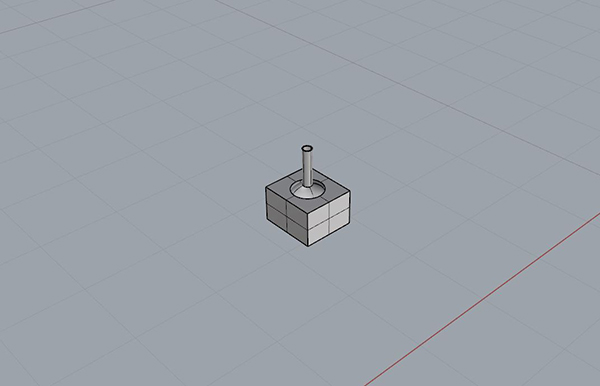

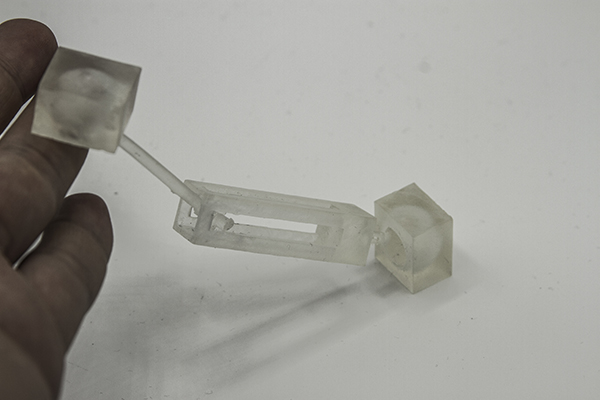

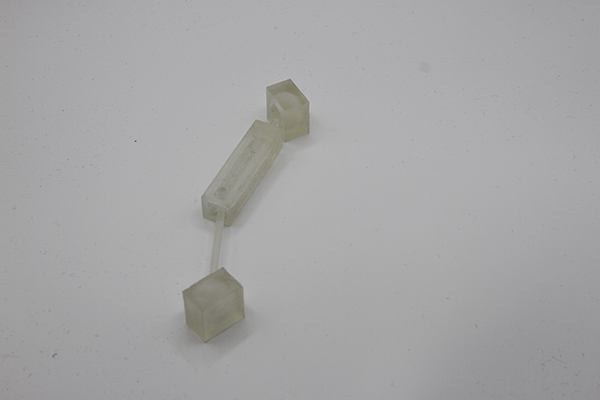

Bionic Joint Construction:

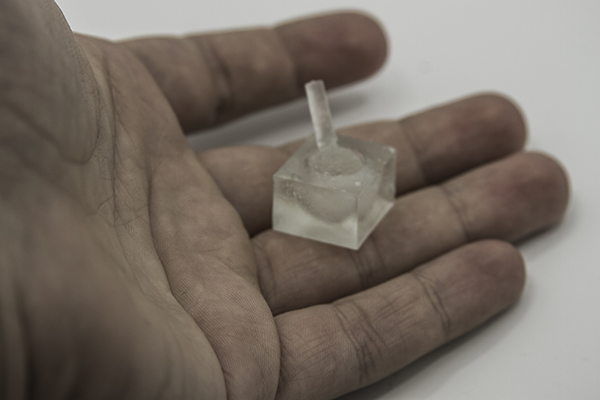

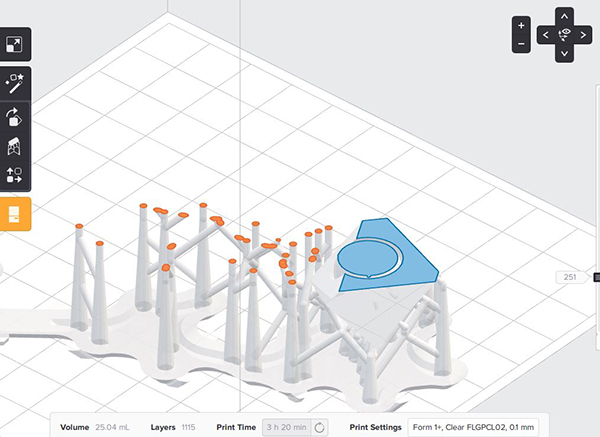

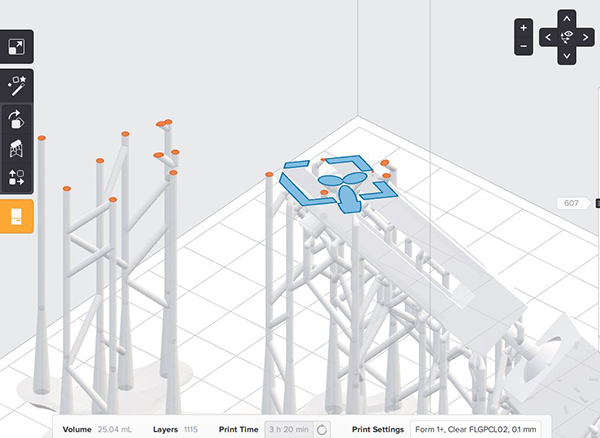

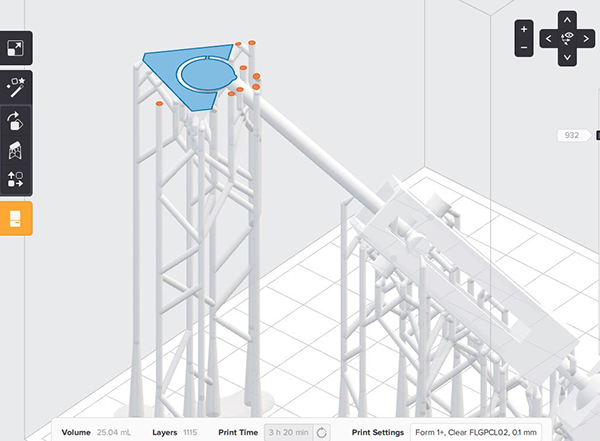

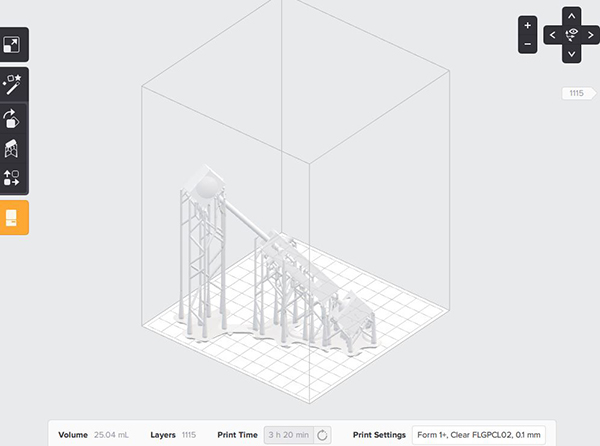

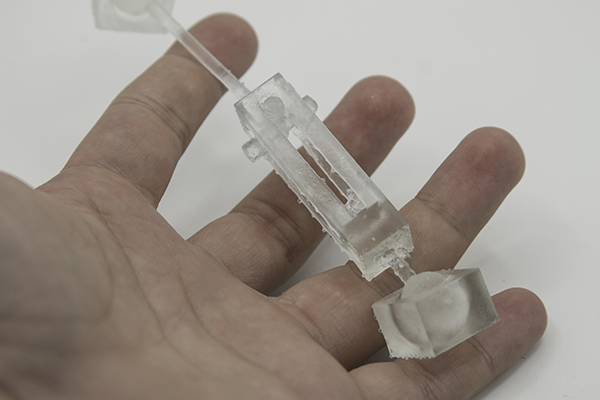

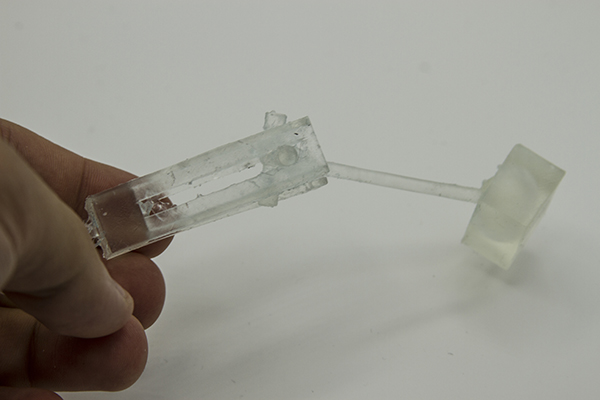

Printing on a SLA printer like the formlabs allows for very littel supports needed relative to PLA printers, and allows for nested components. Looking to create a joint similar to week 01, using a slide and ball joing and very little supports that are just enough to keep the piece in place while it prints, but to be able to pull apart once printed to allow the joint to move.

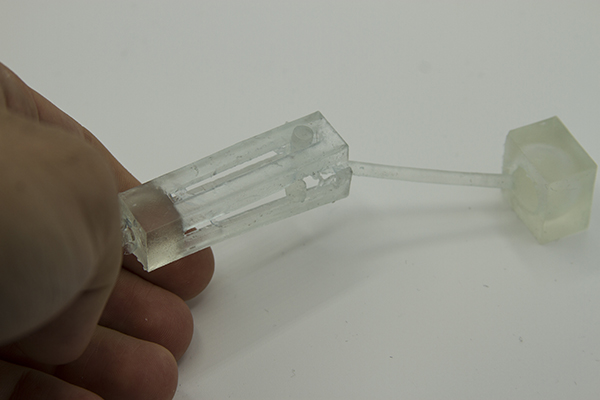

Similar to week 01 - there has to be a lot of protoyping to get the joints just right, and it depends based from printer to printer, sameway it did from laser to laser in week 01. Leaving just enough space that the joint can slide, but also making sure the rail stays in place as it extends otherwise you get tilting and degrees of freedom that is not warranted. The ball joint however, worked very well and easy to rotate around under pressure.