Burlap Composite Tennis Racket

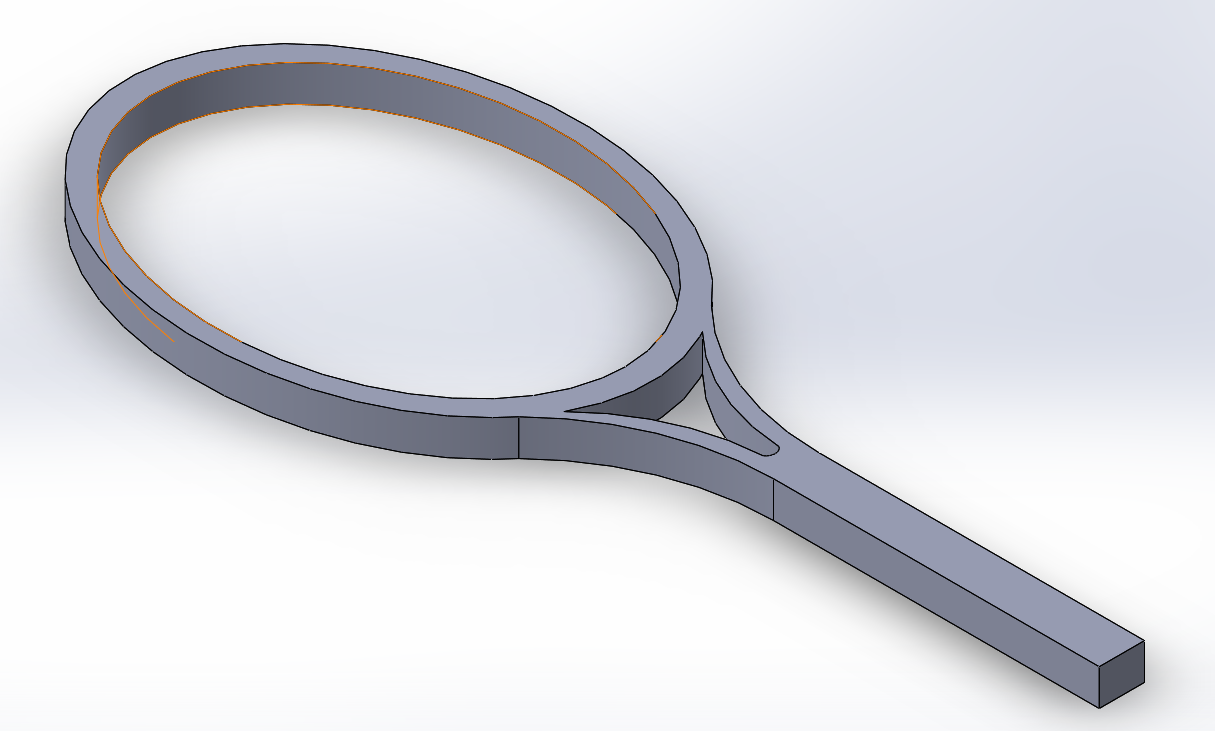

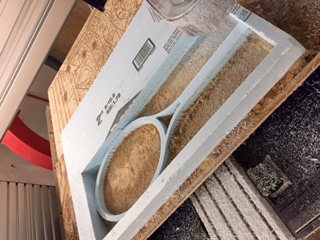

For this week I decided to try to make a burlap composite tennis racket because why not! I started by making a model in Solidworks shown below. For simplicity I decided to keep the handle square instead of hexagonal as that would have required that I mill from two sides or mill two halves and then attach them. This would be ideal in general but seemed like it left a lot of room for error on a project that I'm not sure will work to begin with. If this works out great I will make a slighttly better designed racket that is more usable. Regardless, after the CAD design I then used partworks3D to design a toolpath for the model. Nothing new or exciting on that end. I then send the cut path to the shopbot and cut out my foam core. I decided that I would make the core and then wrap it in composite. The foam core should provide some shock absorption and will help ensure the composite is the right shape. My thinking is that I will drill holes in the finished project to string it (time permitting this week). I'm curious to see how well it holds up to actual play or if it snaps in half instantly!

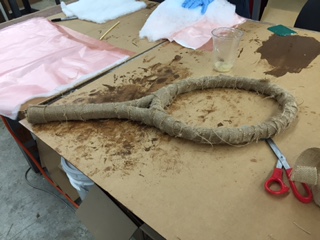

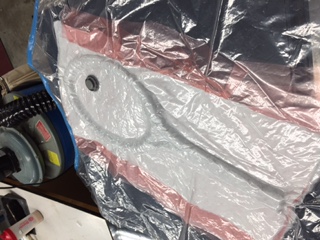

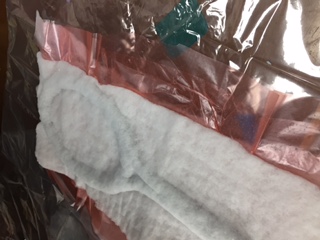

Well as expected it was pretty hard to wrap the racket in the burlap also it requied a lot more burlap than expected. In the end I think I only got about 2 ply over the racket so we'll see if that is strong enough. Also it was hard to keep the strands held tight to the racket as at each end I would lose tension even though I tried to start the next strand overlapping the previous one. If I was to do this again I think I would try to find some way to attach the strands onto the foam maybe with a staple or something to hold them in place. Also the burlap uses a lot of expoxy and I ran out but luckily was able to borrow some from a classmate who made too much. Make sure you work fast enough as the epoxy gets very hot as it starts to cure. Then it was onto the vacum bag. I placed a layer of breathable release material on either side and then cloth to absorb extra expoxy. Then I vacumed it in the bag. This really compressed the burlap and I think will make up for the fact that I couldn't wrap it very tight. Unfortunately, I used a used vacum bag and it had a leak in it somewhere so I had to switch it to a second bag. Make sure to wait 5 minutes to test for this. The second bag worked great and I left it overnight to cure.

After letting it stay overnight it had hardened completely so much so that some of the cloth for absorption stuck through the wholes in the breathable release material to the racket. That said it looks pretty solid. The issues I had though of before, namely that the wrap wasn't tight enough can be seen in the final product as the wrap isn't tight to the core but comes out and meets flat on both sides of the core. This will be a problem if/when I decide to try to drill wholes in it and string it, but honestly, for a first pass, this worked really well. I'm really impressed. A second go at this might actually really produce a nice looking racket. Final pics below!