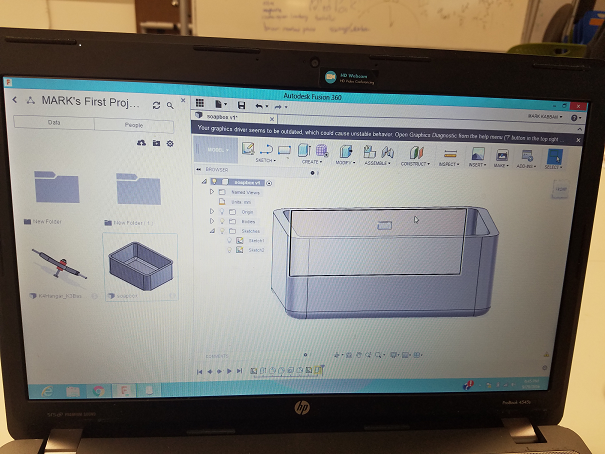

I decided to mmake a soap box holder because I needed one and was excited to make something useful. I started off my design in 123D but I quickly decided I did not like it and moved on to Fusion360 where I finished my project

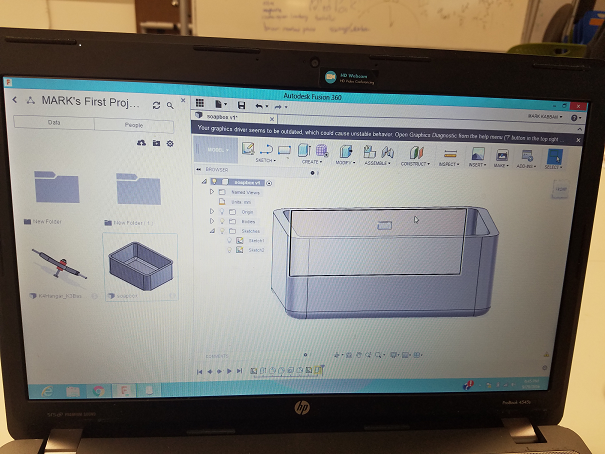

Started to get more familiar with the workflow of CAD's. This was something that I got a hang of. What was tough was to make parametric tabs inside my box. There are 4 tabls that I need inside the box so they can hold up the soap tray. They have to be the same length from the profile of the lid and be the same size. I did not figure out how to do thsi parametically but I was able to do it with my best judgement. Doing parametric design is something that I'm going to work on for my next project.

The biggest challenge for this week is getting more comfortable in a 3d CAD software. This is limiting my ability to bring sophistication to my ideas. This week I started off with Fusion 360 and althought I had some success with it through the help of a classmate. I also found it to be challenging. I'm going to need to put in more hours to tinker, experiment, seek help from classmates, and watch online tutorials.

...

Board

I wanted to create something that I needed at my house. Came up with the idea for a soap holder or soapbox. My challenge was creating pieces inside the rectangle that were all at the same level and could evenly hold up a tray. I was not able to figure out how to do this in Fusion so instead I just did it with a best guess.

Programming

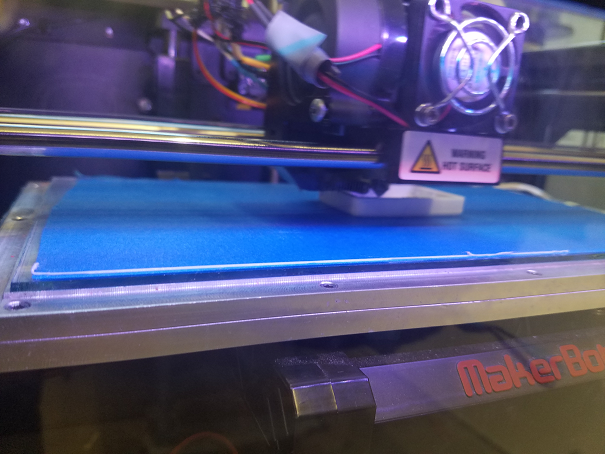

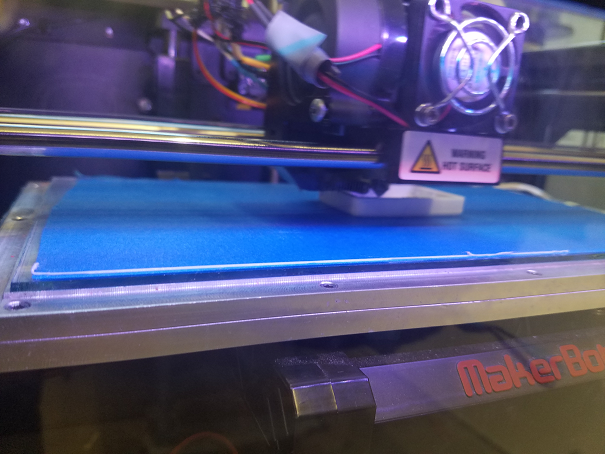

To make my original size the MakerBot was going to take 6 to 8 hours so instead I made it much smaller. I was dissapointed not to be able to make it for my bathroom. It is more the size for a dollhouse. I'll make it back to the 3d printer on an off week to do the real size.