This week, we learned how to machine circuit boards and solder components to create programmers. Having forgotten nearly everything I learned from 8.02 (Physics E&M), I can honestly say that most of what the programmer does is well over my head, but I have a pretty good grasp now of how to build one effectively, and I look forward to learning more about the electronics in future weeks.

Prior to this assignment, I had soldered a bit but only wires and switches and similarly large components and never circuit boards, and I had used wood CNC mills but not the smaller desktop mills, so I learned a lot this week. Shoutout to Justin for providing a great introductory lesson on milling and soldering and to Calvin for helping me figure out how to program my board.

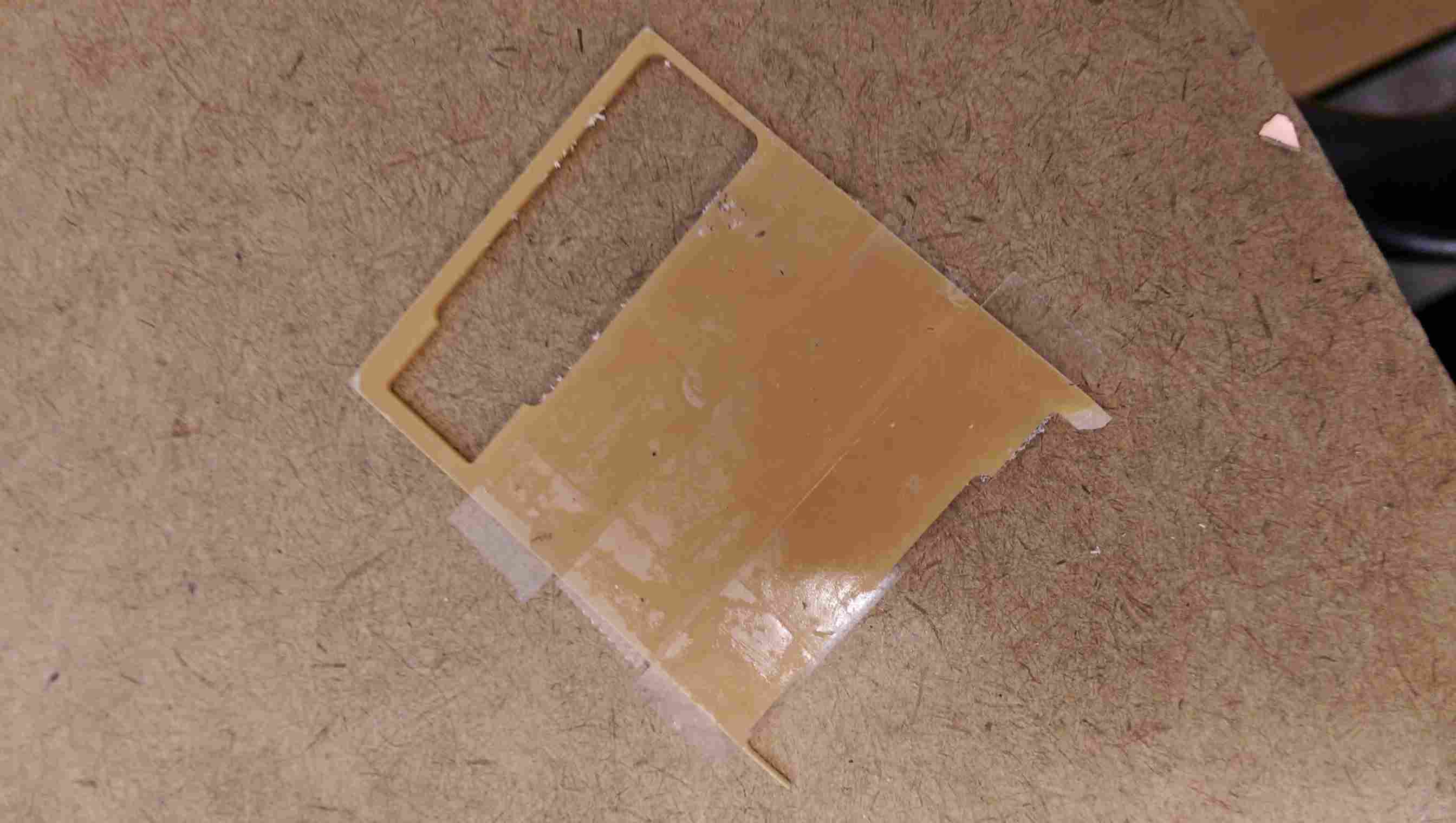

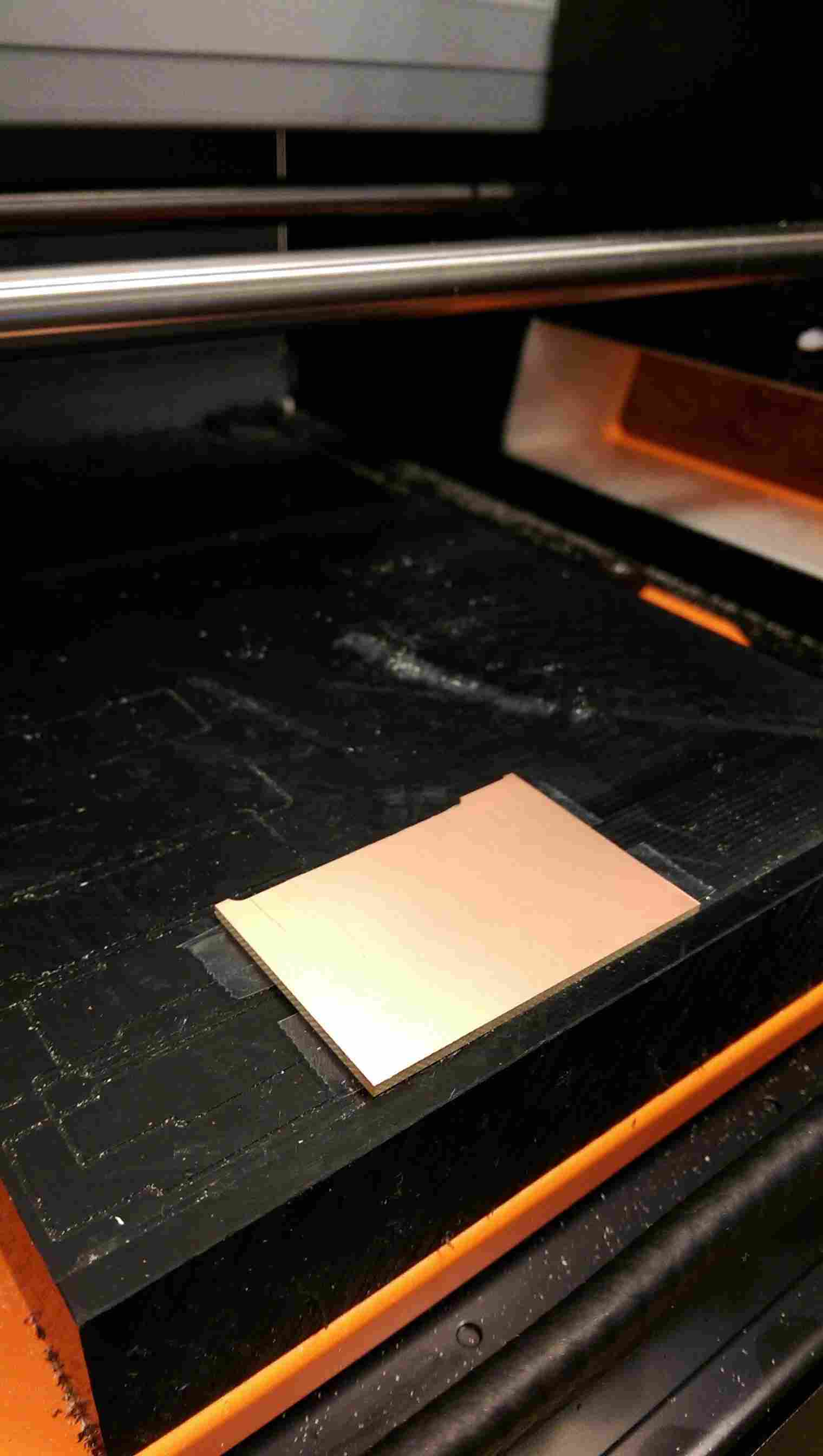

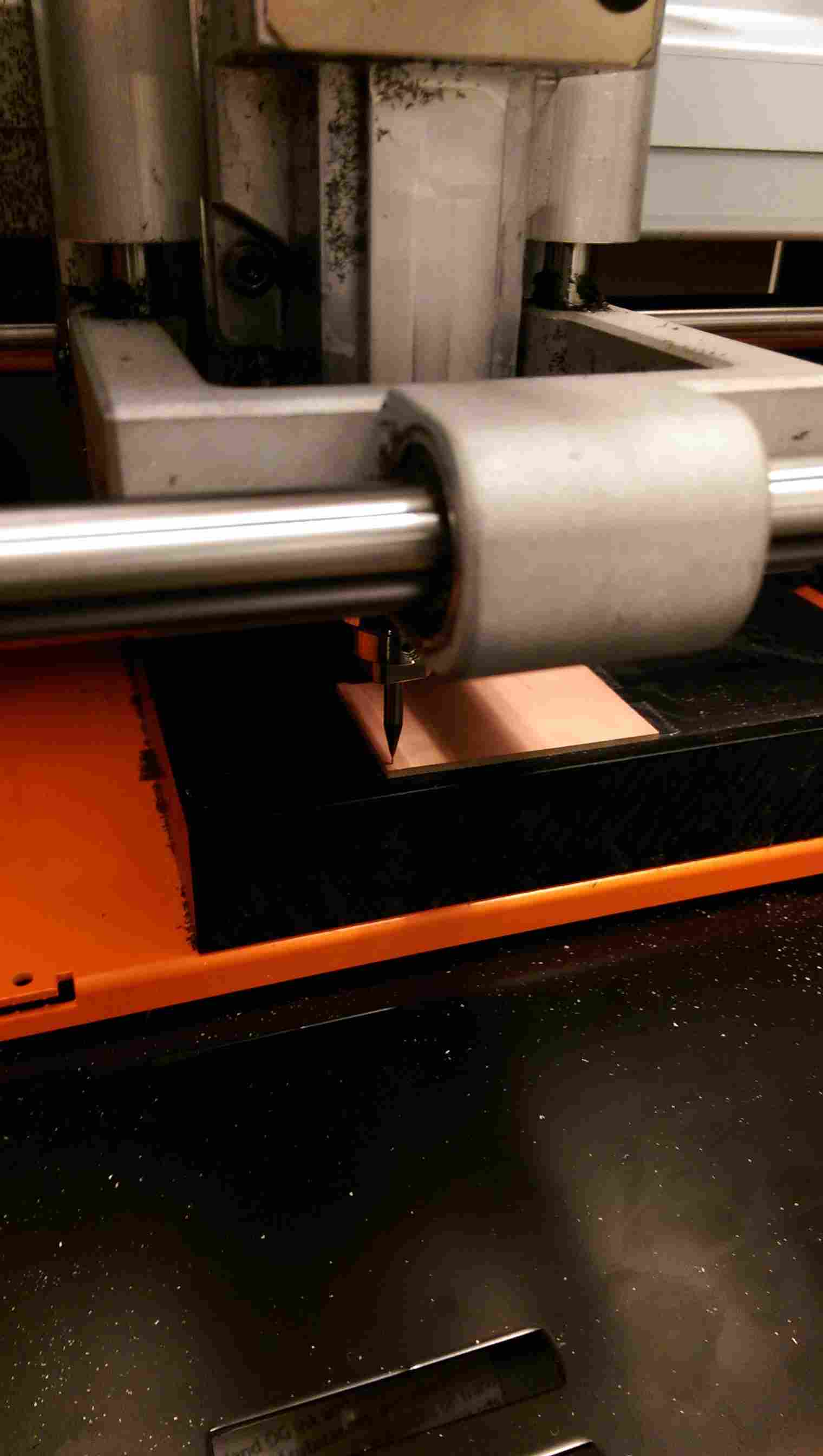

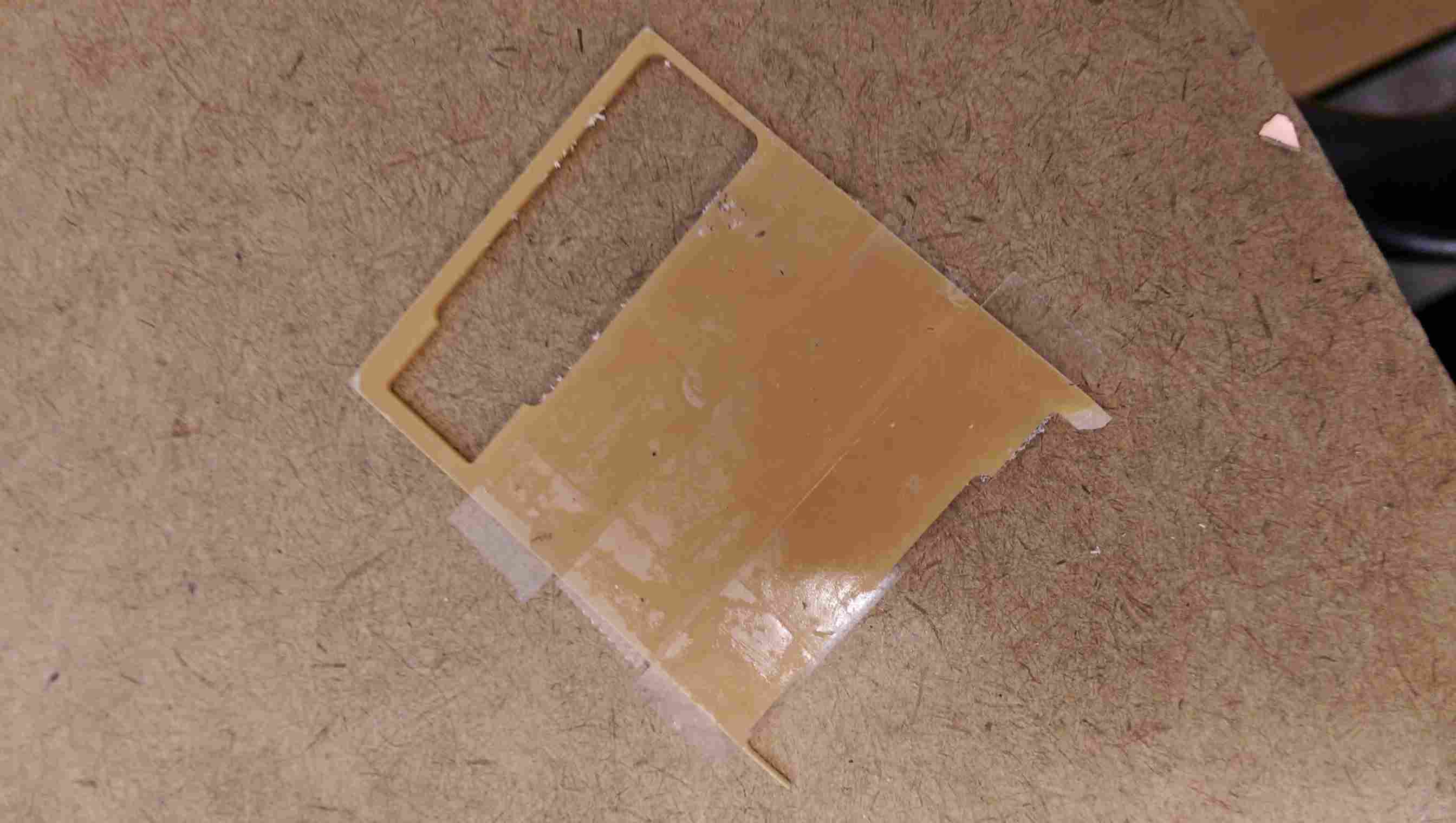

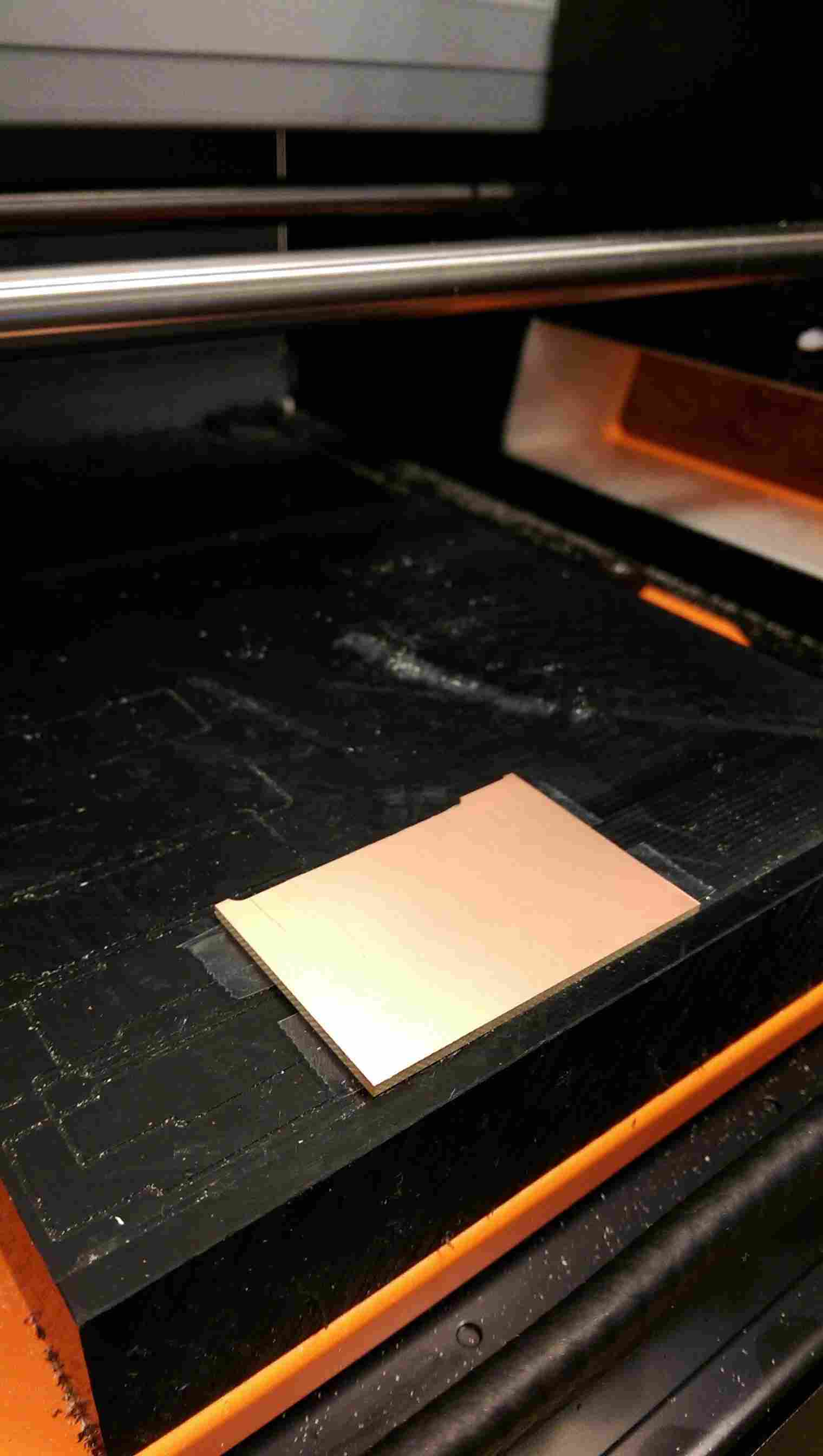

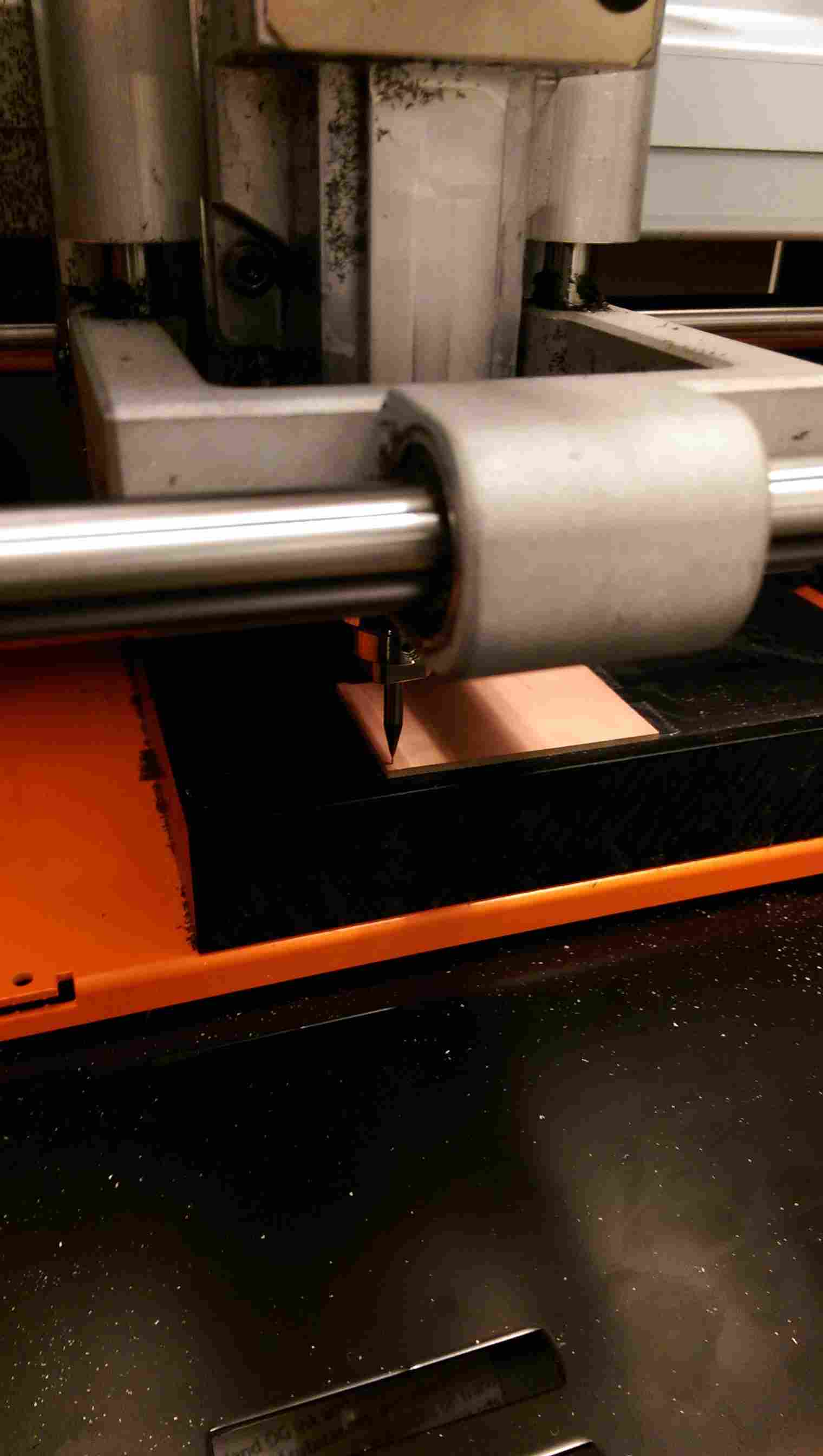

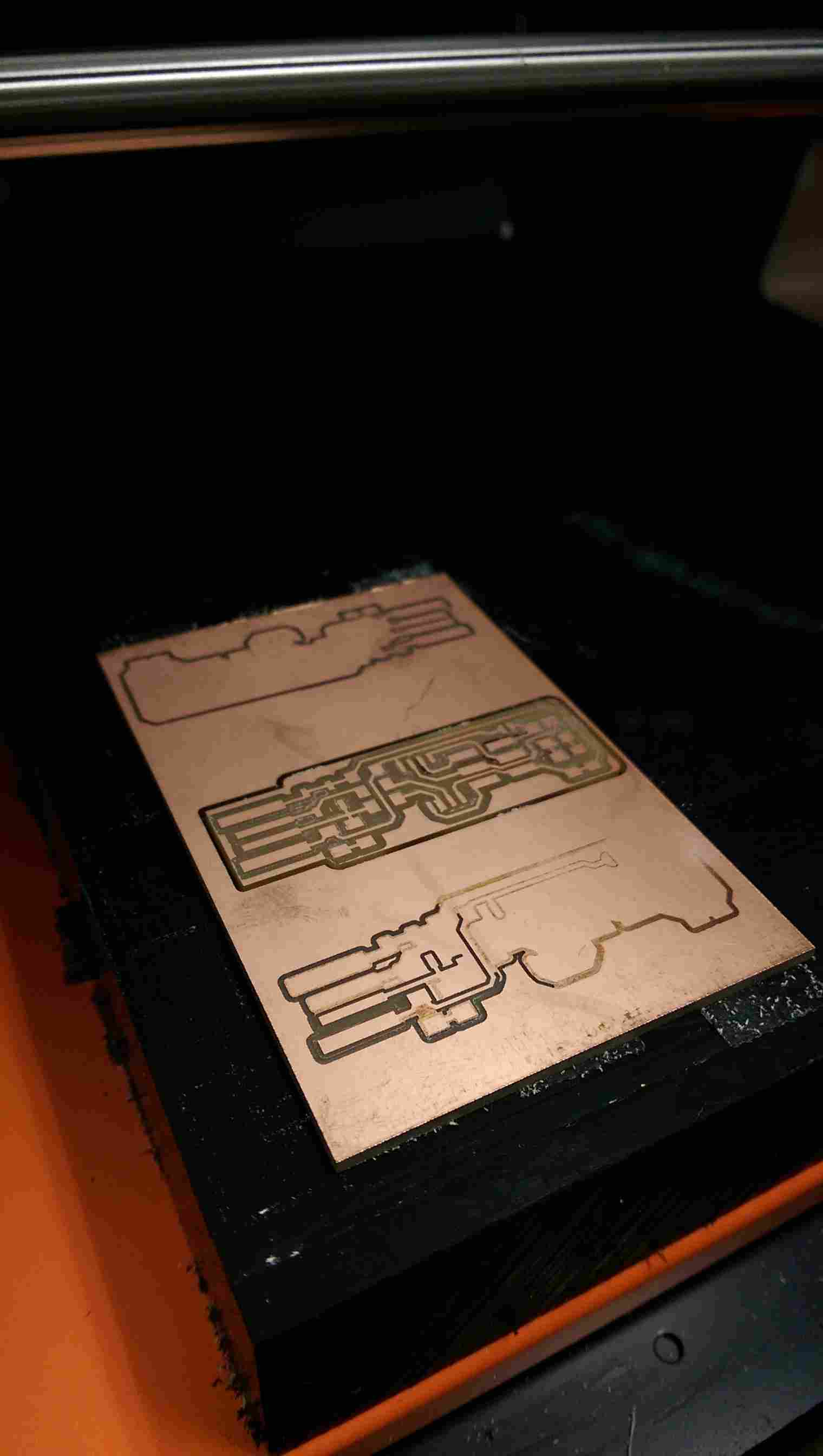

When it came time to actually machine my board, it took a couple of attempts to get it right. While I was very careful to apply double-sided tape so that there were no bubbles or overlaps, I first tried to line up my board in the machine so that it was up against the edge of the underlay, an area which I quickly learned was not quite flat.

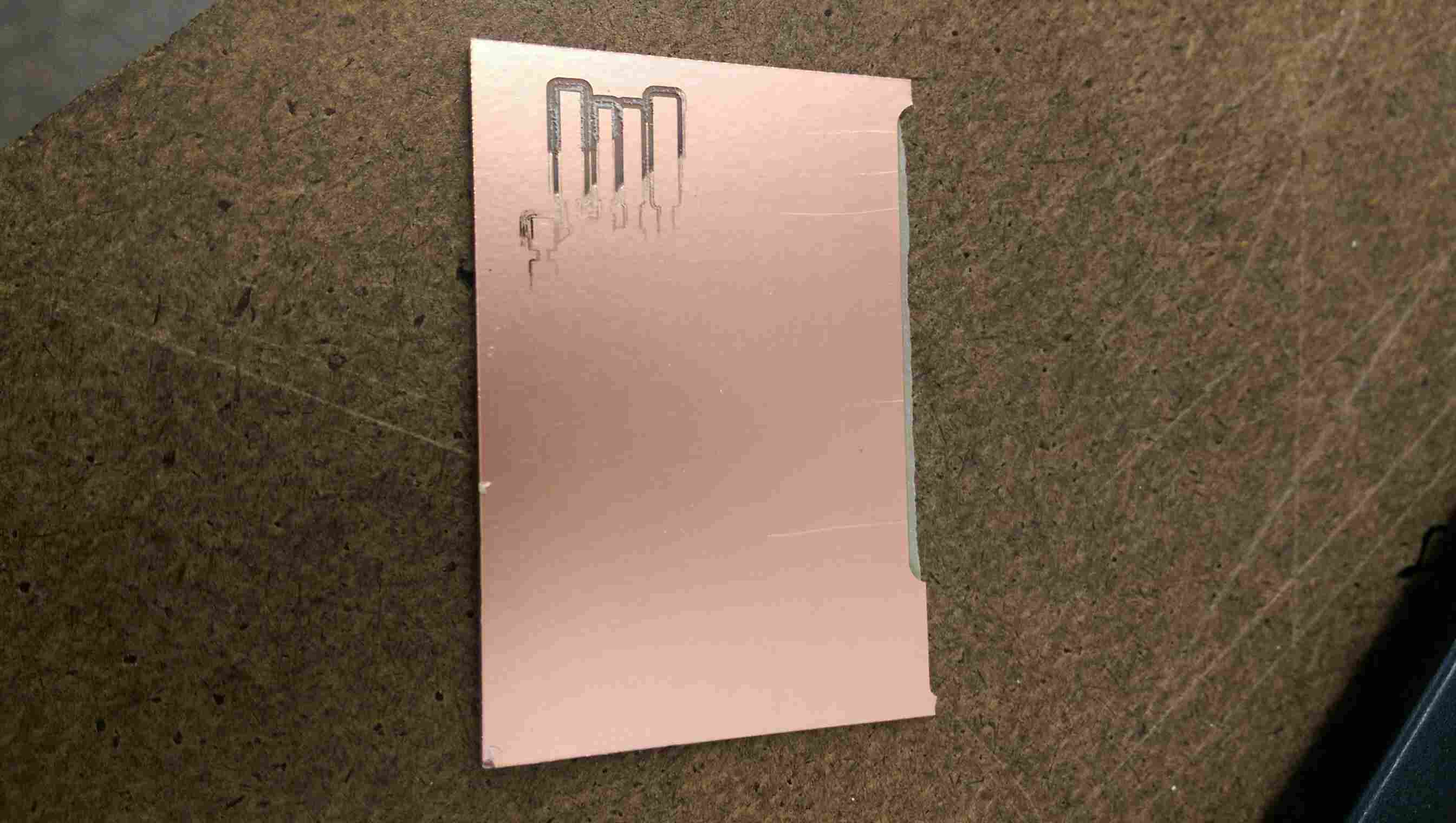

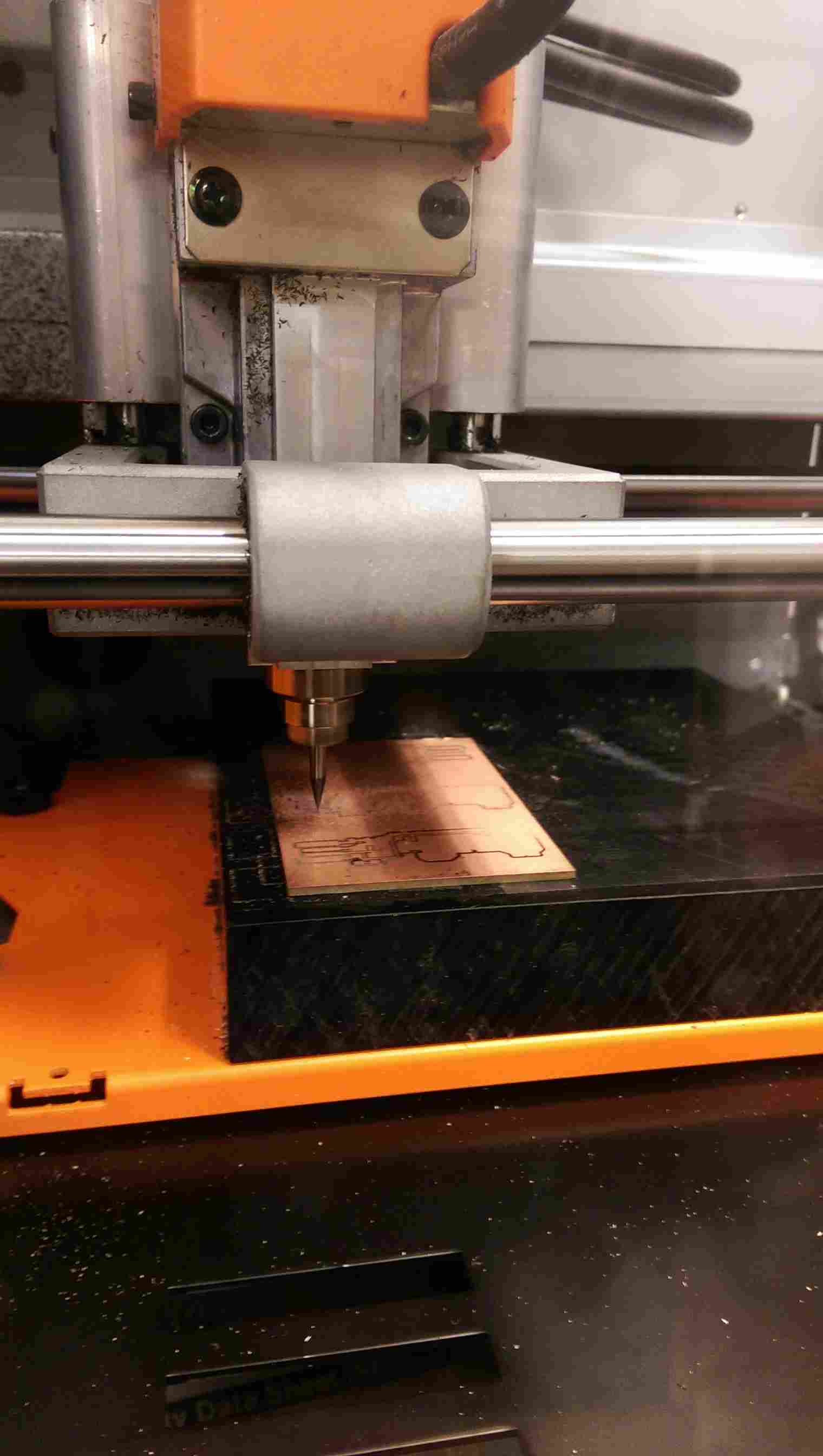

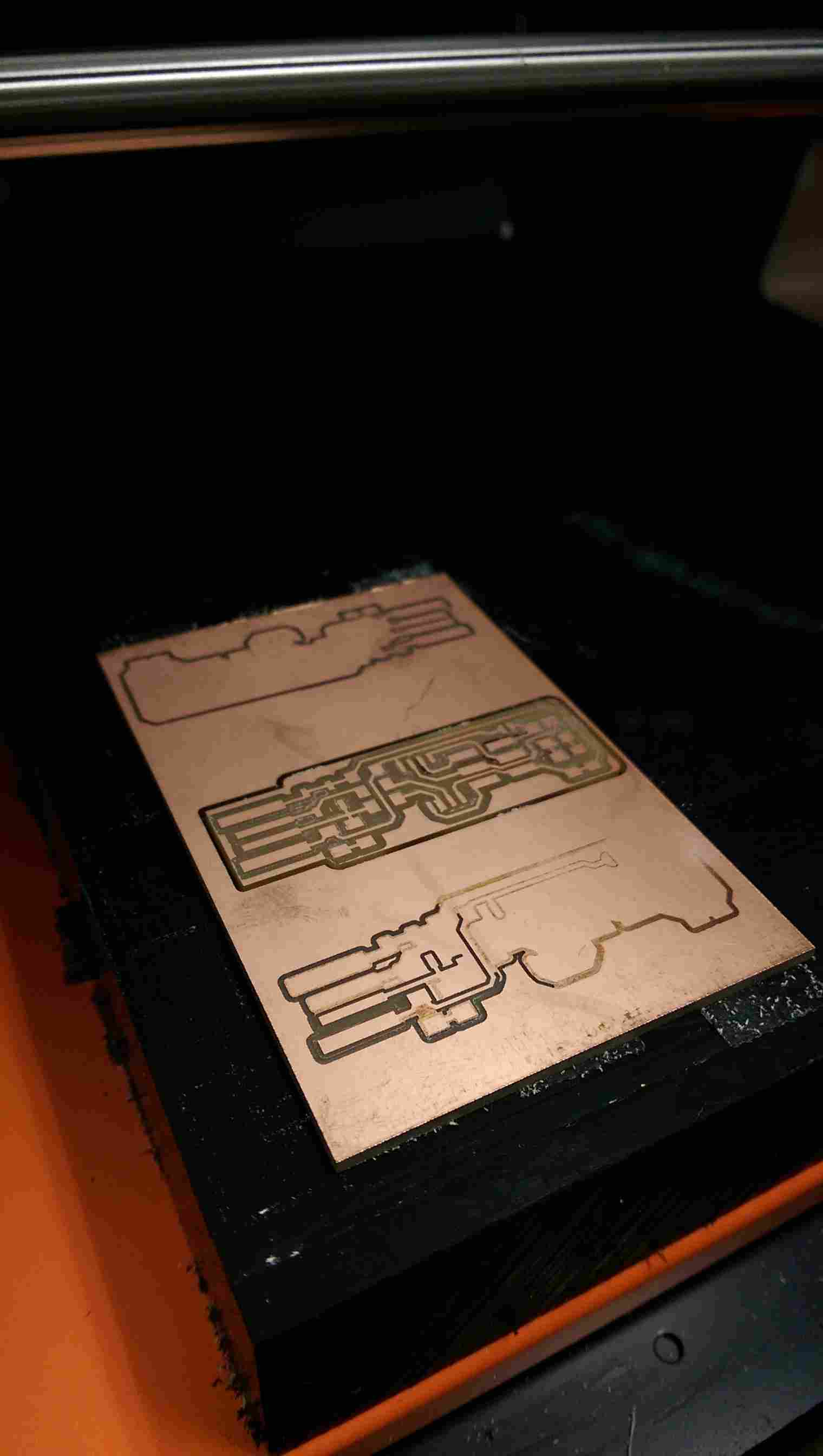

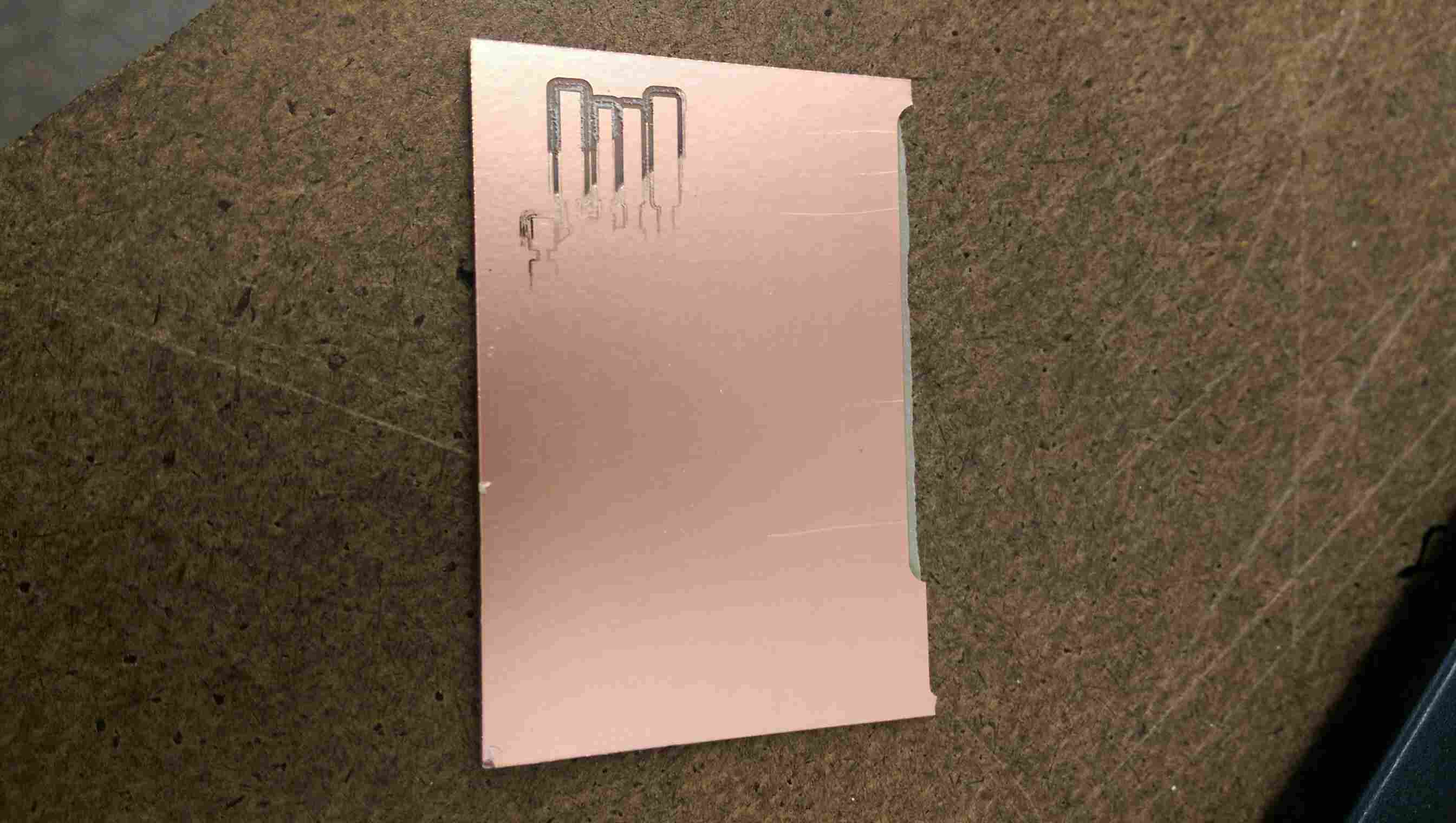

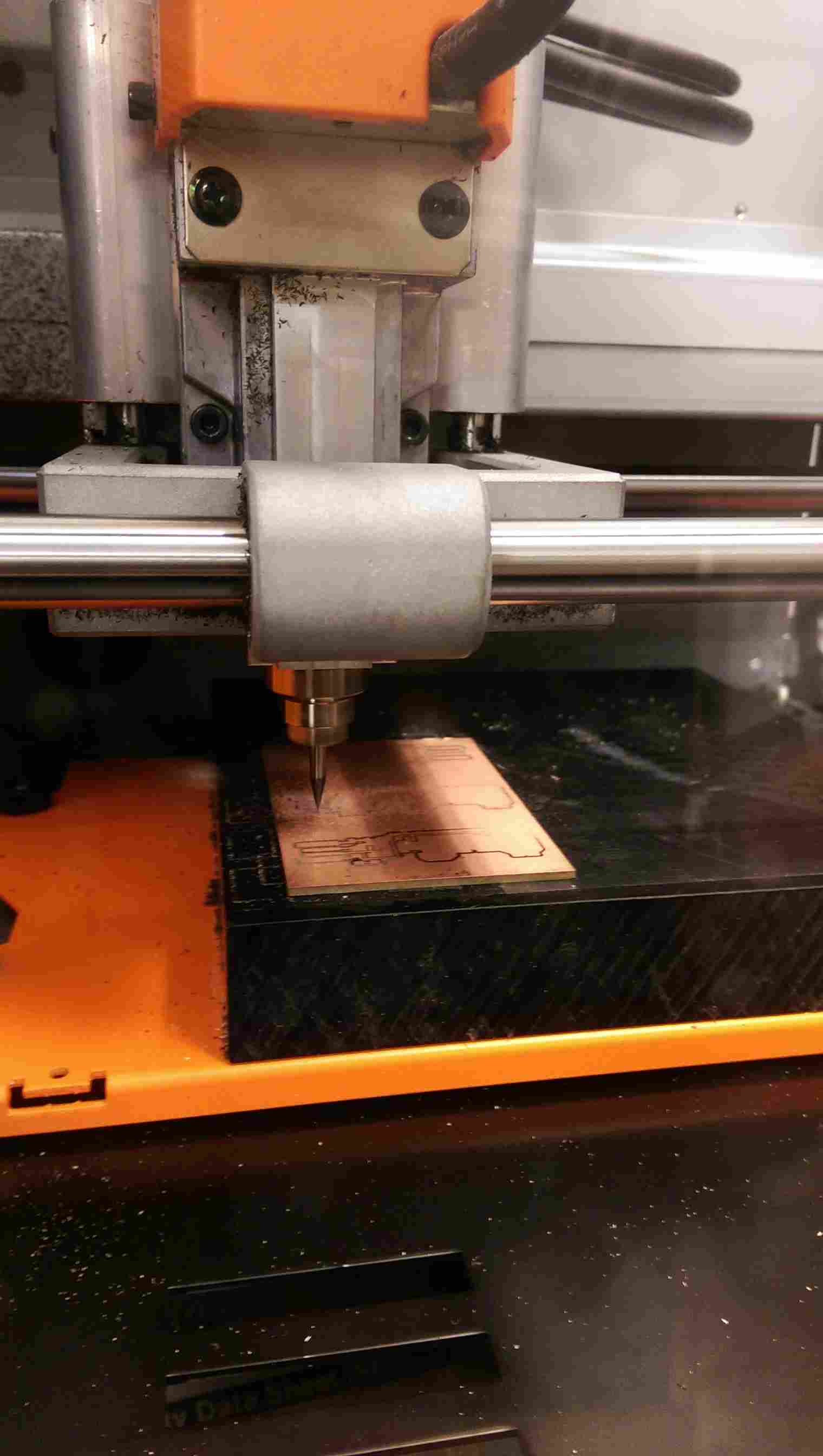

After machine a board that had a dramatic gradient from deeply engraved to not touched at all, I figured the best move would be to try again in a different spot in the machine. The underlay was still fairly new, so I positioned my stock closer to the couple of cutouts already on the underlay, figuring I would learn from the successes of my classmates who had machined before me. This time I was much more successful.

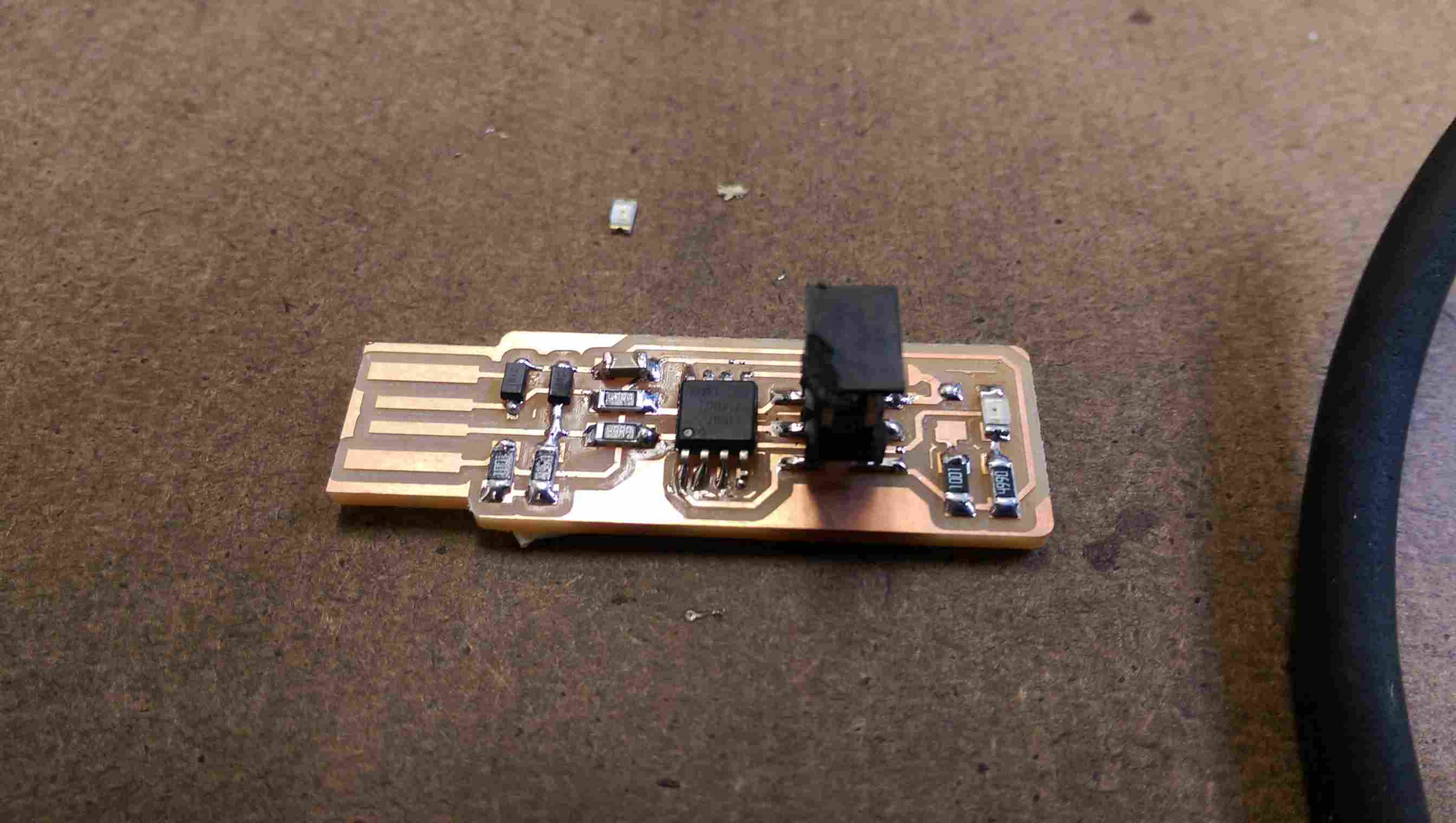

As I moved on to soldering, I quickly realized that soldering is a three-hand job, so I, being a typical two-handed human, needed to find a workaround.

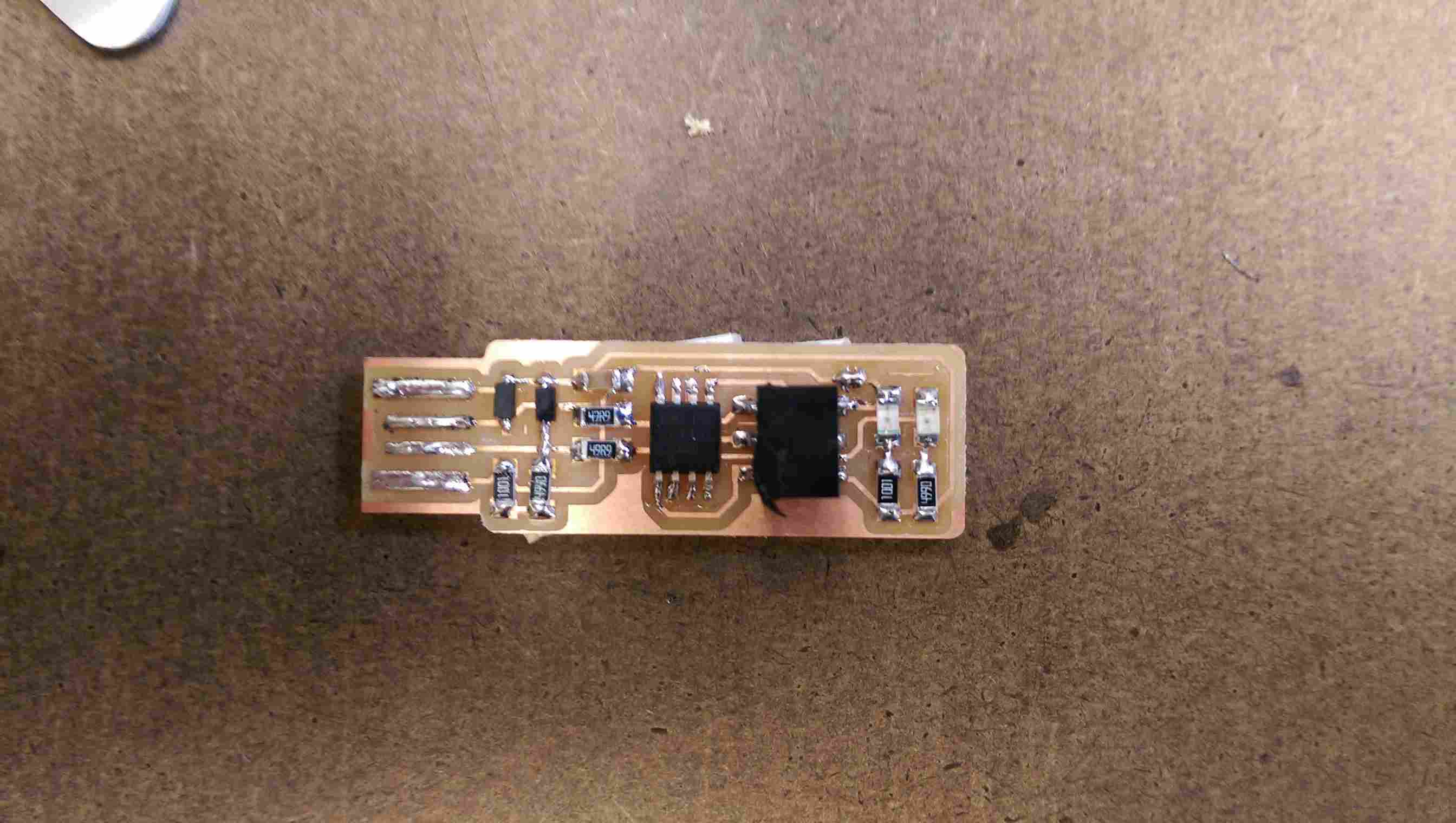

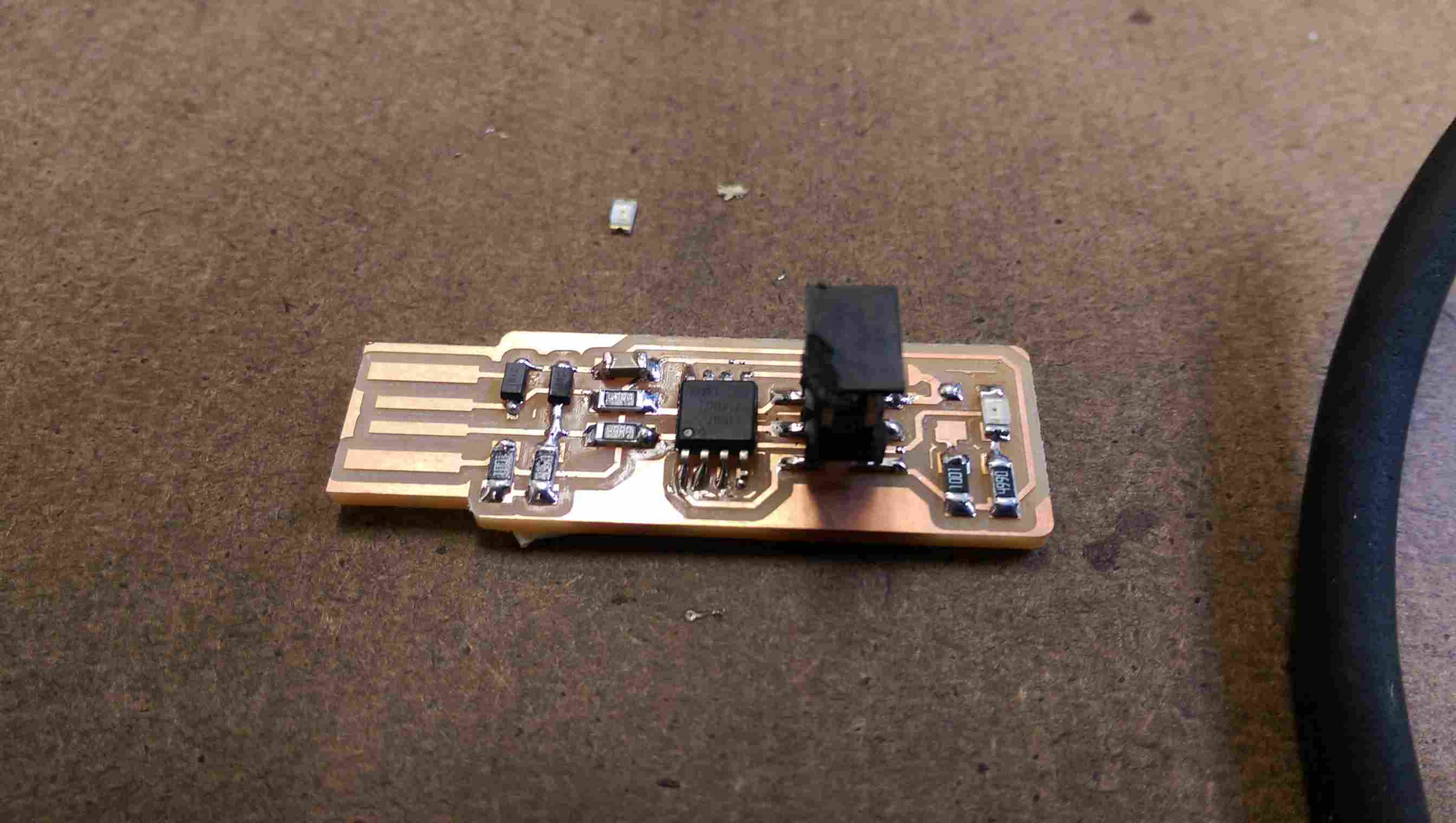

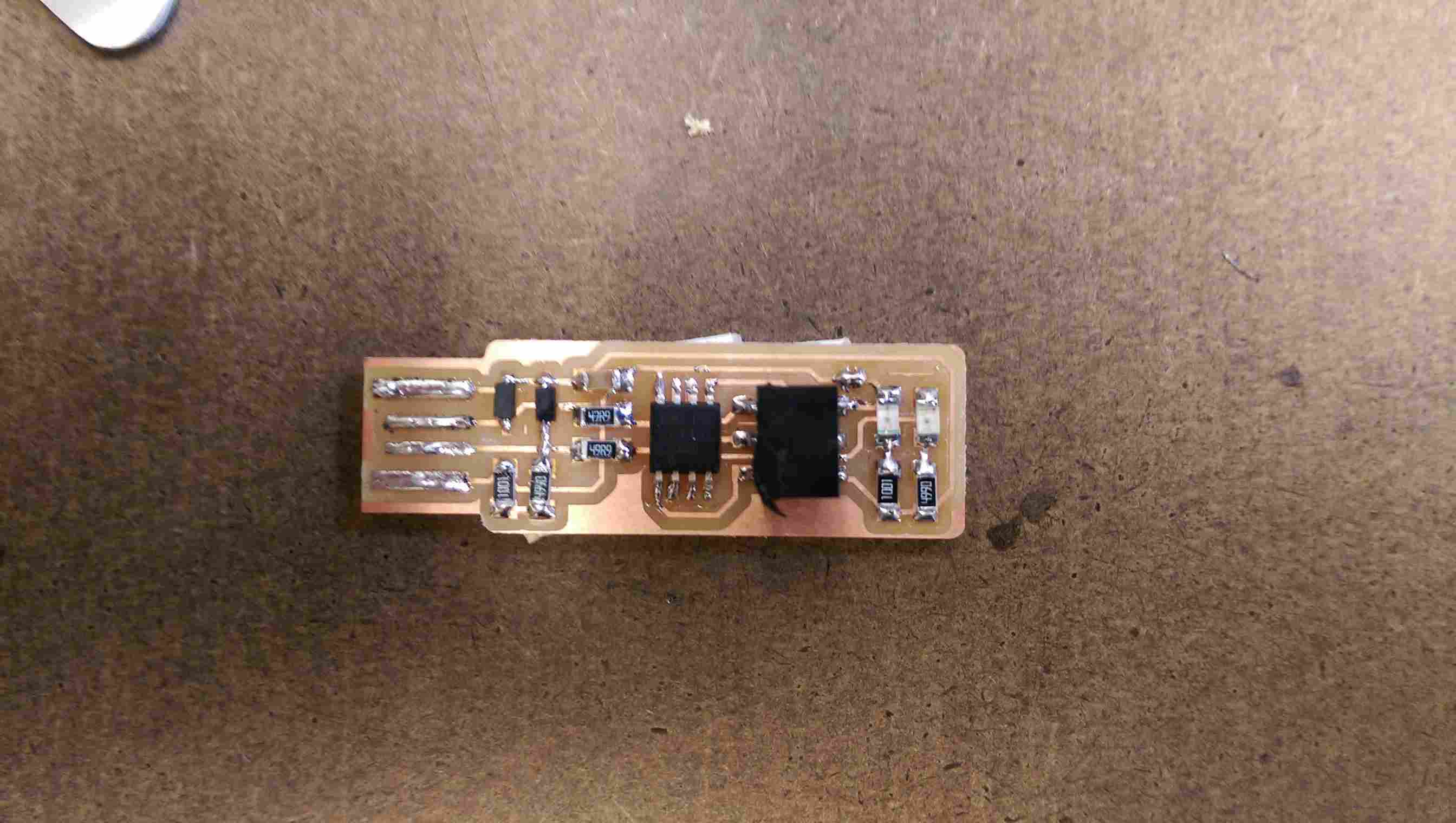

Fortunately there were other people soldering at the time, so they showed me the trick of putting a bit of solder down first to act as glue, letting it cool, and then reheating it as I placed the component to get it to stay in place. This took a bit of practice, but after the first few components, I was able to get in the zen state that Neil described in class.

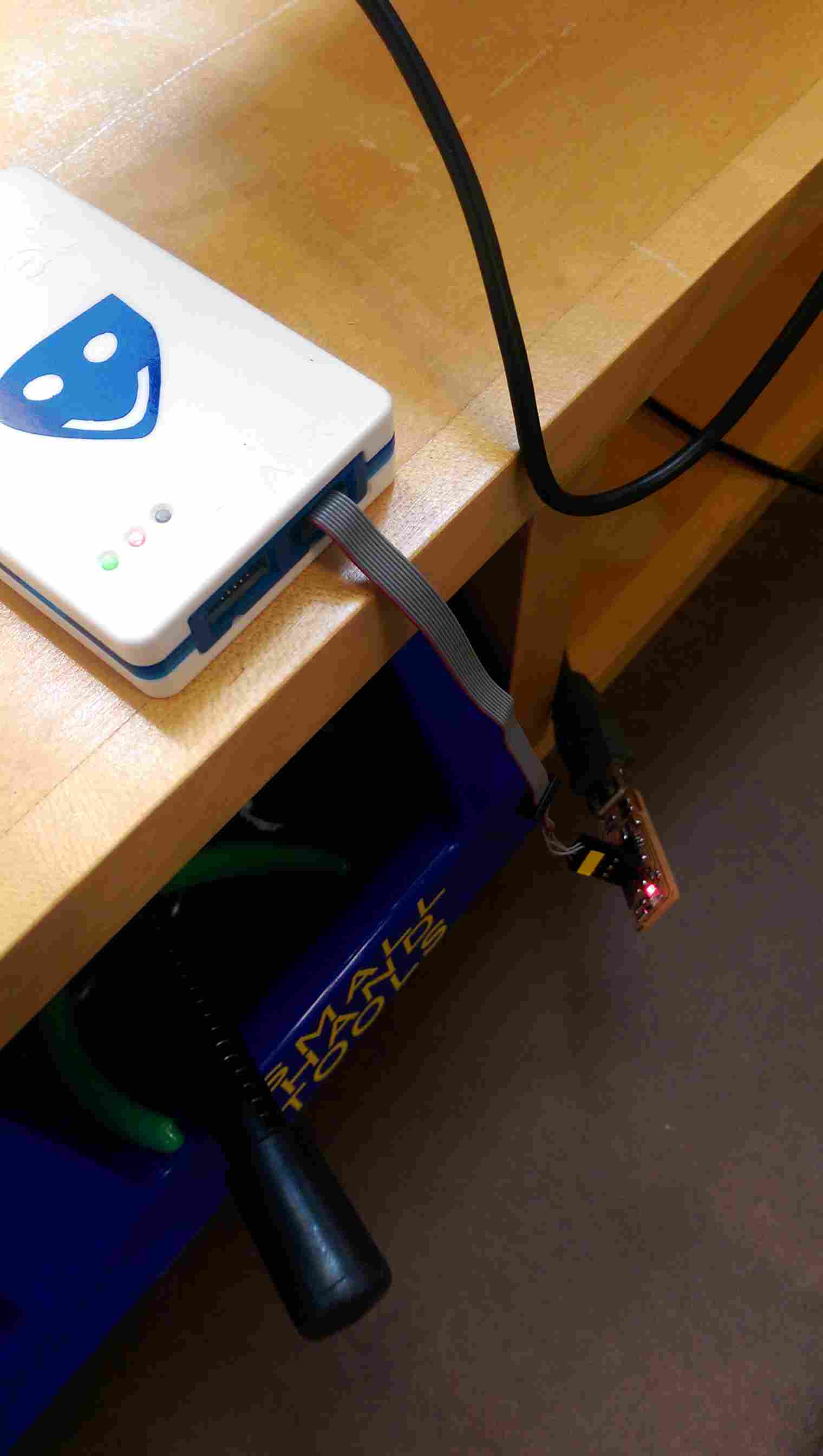

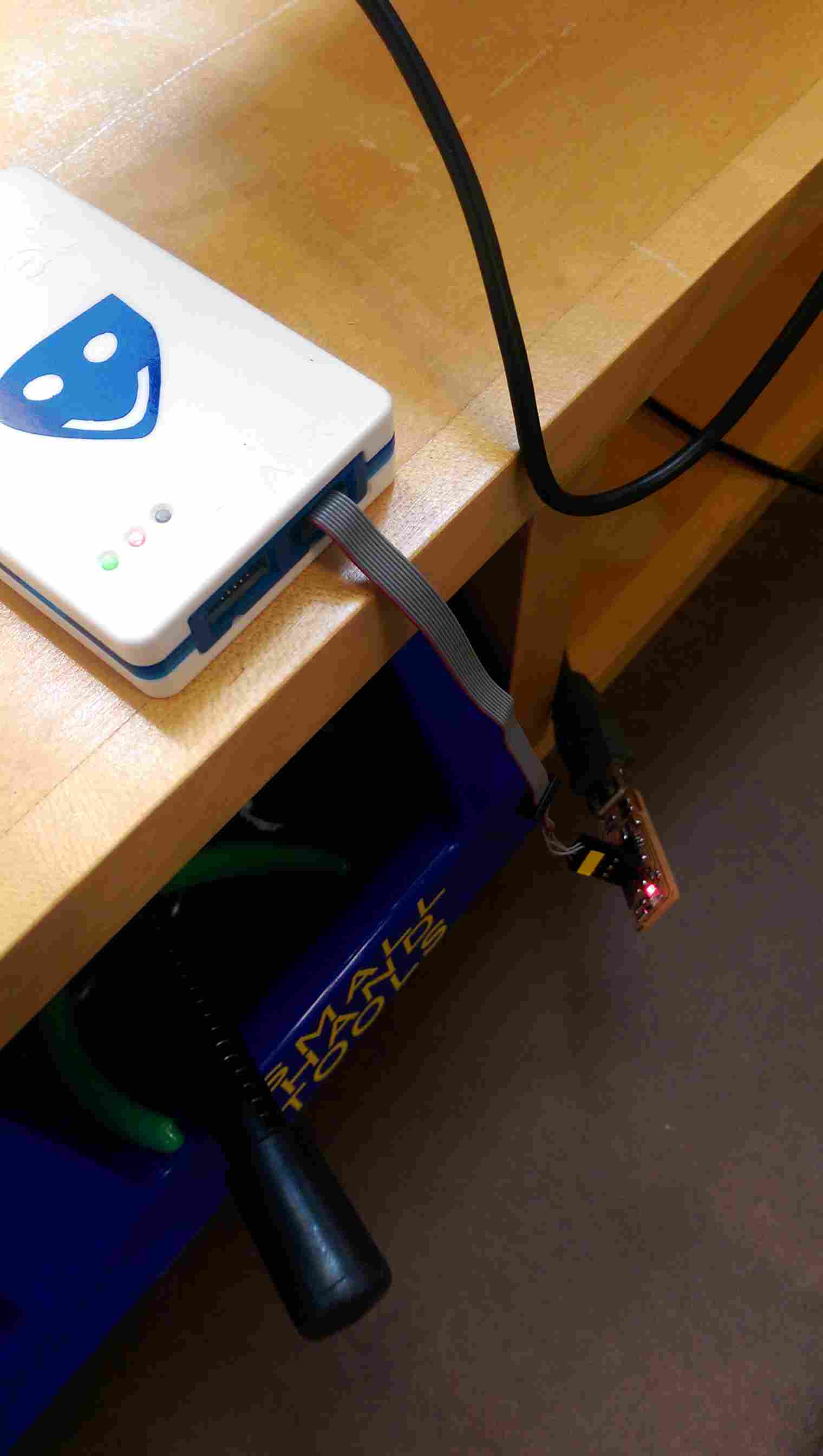

Once I finally finished soldering and my eyes got a rest from focusing on tiny things for so long, it was time to program my board, which was of course a buggy and somewhat painful process. After trying to install everything on my laptop and realizing (with Calvin’s help) that I had the wrong version of avrdude and trying it again on his laptop, still without success, I finally connected to a shop computer and managed to program the board. Finally, after a quick desoldering of the jumper bridge, I had a functional programmer!

Prior to this assignment, I had soldered a bit but only wires and switches and similarly large components and never circuit boards, and I had used wood CNC mills but not the smaller desktop mills, so I learned a lot this week. Shoutout to Justin for providing a great introductory lesson on milling and soldering and to Calvin for helping me figure out how to program my board.

When it came time to actually machine my board, it took a couple of attempts to get it right. While I was very careful to apply double-sided tape so that there were no bubbles or overlaps, I first tried to line up my board in the machine so that it was up against the edge of the underlay, an area which I quickly learned was not quite flat.

After machine a board that had a dramatic gradient from deeply engraved to not touched at all, I figured the best move would be to try again in a different spot in the machine. The underlay was still fairly new, so I positioned my stock closer to the couple of cutouts already on the underlay, figuring I would learn from the successes of my classmates who had machined before me. This time I was much more successful.

As I moved on to soldering, I quickly realized that soldering is a three-hand job, so I, being a typical two-handed human, needed to find a workaround.

Fortunately there were other people soldering at the time, so they showed me the trick of putting a bit of solder down first to act as glue, letting it cool, and then reheating it as I placed the component to get it to stay in place. This took a bit of practice, but after the first few components, I was able to get in the zen state that Neil described in class.

Once I finally finished soldering and my eyes got a rest from focusing on tiny things for so long, it was time to program my board, which was of course a buggy and somewhat painful process. After trying to install everything on my laptop and realizing (with Calvin’s help) that I had the wrong version of avrdude and trying it again on his laptop, still without success, I finally connected to a shop computer and managed to program the board. Finally, after a quick desoldering of the jumper bridge, I had a functional programmer!