Hello CAD / Final Project Design

My fince and I recently bought a condo and we keep talking about wanting a fancy wood table that can expand with minimal effort if we have a large dinner party and can otherwise stay nice and compact to not take over the room. Inspired by the Kayak built in previous years (in terms of size) and my experience last year building a pair of nightstands out of welded steel and wood, I would love to make this a reality and leverage the electronics components of the course to not only automate the expansion but also to provide auto-leveling for the table. I believe this project would not only further cement my woodworking skills but would require extensive input/output embedded electronics control and mechanical mechanism design to provide the correct power and timing control of motors and the correct torque output from the motors. In short -- I would have to learn a ton.

In terms of overall mechanism design, I chose the butterfly leaf design as it is relatively intuitive design with a relatively simple mechanism and mathematical proportions. Hopefully this can be automoated with only two motors and some basic mechanical design. With a couple of days of study it seems pretty straightforward. That said, I'm sure I'll regret saying that in a couple of weeks! (Btw for those of you that are interested in these types of tables you can find a youtube series on building one here that I am using as inspiration)

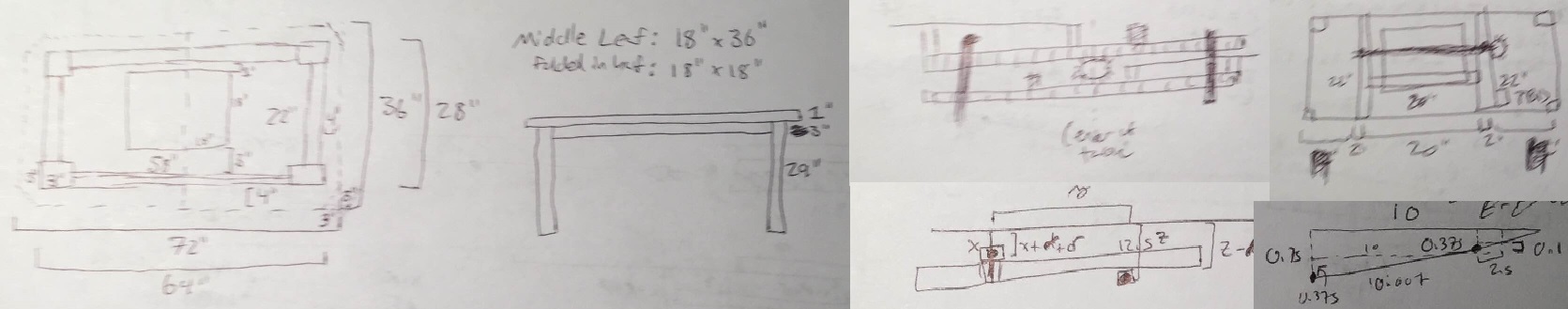

Some sketches of my ideas and initial math follow:

This week was my introduction to CAD (which is super awesome in my humble opinion) although there were a LOT of stumbling blocks to get it off the ground. So for some tips for the rest of you out there here was my experience with getting CAD started:

- I decided to start with Antimony as it was not only recommended by Neil but also because Matt was kind enough to come in and give us a quick demo which for a visual learner like myself made it 10,000 times easier to get started.

- I have a windows PC, Antimony runs on Linux or Mac, therefore it was time to get a VM. I decided to start with VirtualBox from Oracle running Ubuntu (both free and open source and I have experience with Ubuntu). For some reason I COULD NOT get Ubuntu to work – well that’s a lie it worked fine but the screen size kept getting stuck at 600x800 pixels. I tried everything I could find online and after wasting a couple hours getting nowhere I decided to scrap VirtualBox and try VMWare.I wish I had just started there – VMWare worked perfectly the first time and Ubuntu was up and running. Matt’s install guide worked perfectly (except me making a typo but he was kind enough to answer my email and show me my error) and Antimony was up and running. I will now have to figure out a way to get a VMWare liscence once the MIT one expires.

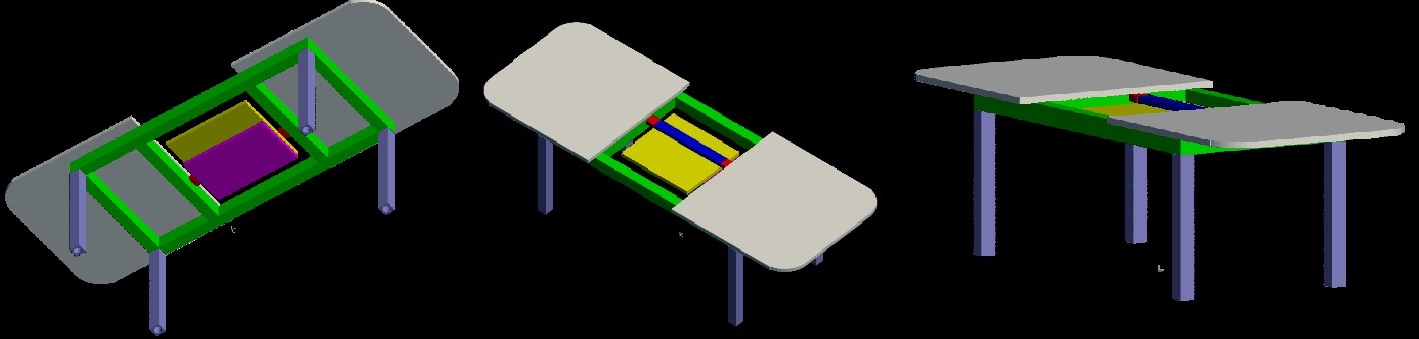

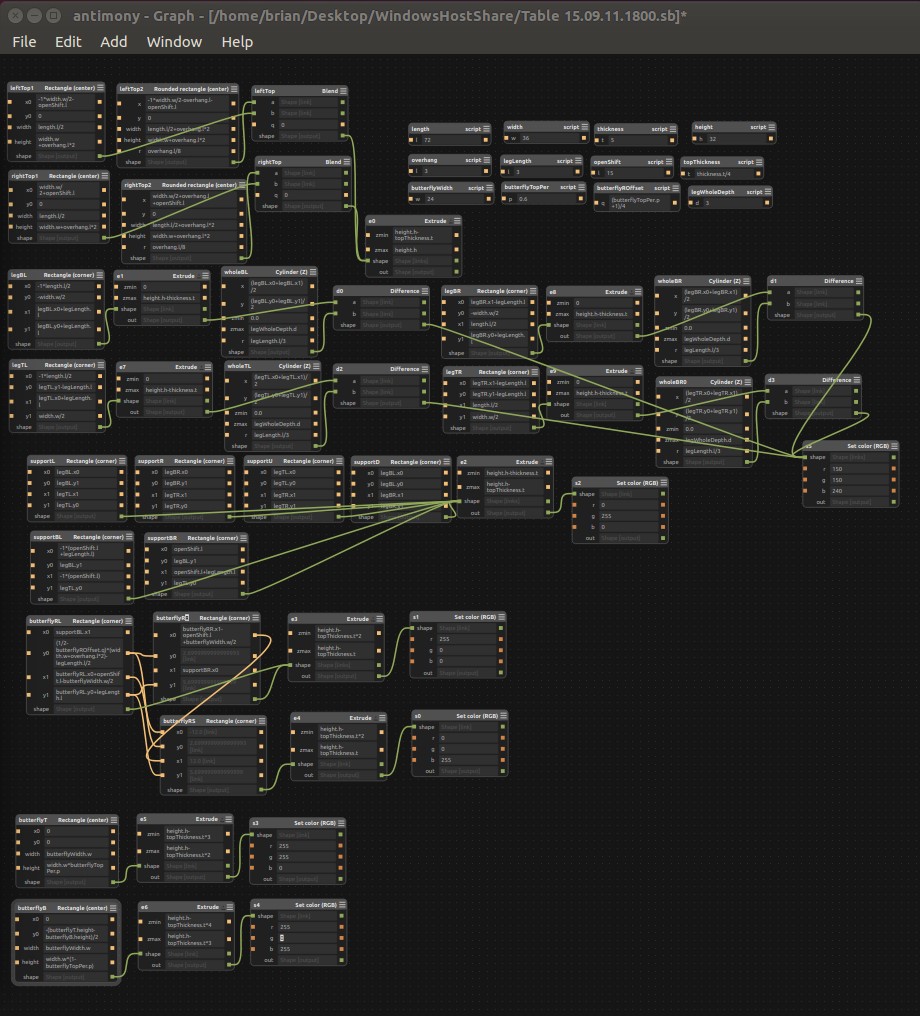

- Fast forward 7 hours later and I’d missed about 4 calls and 50 texts because I was so intensely working on the CAD model (surprisingly fun) and I had the table concept sketched up in CAD with all of the major components for the outline of the table. I found antimony very intuitive after Matt's lecture as it is simply a series of mathematical operations. My model is still missing all of the mechanical mechanisms and electronics -- which is a substantial part of the project BUT should be simply add-ons attached to the current model (although I need to do some serious research on which ones will work best).

The finished project and Antimony code graph can be seem below:

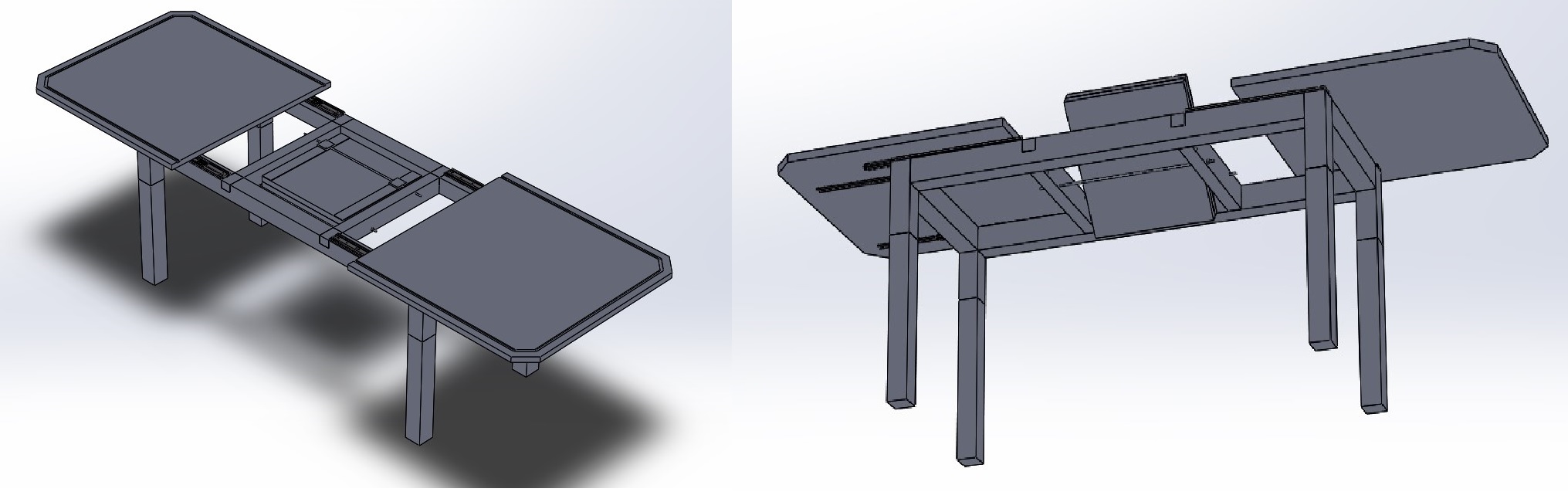

After my experience with Antimony, and at the suggestion of many peers in my lab, I decided to try to use Solidworks to do the same table CAD model, this time being careful about measurements of the various parts and allowing the parts to slide and rotate as they should in the model.

Unlike Antimony I found Solidworks to be relatively un-intuitive to use, but with some quick googling I found a plethora of youtube tutorials and help pages that explained everything I wanted to do. I first attempted to make the entire table as one part but then realized I could make sub-parts and use the Solidworks Assembly file to combine the various parts allowing for closer introspection of each individual part in their own file and then the combined view to make sure everything is connecting properly.

I probably took my again a good 5-7 hours to get the basic table as one part built, but then with only another hour or two of learning how to "mate" various parts in an assembly, rebuilding the separate parts took no time and I was able to download the CAD file for a slider I plan on purchasing and placed it on the table as well. Based on this experience here are my quick tips on Solidworks:

- Solidworks functions based on you drawing a "sketch" in a "plane" of which the standard 3 planes are provided for you on program launch. If you need to create more planes you can use sides of currently existing 3D shapes in your file by default as a plane or you create new reference planes from which you can do more sketching (e.g., on curved surfaces). Your "sketch" is a 2-D representation of your object which you can bring to 2.5D or 3D via a revolution or an extrusion in general. So you need to think of your object in terms of their flattened or de-revolved shapes.

- The "Smart Dimension" tool is your best friend for making things the size you want.

- If you cntrl+click on two object or lines you can equate then or create other relationships with them to make things equal across a sketch (then you don’t have to dimension all of them).

- If you draw a centerline on your sketch, you can mirror things across the sketch.

- Remember you can default sketch on extruded surfaces so if you want to drill a hole in the size of a block just click on the side and sketch a circle and then use the "extrude cut" feature to bore a hole through it.

- "Mate" is your best friend in assemblies. Check out all of the features – the advanced features also allow you to set things to be within a distance with min and max bounds so you can let things slide on each other.

- Changing your viewing angle makes it a lot easier to do various tasks!

- Finally as I said before someone has done the thing you want to do and posted a video on youtube explaining how to do it so google it!

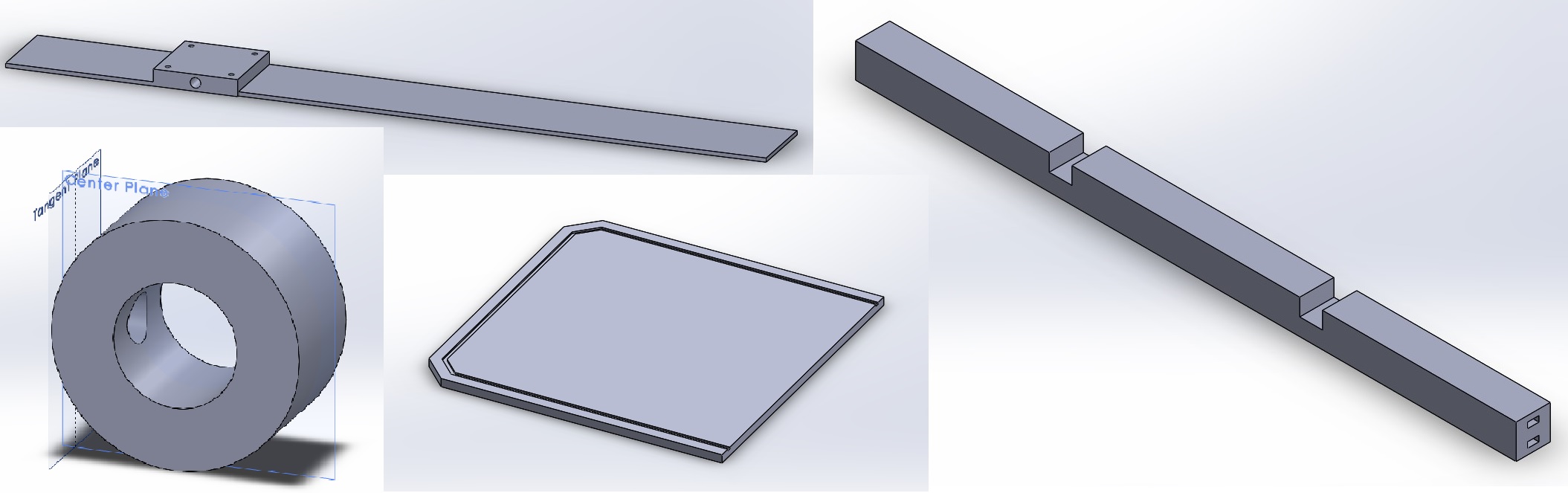

Some parts and the finished assembly can be seem below:

I think that overall I find Antimony easier to use for quickly making a complicated and curved part. That said, all of the built-in modules for Solidworks and the extensive online documentation and tutorials probably makes it a better choice in my opinion for quickly getting large assemblies of parts built. Also the ability to easily import a model from a supplier that immediately plays nice with the rest of the files is super helpful.

[UPDATE week 4]: The mechanism for turning the butterfly leaf will be relatively simple. Conveniently, the leaf itself only needs to be turned along the metal bar axis and it will automatically open correctly due to the design and the fulcrum bar. This makes it really easy. I will simply have to attach a gear to the bar and drive it from a motor. What I am thinking about on that is what kind of gear reduction do I need based on my torque and electrical requirements. I will definitely be working with motors during outputs week with electronics to make sure to be ready to control the motors with a microcrontroller.

The sliding table tops are a little more complicated. I have decided to use heavy dutry drawer slides across the top rails to provide free gliding motion. Which is great except for the fact that drawer slides are not meant to hold things in place in that direction so I worry if someone sits on the end of the table with it extended that the top will rip off. To compat this I am plannign to do a couple of things. First the drawer slide inside rides about an eigth (exact measurement TBD) of an inch above the bottom of the drawer slide which will be screwed into the wood. I want to provide an equal height metal plate that runs along the rest of the tabletop so no force is uneccesarily transmitted to the screws when the table top is exanded and at rest. Second I want to provide some support agains the top flipping under pressure from someone sitting on the end. I am thinking of running a metal bar down the length of the table and attaching a Y shaped metal piece from the two runner up to the middle of each half of the table to provide some more support in that direction. I may cast this piece during molding and casting week. As for a mechanism for moving the table top I intend to use a worm drive with a rack and pinnion type bar of metal attached to the center of the table top and powered by an electric motor to drive the mechanism. Again working off of embedded electronics.