For my final project, I'll need to mount many different sensors and devices to my bike. I decided the molding and casting week would be the perfect opportunity to make a mount that could be attached to a bike tube or handlebar. Once the mold was made, I could make dozens of mounts in the same amount of time it would take me to 3D print one.

My current bikelight and my design inspiration.

My current bikelight and my design inspiration.

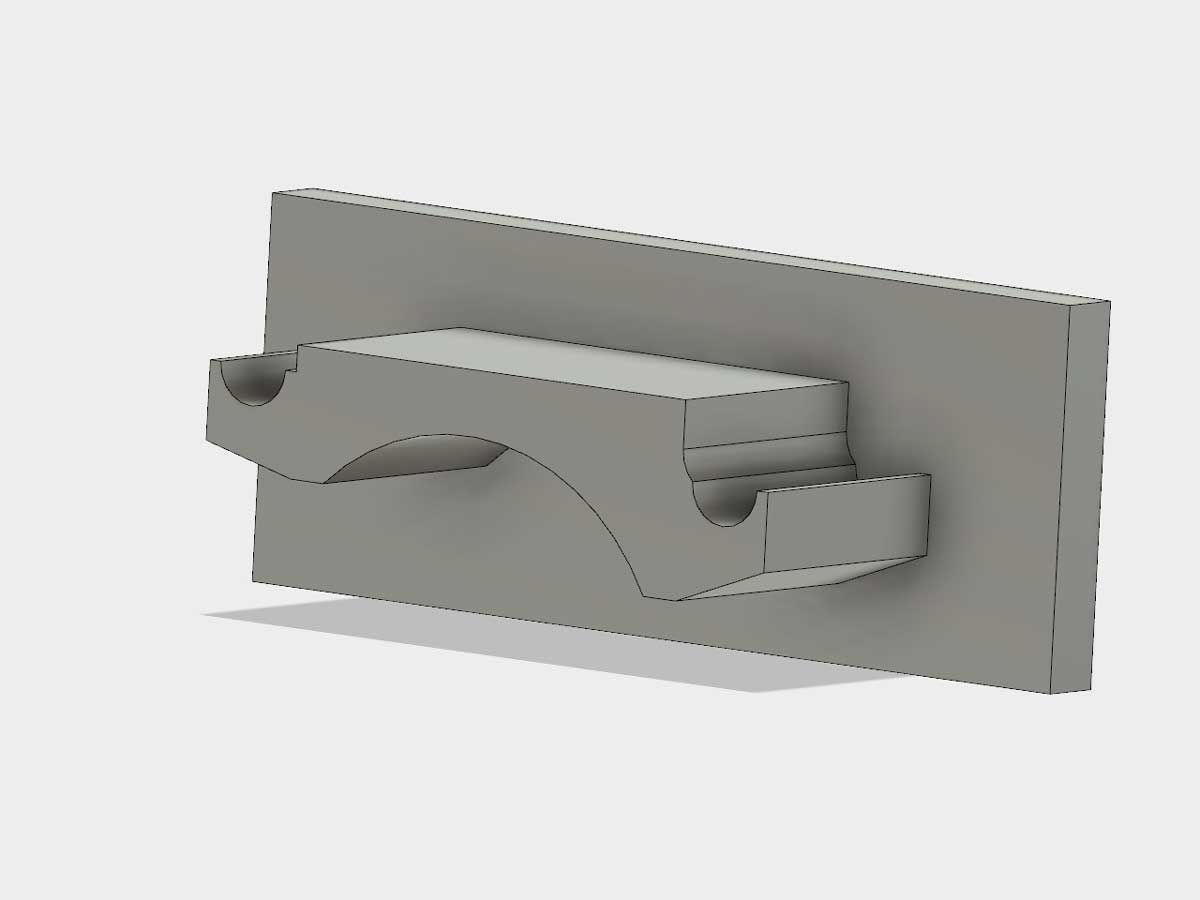

My copycat design in Fusion 360.

My copycat design in Fusion 360.

I decided to copy a mount that my bike light uses because it can be installed without tools but is also strong enough to survive the bumps and scrapes that come along with riding in Boston.

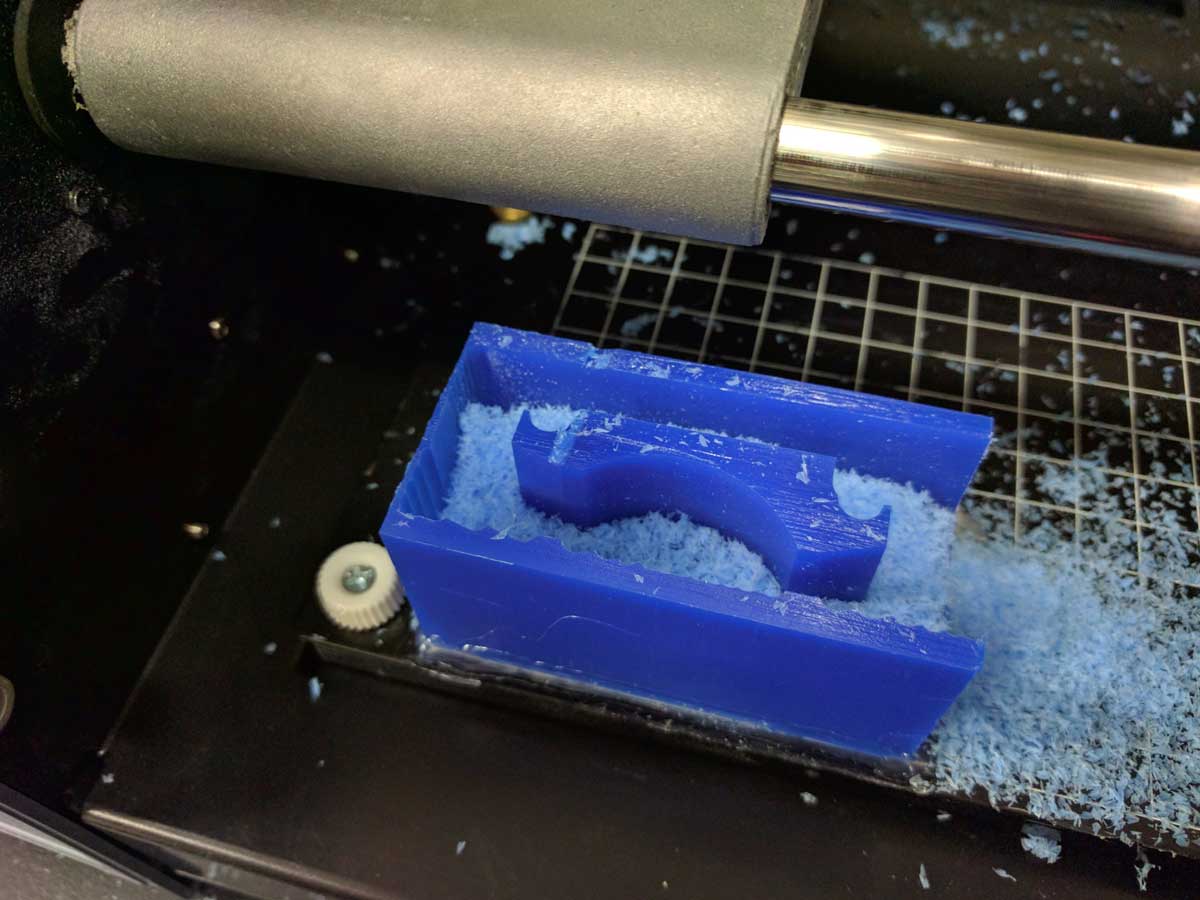

I milled my design on a Modela in machineable wax. This only took about 30 minutes and since my design was really only a 2.5D design, I was able to get away with a great surface finish using only the rough cut and the flat 1/8" end mill.

The Oomoo did not go as smoothly. I tried to use what was left in two containers and ended up not getting the proportions right. After it was clear that the mold was very bubbly, I threw it in a degassing chamber only to find that I had made the situation far worse by distorting the mold.

Yuck!

Yuck!

Fortunately, the top came out smooth enough that I was able to get the wax block out. However, I tore part of the mold while removing it.

In my one previous experience casting, I had minor success using the Smooth-Cast 300 for both the cast and mold. Since my Oomoo mold had gone so poorly and was very soft, I thought I would give it a try. NOTE: Smooth-Cast 300 should only be used with proper ventilation!

I milled a second piece of wax and then made a mold using the Smooth-Cast 300. However, unlike the soft Oomoo, I had to destroy the wax part to get it out.

I then applied a liberal (LIBERAL) amount of mold release in the spray booth and proceeded to make casts in both the Oomoo and Smooth-Cast molds. In the plastic mold, I poured more material on to act as a handle to hopefully make removing it easier.

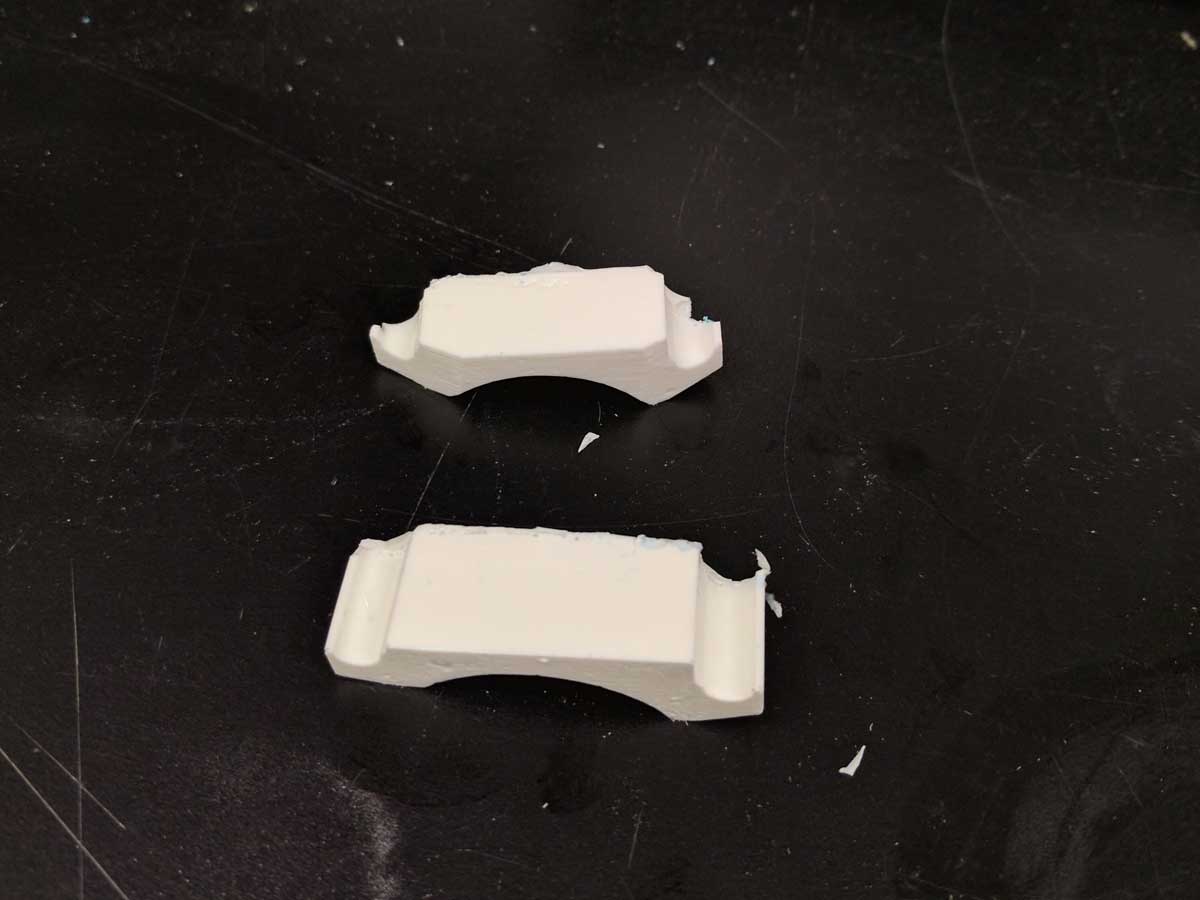

Incredibly, both parts came out of their molds without too much trouble. The Oomoo one came out with a few distortions where the tear had occured and the Smooth-Cast 300 cast had to be worked out with an X-acto knife, but eventually came out with ease.

The casts after some sanding and removing of excess material.

The casts after some sanding and removing of excess material.

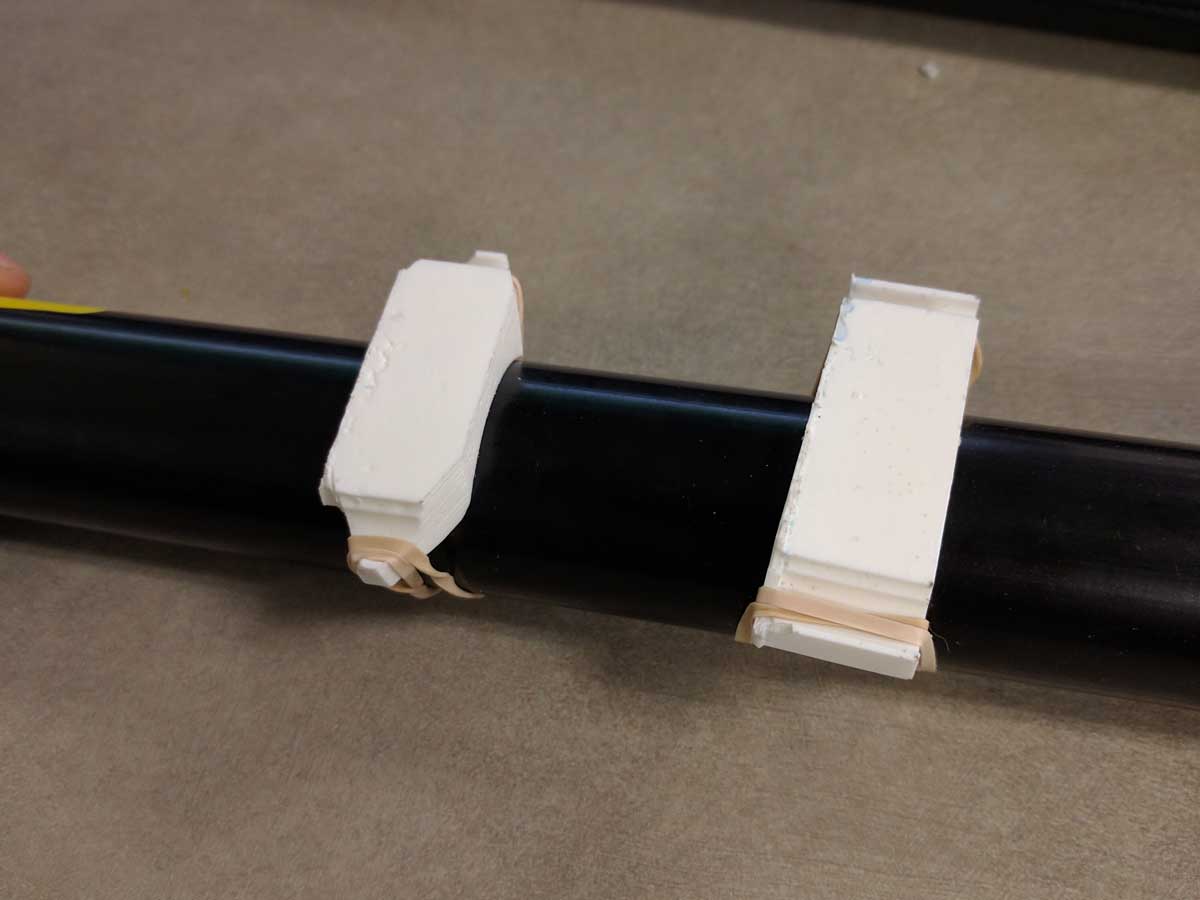

The mounts attached to a cylinder with rubber bands!

The mounts attached to a cylinder with rubber bands!