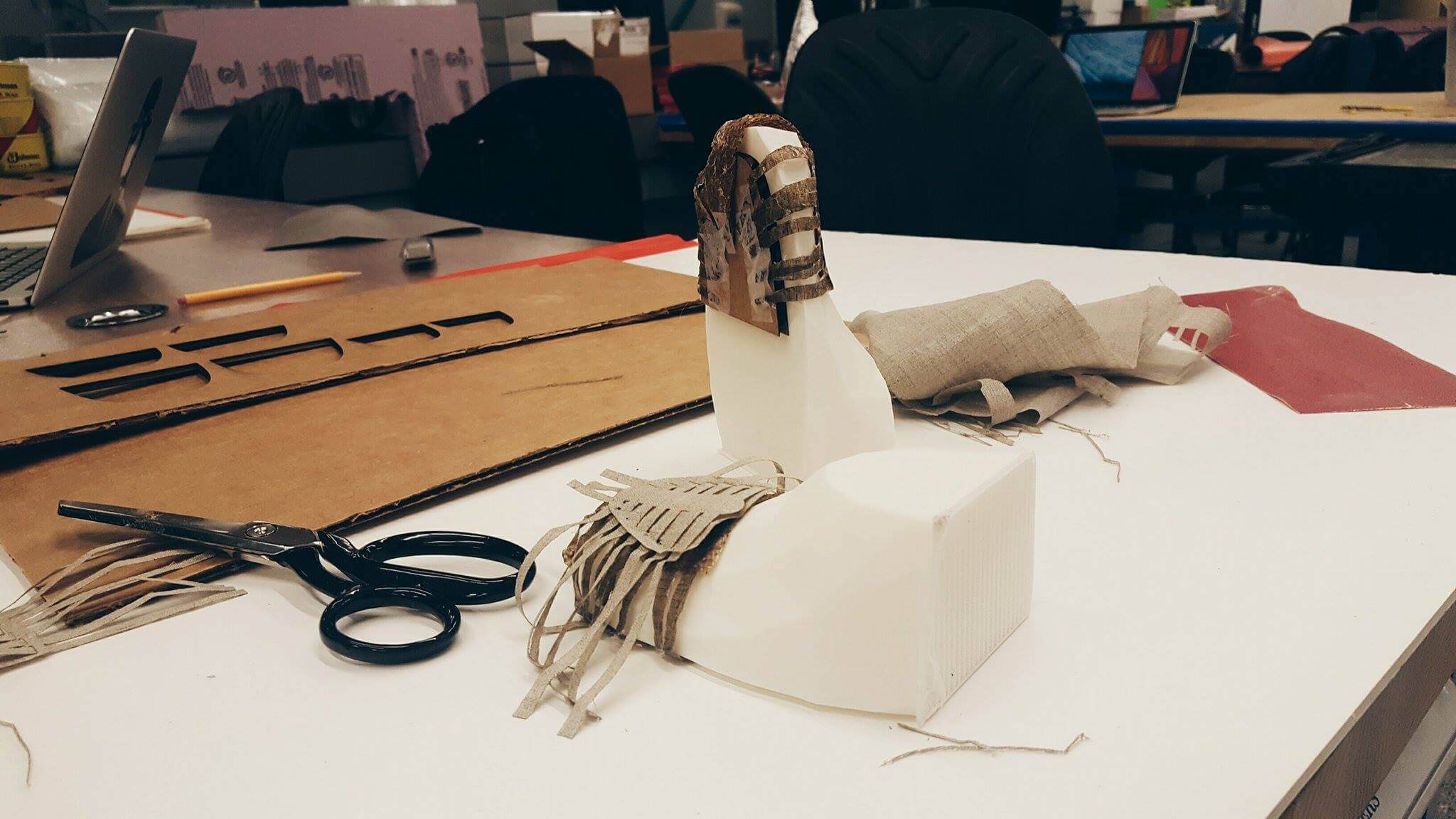

After a lot of sanding, cutting and finishing, here's the part out of the vacuum bag! I didn't like the look of the resin finish so I decided to top the shoes with another layer of linen. You can also see the cardboard I laser cut as an insert into the soles for selective stiffness.

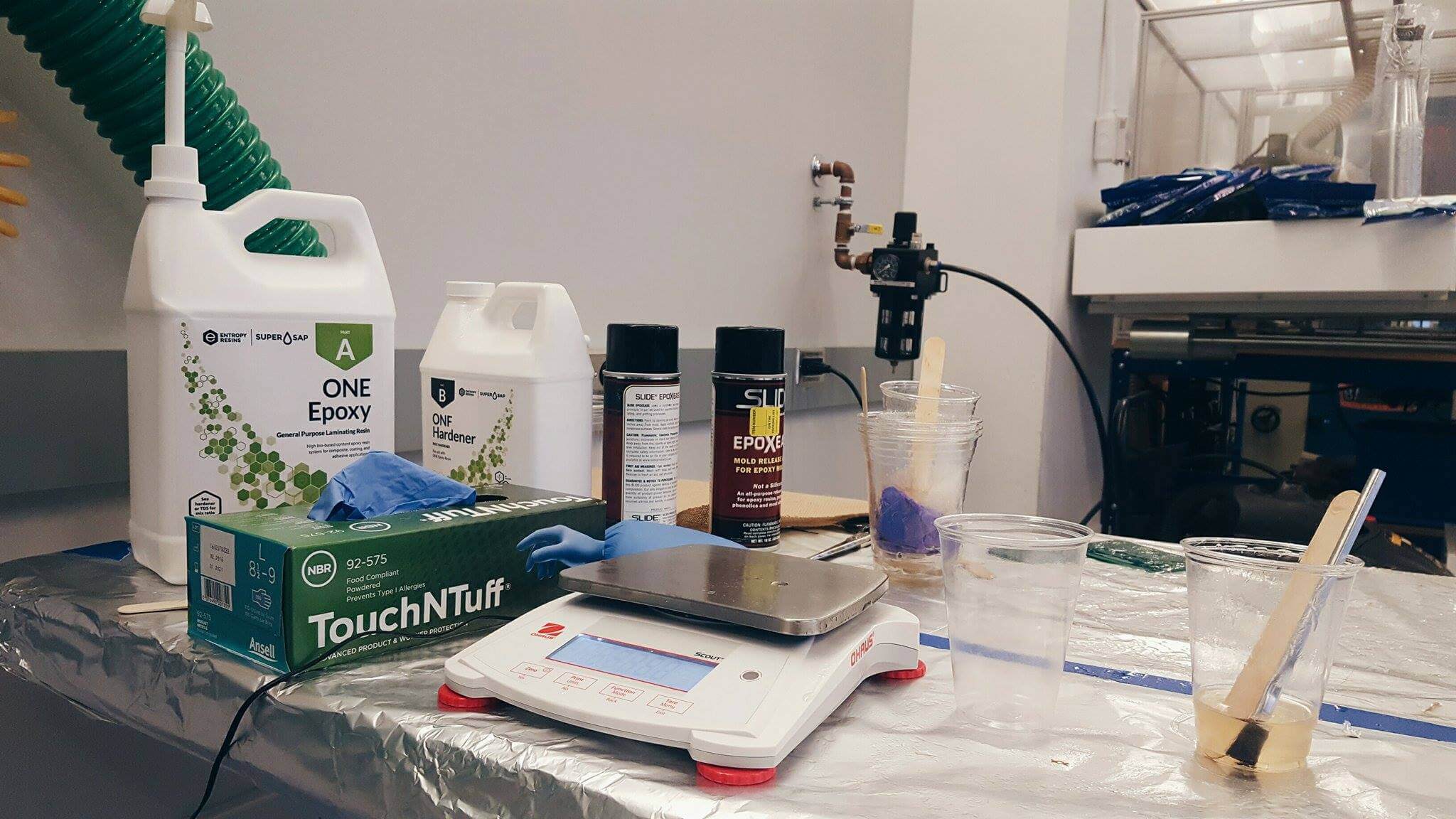

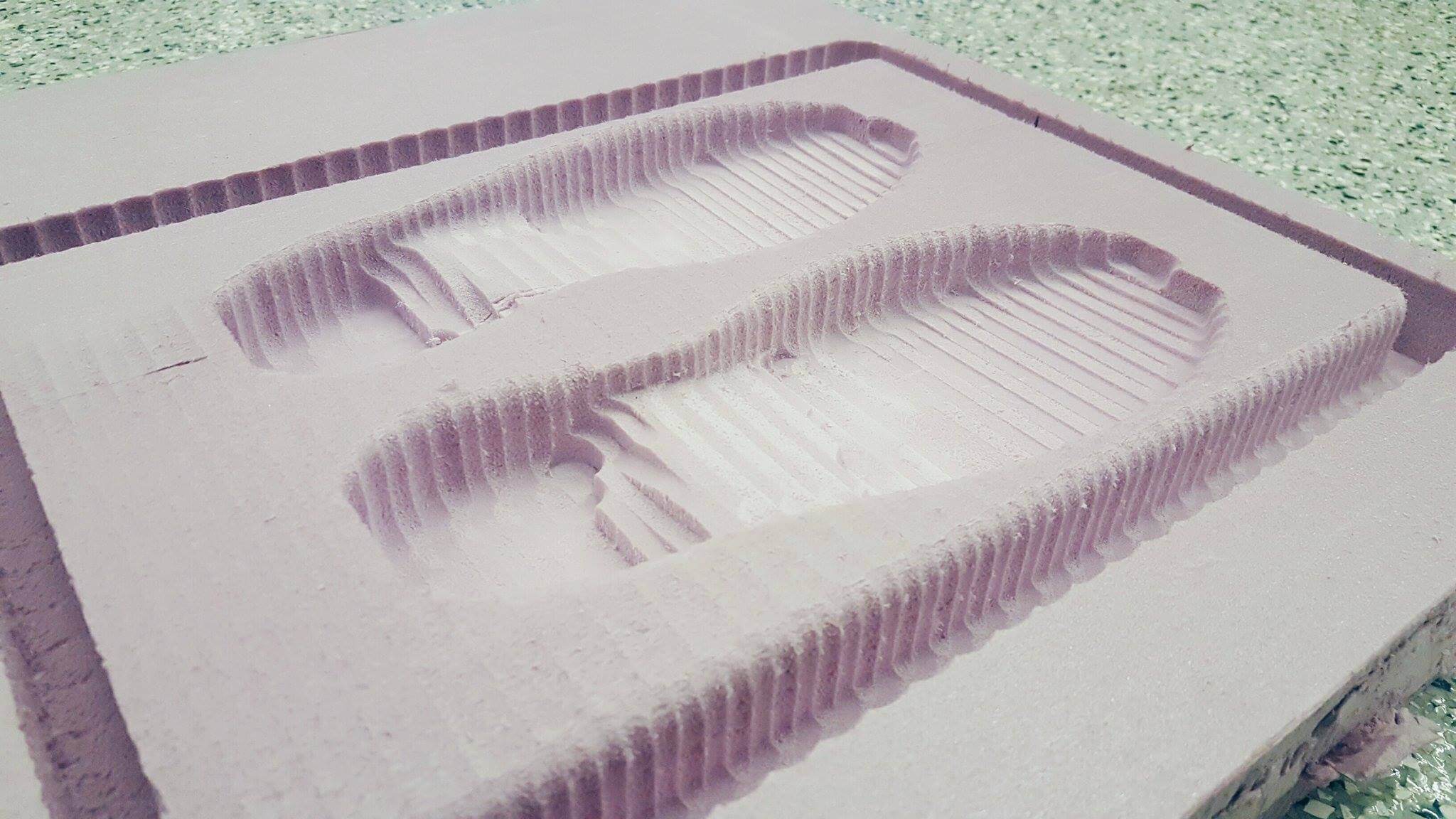

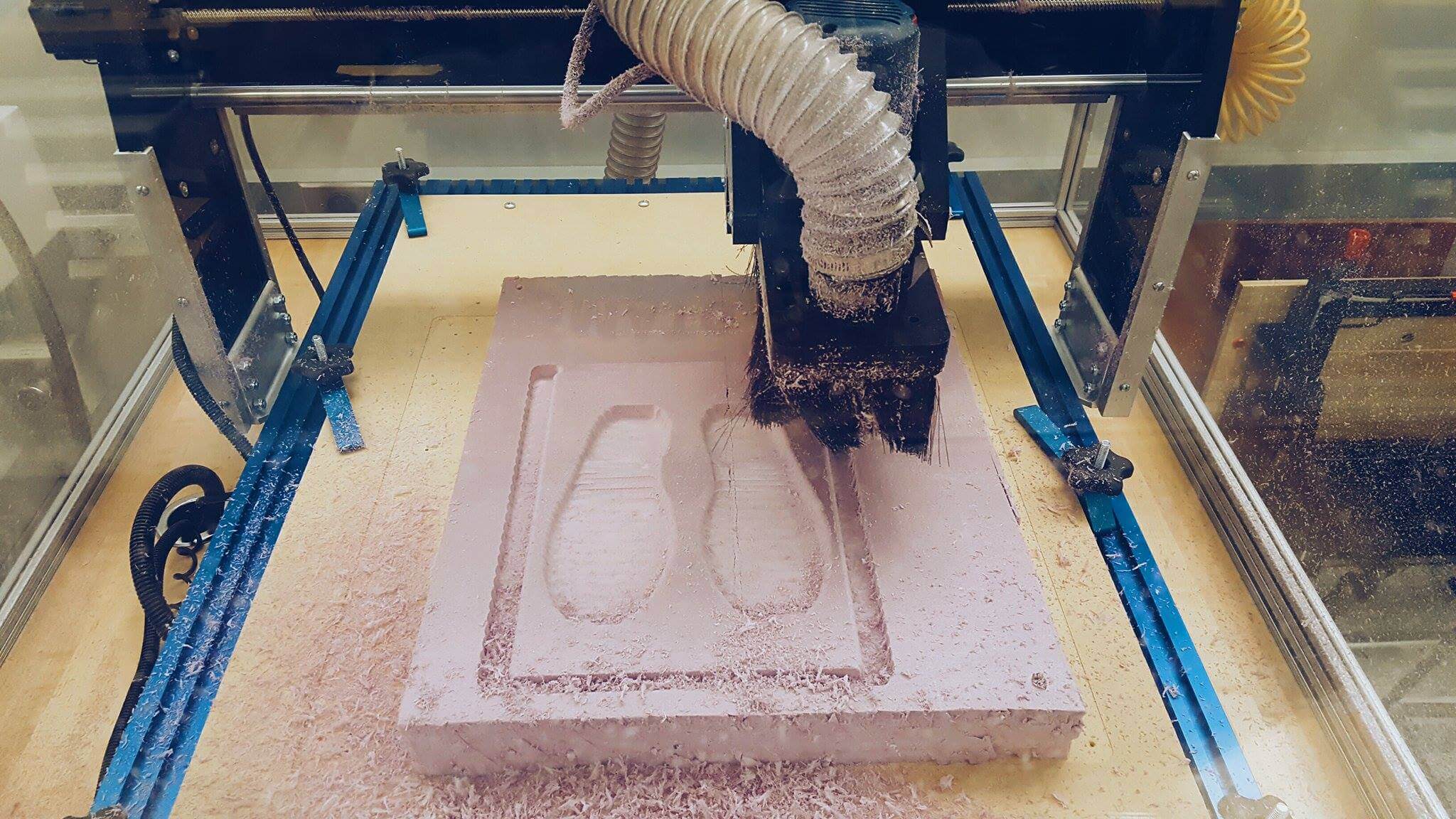

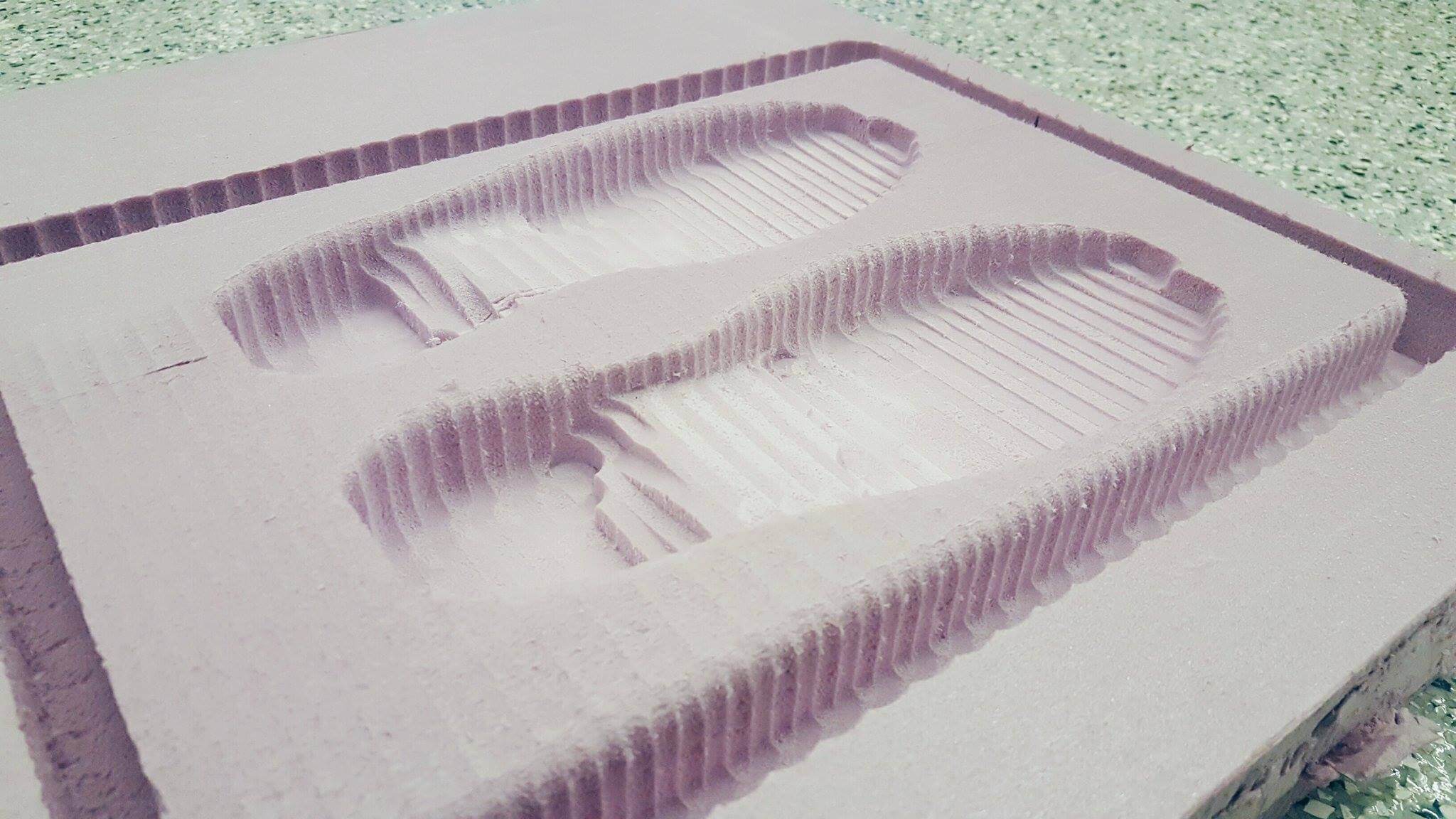

Finally, I used the CNC router to cut foam to function as a mold for my shoe soles.

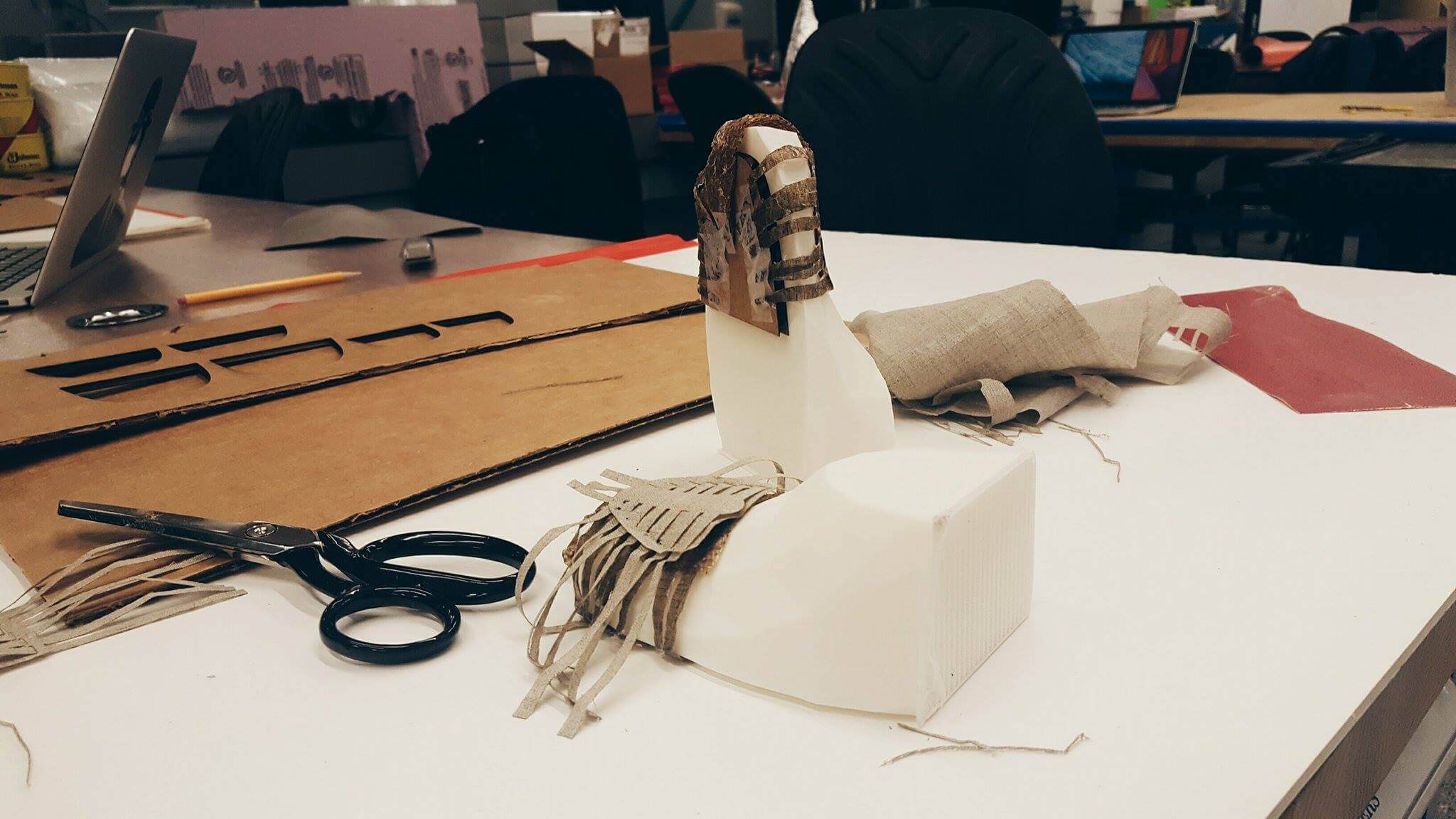

Here's the assembly in progress! Getting ready to pour the rubber soles involved first making sure the parts of the shoe were combined so I could put that into the liquid rubber before it set.

Shoes!