I'm interested in builiding "things" that can determine internally how they are assembled, specifically if they are assembled correctly and what they are assembled of. For example, take a flat pack portable crane:

One of its key features is its portability and flat pack design. However, that means it needs to be repeatedly assembled in the field. If it is not assembled correctly, the crane could fail. So having hardware "error correction" would be adventageous.

Additionally, if a part needs to be repaired or substituted, it would be useful for the crane to understand the change. If a plywood piece was substituted with a cardboard piece, the crane should adjust the max weight it will attempt to lift.

The "thing" (e.g crane) will be built using the ideas covered by computer controlled cutting, 3D printing, molding and casting, etc. During the electronics section however, a way of identifying each part (e.g. EEPROMs on a bus) will be devised. Then the embedded microcontroller will be used to verify and read the material properties of each device and adjust it's functionality accordingly.

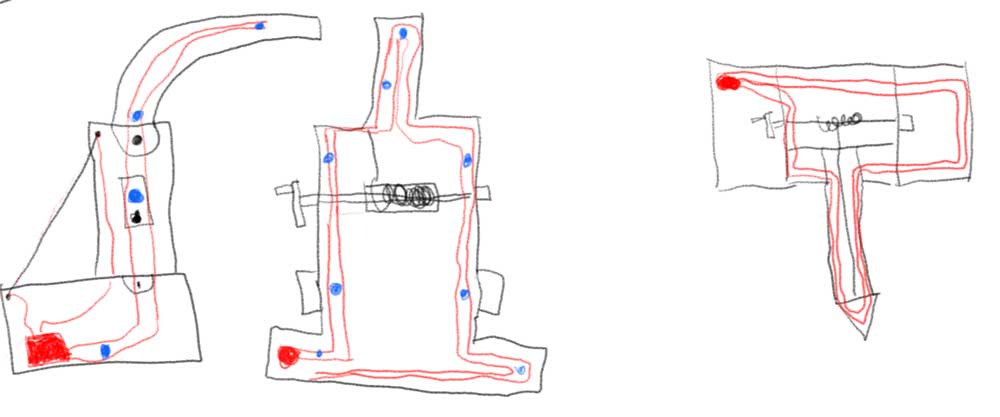

a) MyPaint Sketch of an example "thing" (a portable flat pack crane)

using a Wacom Bamboo. Blue denotes locations of sensors or material

nodes and red denotes electrical connections.

a) MyPaint Sketch of an example "thing" (a portable flat pack crane)

using a Wacom Bamboo. Blue denotes locations of sensors or material

nodes and red denotes electrical connections.

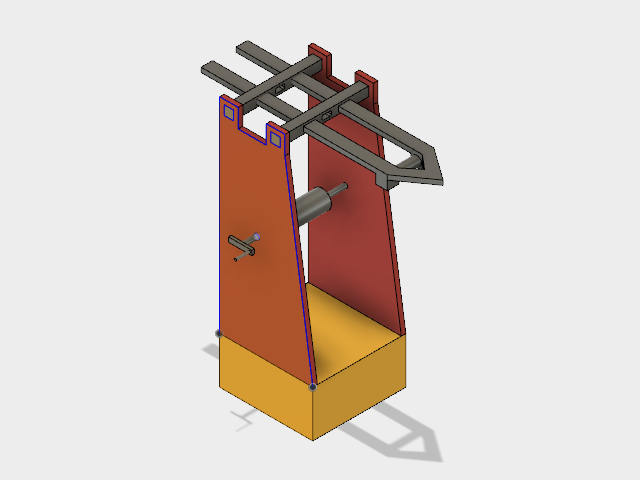

b) Fusion 360 mockup of the sketch in a. (Not to scale)

b) Fusion 360 mockup of the sketch in a. (Not to scale)