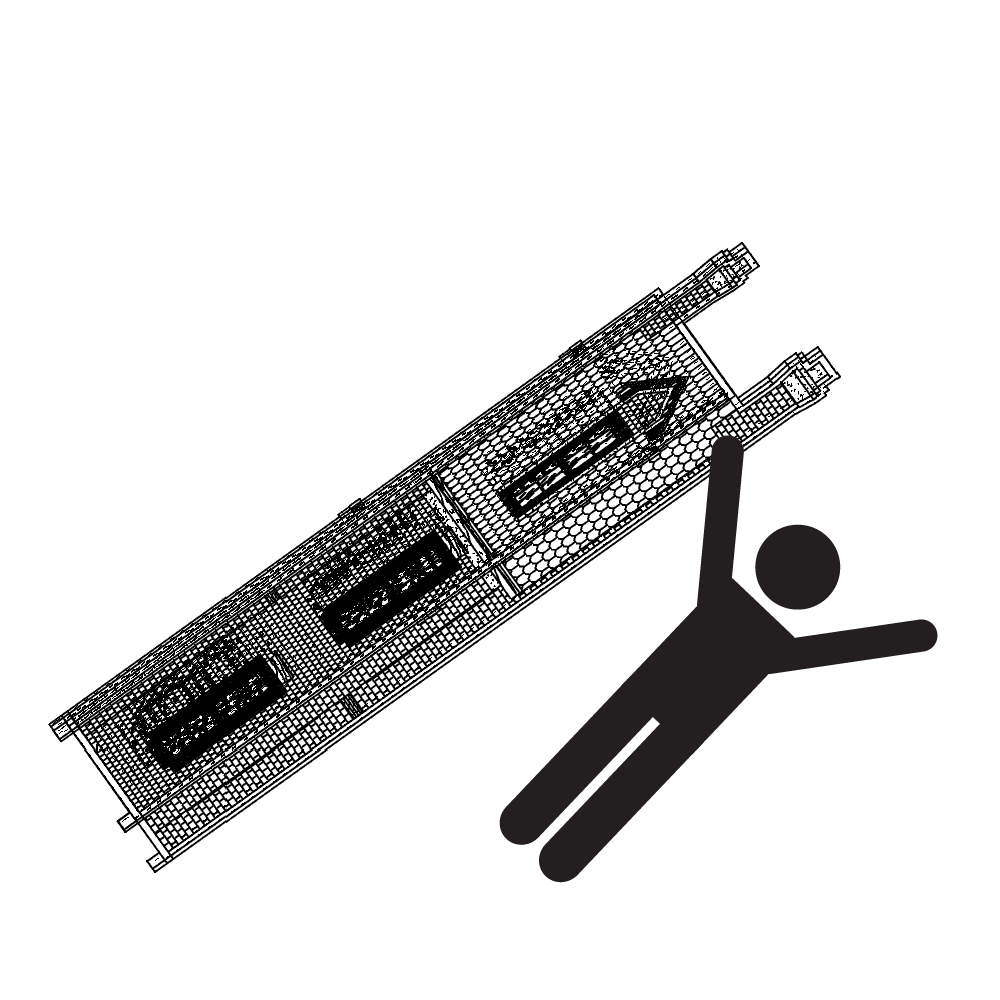

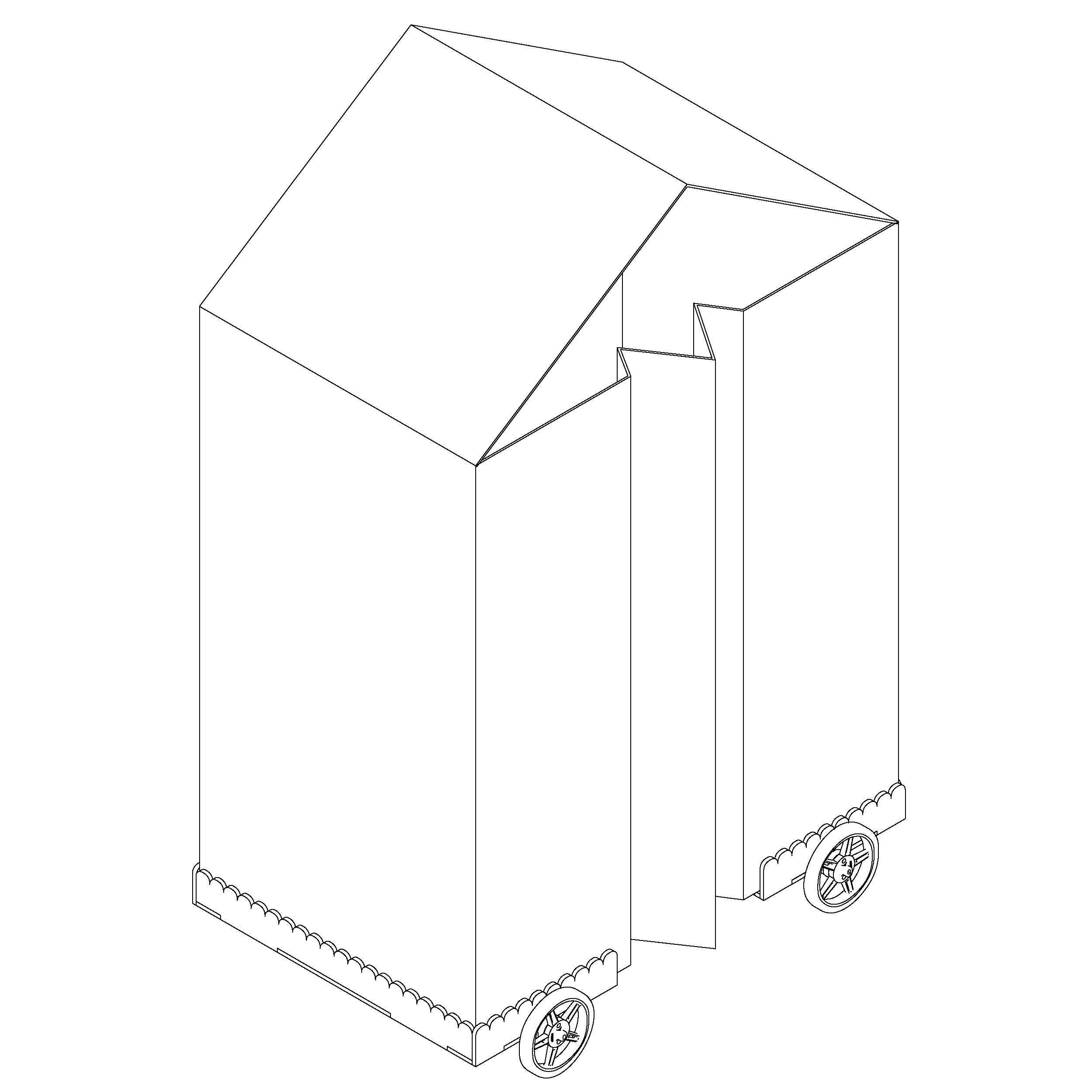

Mobile Home is a Home that is Mobile. The project succeeded in meeting the goals set forth in the final project proposal. Specifically looking at folding mechaninisms for a compressing and decompressing robot.

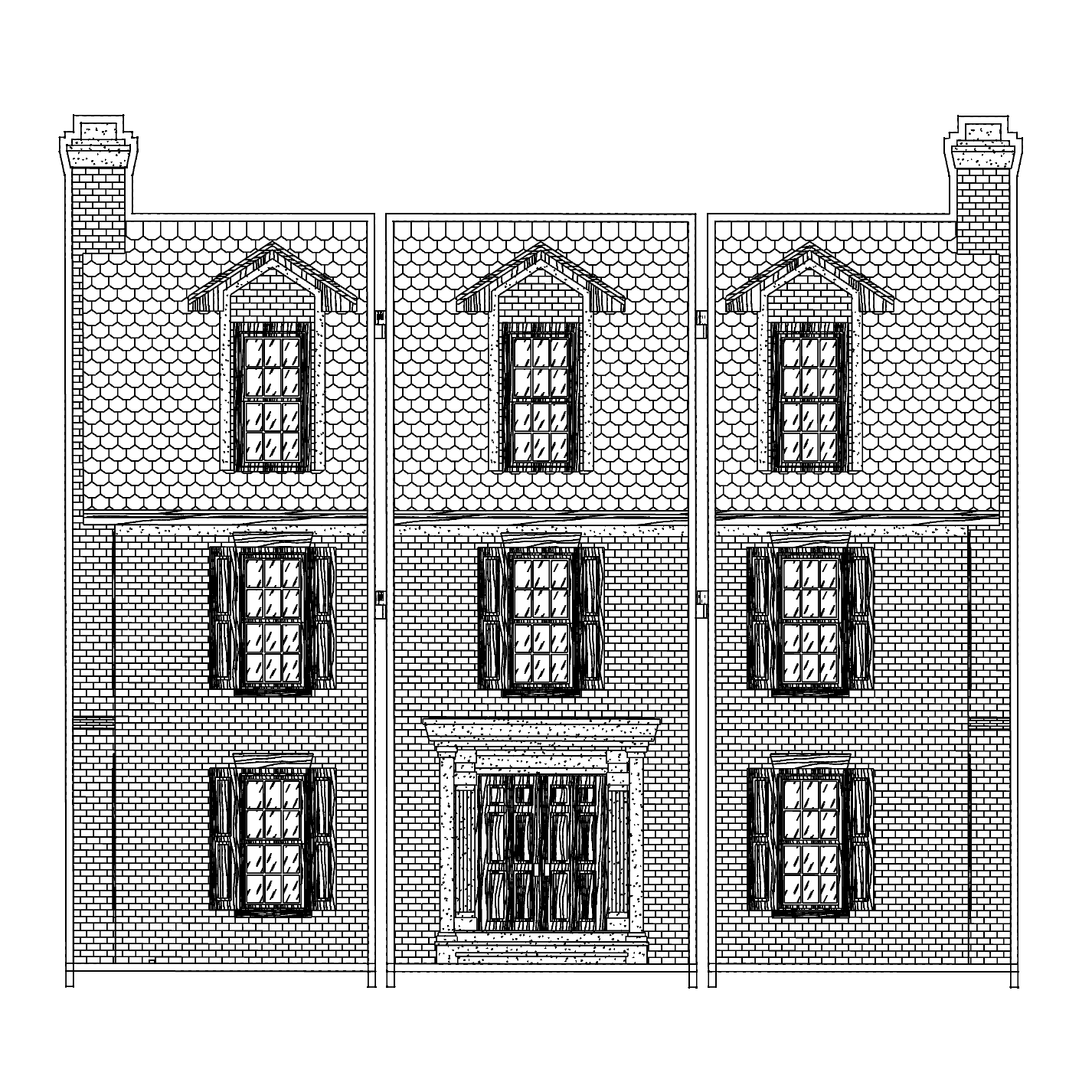

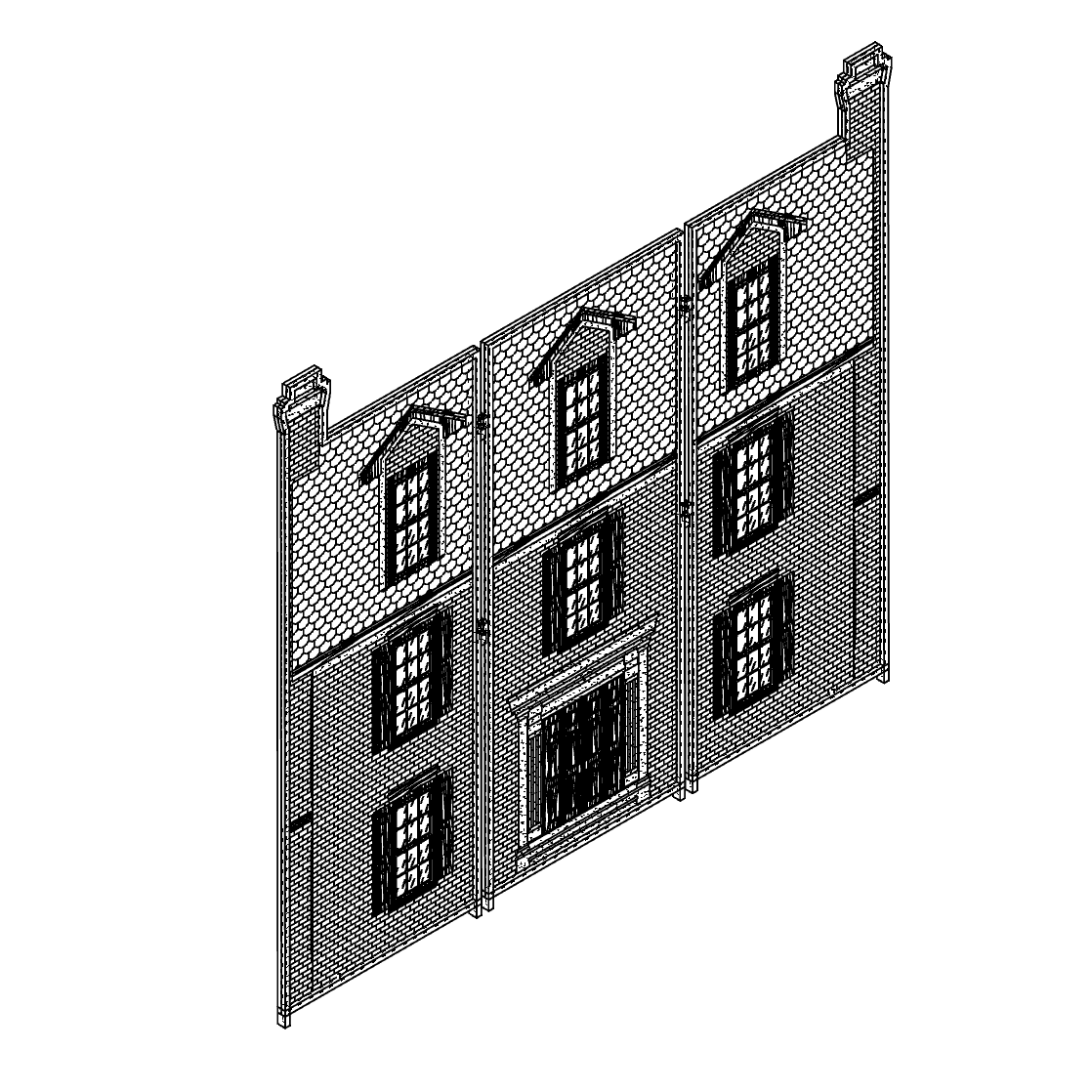

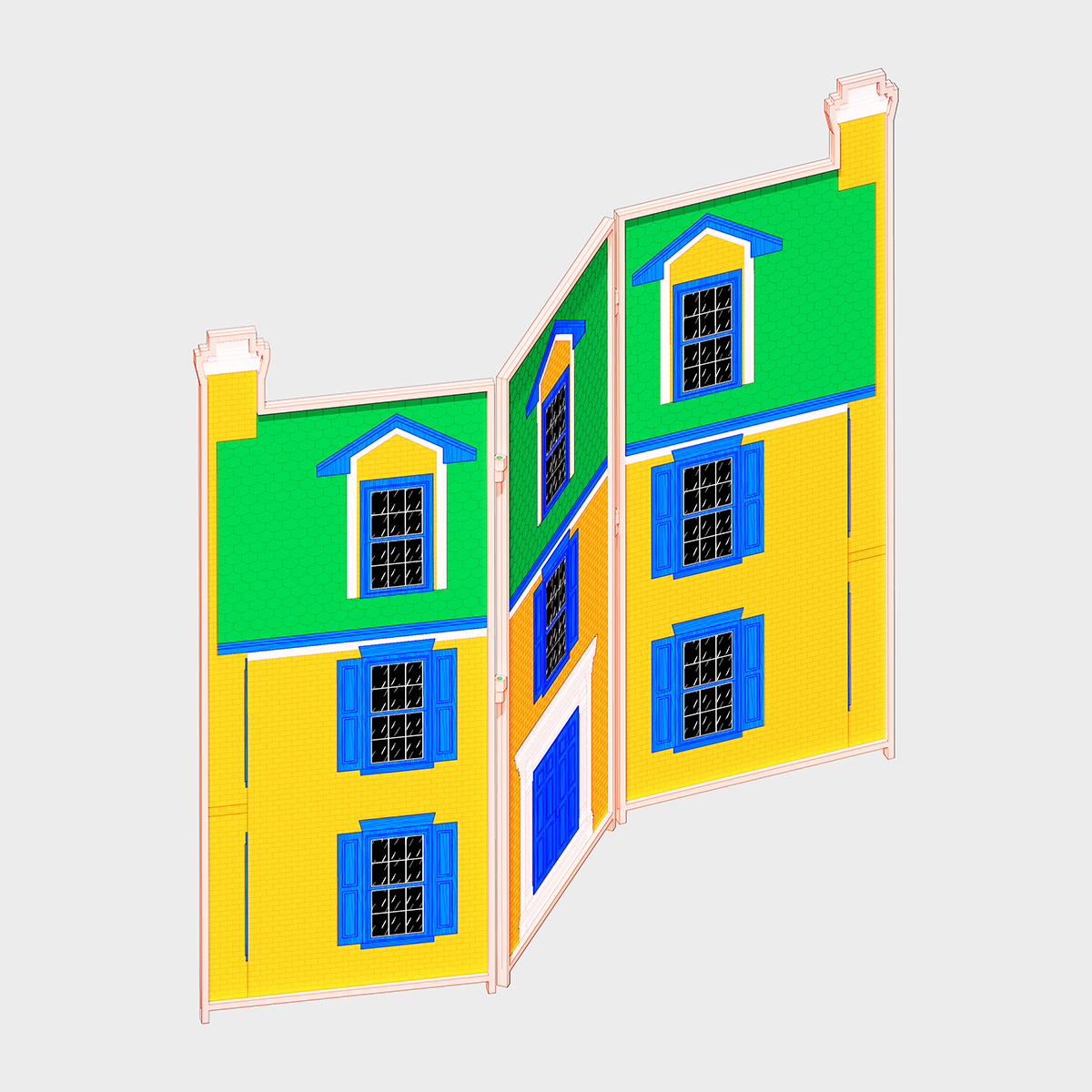

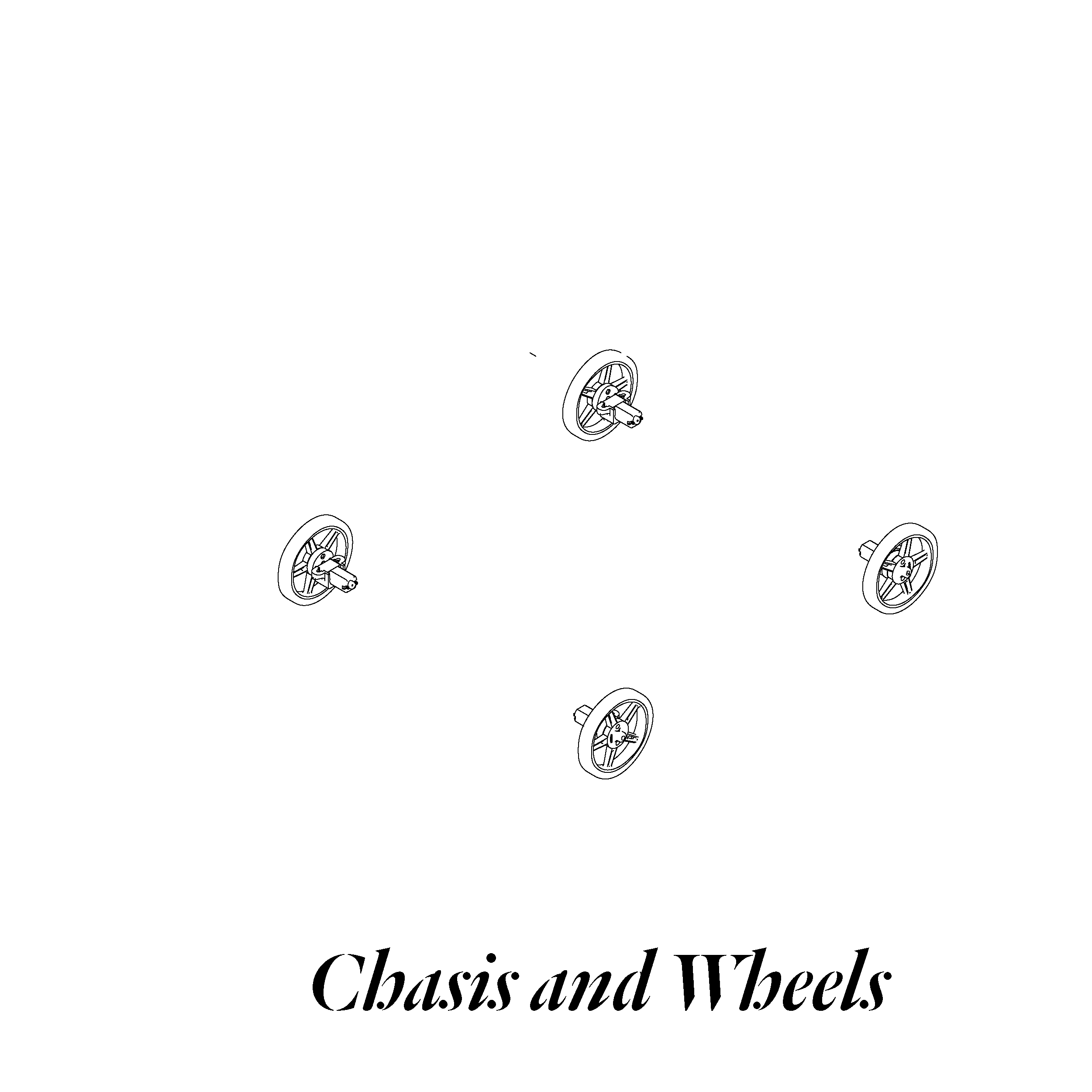

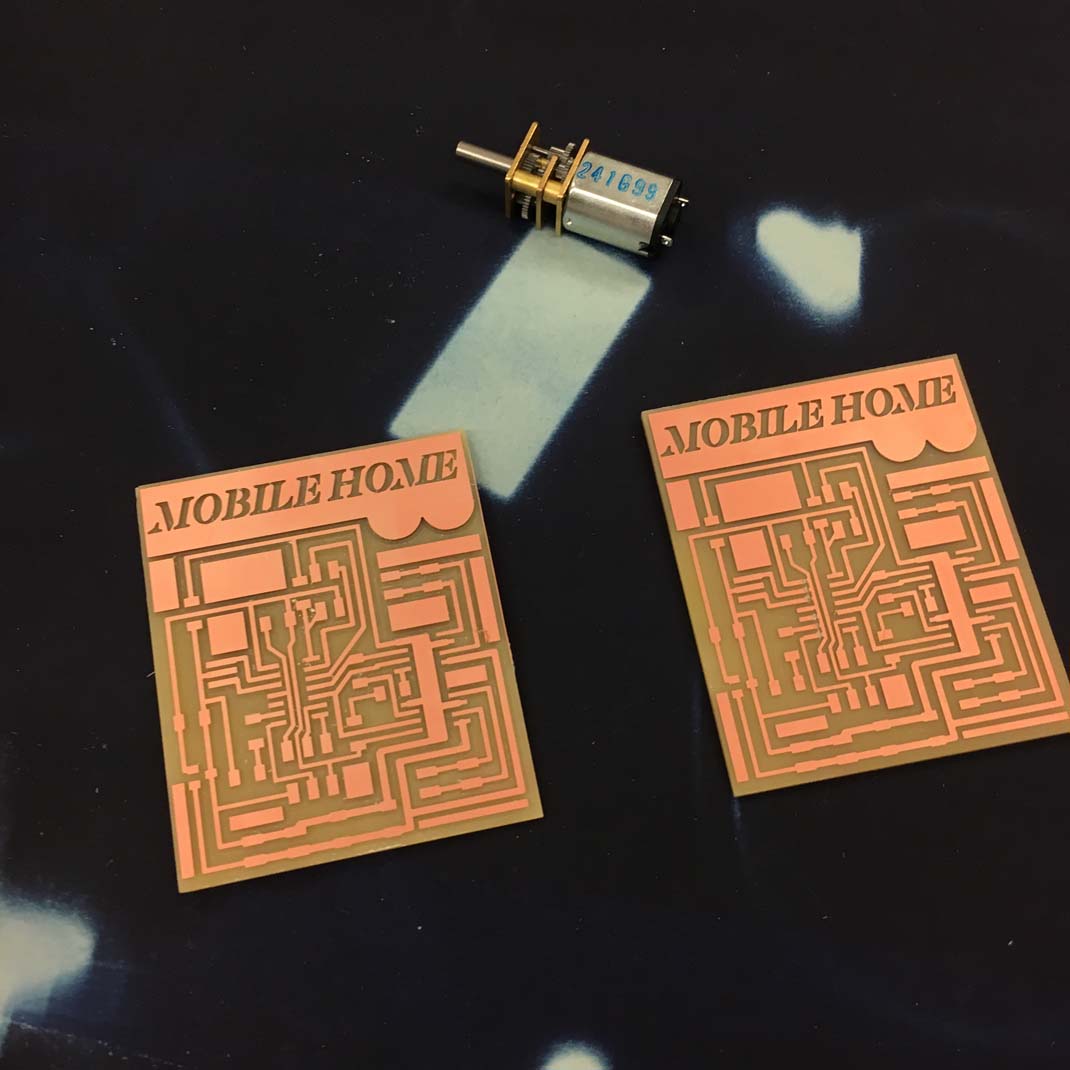

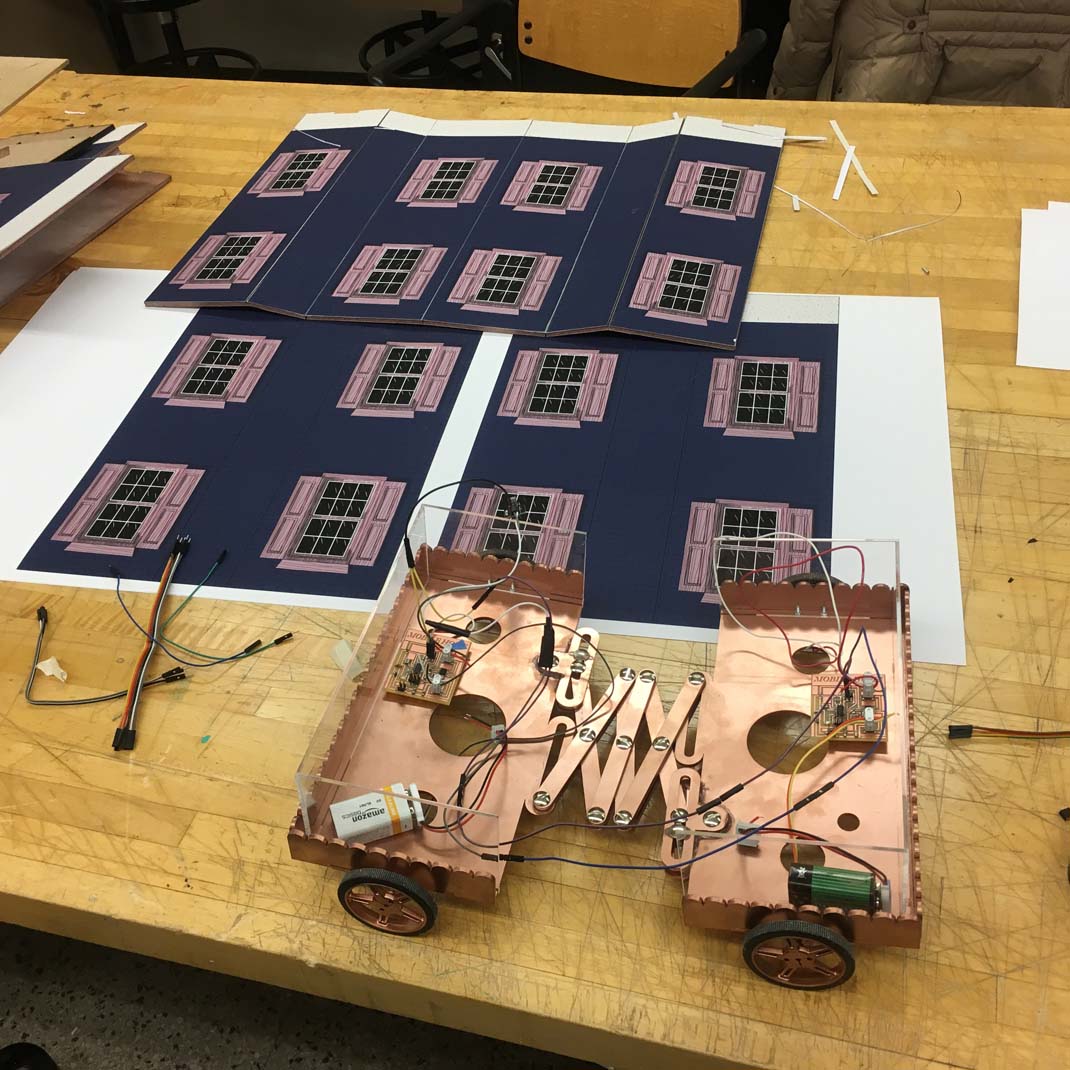

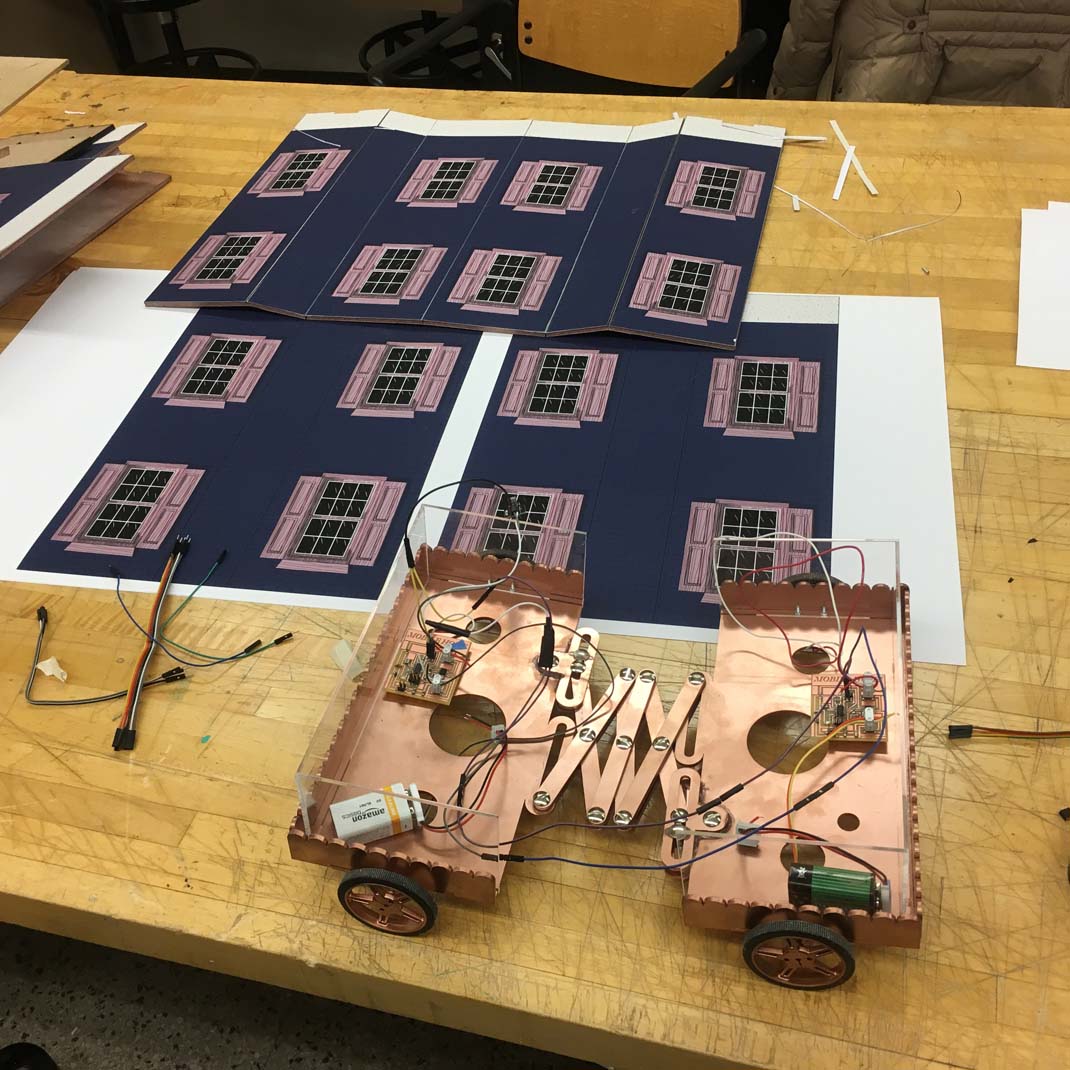

The inspiration for the project came from Japan Byobu / Shoji screens. I wanted to make a walking one in the form of a typical Georgian style home. The final project was done for less than $100. THe most expensive portion of the final outcome was the 4 small gearbox reduction DC motors that are attached to each of the 4 wheels.

This project stems off of the vary many movable structures that have been produced within fab labs. I was not able to find one that resembles the same style and soul that Mobile Home exhibits. In the end Mobile Home is a robot that walks like an accordion - a two part step, I want to further advance the project over IAP to really look at and study the flexibilities of brackets in robotic and machine design - and look at various ways we can start to mend and transform the built environment. The next logical step for me, the next circle of development, would be looking at the possibility of all 4 wheels moving independently of eachother - this would result in substantial study of both flexible materials and a chassis that can handle 4 different movements.

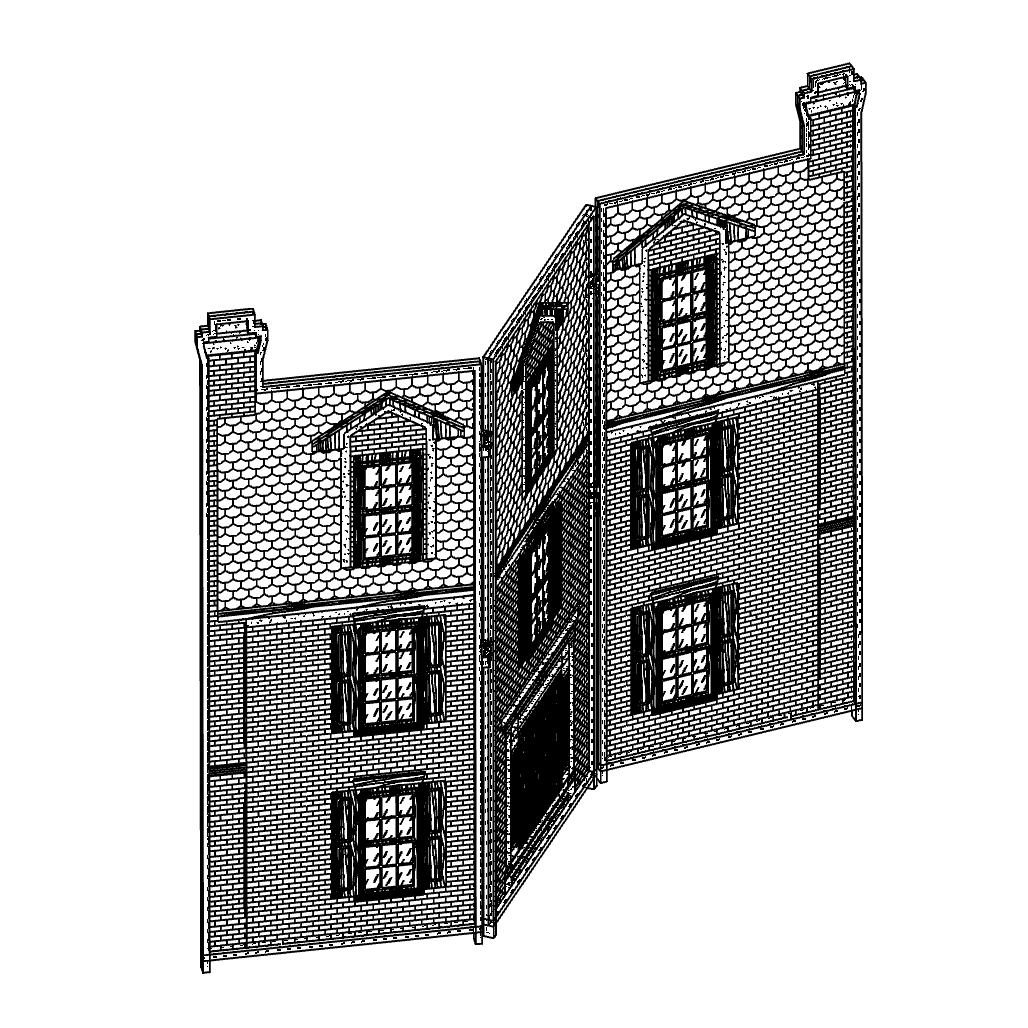

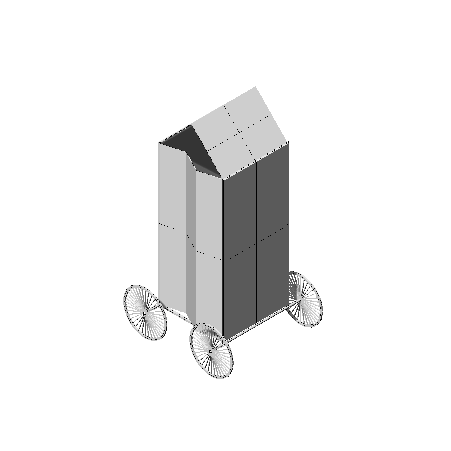

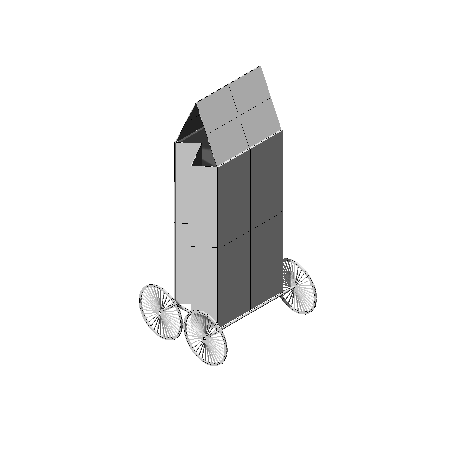

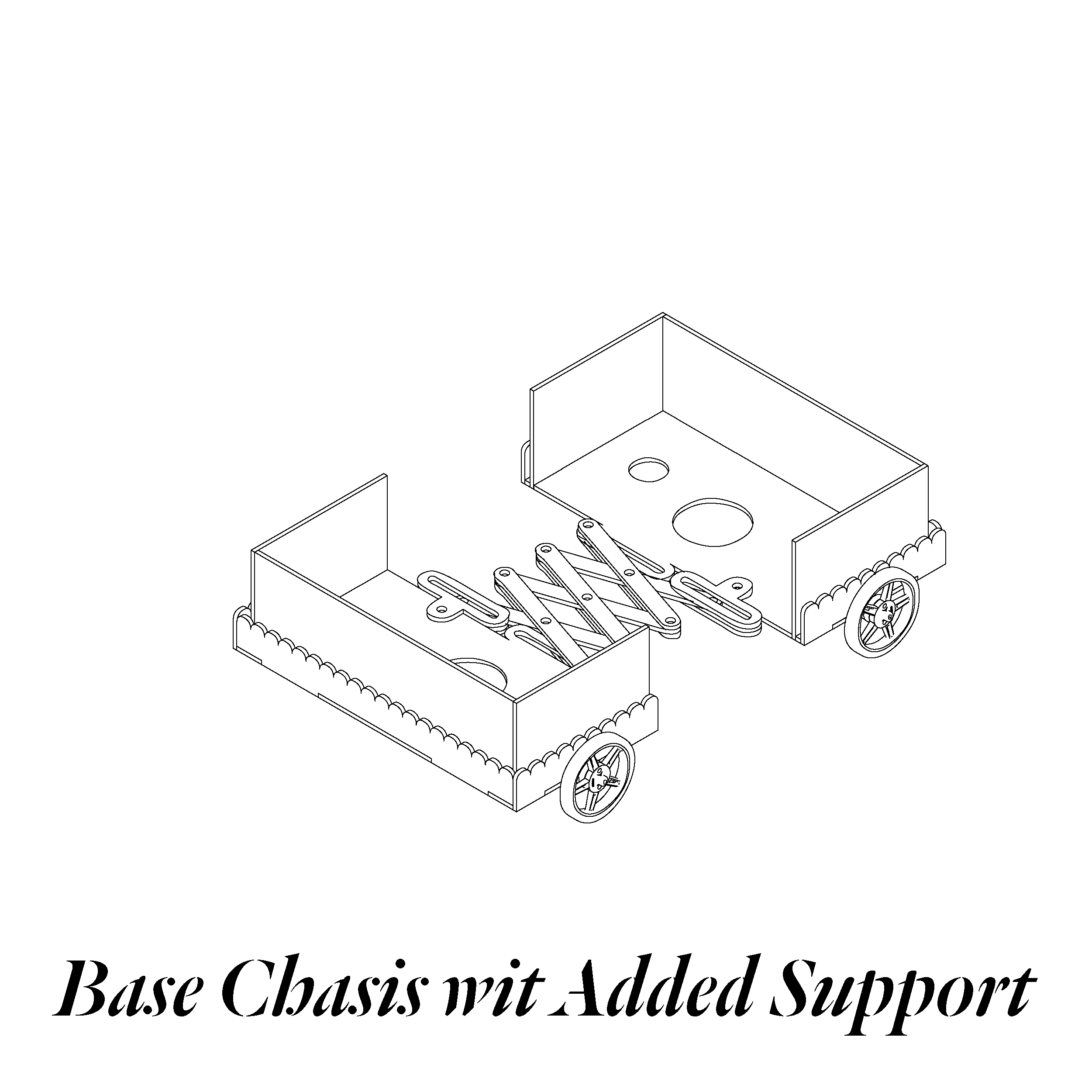

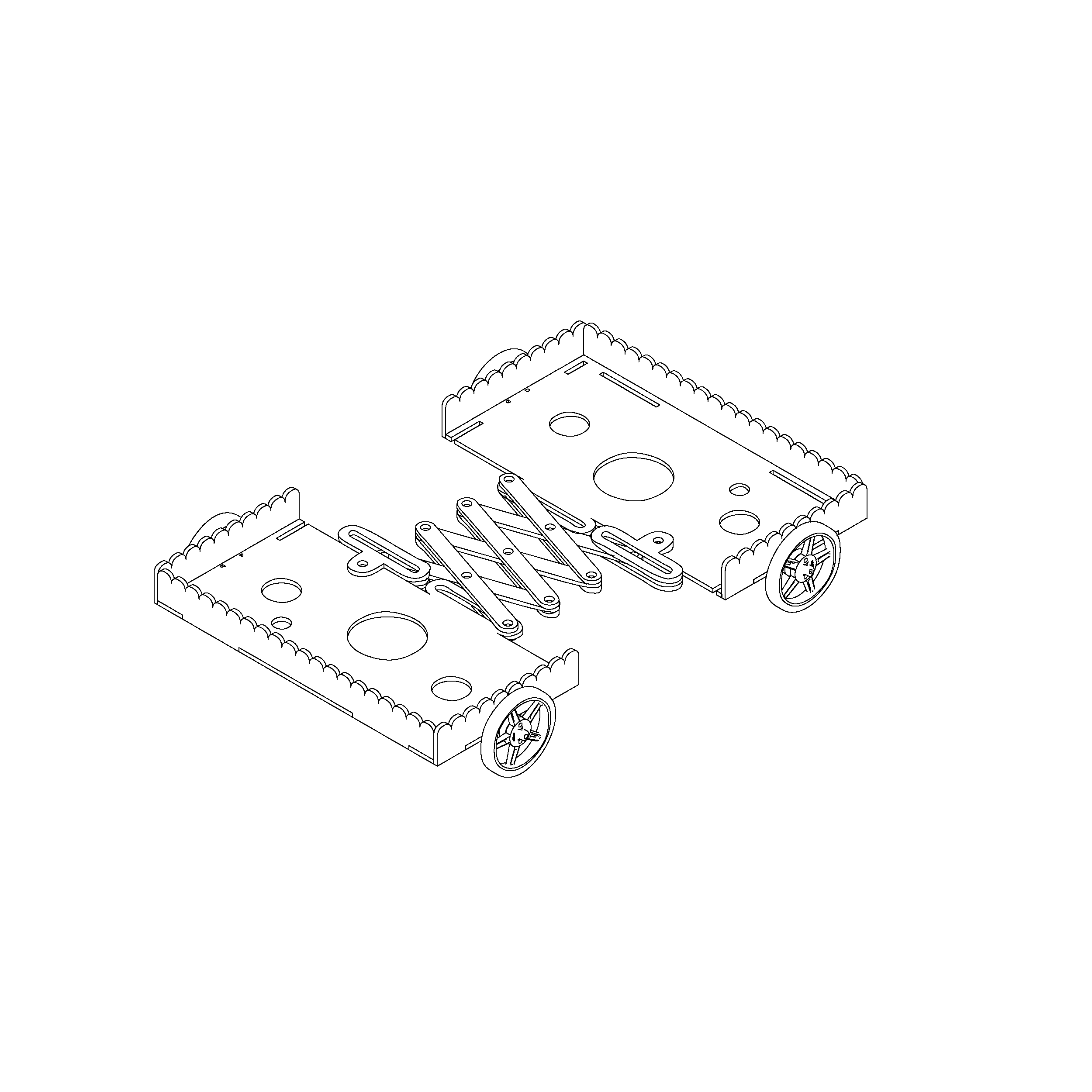

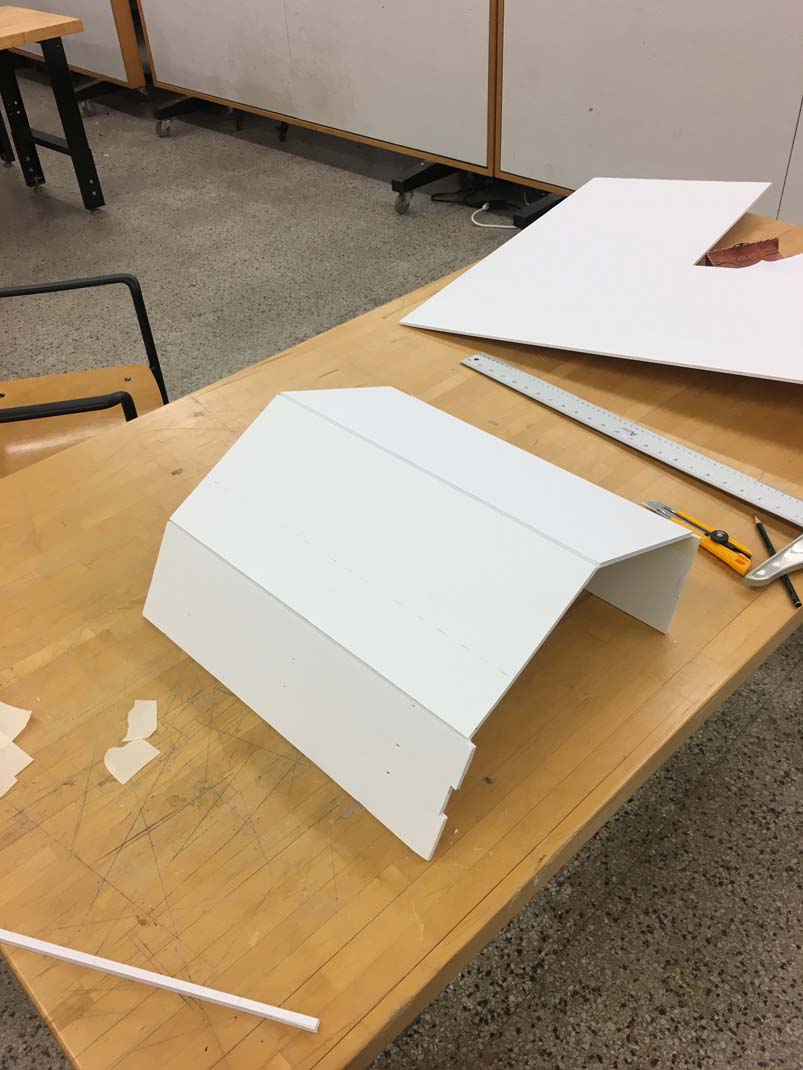

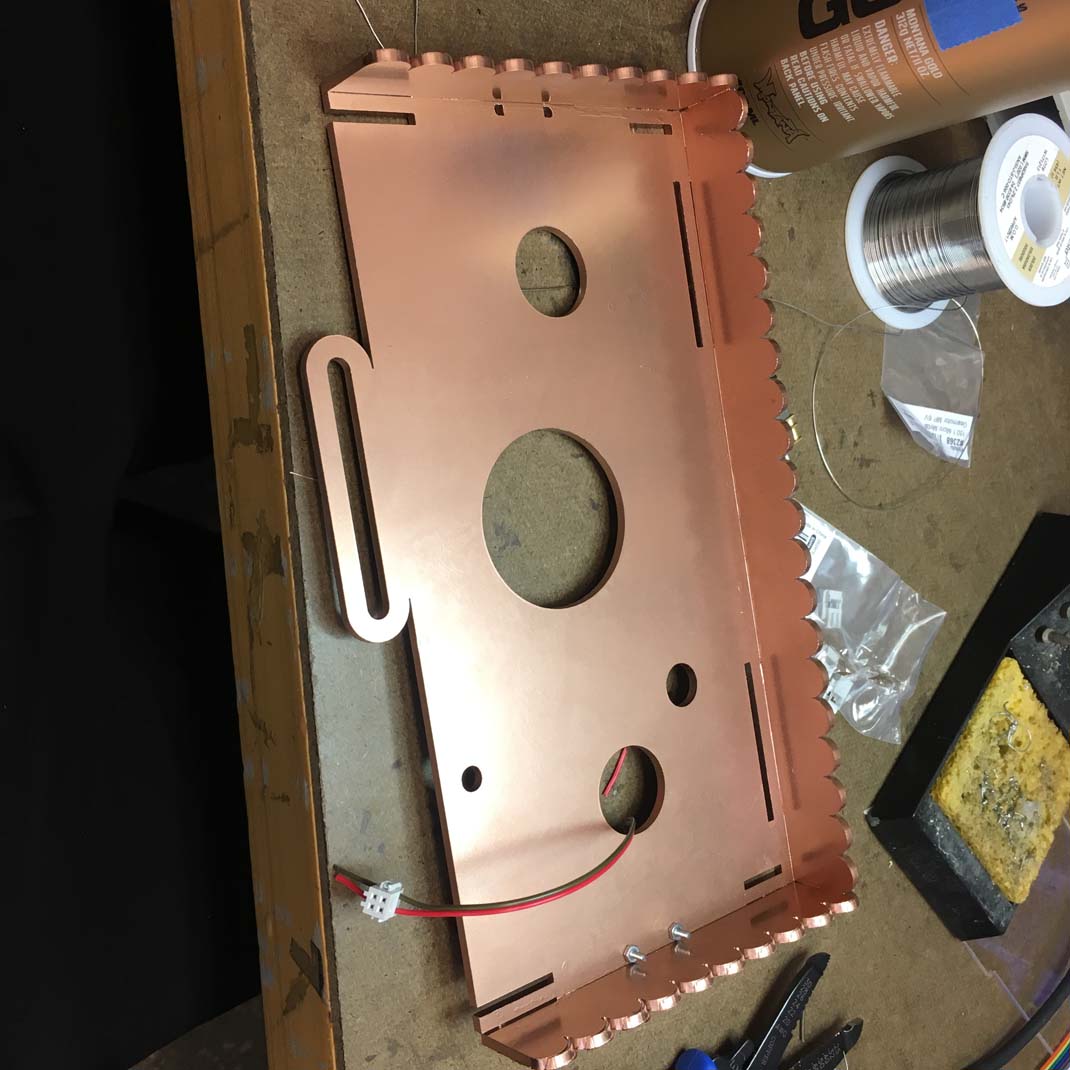

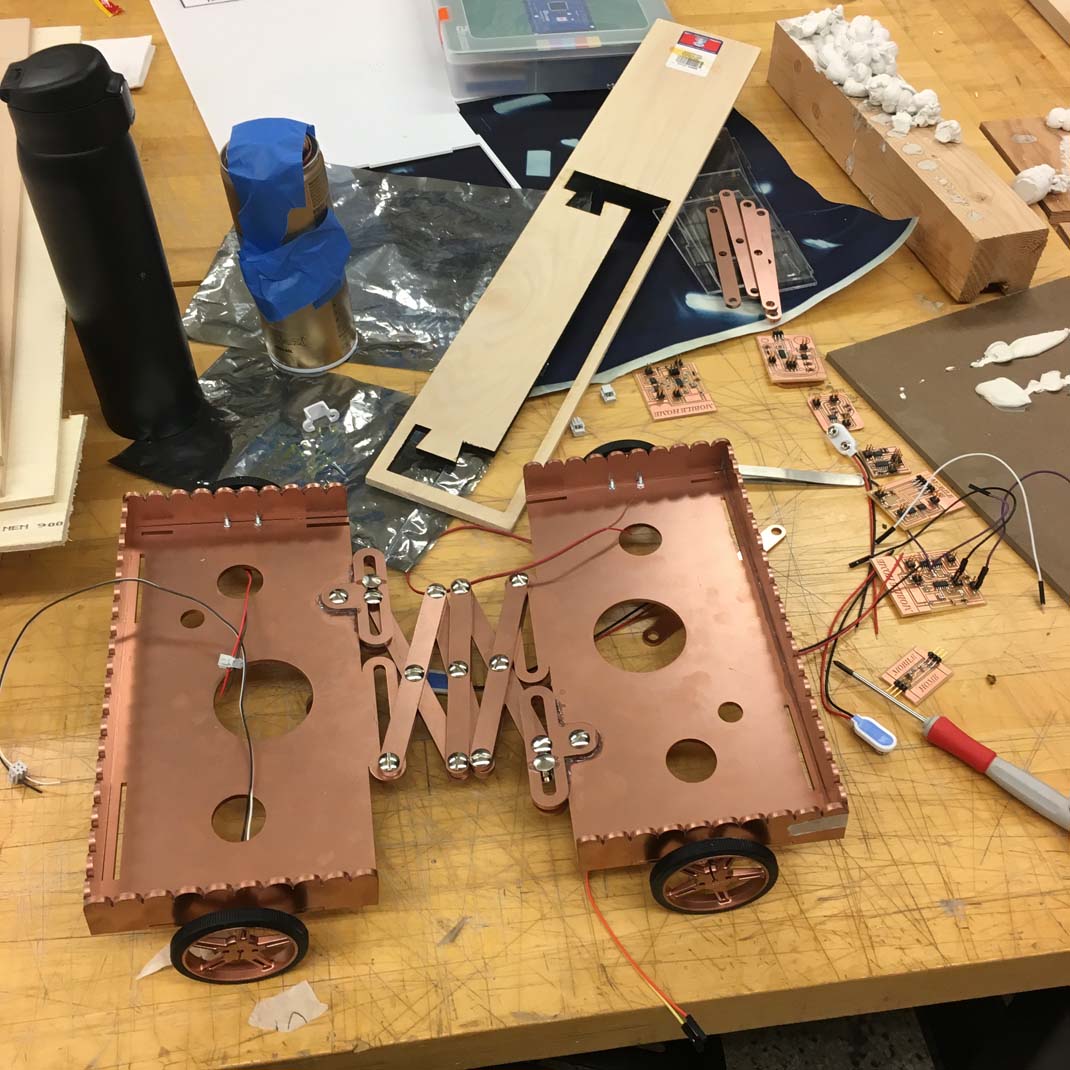

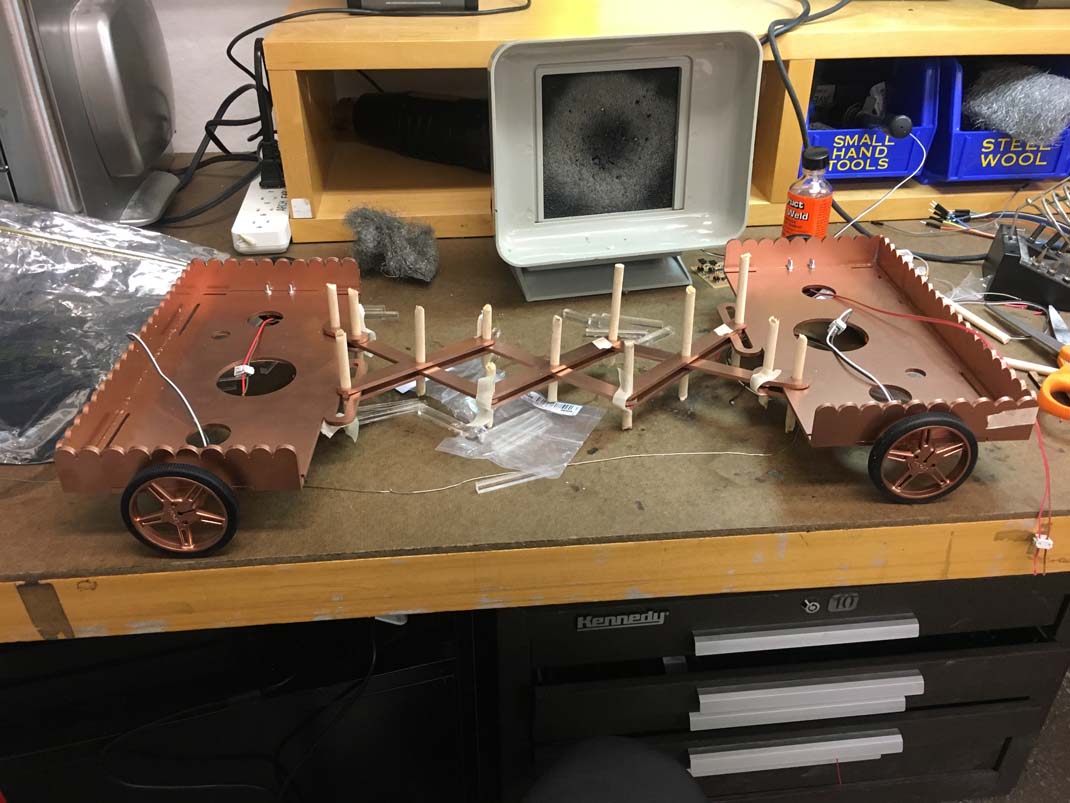

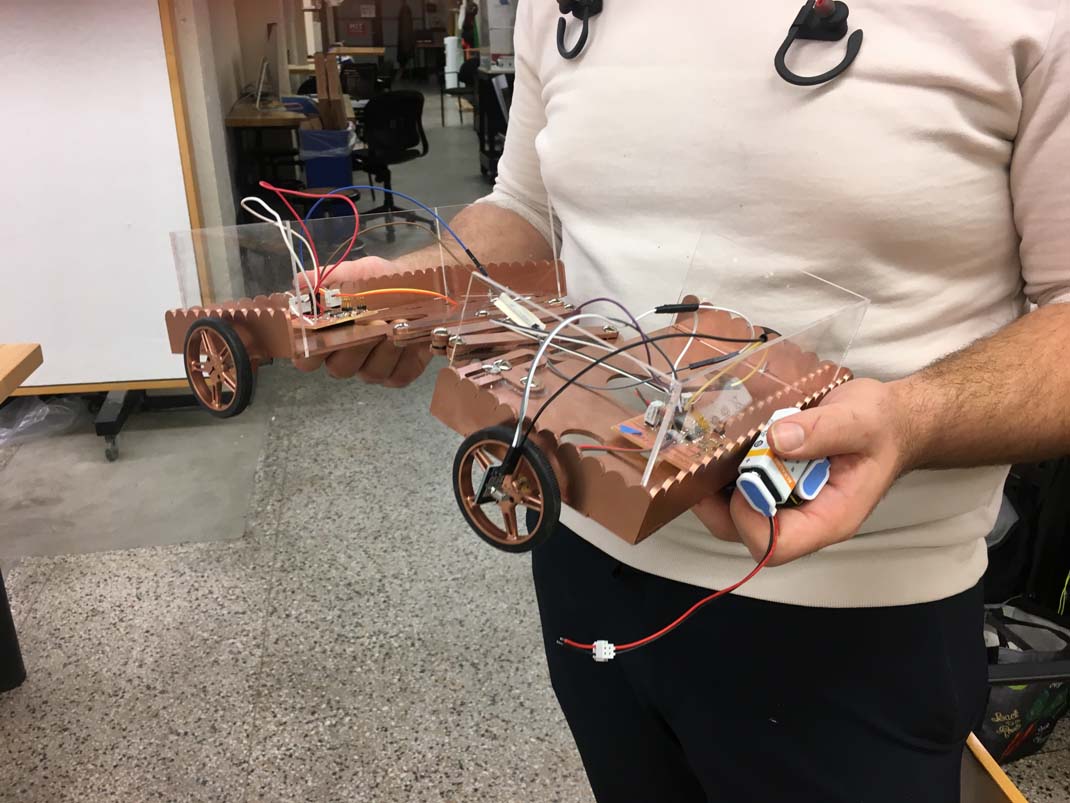

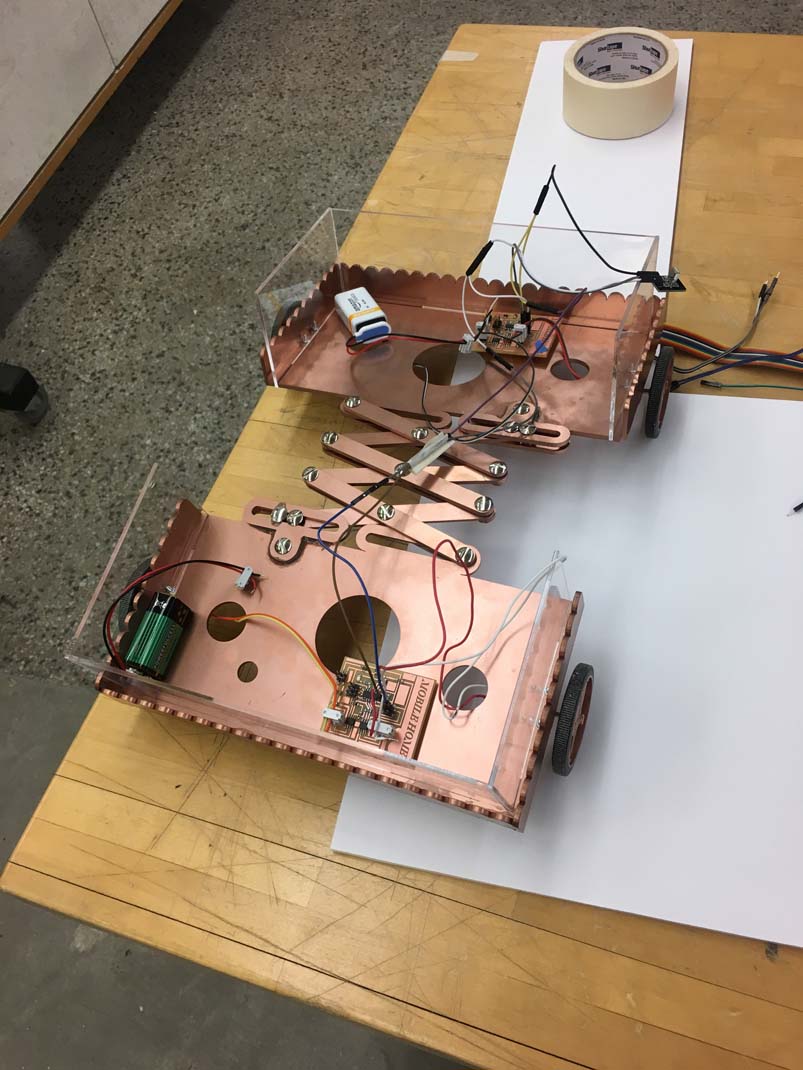

The design for Mobile Home was primarily based on two factors - the folding form of Mobile Home and the position that the motors needed to be in. This led to a flexible accordion style body and a plank chassis with an scissor bracket which would allow Mobile Home to open and the close.

The scissor bracket was the most vital component of the house and I should have anticipated it to be far more of an issue than I gave myself time to deal with. I kept rigging the first take o nthe scissor bracket but in reality I wish I had the time to redesign the bracket ro mthe beginning to be more sturdy. I found out that the bracket is not stable without a caster type object holding up each side of the plank chassis'.

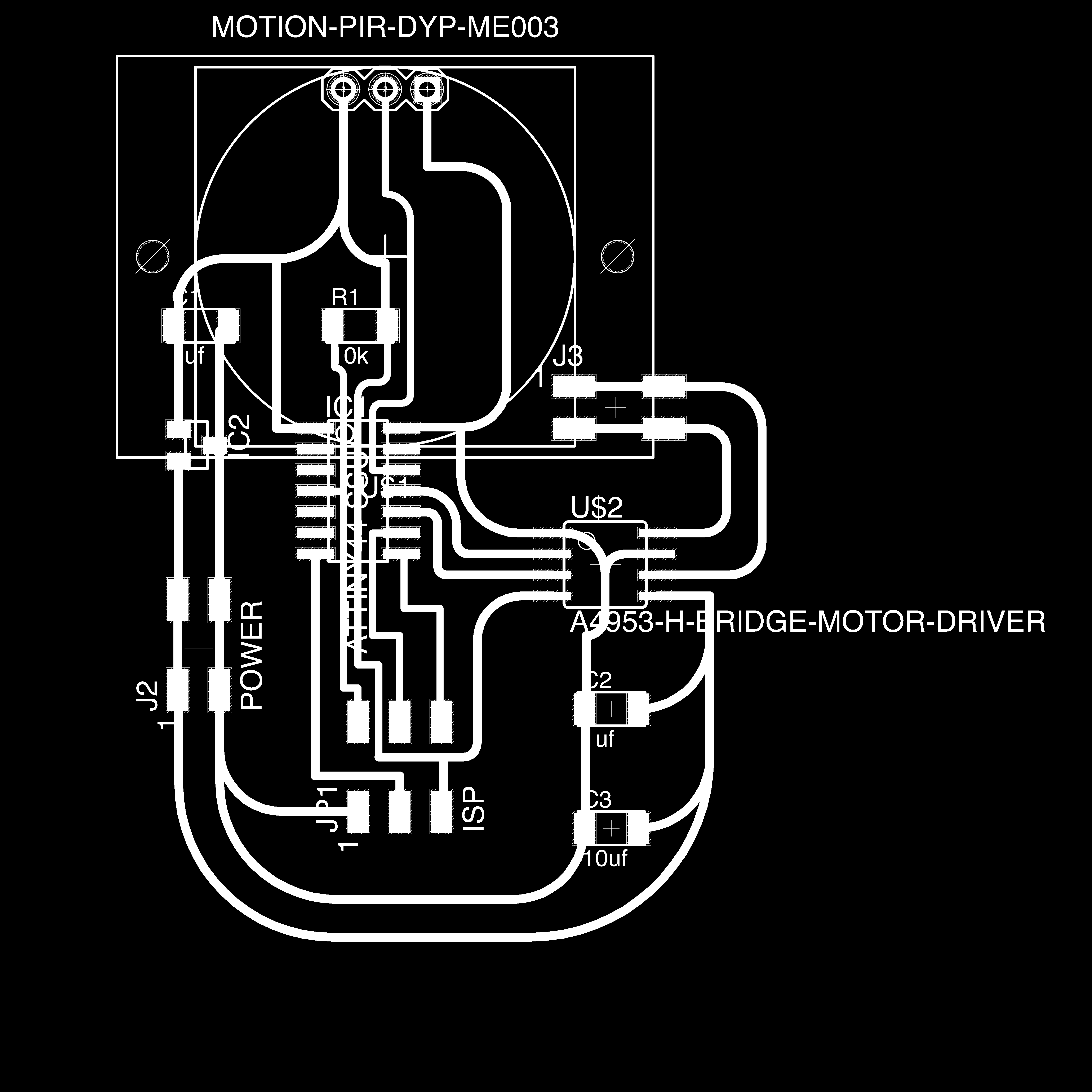

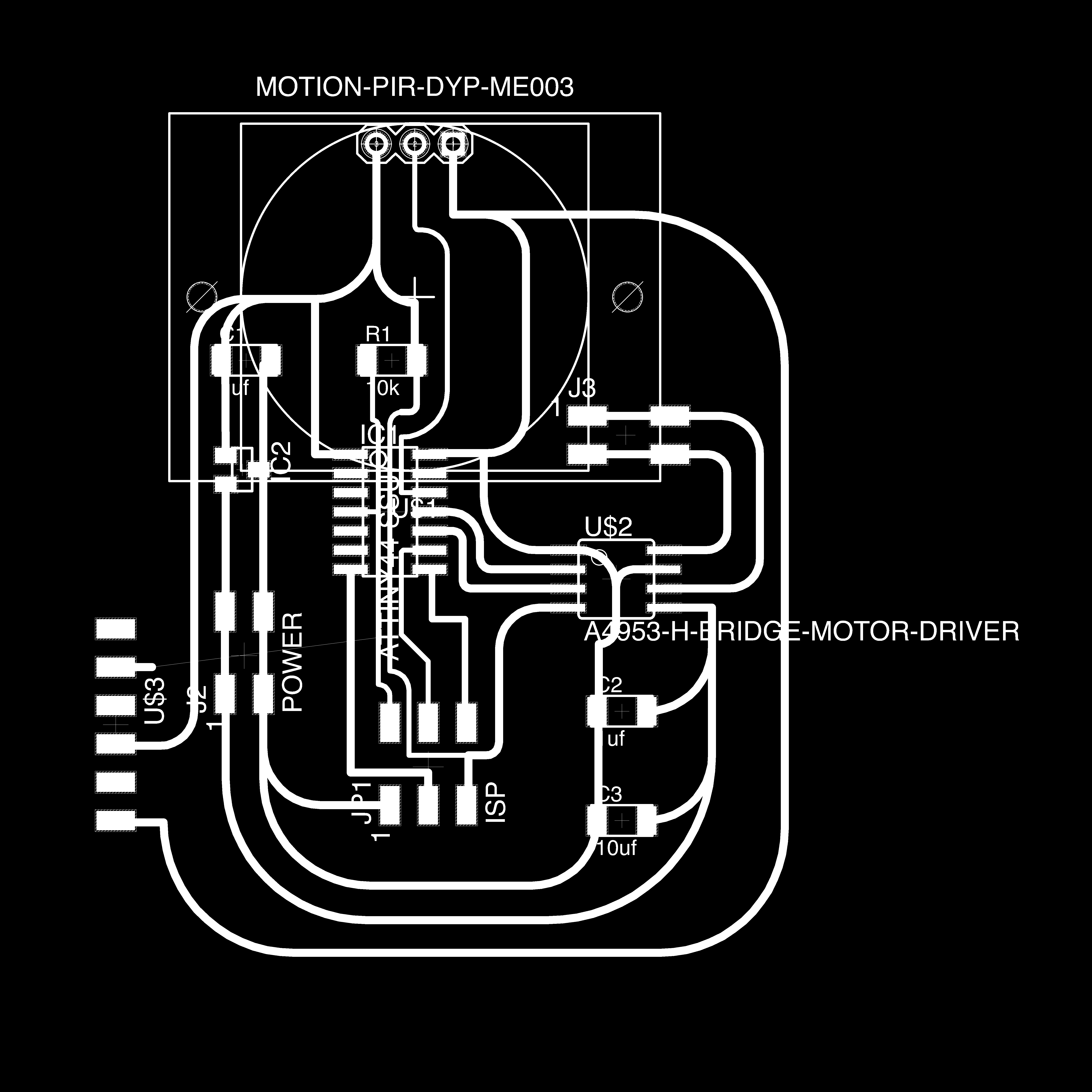

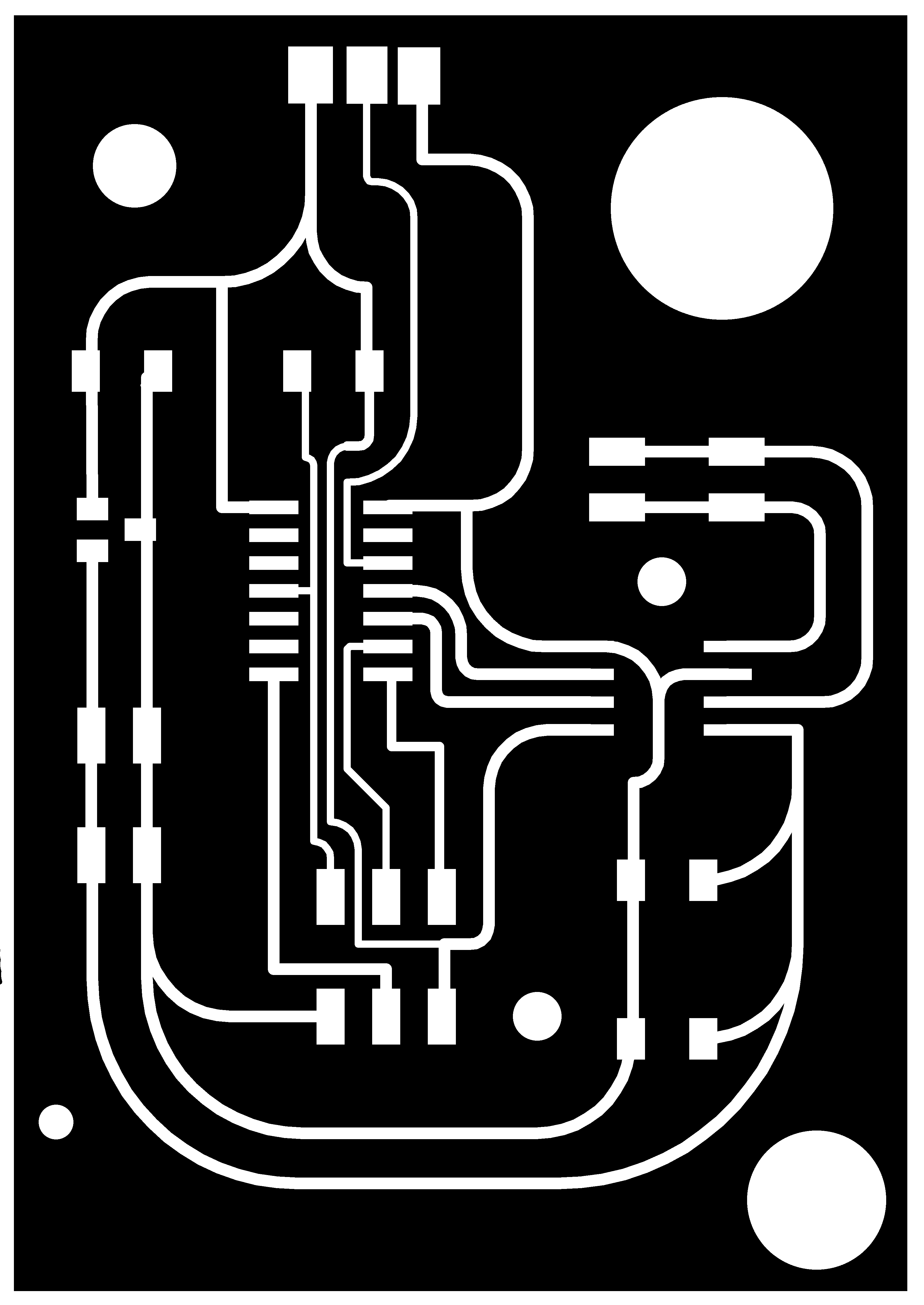

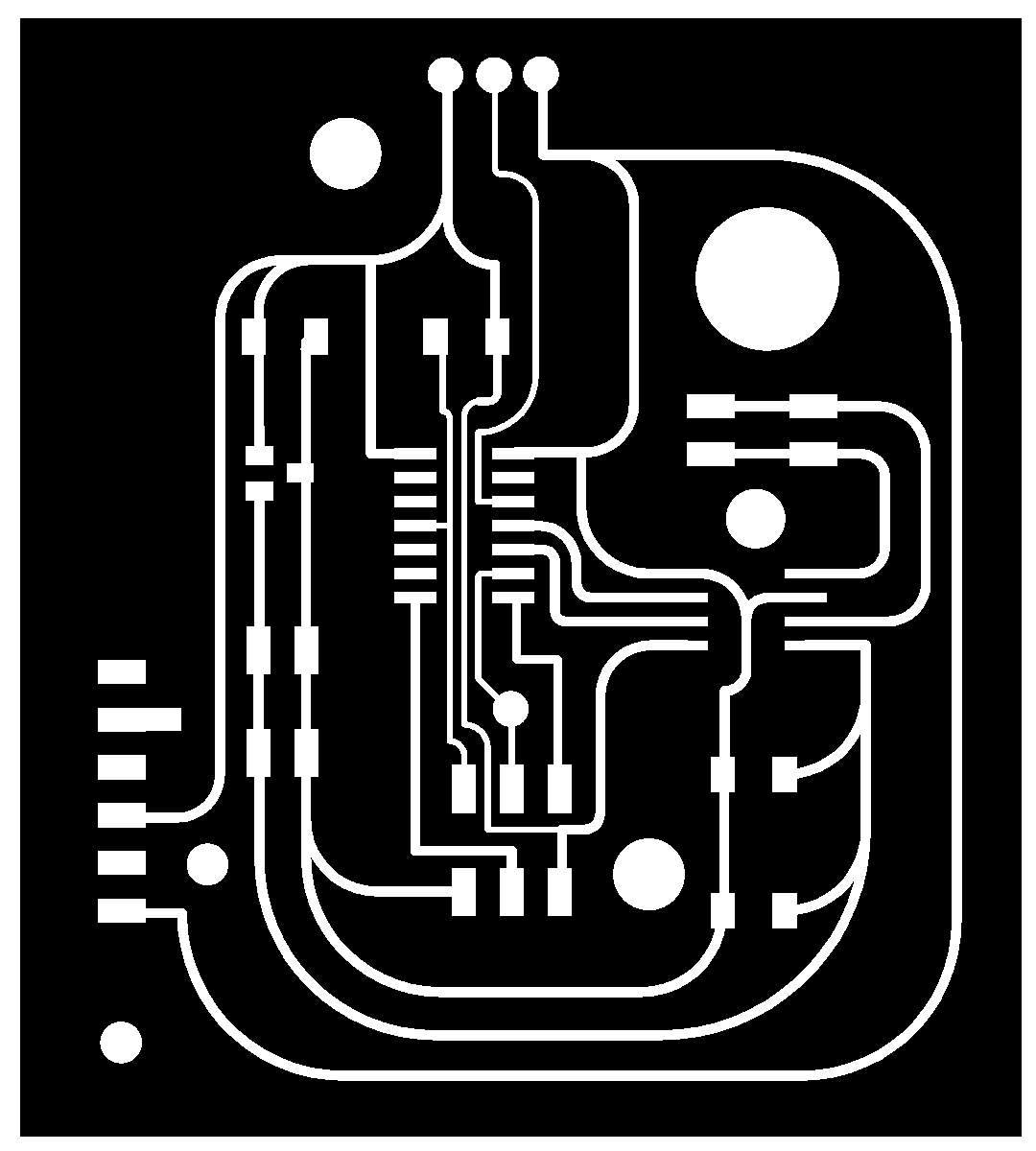

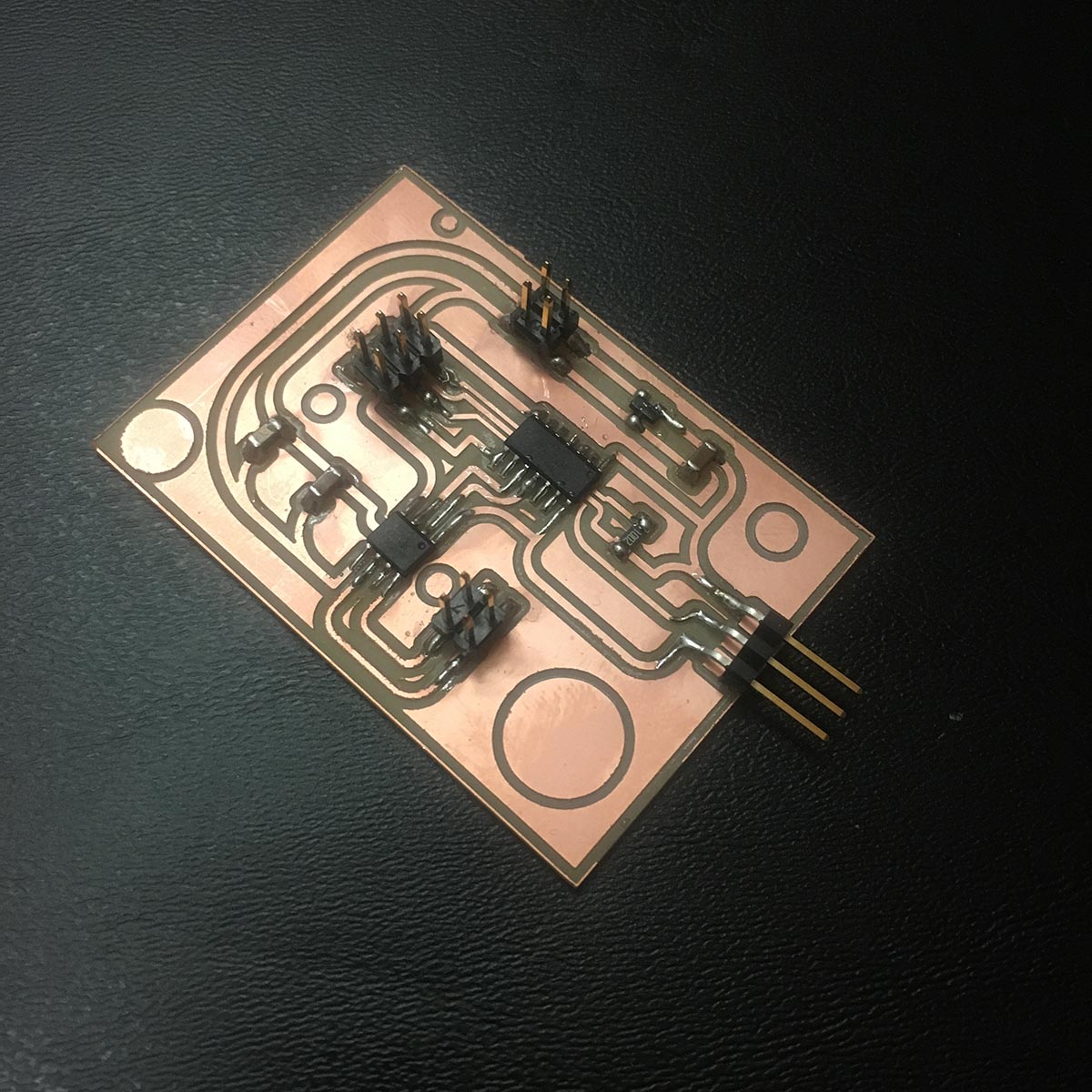

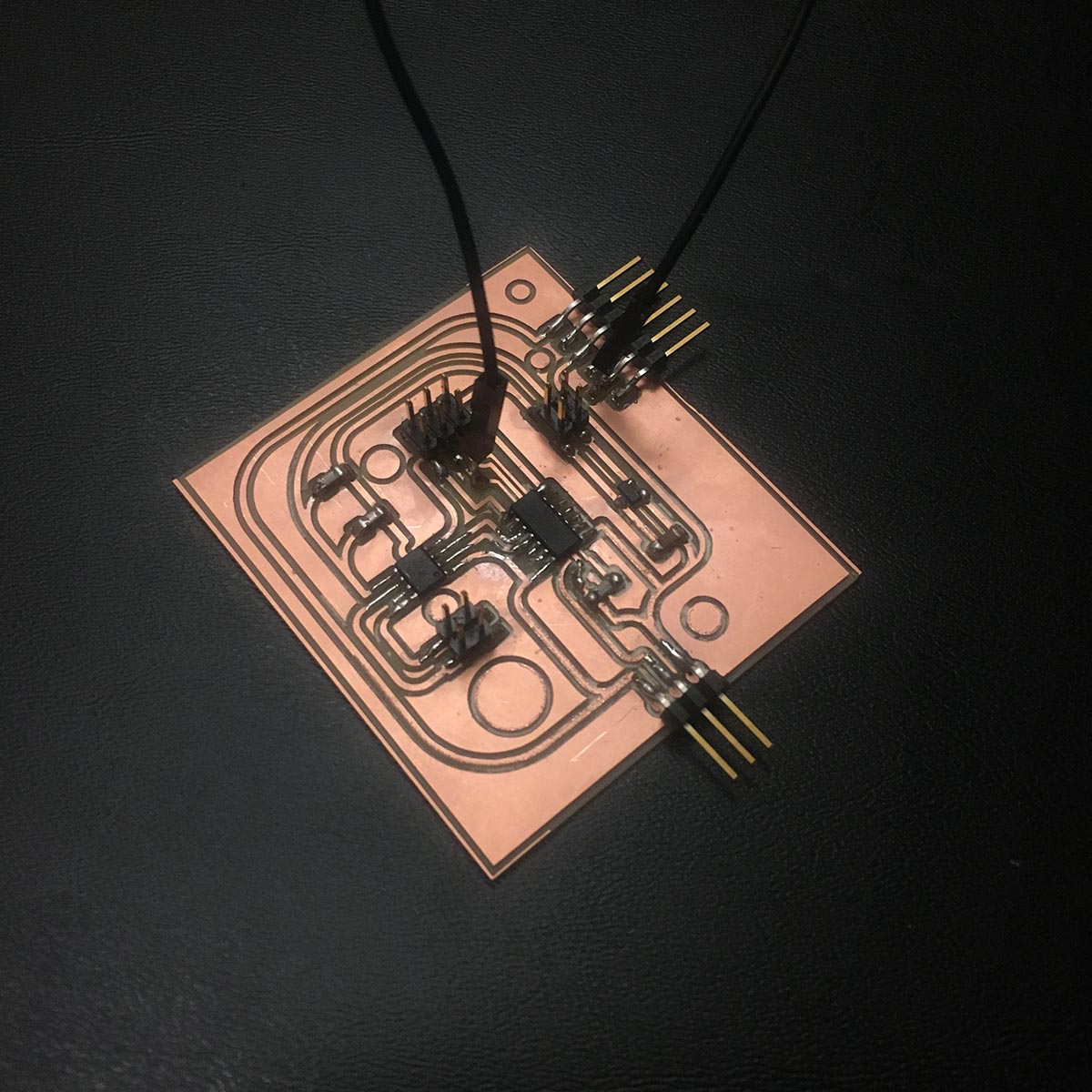

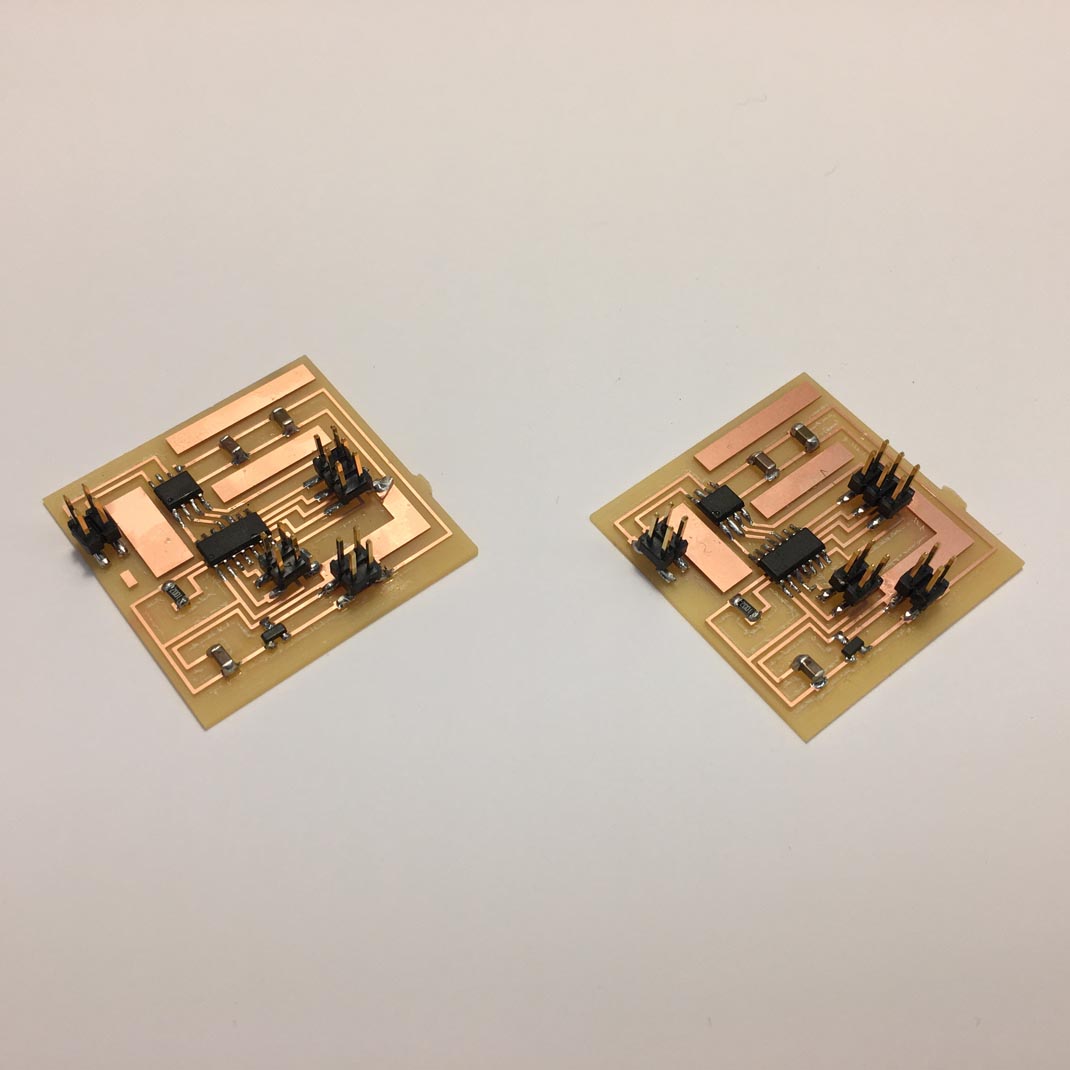

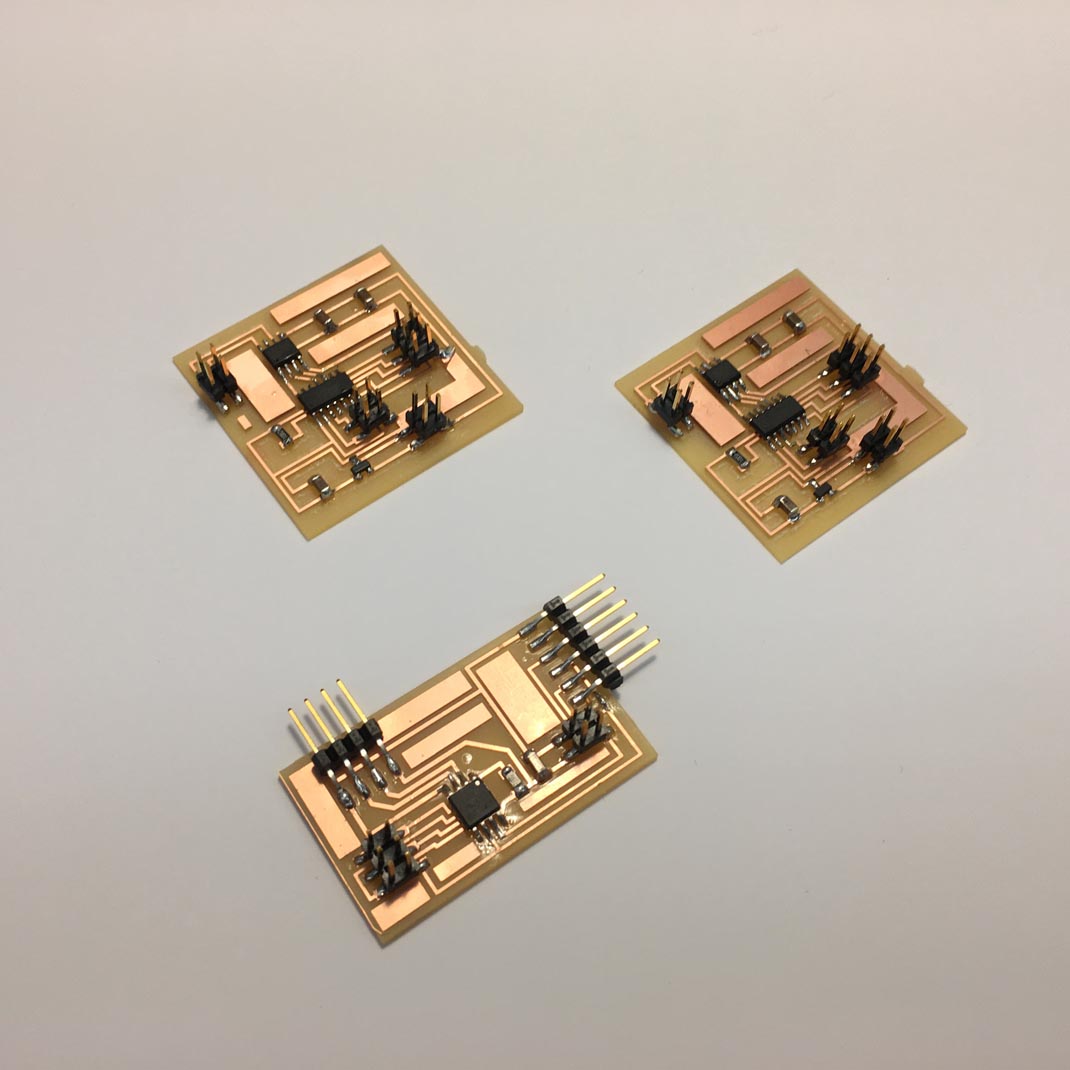

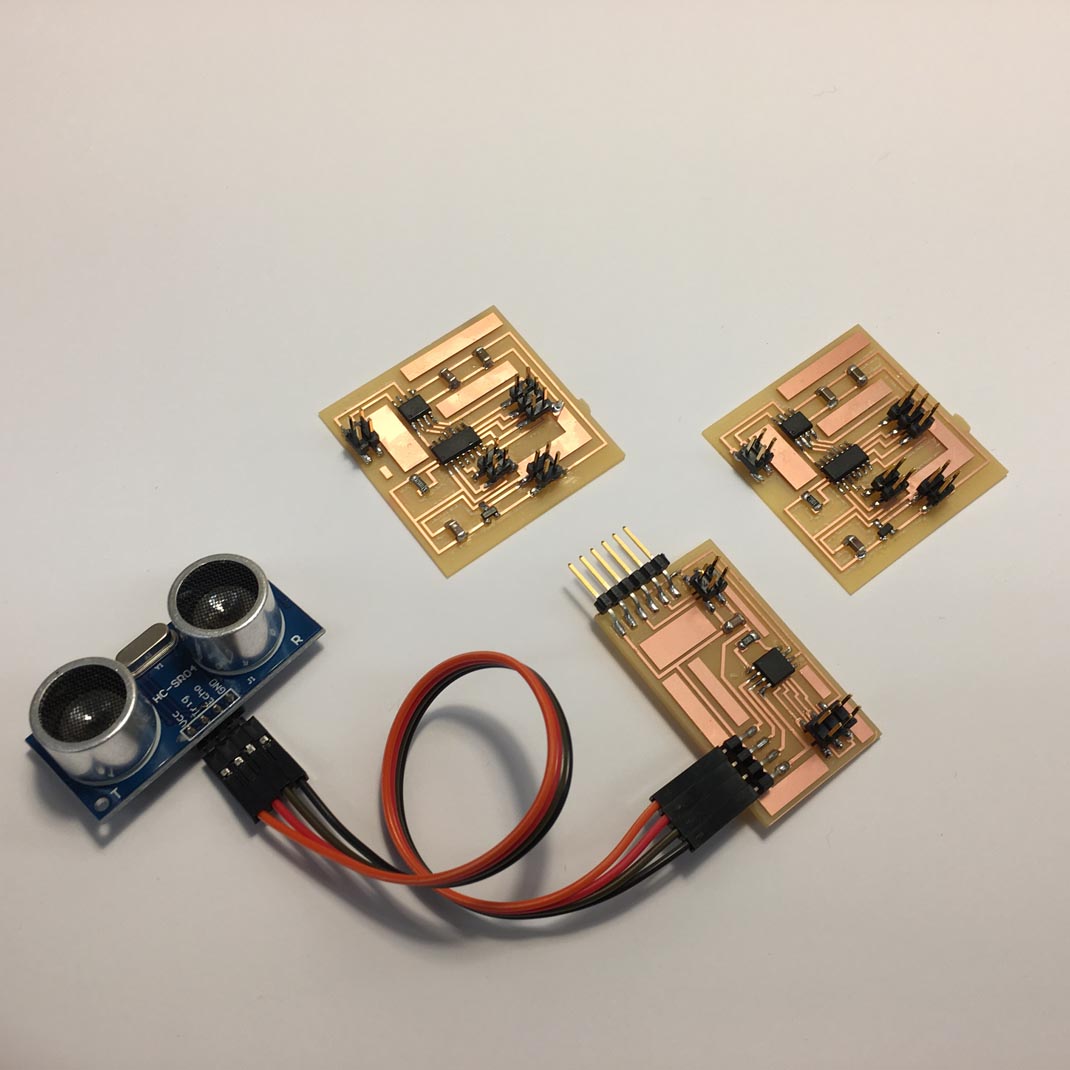

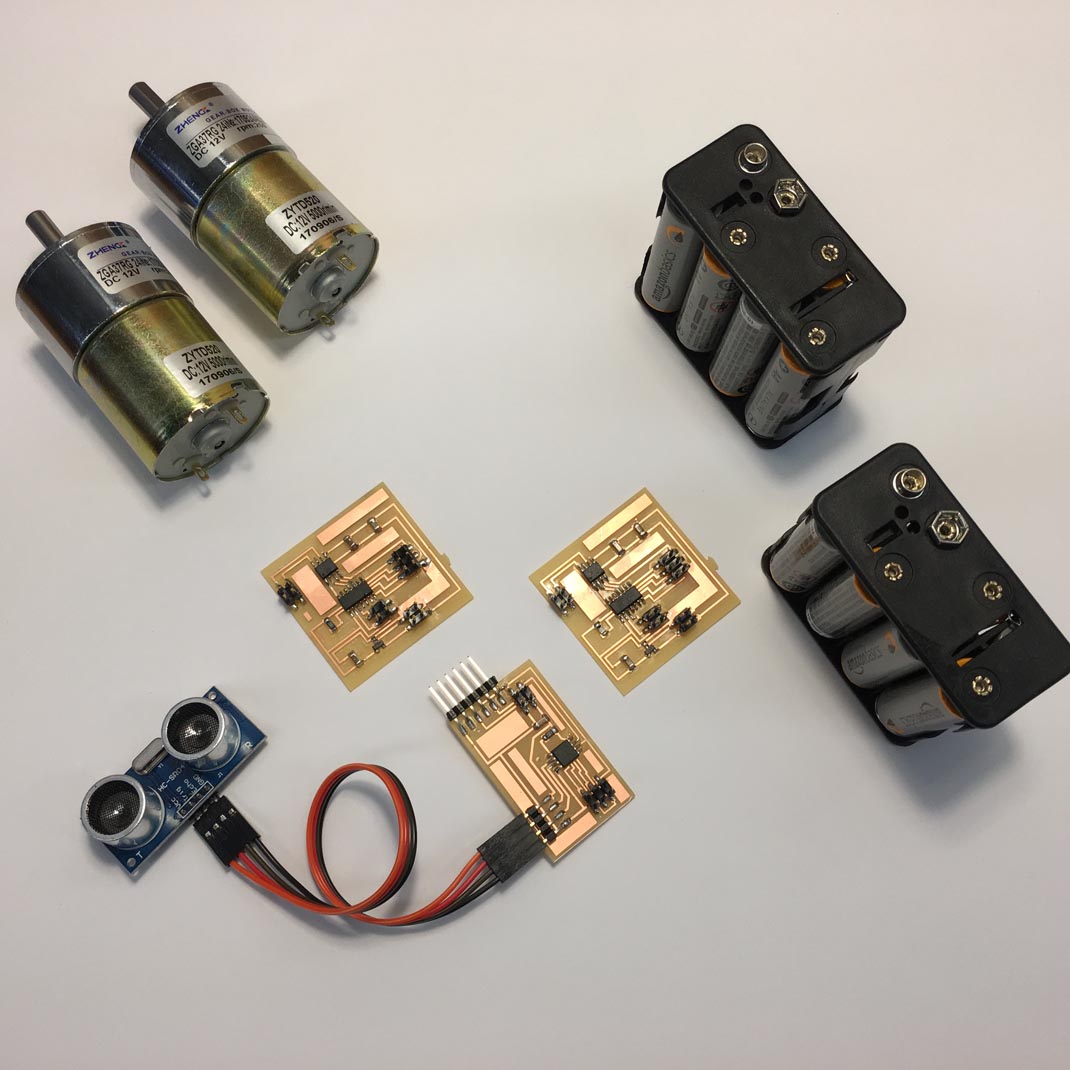

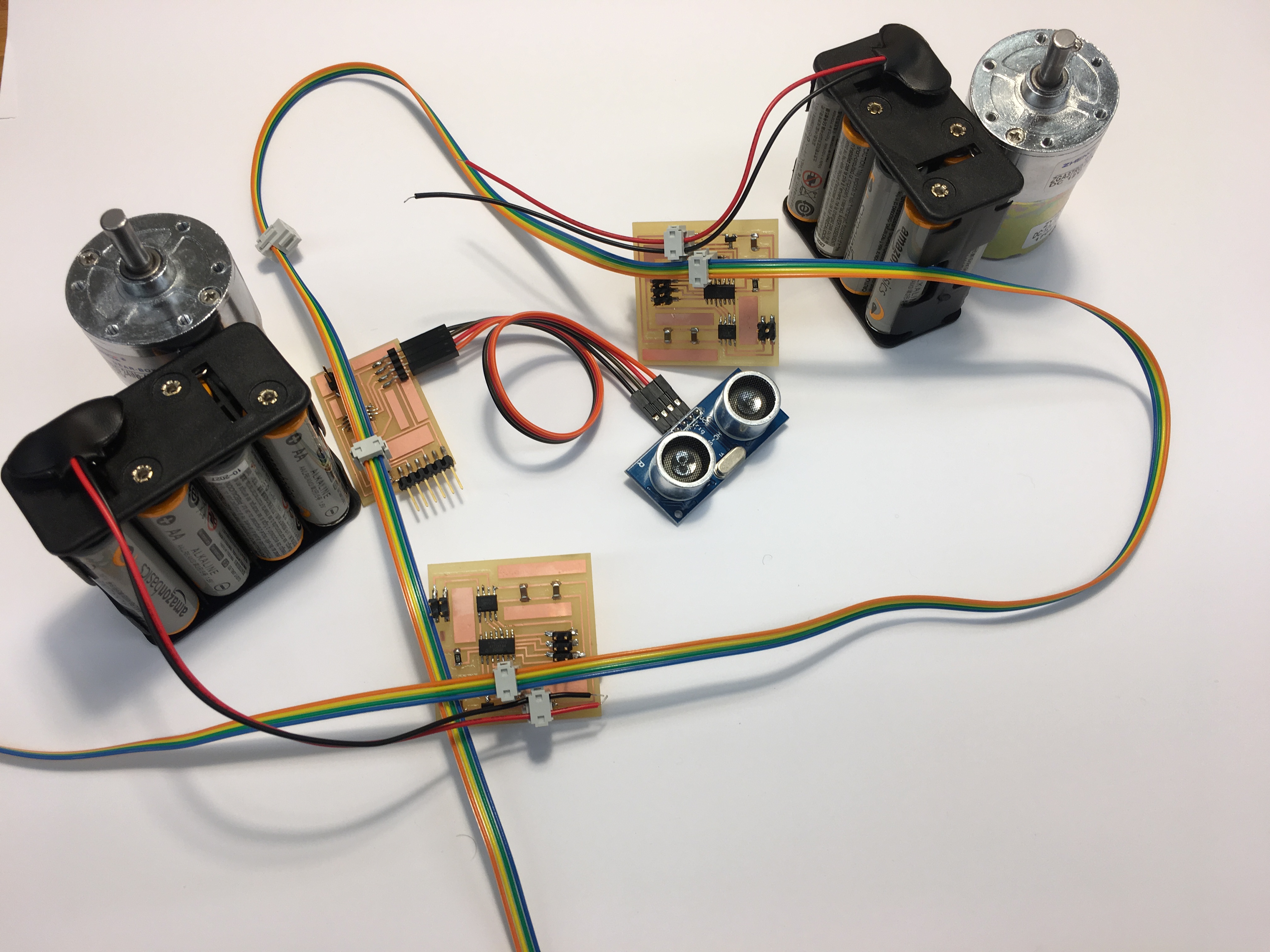

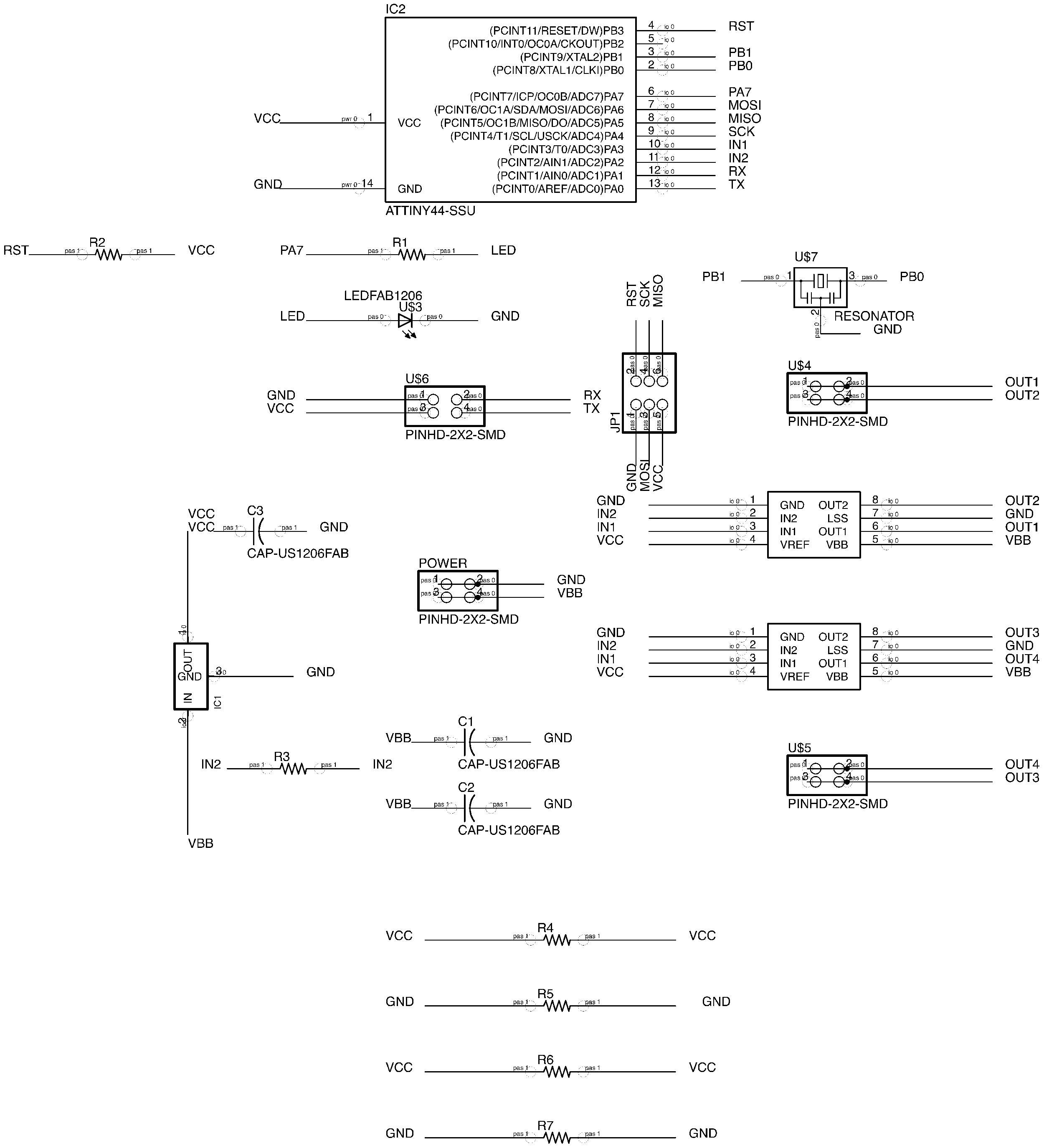

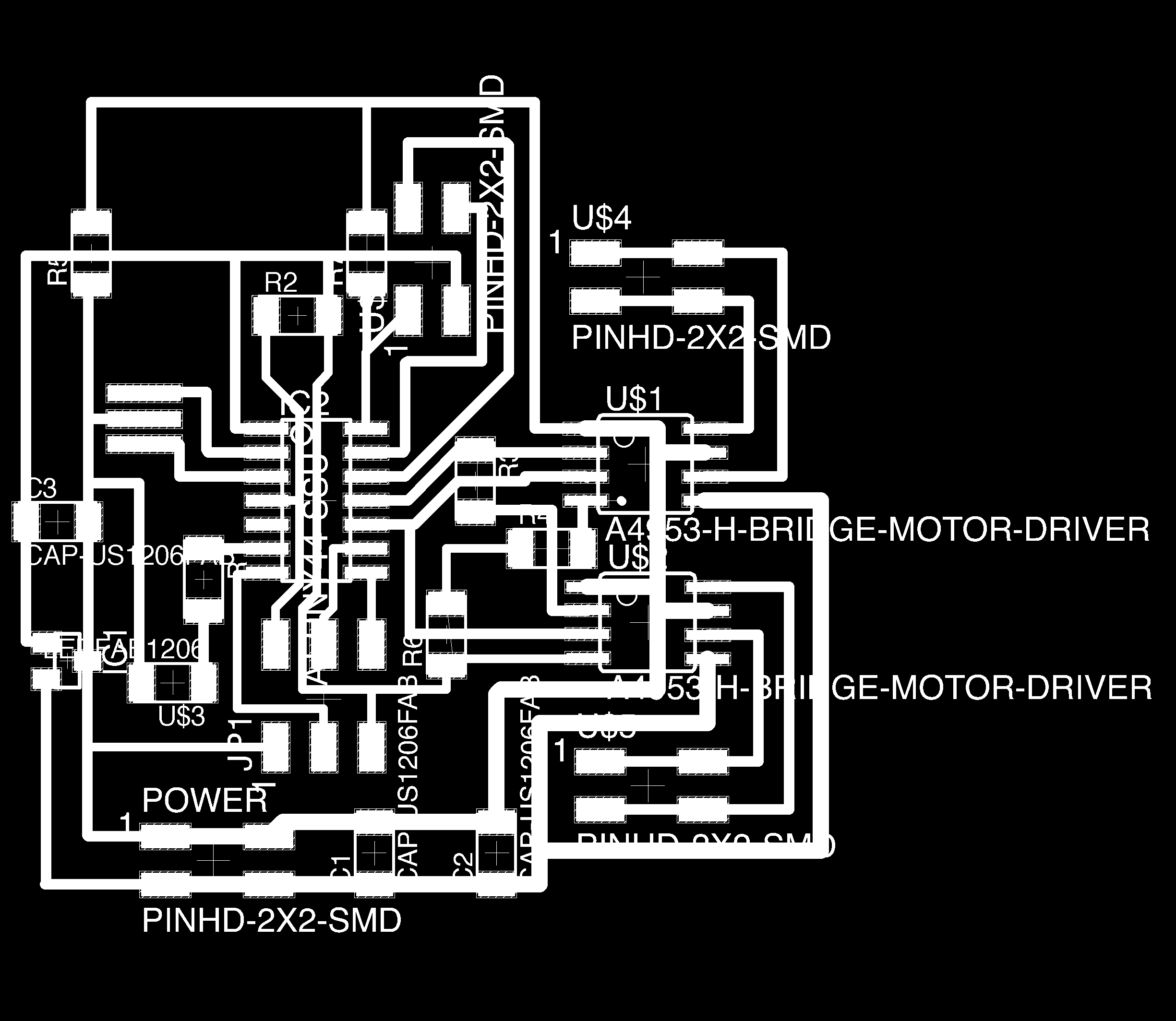

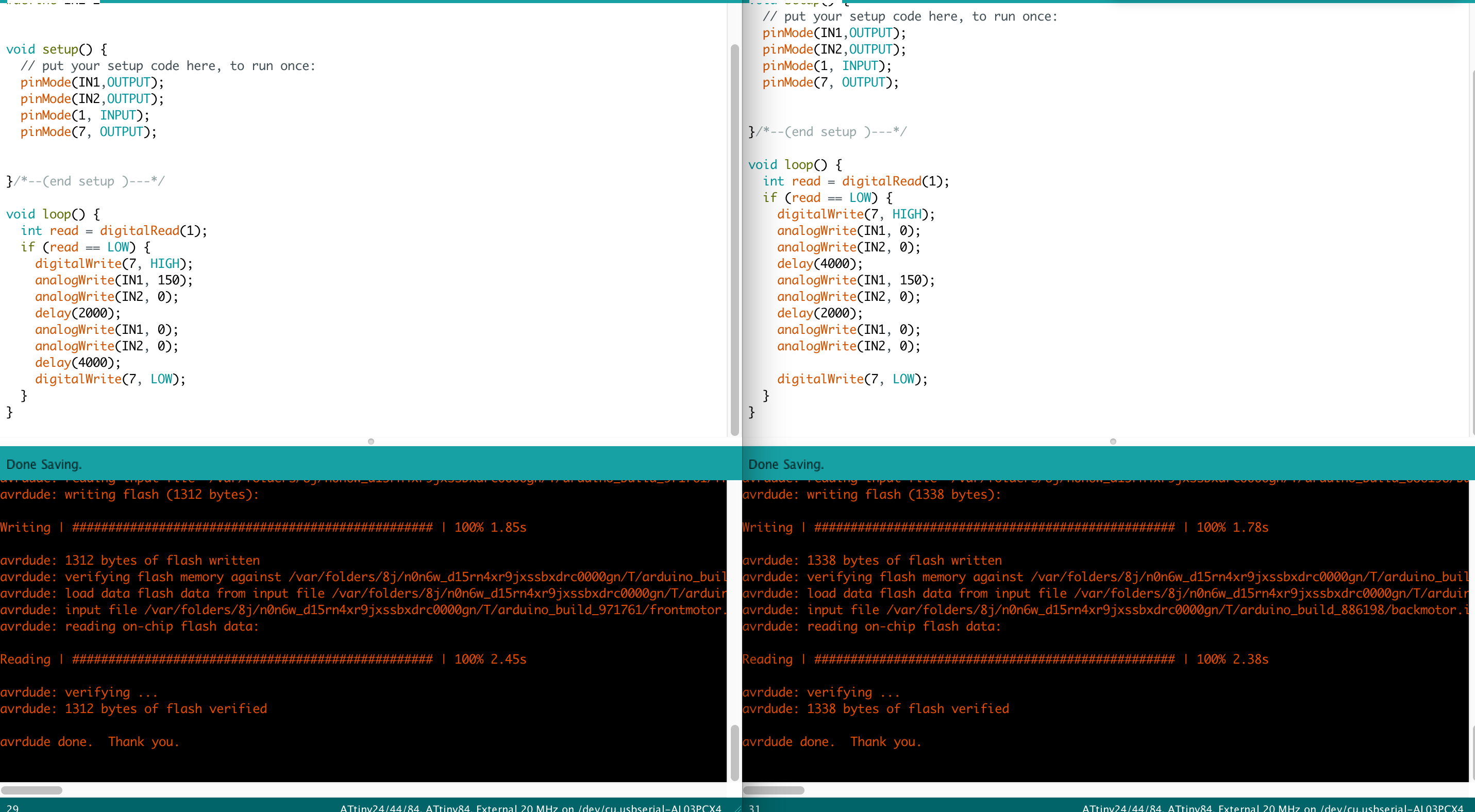

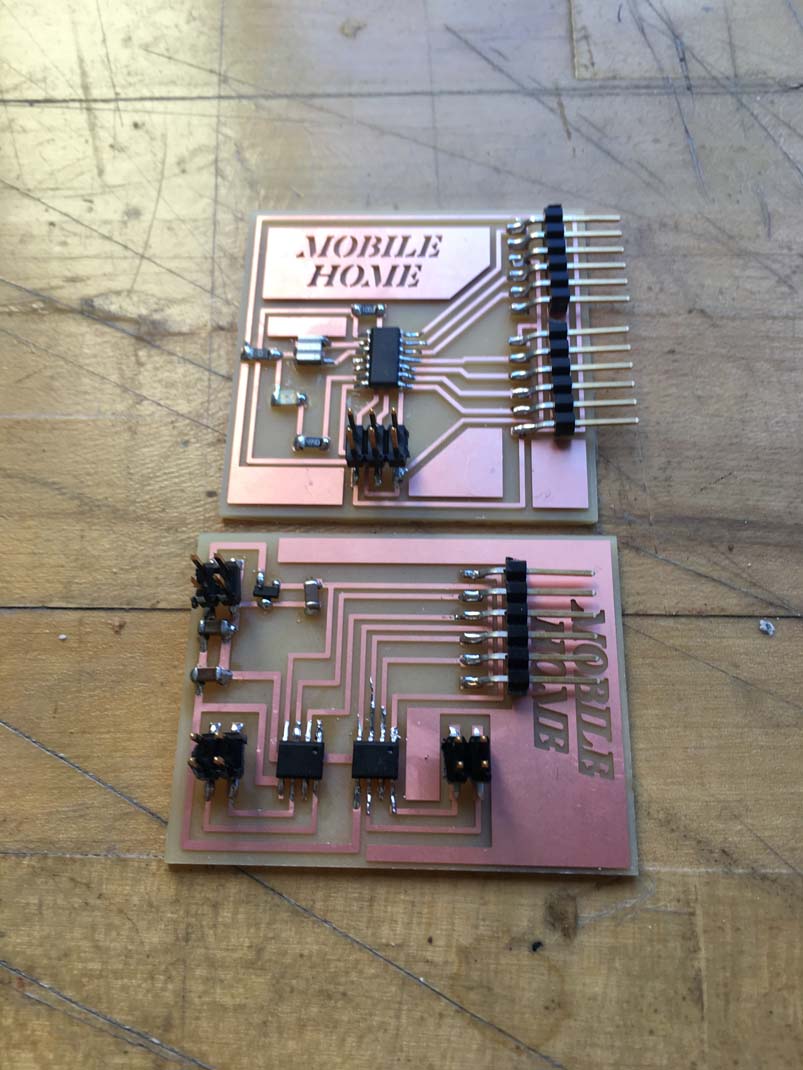

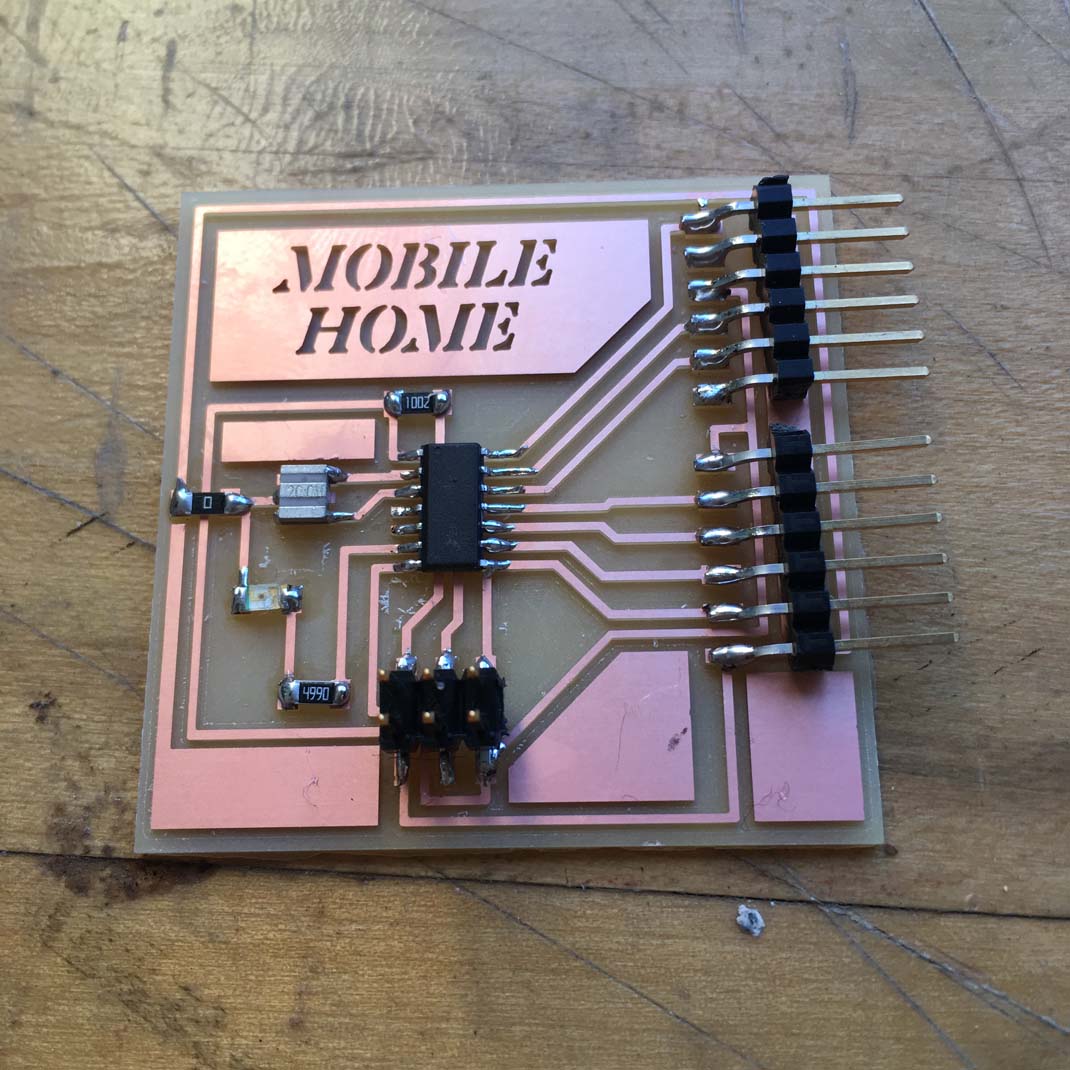

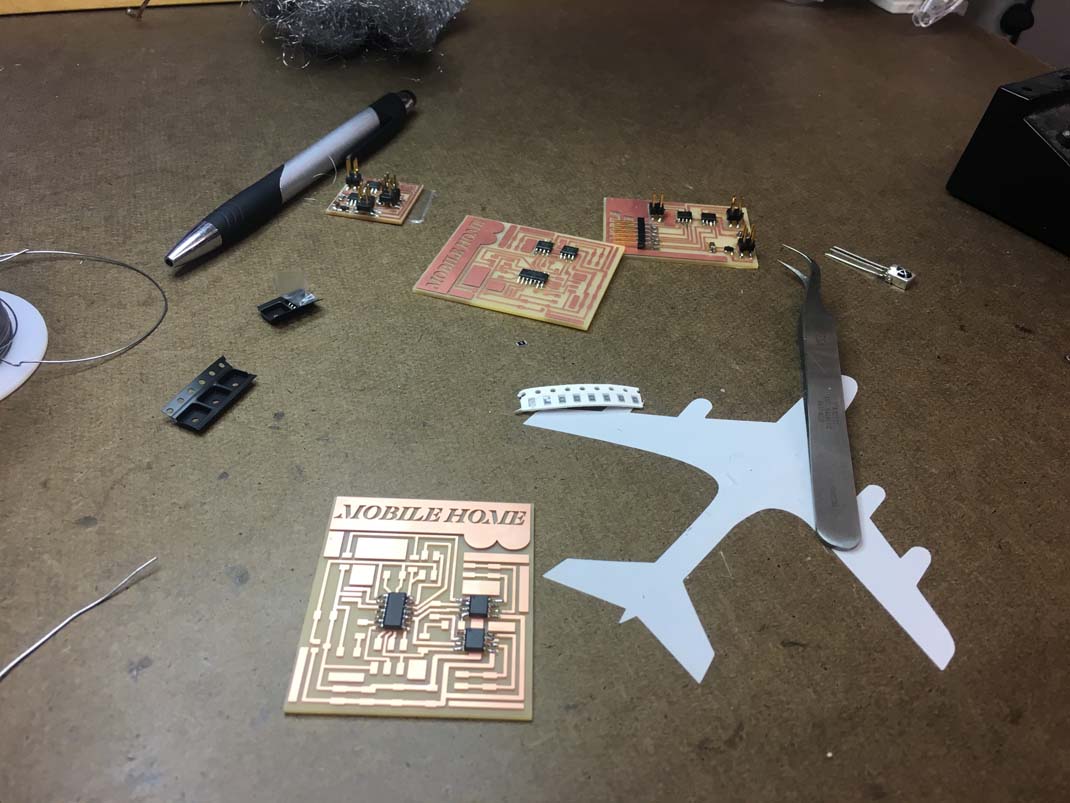

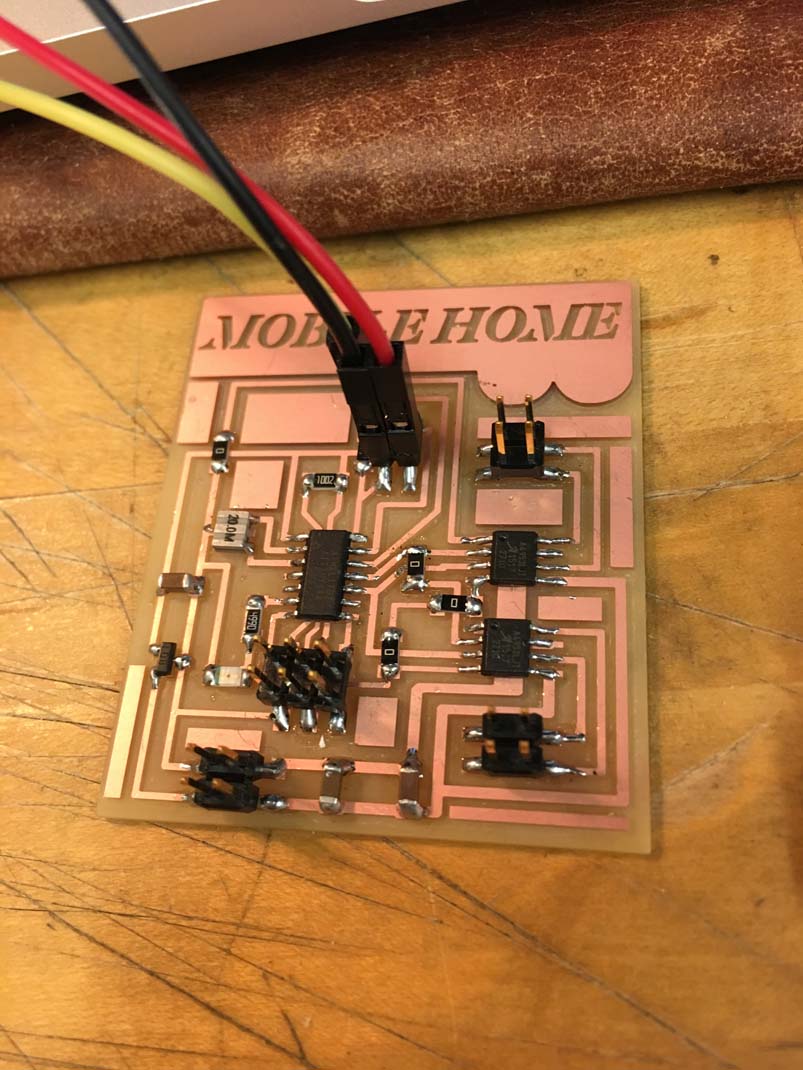

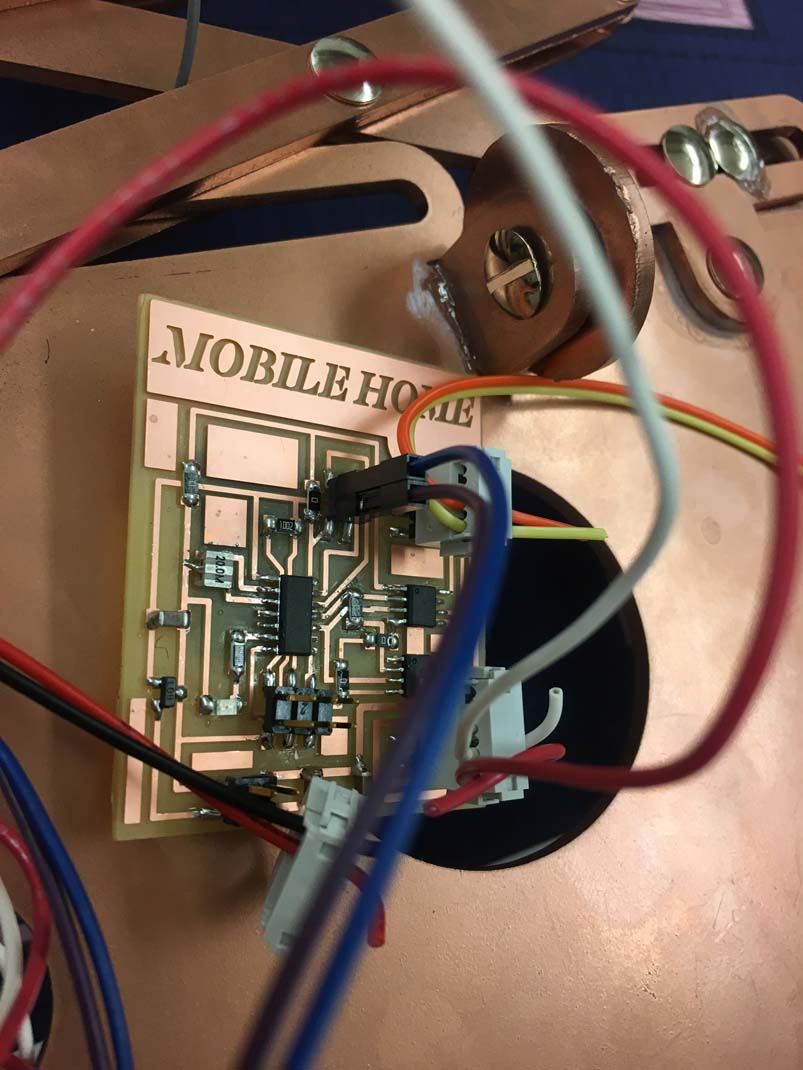

This is my weakness - electronic weeks were quite intense for me and I decided I wanted to keep it to a level that I would have a shot at achieving for the final production. The final electronical components of the project consisted of two main microprosessor boards - that at first used the Atmel ATTiny 44 but then later jumped up to the ATTiny 84 for memory reasons (AND THIS WAS STILL AN ISSUE SO I SHOULD HAVE USED THE ATMega's AND NEVER EVEN BOTHERED WITH THE ATTinys)

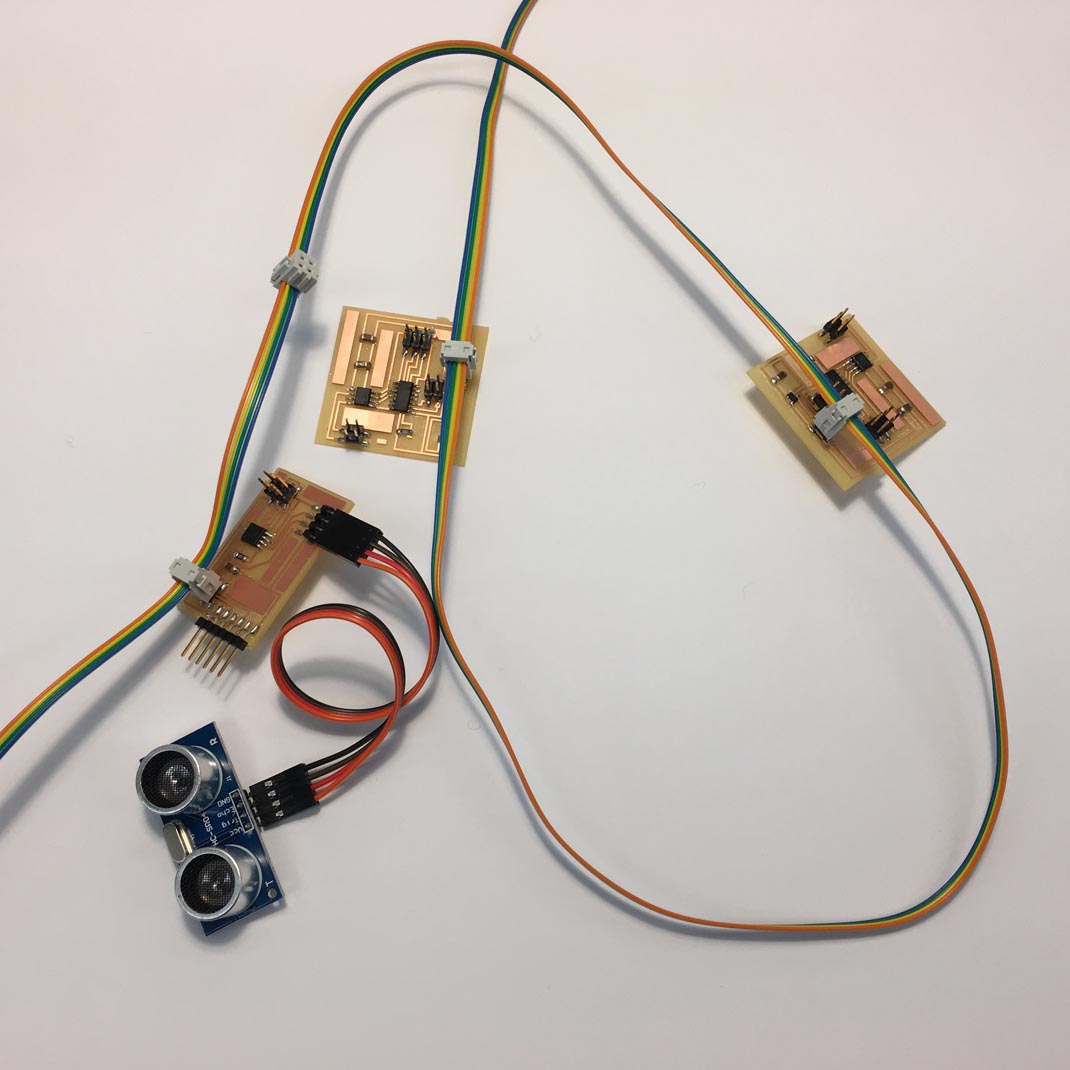

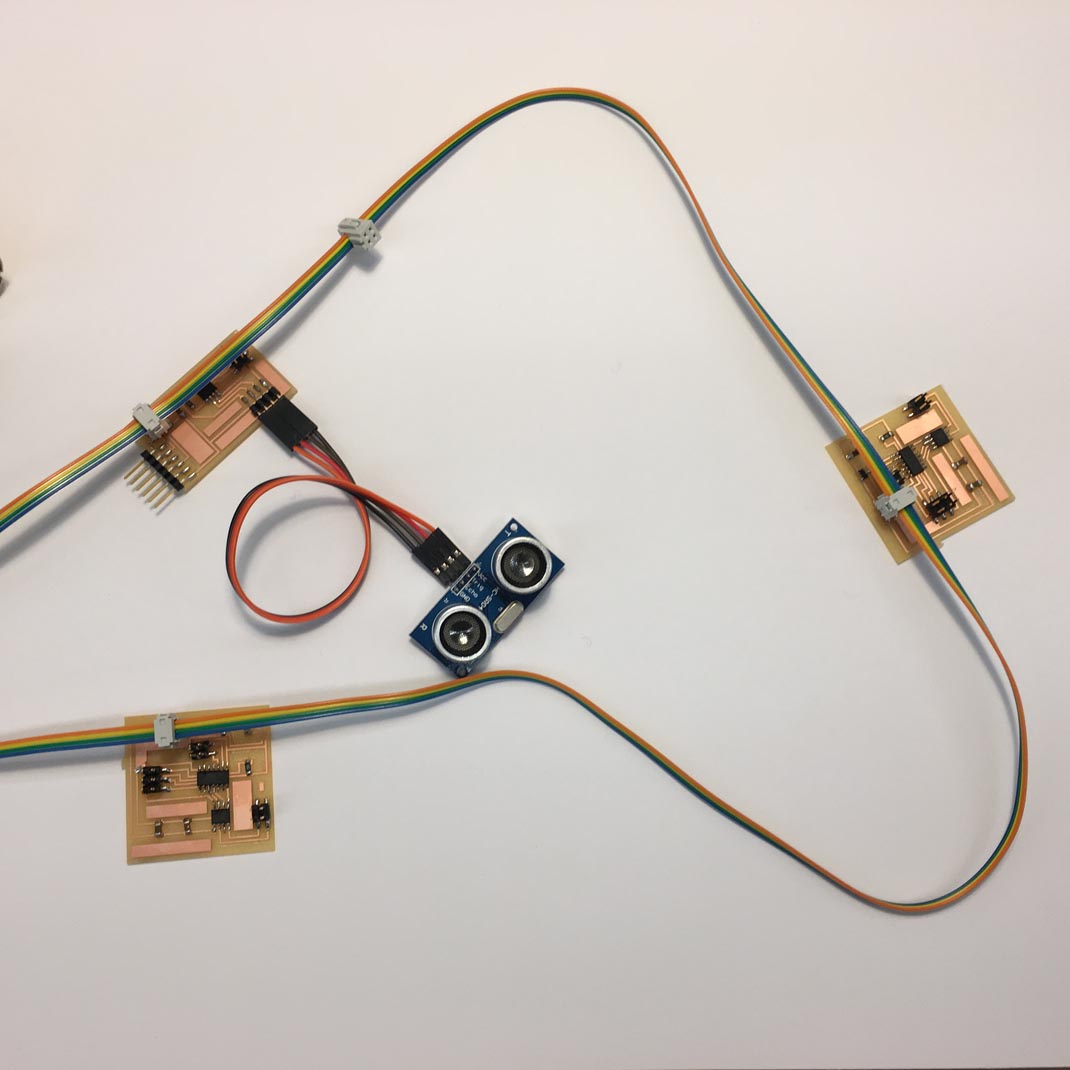

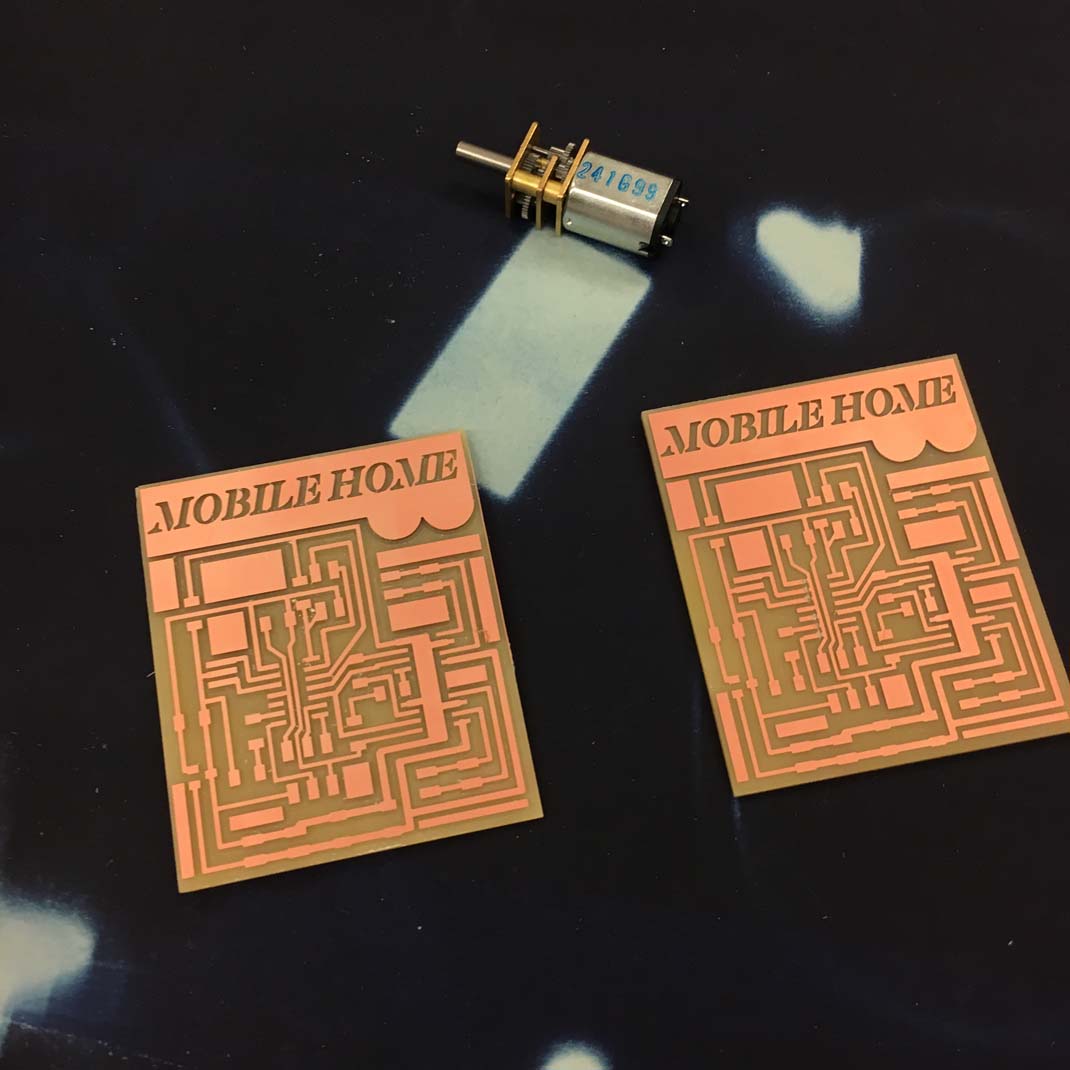

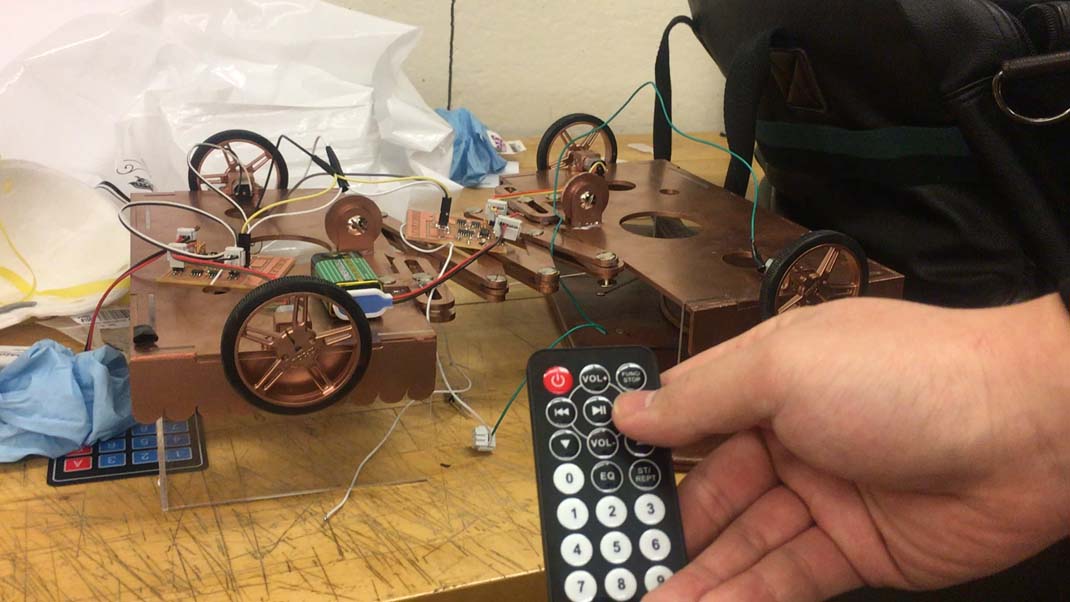

Four DC motors run off two microprocessor boards, each of the microprocessor boards are identical, both powered with a 9v battery (though at first they were 6v battery packs which after many days of failure realized the H-Bridge motor drivers do not work with less than 8v of power - even though the motors were 6v gearbox reduction motors). The two boards get communication from an IR Receiver - the receiver sends information to the ATTiny's and tell the motors to run.

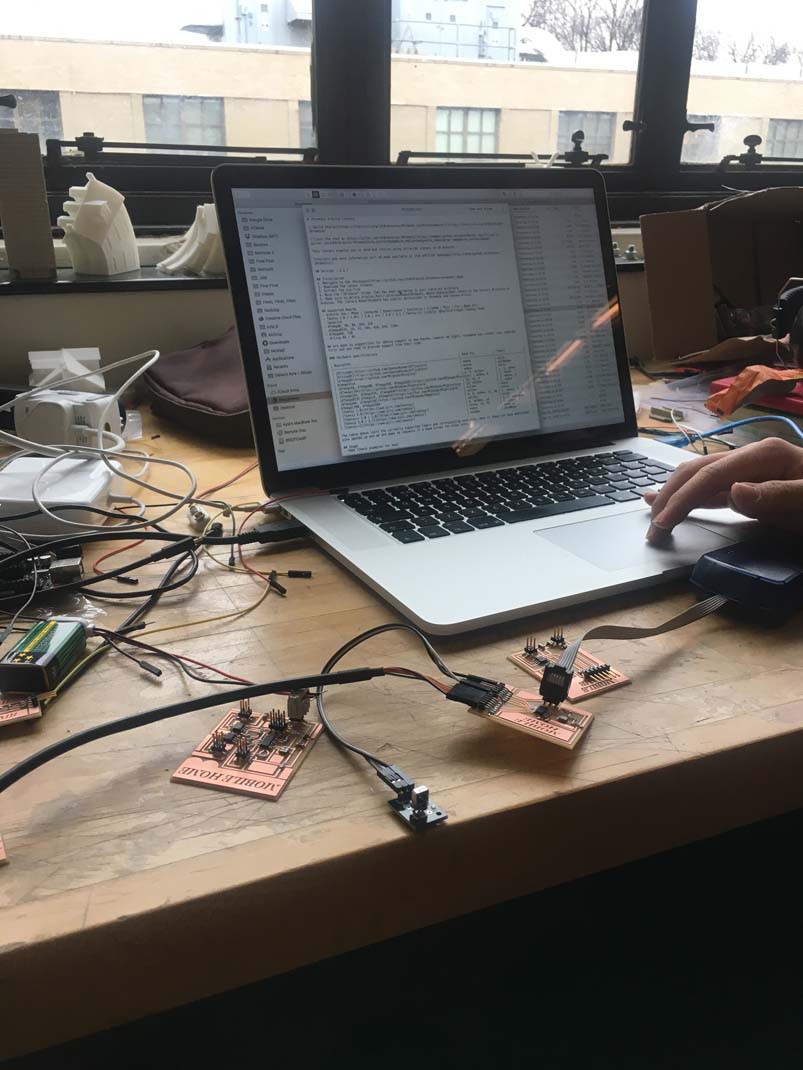

The programming was all done in Arudion - which while it was the first time I used Arduino it did simplify the project and provide a bit of relief. There was a lot of issue getting the IR Receiver to work with the ATTInys. The IRremote library does not work with the ATTiny's and the libraries I discovered that do were too large for the ATTiny to use. This ultimately limited the value of the IR receiver to a simple basic input and the programming code was altered to adjust for this inability. Any button on the IR Remote sent a signal to the microprocessor - when the microprocessor received the signal it would run the front wheel for 1 second and pause them for 2 second. The board that controlled the back wheels took a different take - it would initially pause for 2 seconds and run the wheels for 1 sencond. This resulted in a 3 second repetition that allowed Mobile Home to open and close accordingly

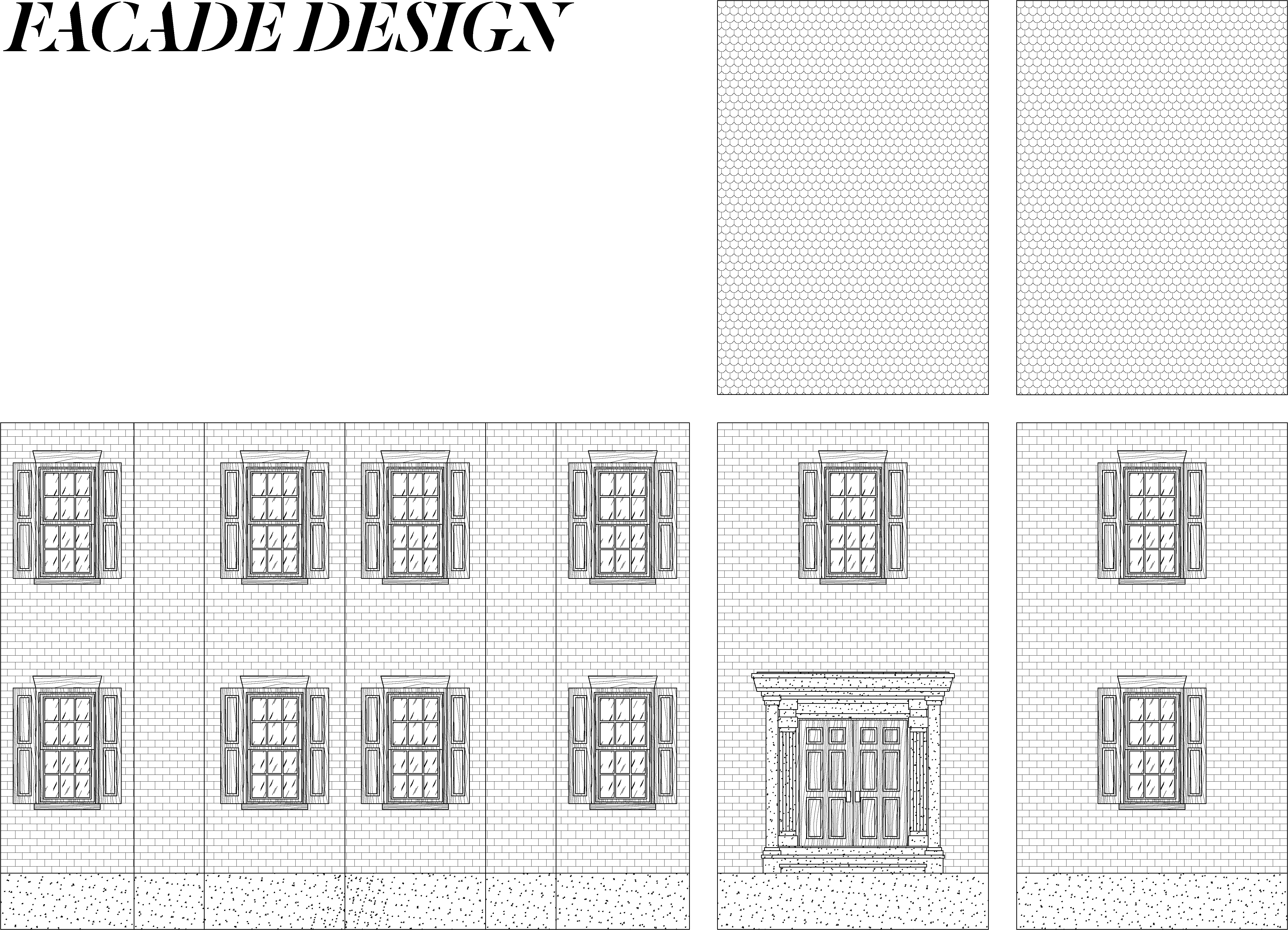

Assembly was both a pure hell and successes - definitely did not give myself adequate time or anticipate the many errors that I myself made and many issues that would arise both because it was the end of the semester and because things just don't work. In the end the assembly o the physical body went smoothly - I tested Paper for the facades of the house and spent a day designing and rendering out what it would actually look like. The electronic assembly failed in just about everyway it could - in the end the issues were a tremendous learning oppotunity - from failed circuit boards to bad soldering to missed connections - the most important thing I learned was how to debug the issues. I really really really need to thank Jacki Berry as a fellow student in our group who helped me tremendously learn things as well as Calvin Zhong our TA who really used the opportunity to show me how to properly debug and find the issues. While stress amounted and time constraints amounted to higher tension - there was a calmness in knowing the ways in which I could figure out what was going wrong.

A series of robots that are all shaped like houses that can organize and rearrange themselves into streets, neighborhoods, grids etc...

A walking byōbu screen that will topple on top of you