Form CNC:

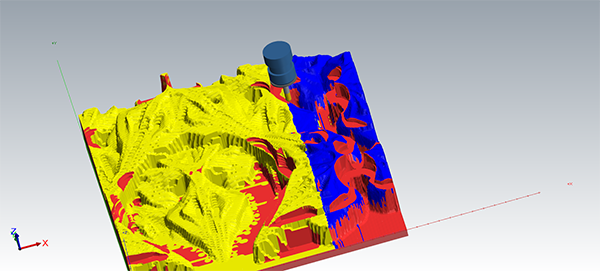

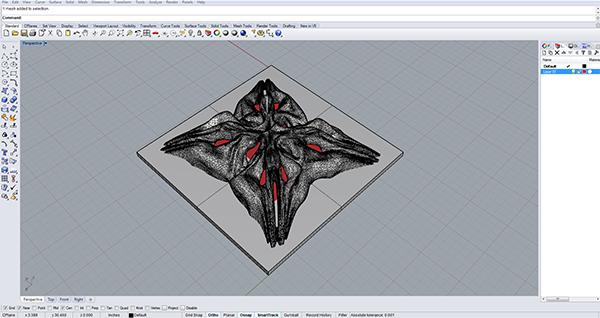

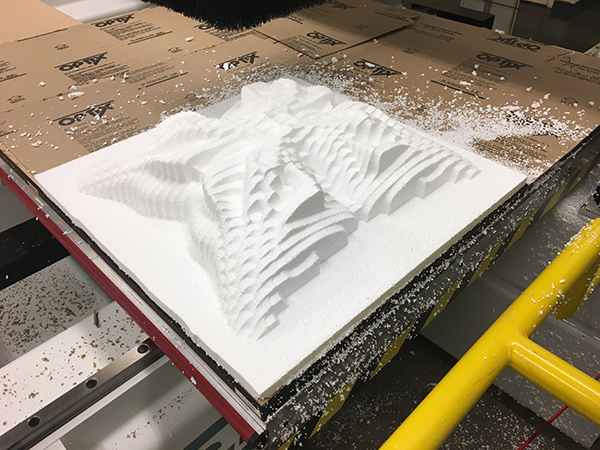

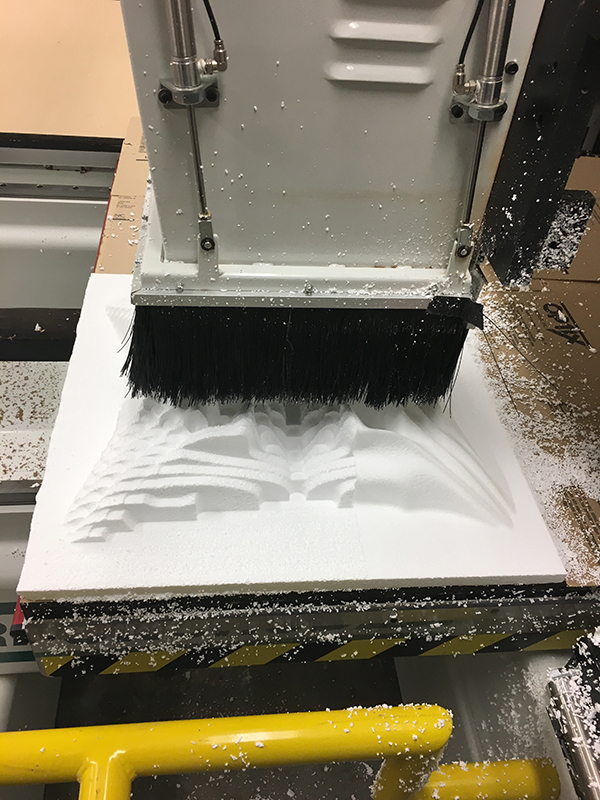

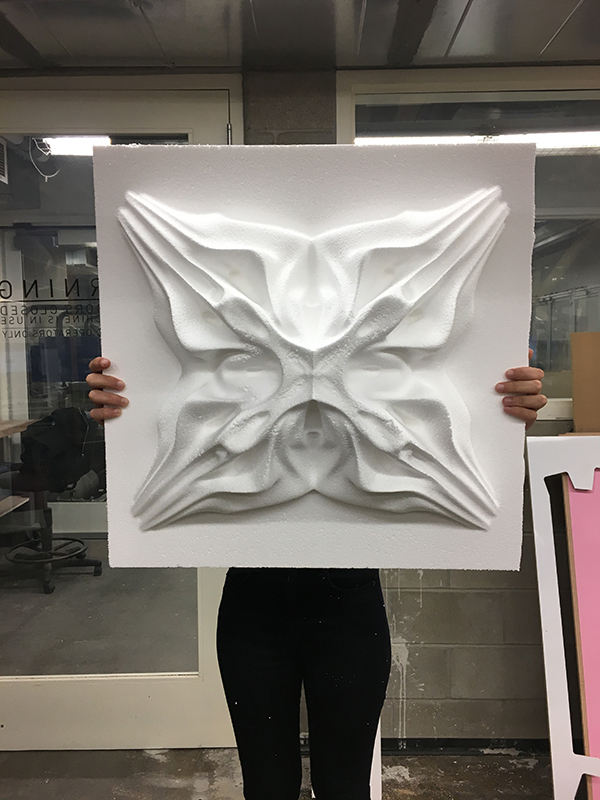

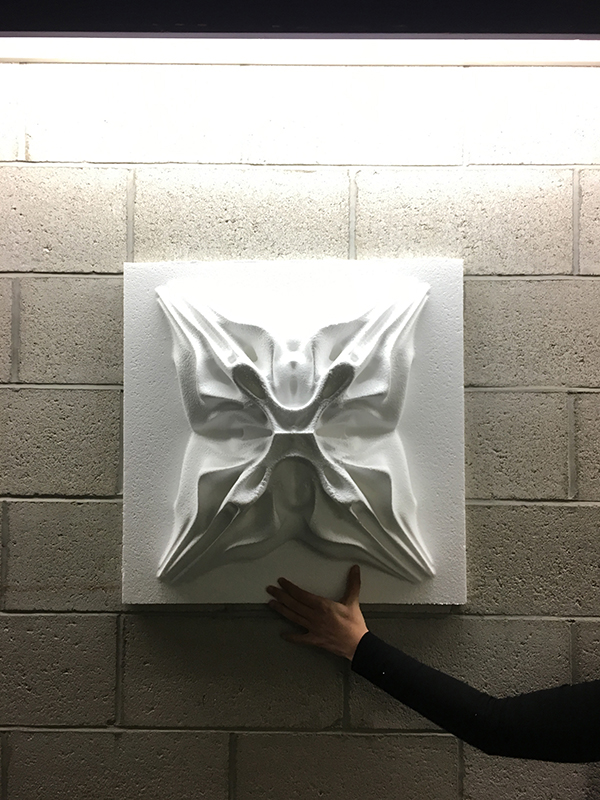

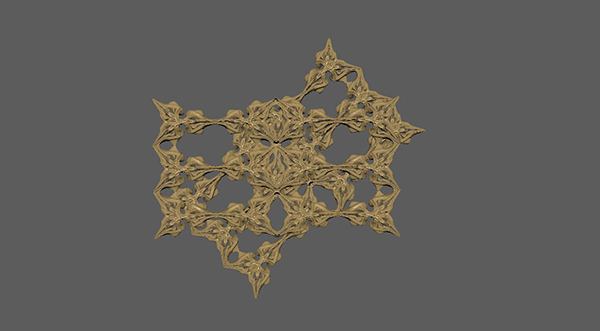

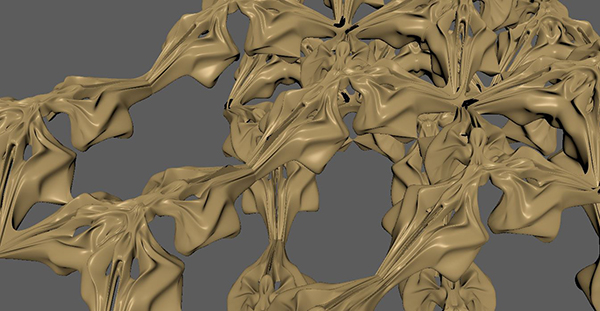

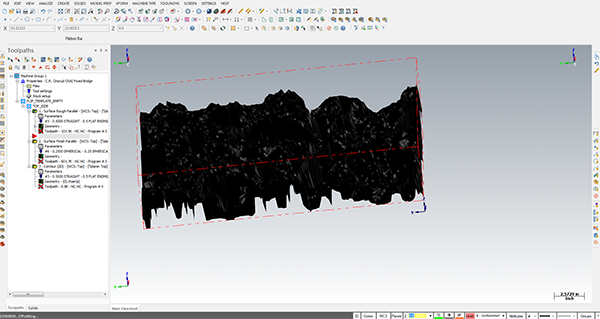

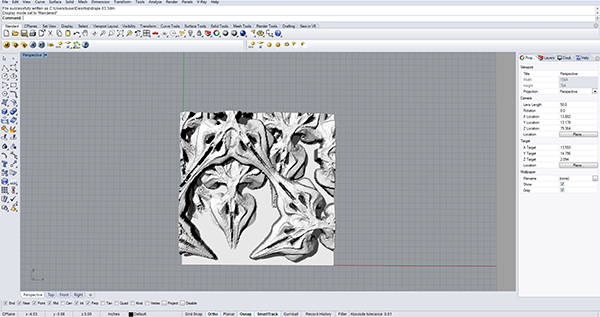

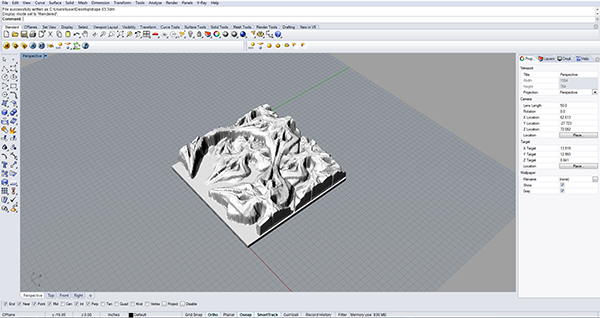

Looking to create a lattice pattern and have the CNC drill bit to negotiate all the areas that merge the meshes together as opposed to modeling those areas. As seen in the first two photos, the height difference getting captured is the area optimal for the CNC to solve surface conditions. Using Autodesk Maya, a mesh modeling tool, made it very easy to create a floral form from pushing and pulling and mirroring and exporting to stl.

The problem however, comes when the offsetting of the surfaces as well as the toolpaths the machine has to calculate is way to dense to even process or hold. Turns out the machine can only hold up to 24 megabytes of code data?

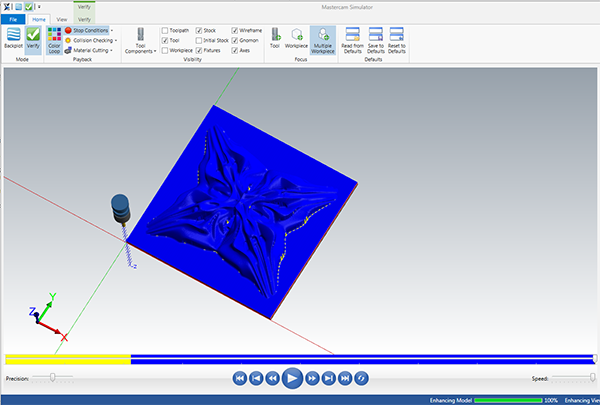

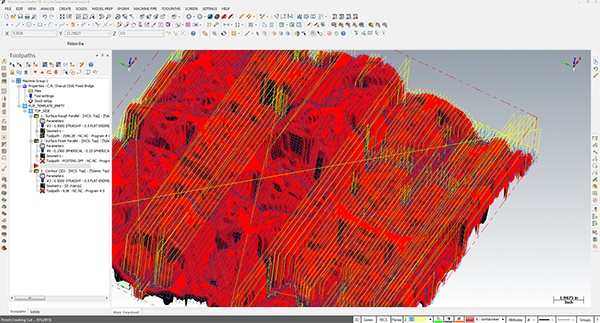

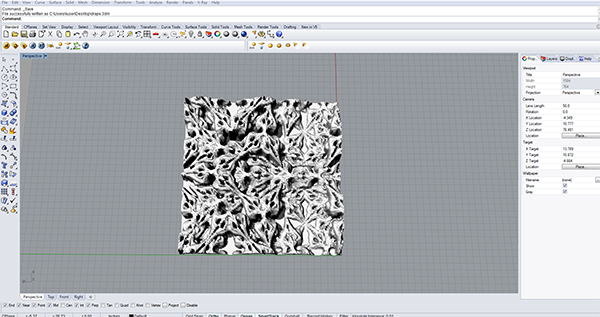

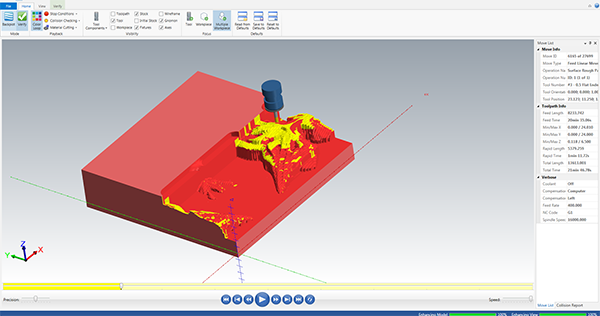

Going around this, attempting to drape the surface in Rhino, to create that single surface above all the latice intersections, and then brinign that back into Mastercam. This however was still to dense, therefor in the picture above, zooming in and making it larger for the offset portion of Mastercam to be able to handle better. It however was still too dense, and more importantly the collet would be hitting the actual surface.

Deciding to go with one latice knot, at a larger scale, and the red surfaces placed under the holes within the lace where placed there so that the CNC machine does not have to go all the way to the bottom surface and intersect with the structure.