Technologies Used:

❖ VCarve Pro

❖ Rhino/Grasshopper

❖ Shopbot

Part 1: 3D Design

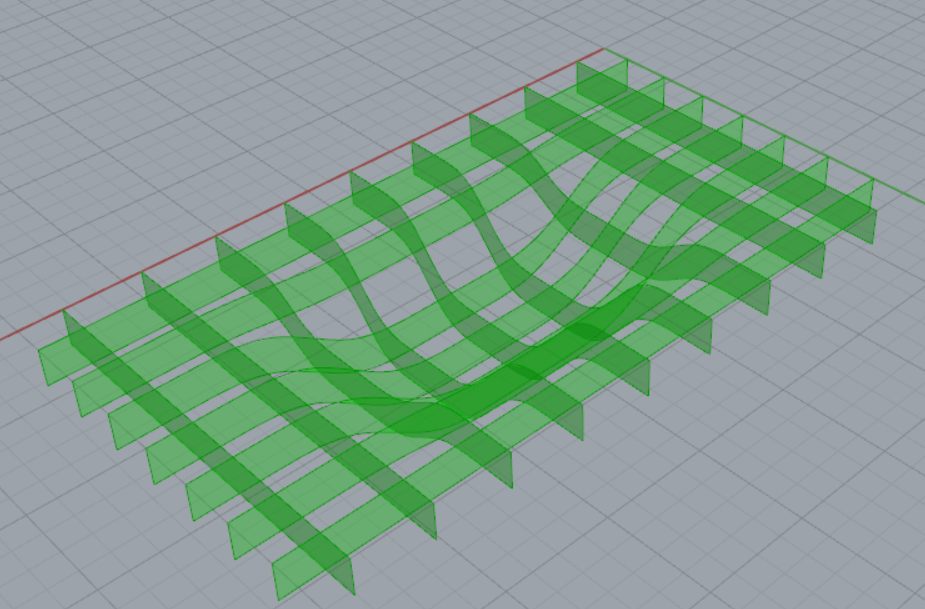

This week our assignment was to "make something big". From the start I wanted to create furinture but I wasn't quite sure what it would be. I wanted to further explore the idea of press-fit

from the first week, and have an excuse to continue to practice CAD and parametric design. After skimming through some projects last year I decided to create a table by constructing cross-sections of a

3D surface. Initially I played around with AutoCAD 123D Make, but decided the structures automatically generated were too sloppy. I hadn't worked with Grasshopper previously, but I decided this week

would be a good opportunity to try.

Youtube tutorials got me off the ground, and after many hours of debugging and an enormous amount of help from my TA Nathan, I was able to create the waffle structure I was looking for.

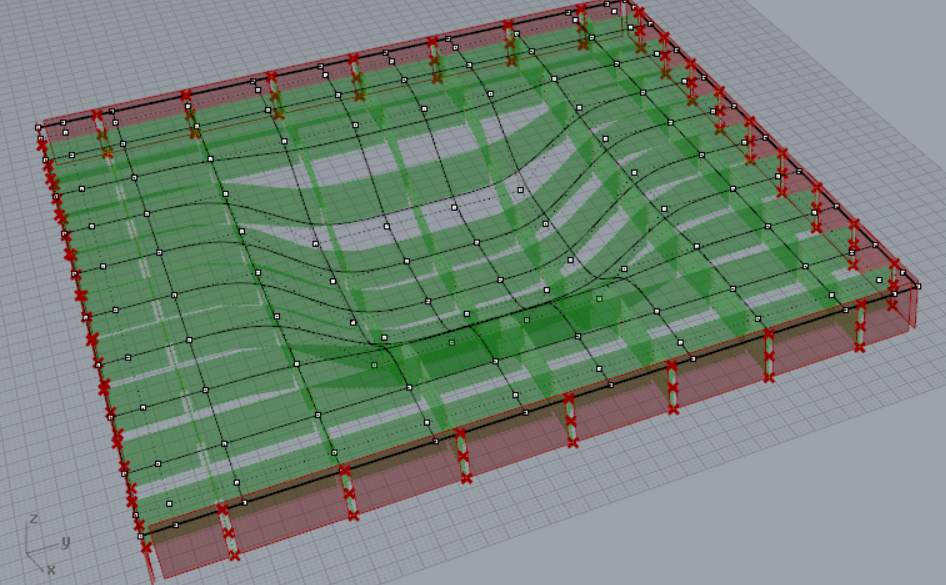

With a bit more Grasshopper magic we were able to automatically project the 3D model into surfaces onto a 2D plane suitable for cutting.

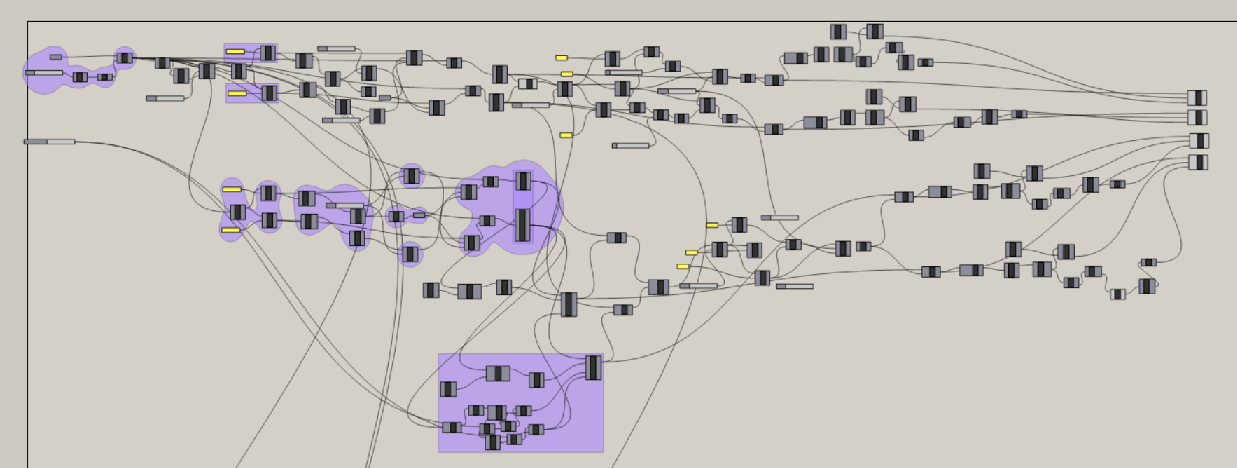

My grasshopper script looks like a concoction from hell but it works!

Part 2: Shopbot Milling

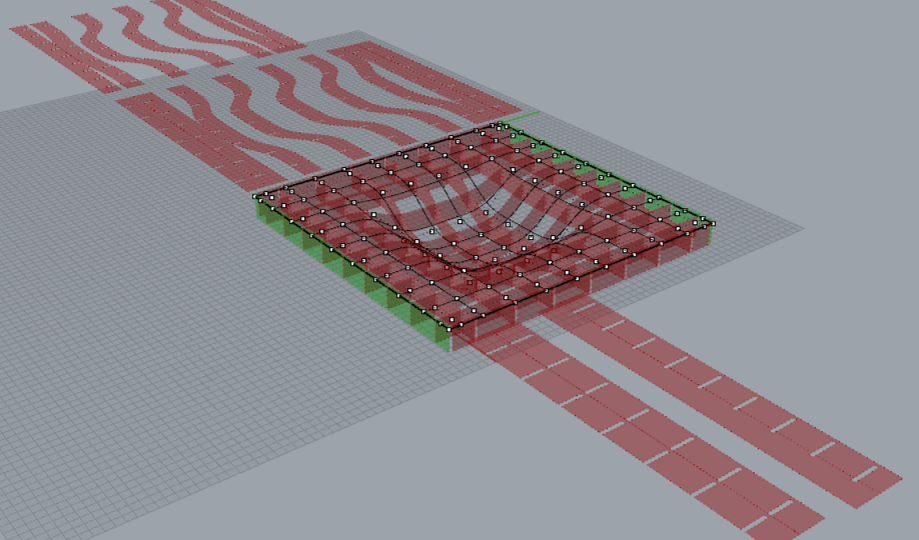

My biggest challenge this week was getting enough time to cut all 20 pieces on the shopbot. I needed to prototype my design on OSB, and cut in piecemeal to make sure all my joints properly fit. Unfortunately

I didn't have enough time to fully construct the OSB prototype, but the joints seemed to work fairly well.

I went to home depot and picked up 2 4x8ft pieces of Sande Plywood to make my final version. Aside from not having enough time to cut, one problem I consistently faced was not inserting enough tabs,

which made my pieces lift up on the ends if there were not held down tightly enough. However, each tab was hard to sand down given the type of wood I had so I had to balance utility versus aesthetics.

My design itself suffered a few minor flaws in terms of joint width and base design, but puckily parametrics saved me and I was able to quickly adjust any necessary tweaks.

The last issue I faced was trying to fit all my pieces together. The final pieces were particularly hard to fit due to the wood being relatively inflexible.