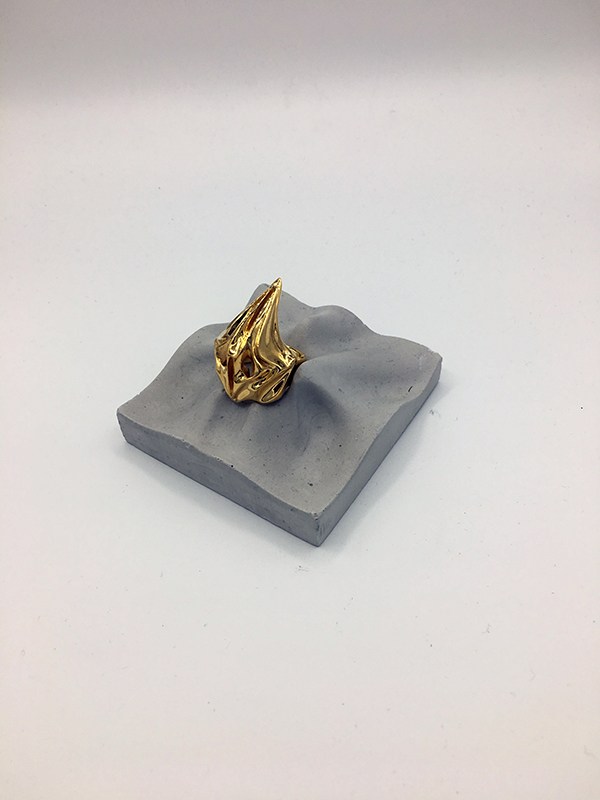

Casting and Molding:

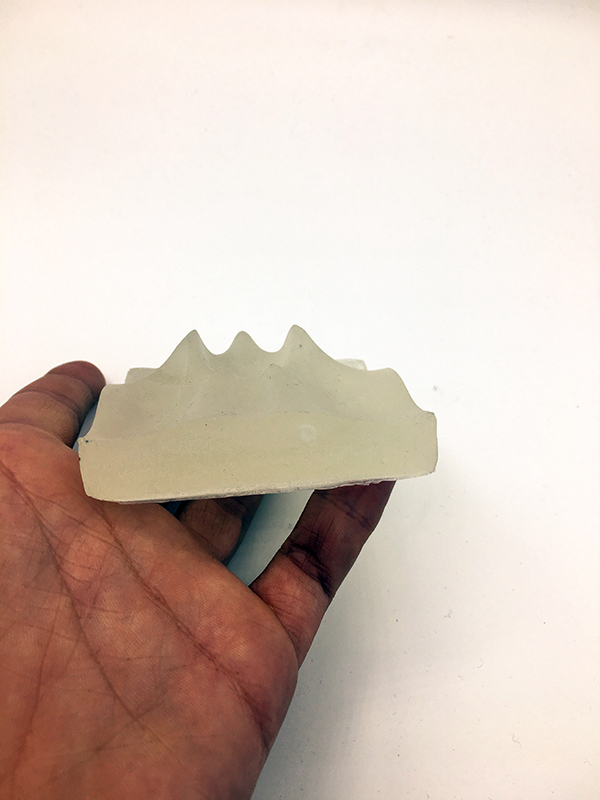

In looking how casting and moulding can be used in fashion or wearables, starting with soemthing simple by creating a stand for a ring. First, modeling the stand in digital software such as Maya and Rhino and milling it out of high density foam. Then using that foam as the basis for a quick cast silicone mold. Also, Reynolds contained virtually every single type of casting material and color variation and viscosity, which will be important for the amount of air bubble control and casting time of the pieces.

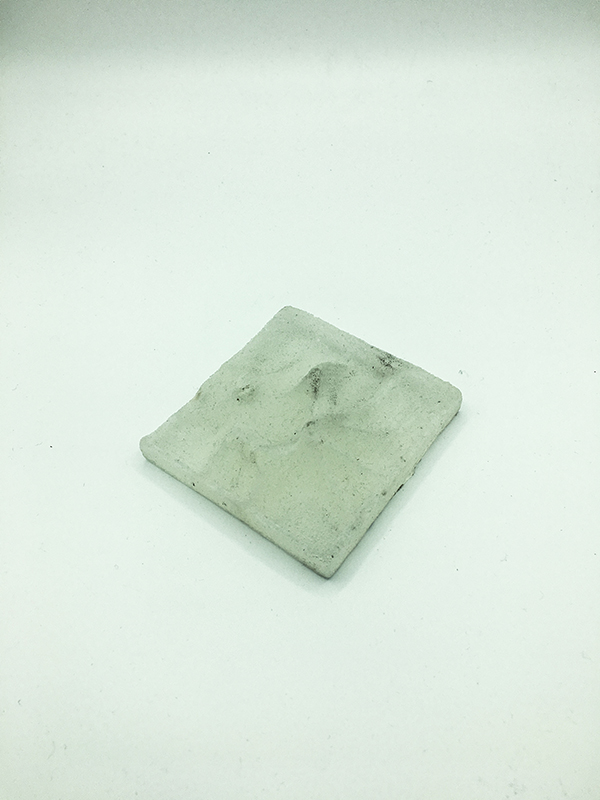

After creating the mold, experiementing with many different types of materials was easy to do as nothing sticks to the silicone mold.

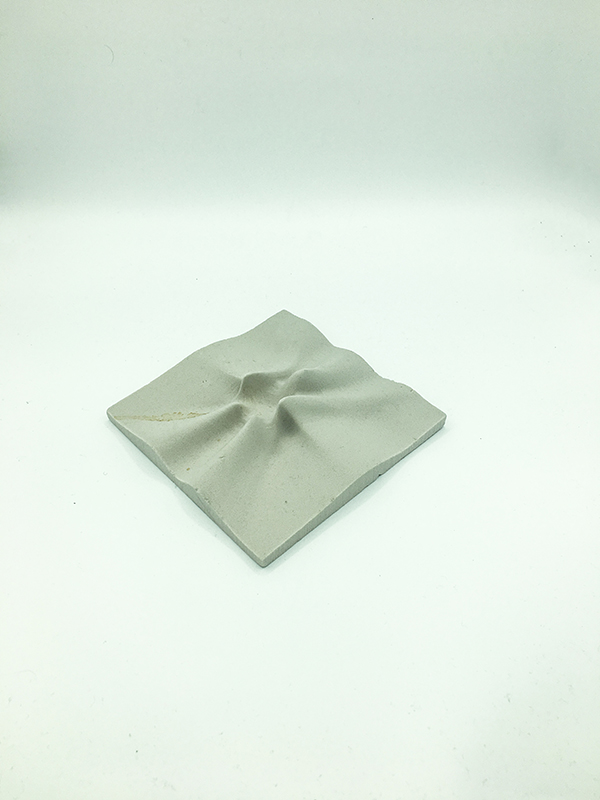

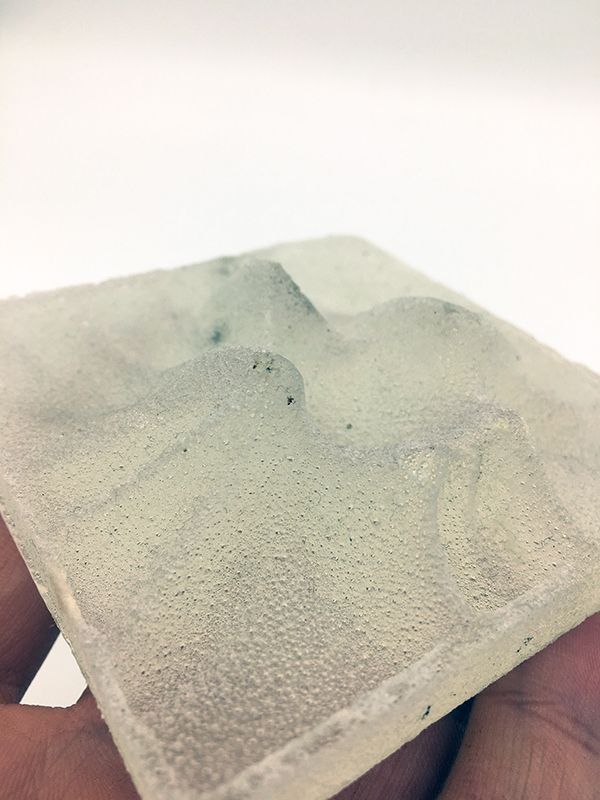

The rockite worked very well as it is typically used to patch walls in dry wall or concrete walls, it dries very quickly and is relatively brittle.

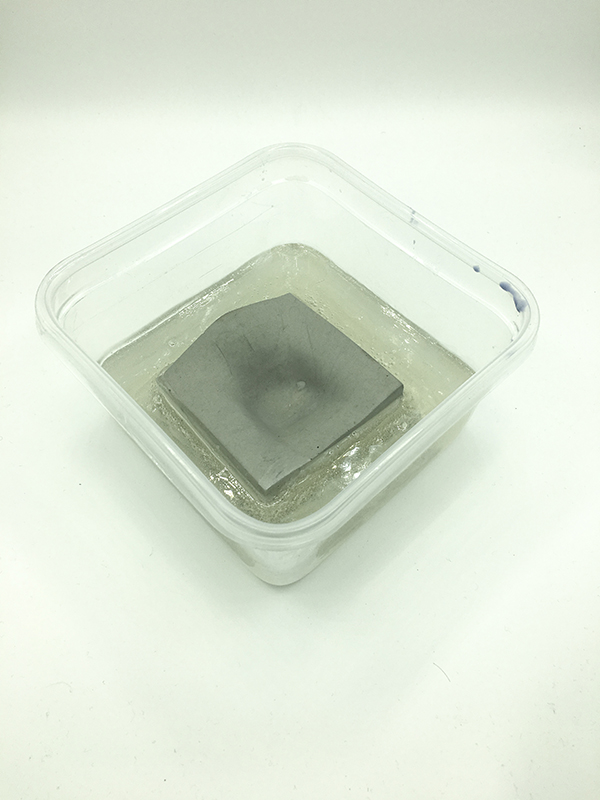

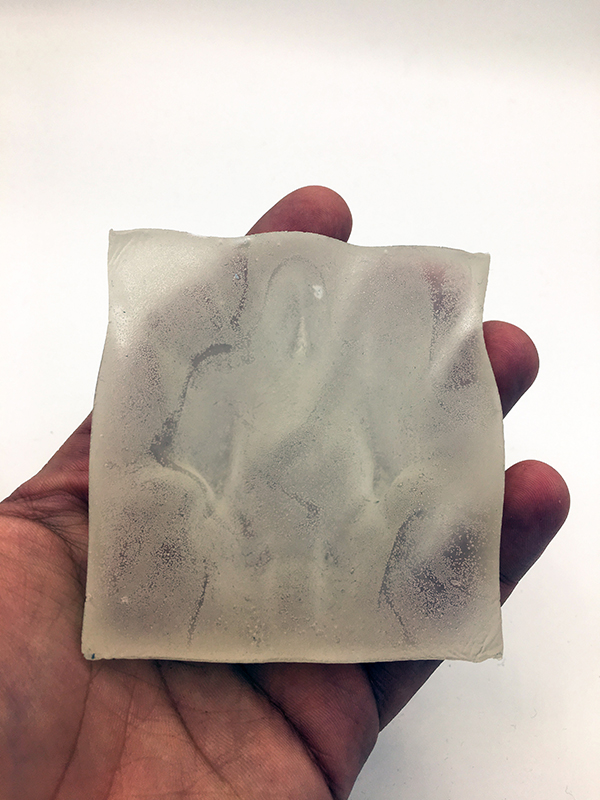

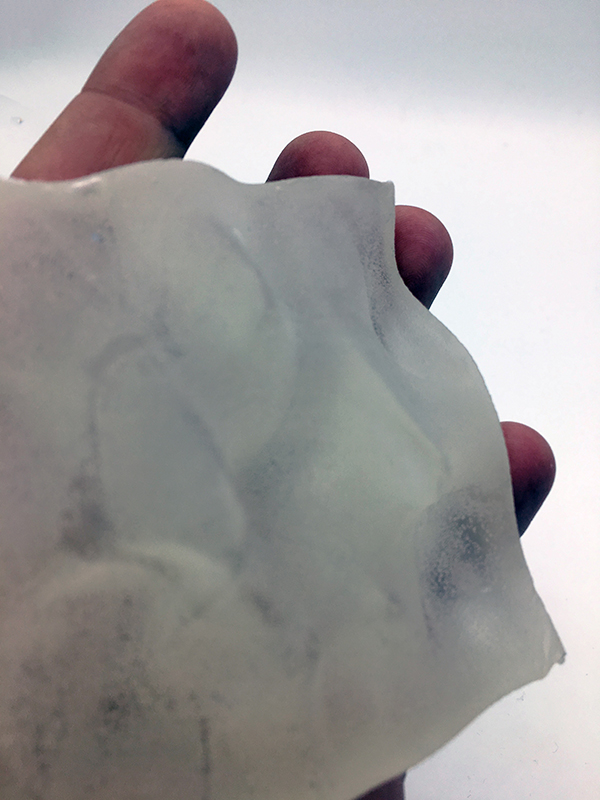

In wanting to create a cast out of a clear material that is not toxic. In visiting Reynolds and looking at all the materials that cast the clearest, tend to be the most dangerous during the casting process, requiring a gas mask and heavy ventilation. So resting on two materials one that is thicker and one that is almost liquid like in its state. The one that is thick gave a lot more air bubbles on the surface as they are trapped on the bottom and cant come out. The liquid like resin cast worked much better.