Composites

surfboard, parts only

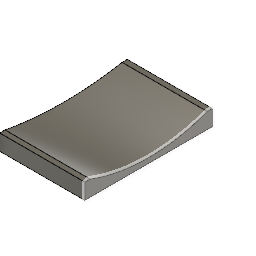

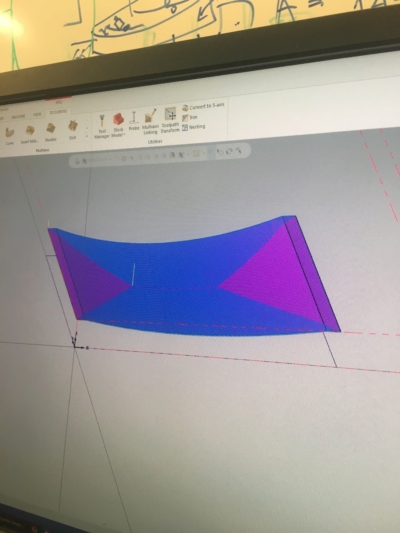

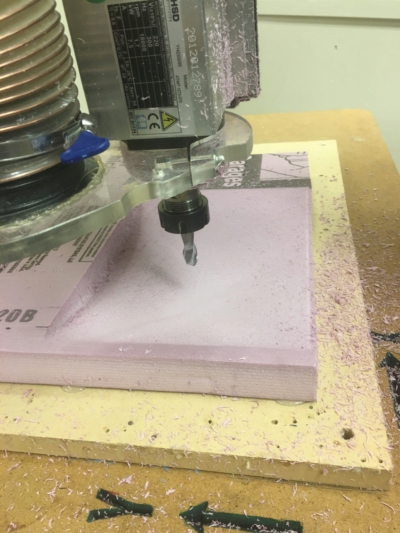

For this week I decided to make a surface out of composite as a part of making a surfboard for my own use. I started by making a curved surface on fusion/rhino, that changes over distance. with Jen's help I cut the piece on shopbot. We tried scallop cutting on the machine for this section.

Afterwards I use gesso to create a clear finish on the part. I applied one layer of gesso and after it dried, used sandpaper to clean the surface. I added a second layer of gesso. finally I added wax on top of the gesso

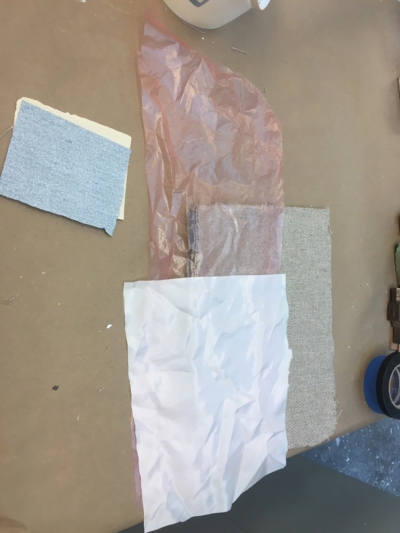

I decided to use a layer of fiberglass on one side of the composite and fiber on the other side to compare their finish. After mixing the epoxy with ratio of 3 to 1, and adding it to the fibers, I added extra layers of wool, and plastic with opening, in order to allow the excess epoxy to move away from the part.

After a couple of hours I came back to take the part out. To my suprise taking the parts out was quite hard and I couldn't do it without damaging the surface. Jen mentioned that the fact that in the initial design I had the small borders around the piece makes it harder for taking the part out, because they fold in and squeeze the foam. Definitely something that I didn't predict, and a learning experience.