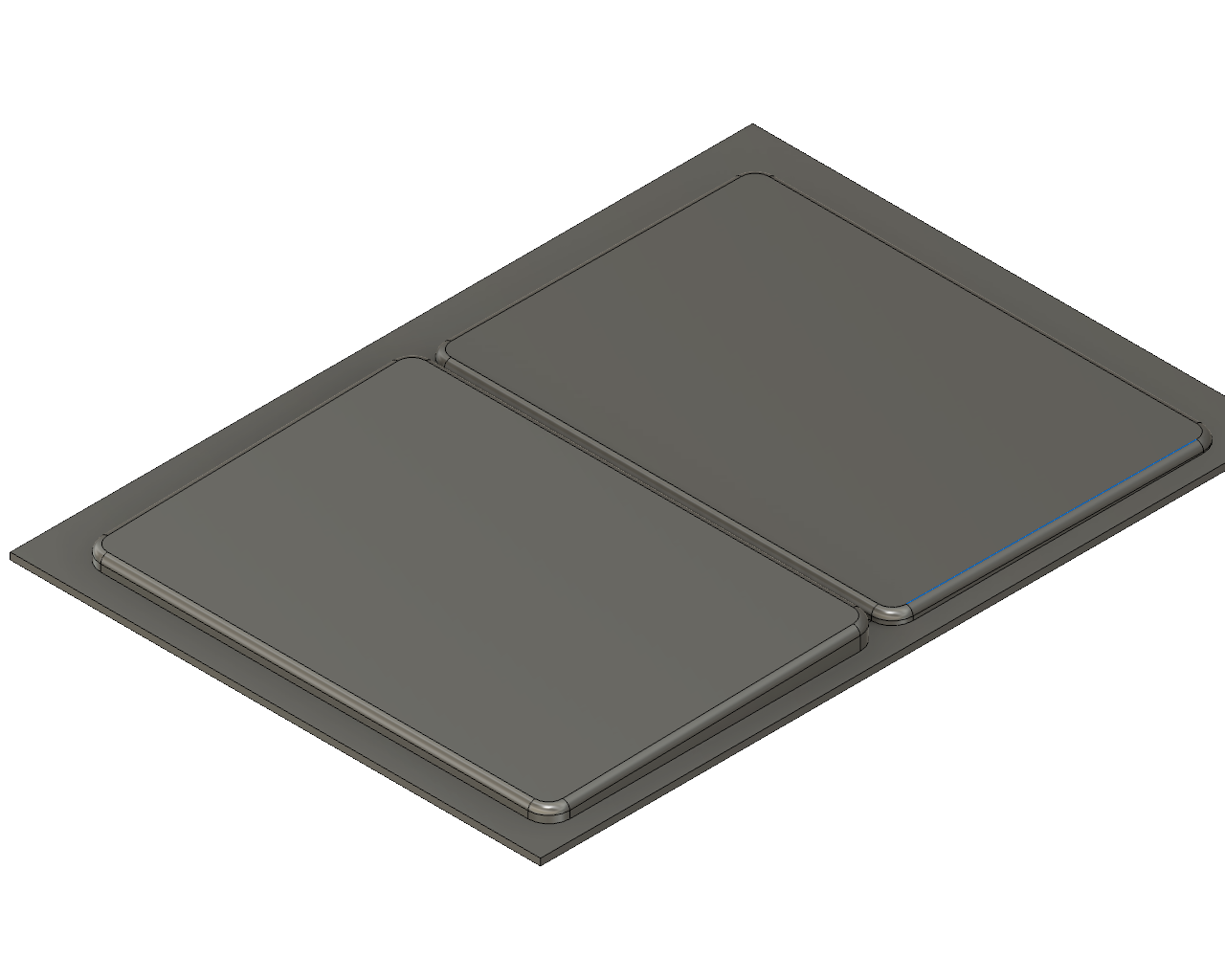

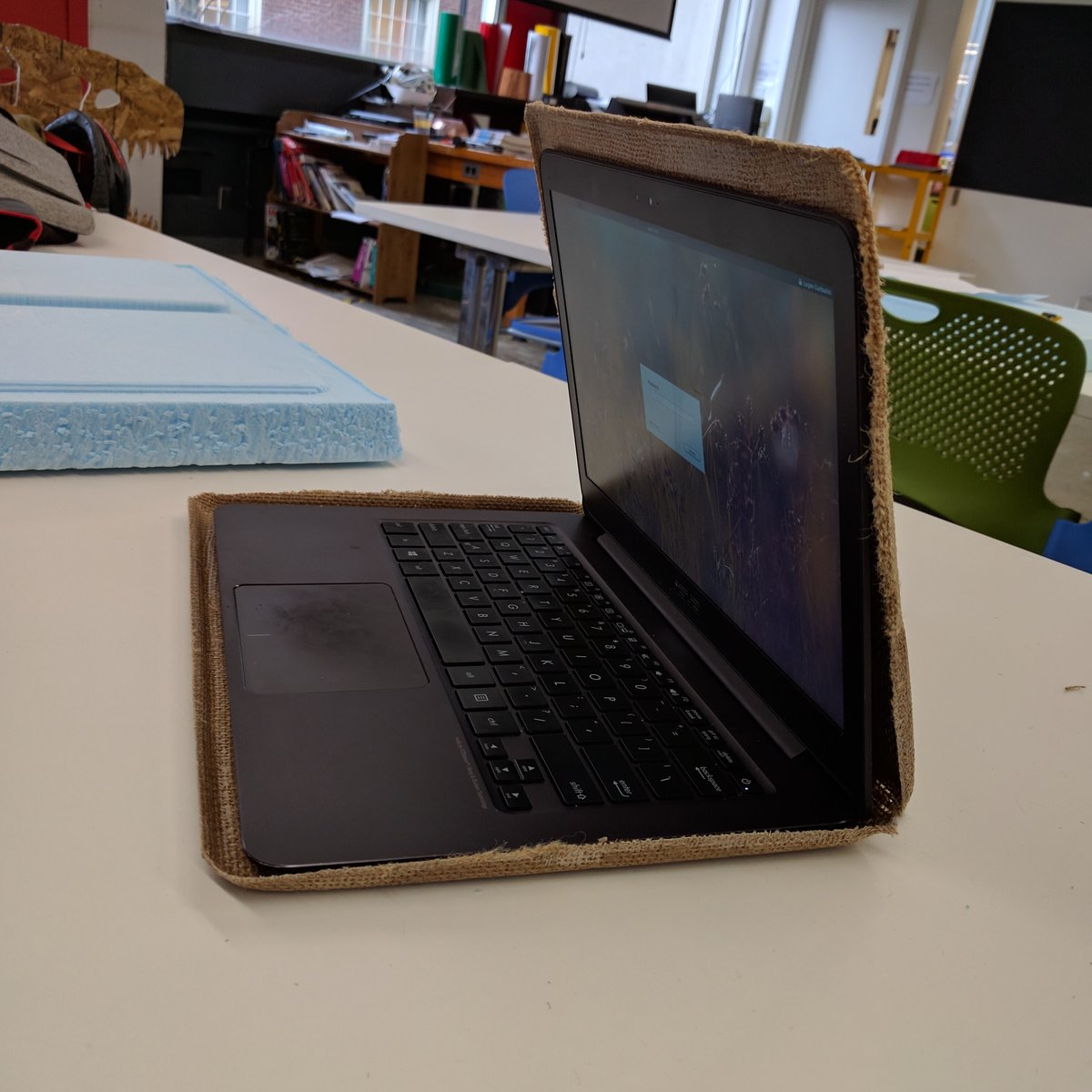

I know that the composite laptop case is made quite a bit, however, after working my way though a few design ideas, I decided I wanted to make a laptop case that integrated a hinge in the composite.

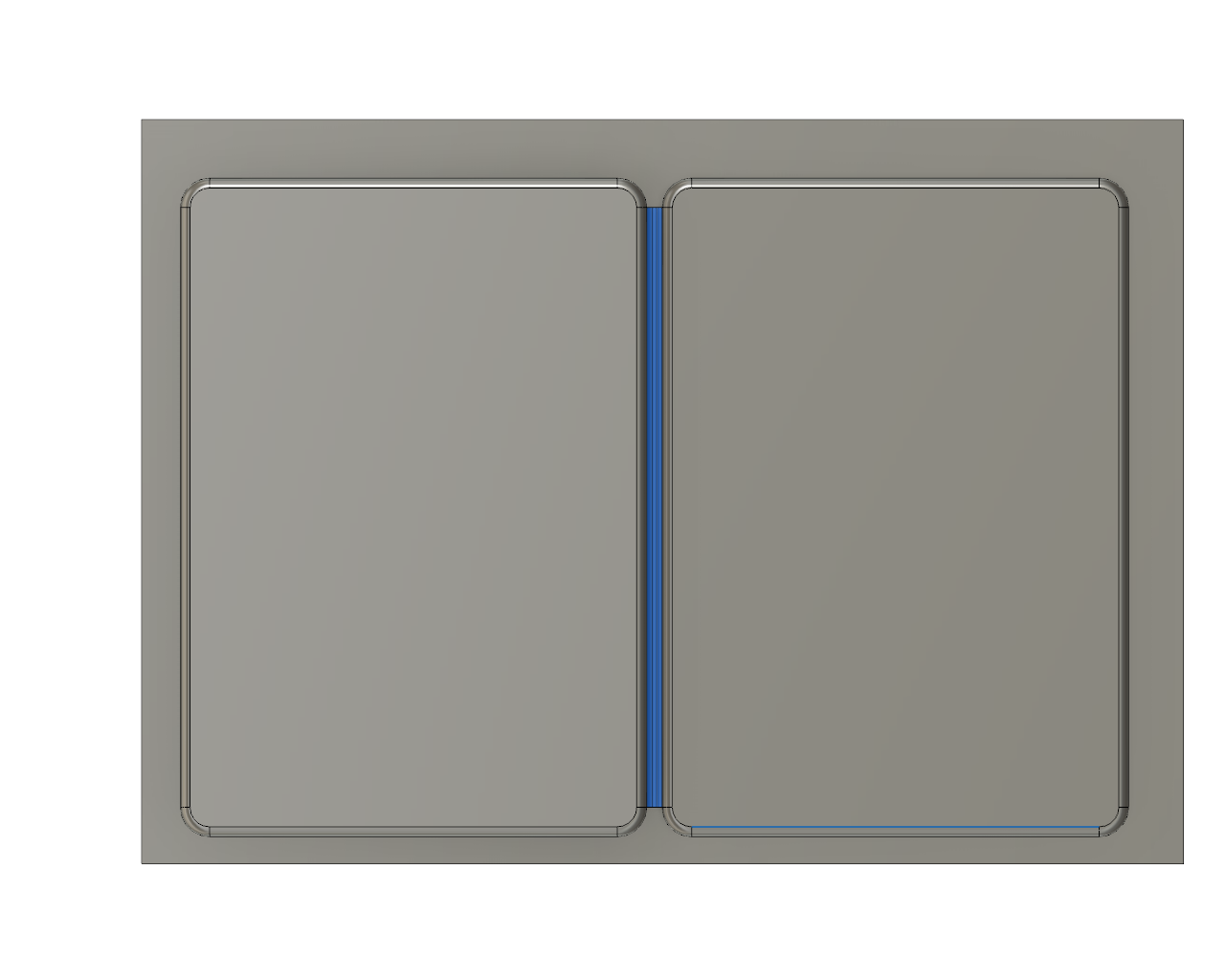

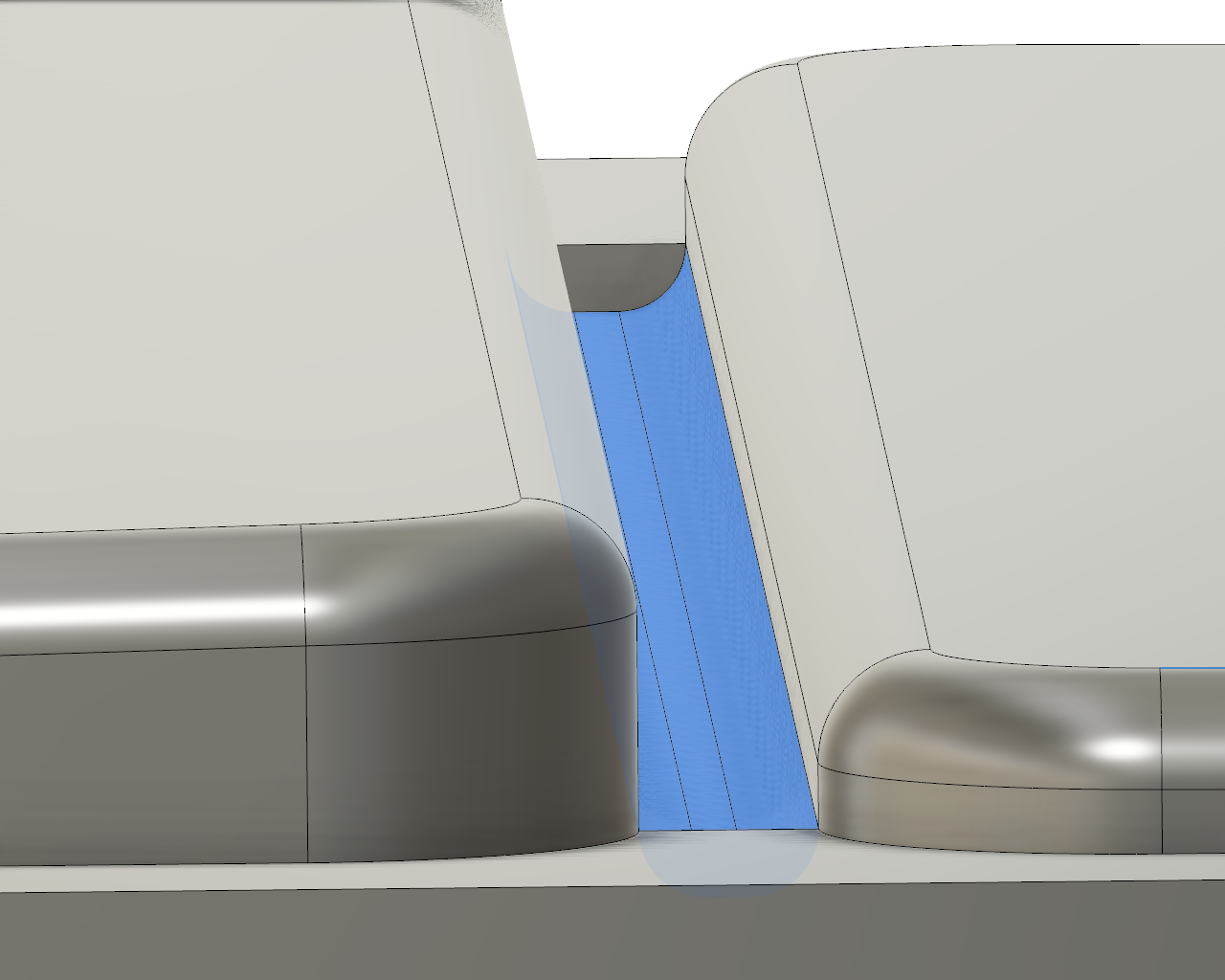

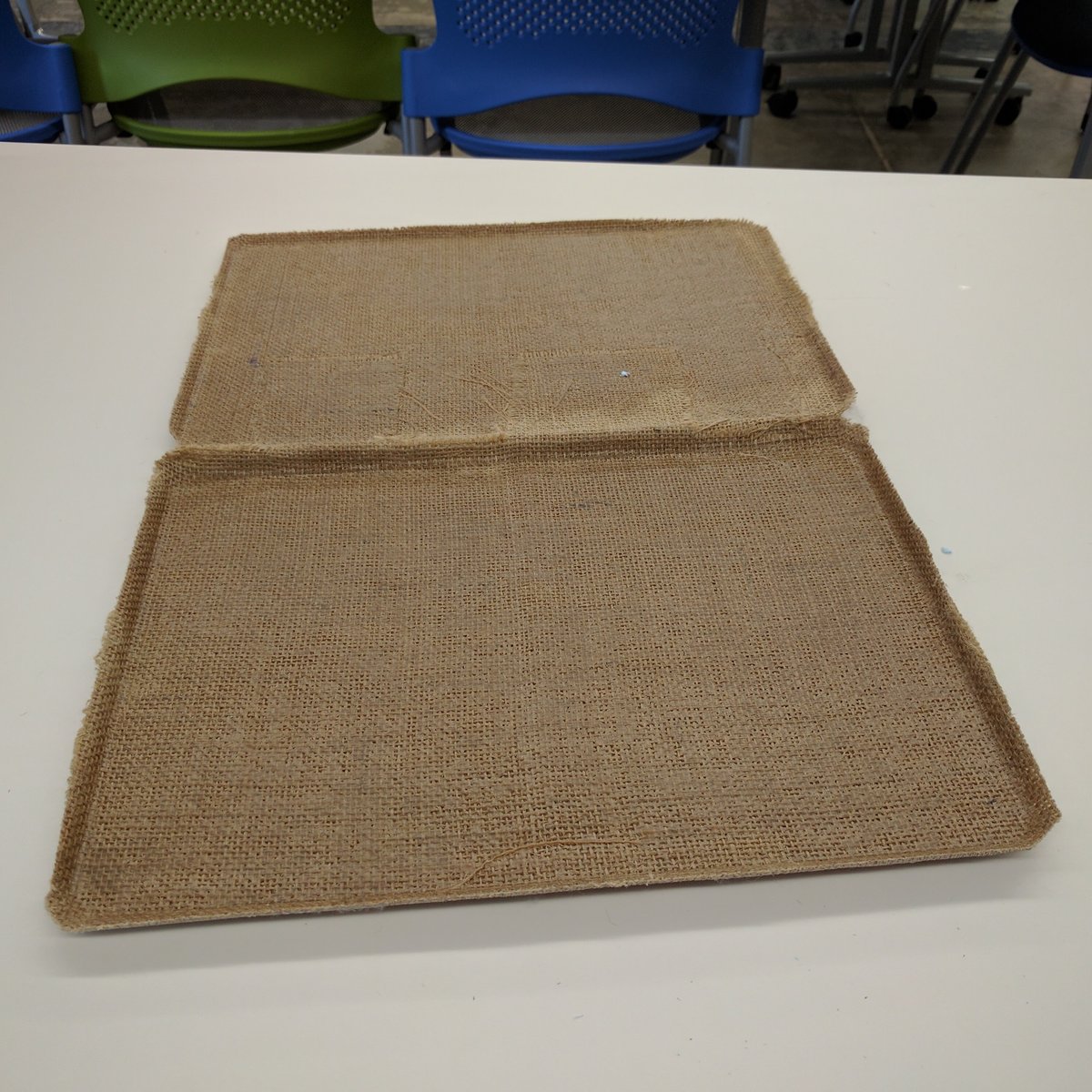

I designed the file in Fusion 360 with the two sides of the laptop case only 1cm apart. I then added a grove for the hinge to be laid up in between the two pieces. The hinge was initally designed to rotate with respect to a metal axle. However, I was concerned that laying up composite onto metal would result in the epoxy bonding with the metal blocking hinge movement. Instead, I opted to use the burlap itself as the hinge by leaving the parts that would flex free of resin. Each layup layer would cross over the hinge area and be layered in with the other side's layers.

Groove for hinge in blue.

Groove for hinge in blue.

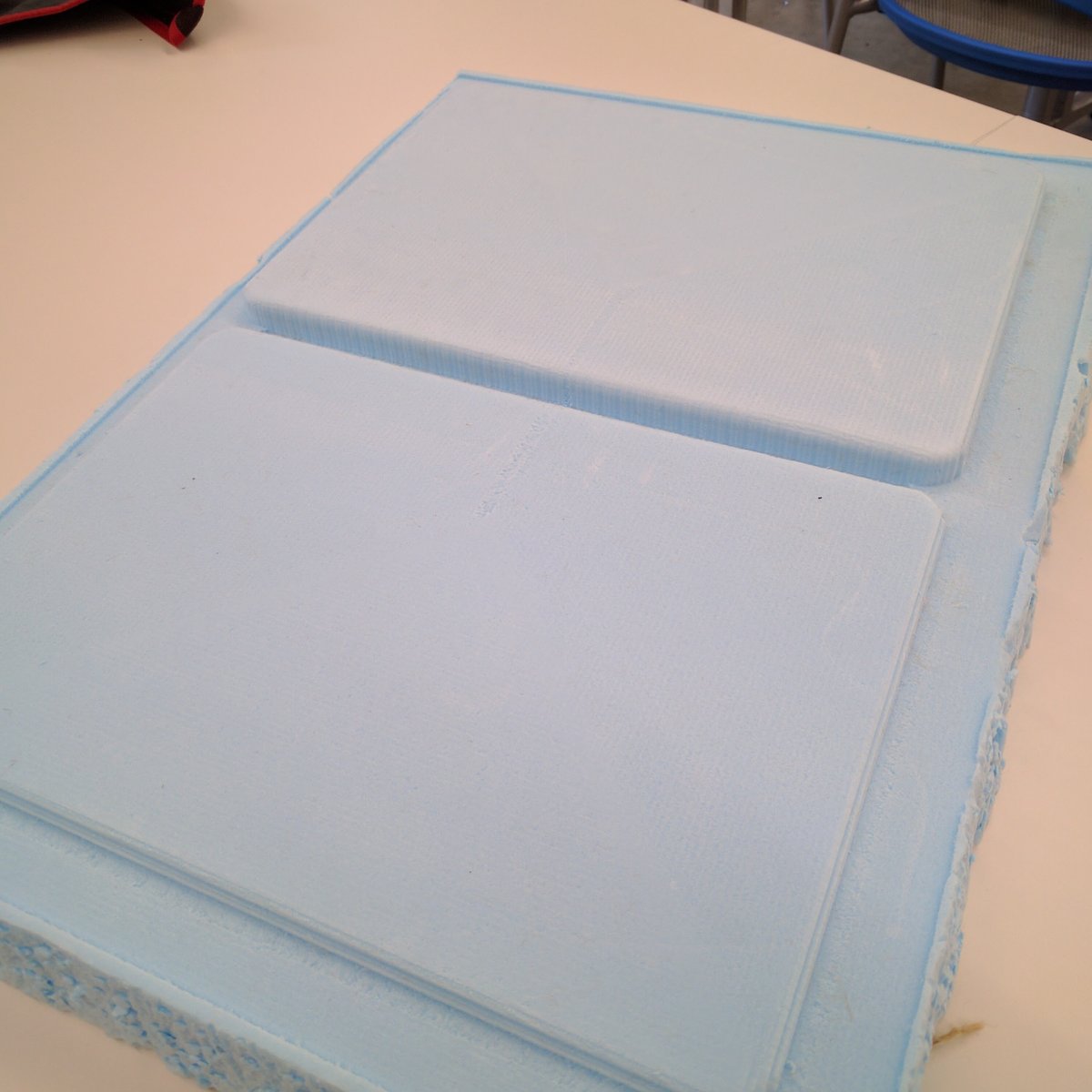

I used VCarve to generate the toolpaths and used a rough and final cut to get the design milled.

I used burlap as it would give me the closest surface finish to what I wanted and would hopefully make the hinge durable enough to survive constant flexing. I simply masked the hinge areas with tape when I was applying the epoxy and then carefully layered the epoxy so it wouldn't get in the hinge area. I then removed the tape right before layering.

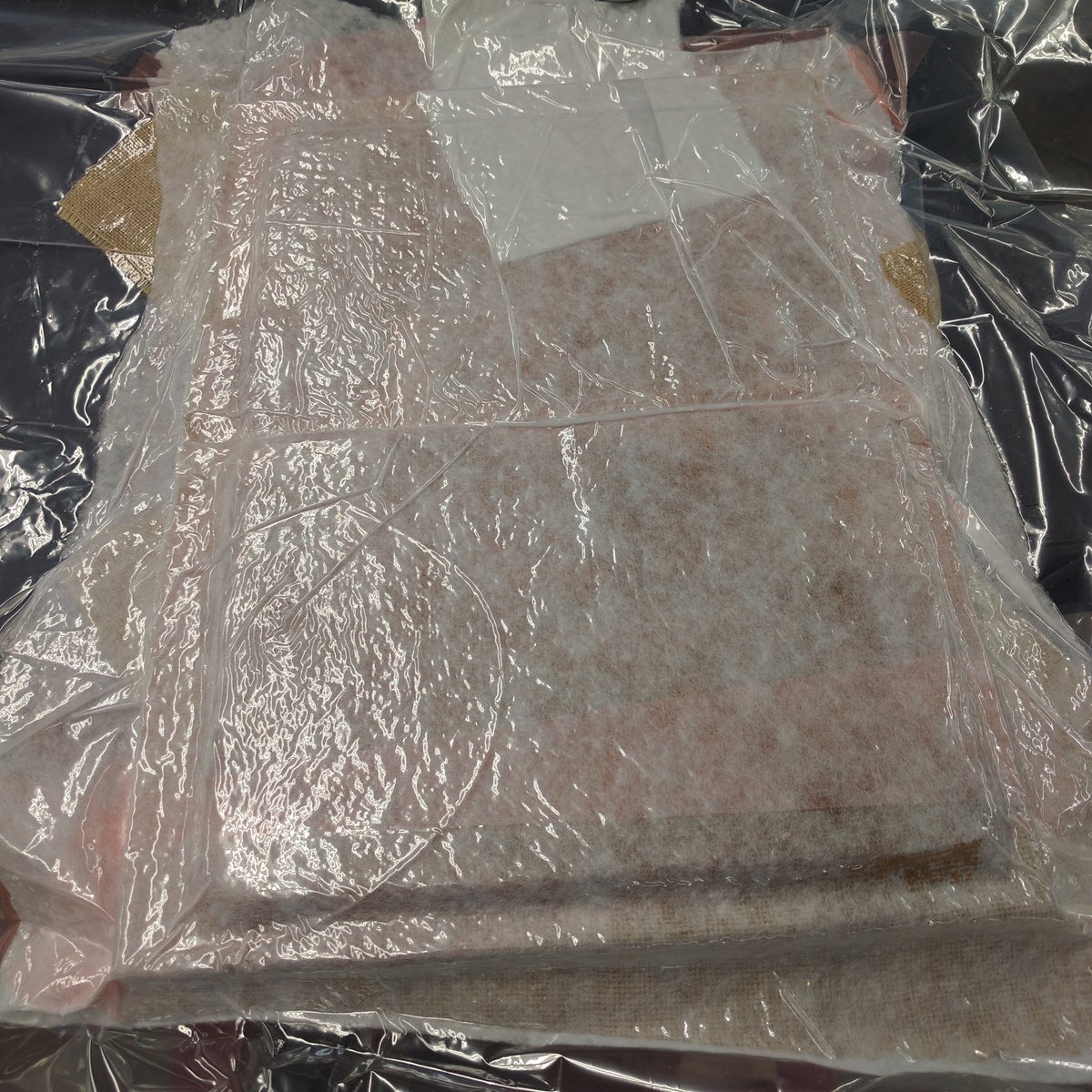

Close up of the folded over porous layer (pink). Note the epoxy has soaked in more

heavily to the bleeder where the porous layer is absent.

Close up of the folded over porous layer (pink). Note the epoxy has soaked in more

heavily to the bleeder where the porous layer is absent.

Unfortunately, when I stuck everything in the vacuum bag, part of the porous perforated film folded onto itself causing the breather batting layer to be adhered into the resin.

Since it the vacuum was already applied, I let it adhere and then spent the next 15 minutes ensuring the burlap was pressed as closely as it could be to the mold.

Note the alternated patches that form the hinge

Note the alternated patches that form the hinge

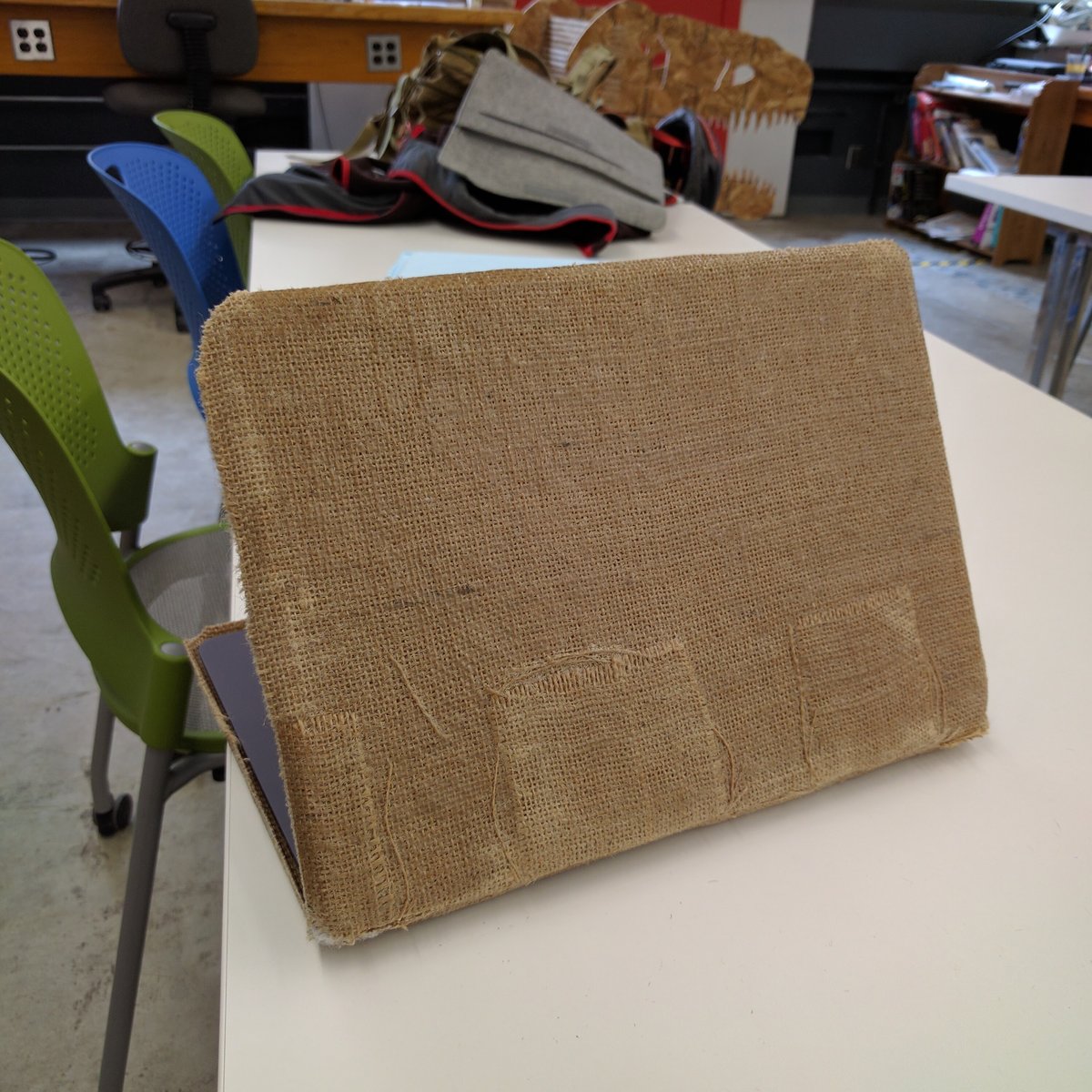

The end result was not perfect, between the adhesion of the bleeder layer and the seepage of epoxy into the hinge area, the laptop case didn't turn out particularly well. Overall, the non-flexible parts of the composite were quite strong and light which is a good sign for any future iterations.

Cracks in the hinge

Cracks in the hinge

More cracks

More cracks

Next time, I might try and wax or treat the hinge portions before applying the epoxy. This should protect the hinge mechanism. Finally, being more careful should prevent mistakes like the batting getting attached to the final lay-up.