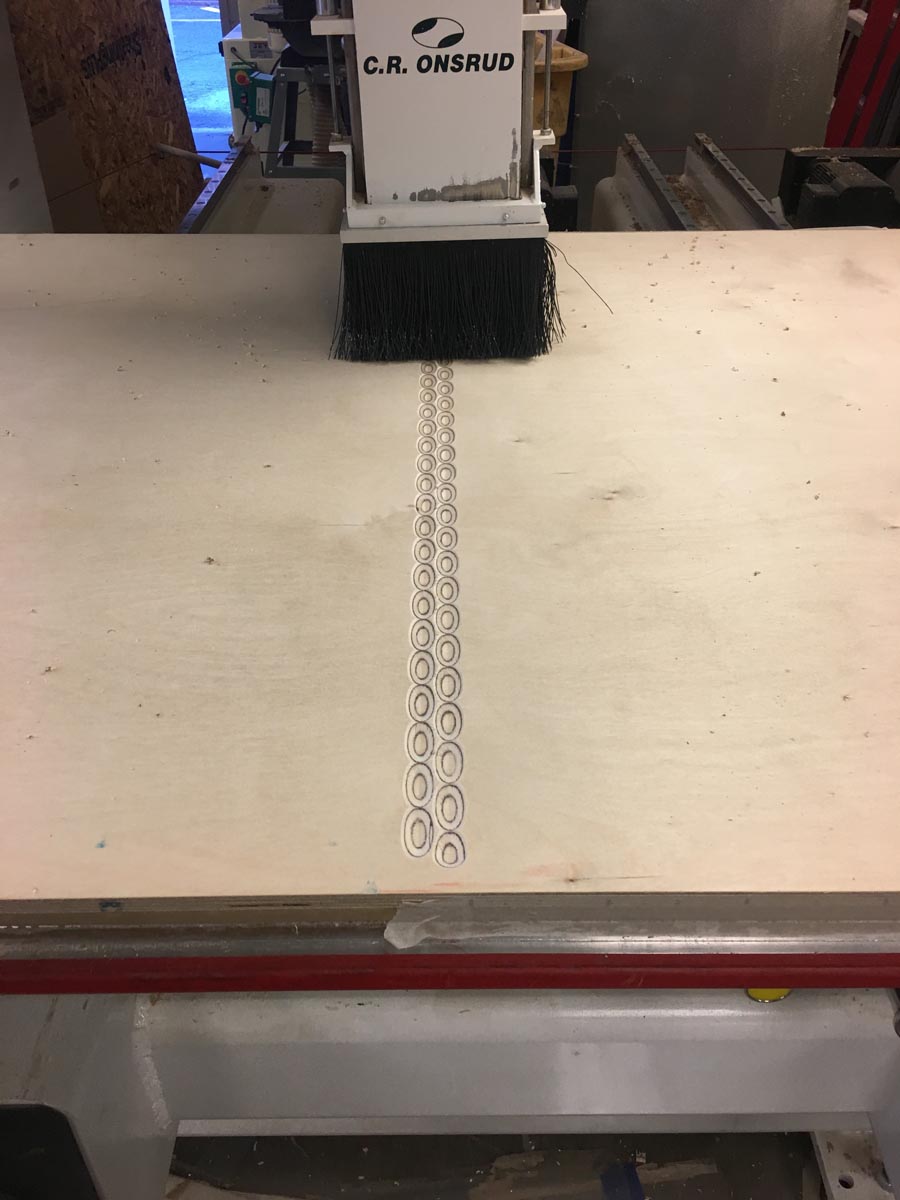

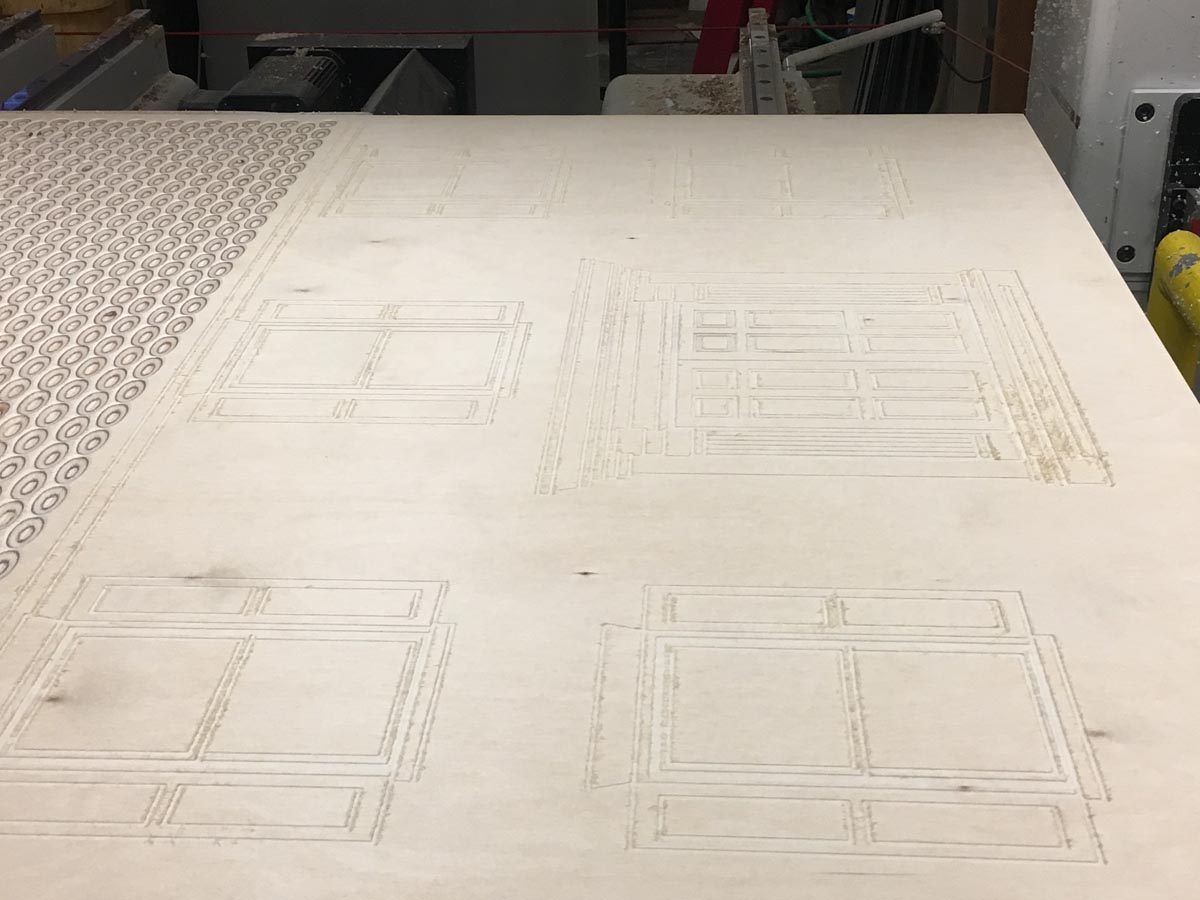

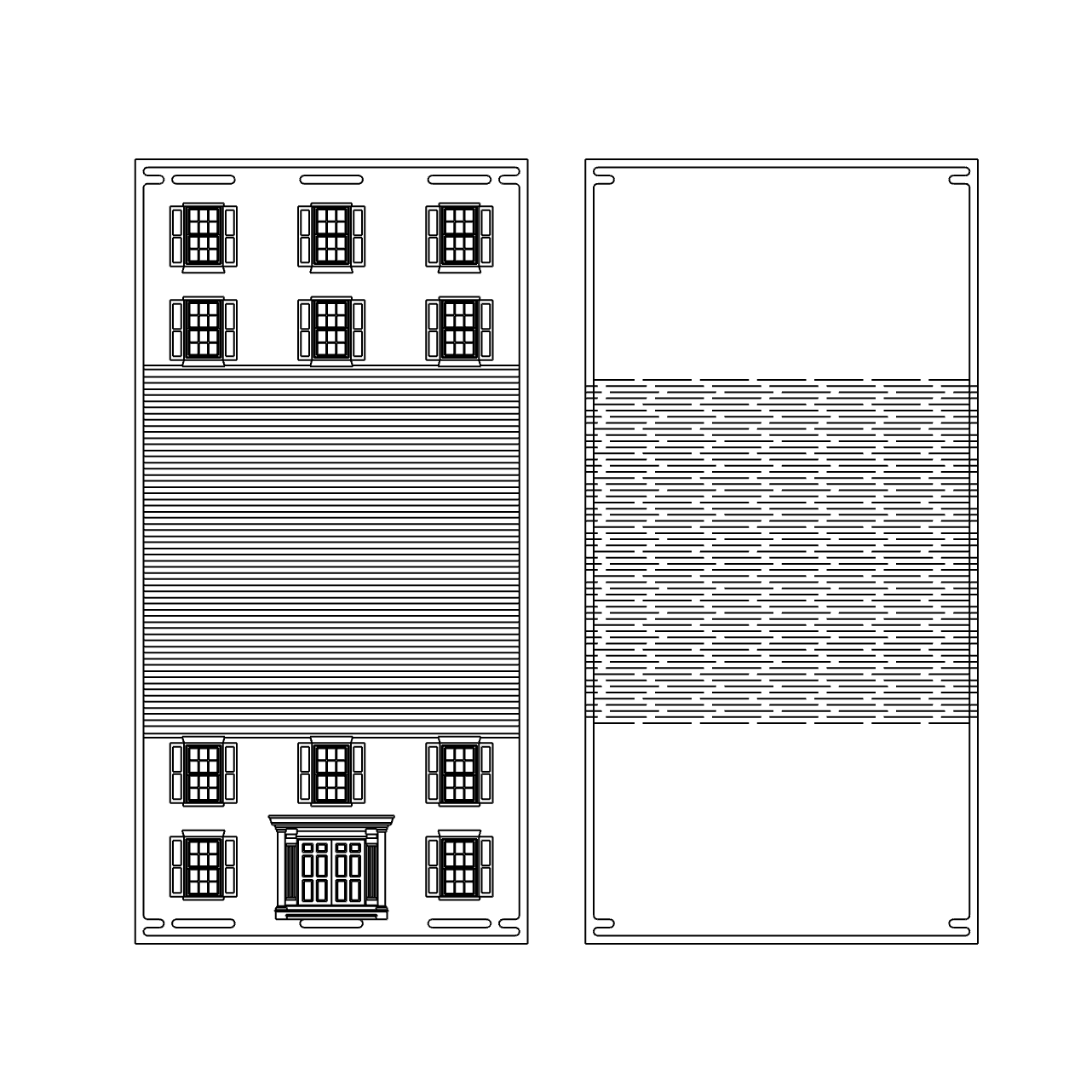

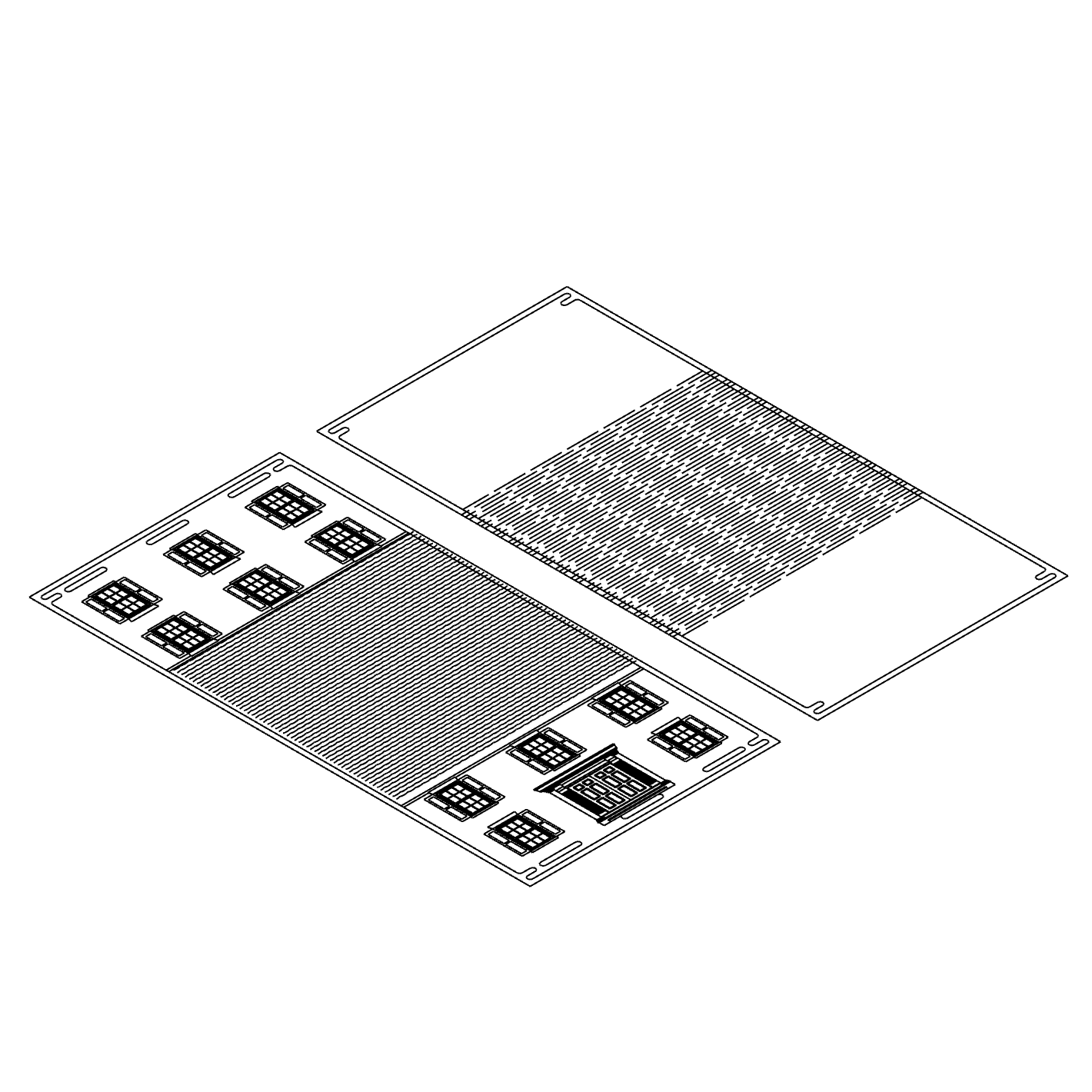

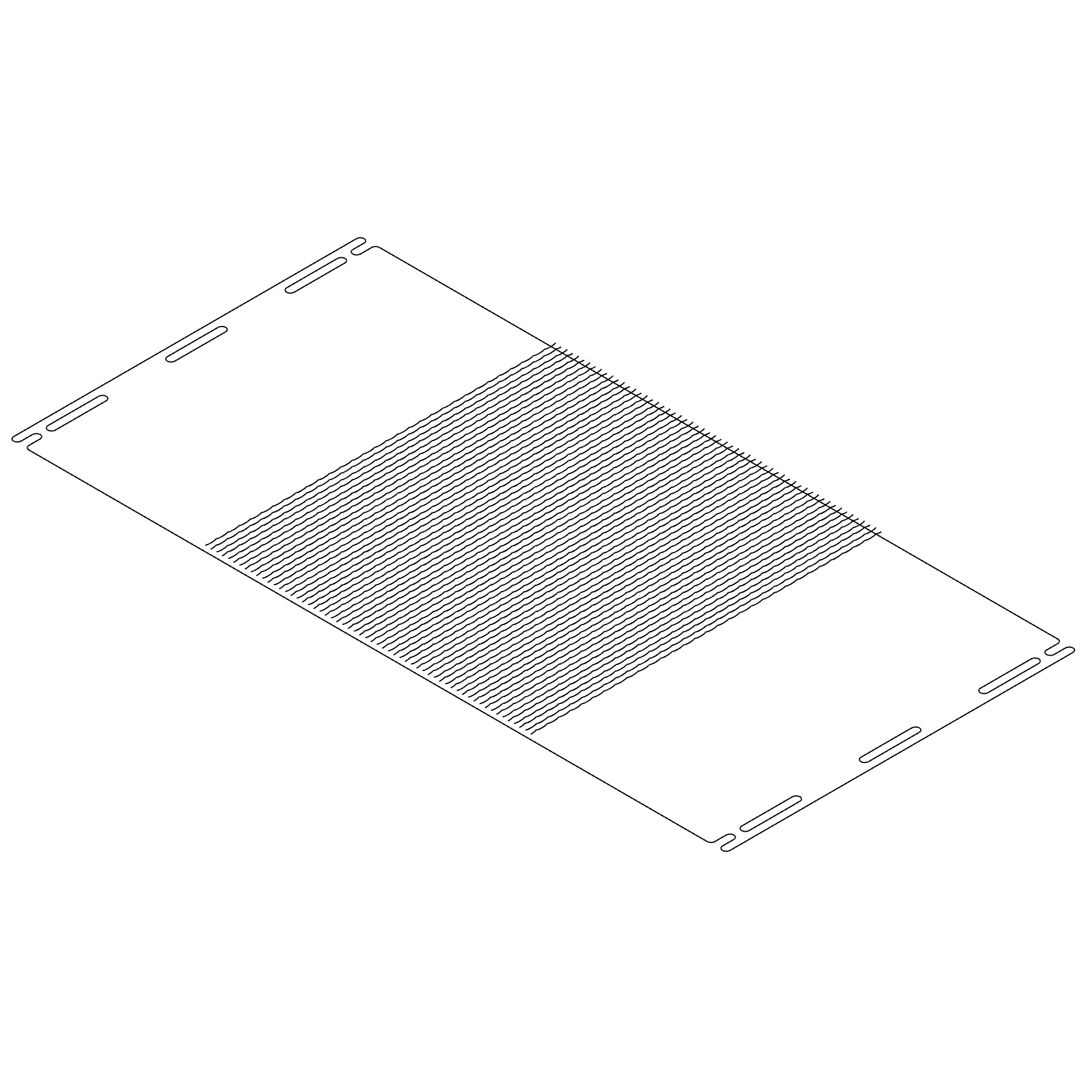

I began by replicating the project done in week 01 when we used the laser cutter. For this project I used ply wood that was purchased from The Home Depot - with a birch finish layer. Unfortunately the wood was shit and I learned a lot about the quality of ply-woods this week. The test began by scalling up the cuts originally done for the laser cutter and cardboard.

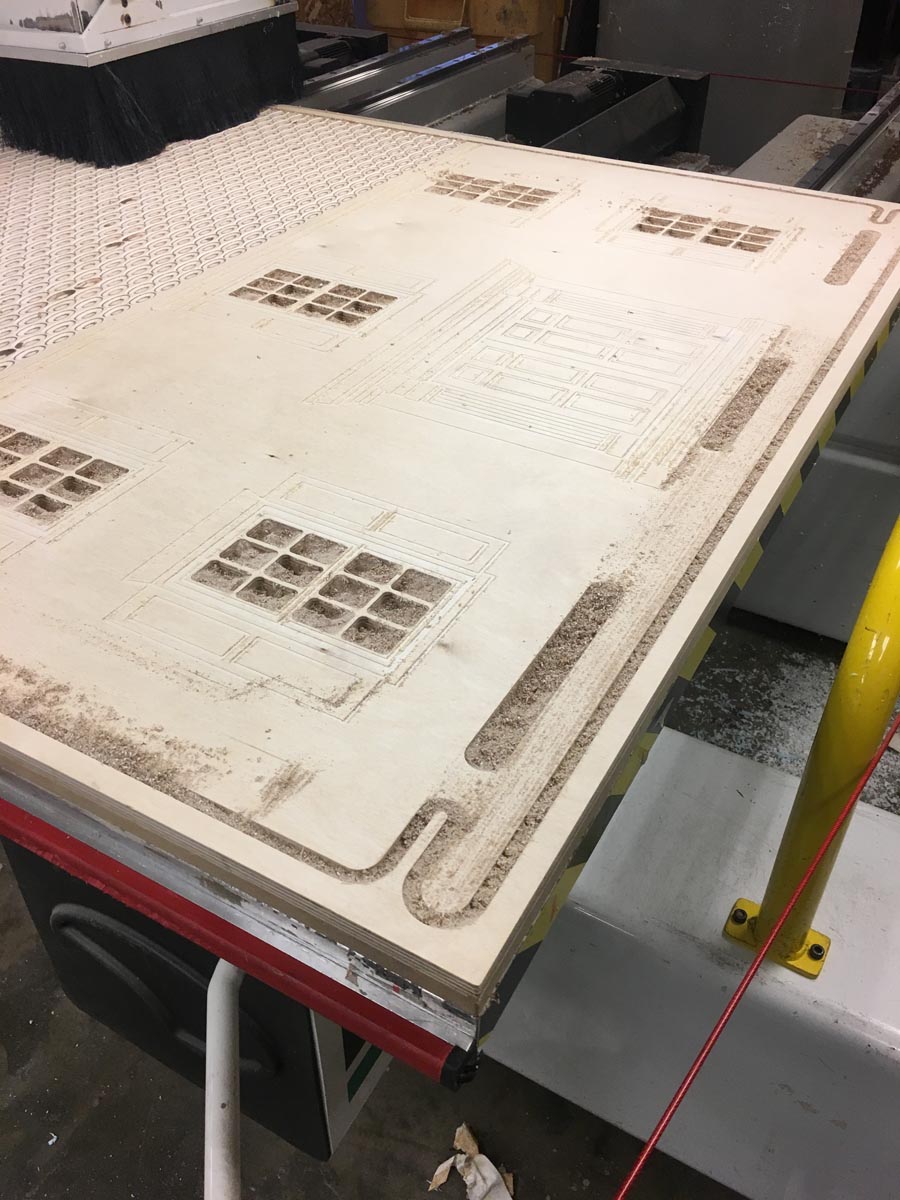

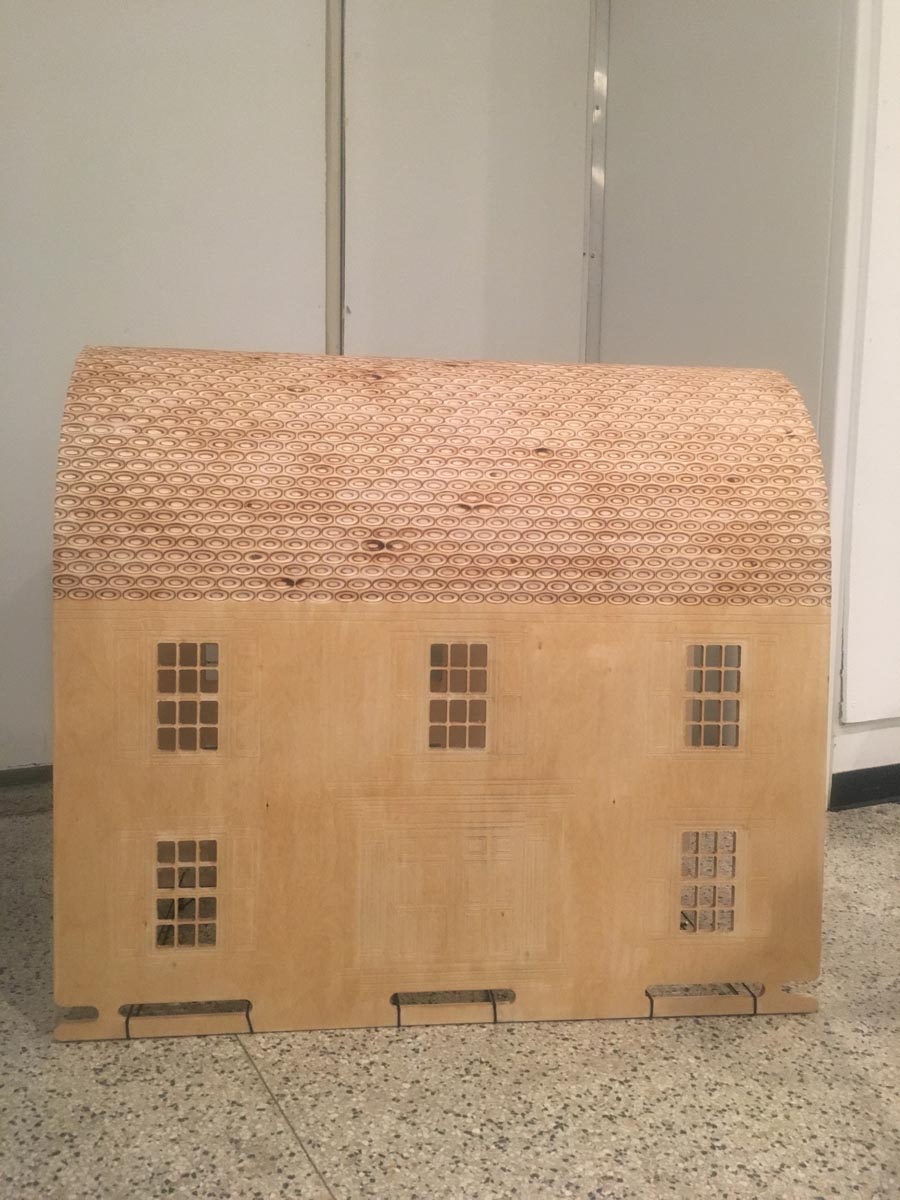

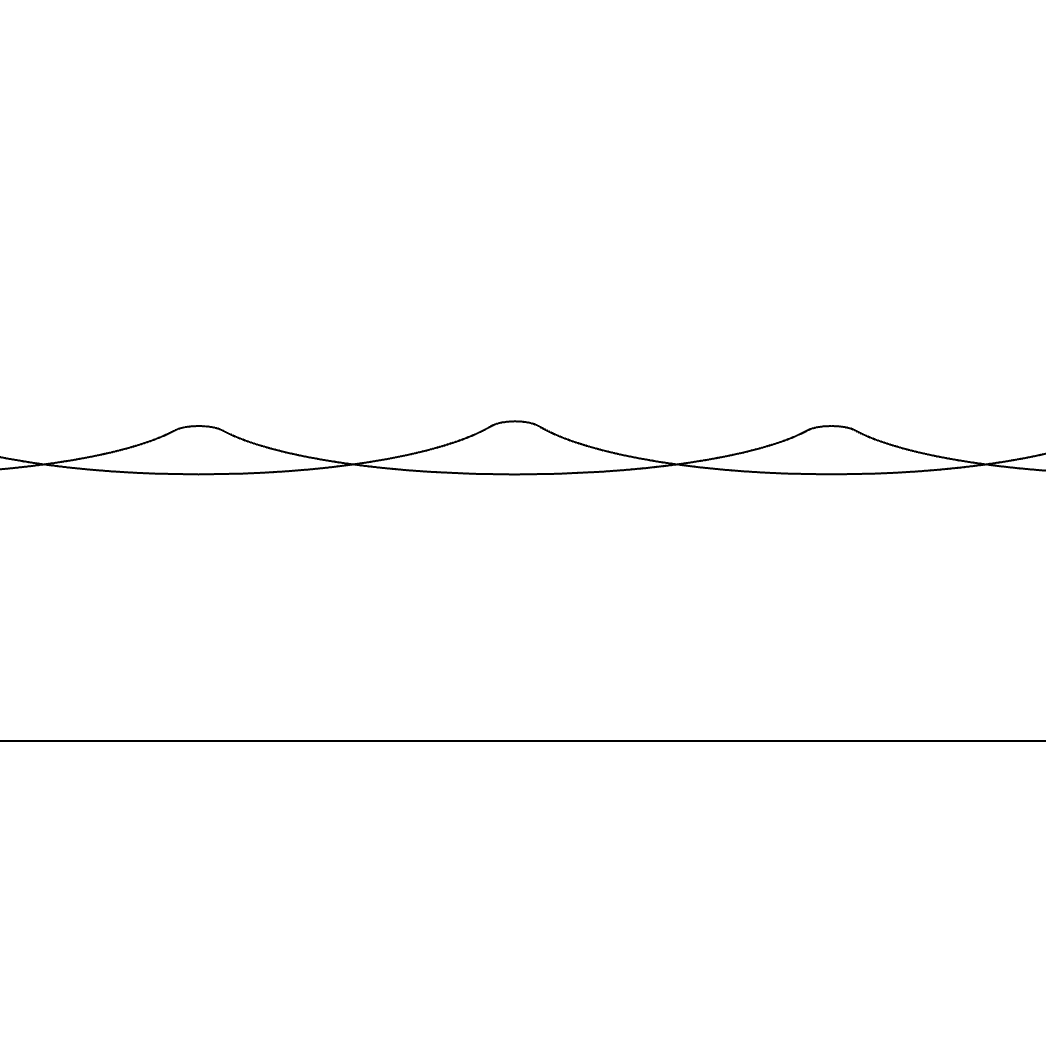

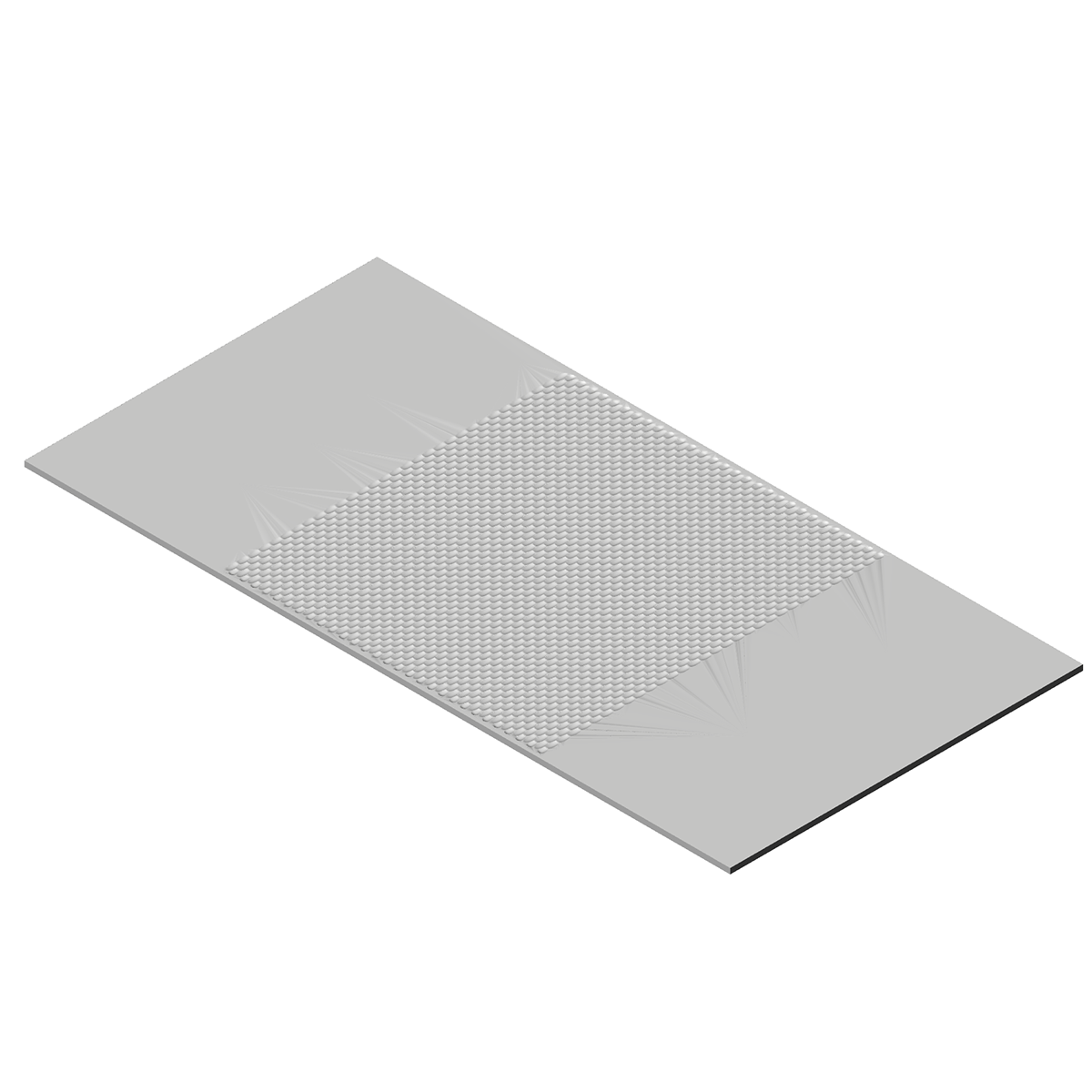

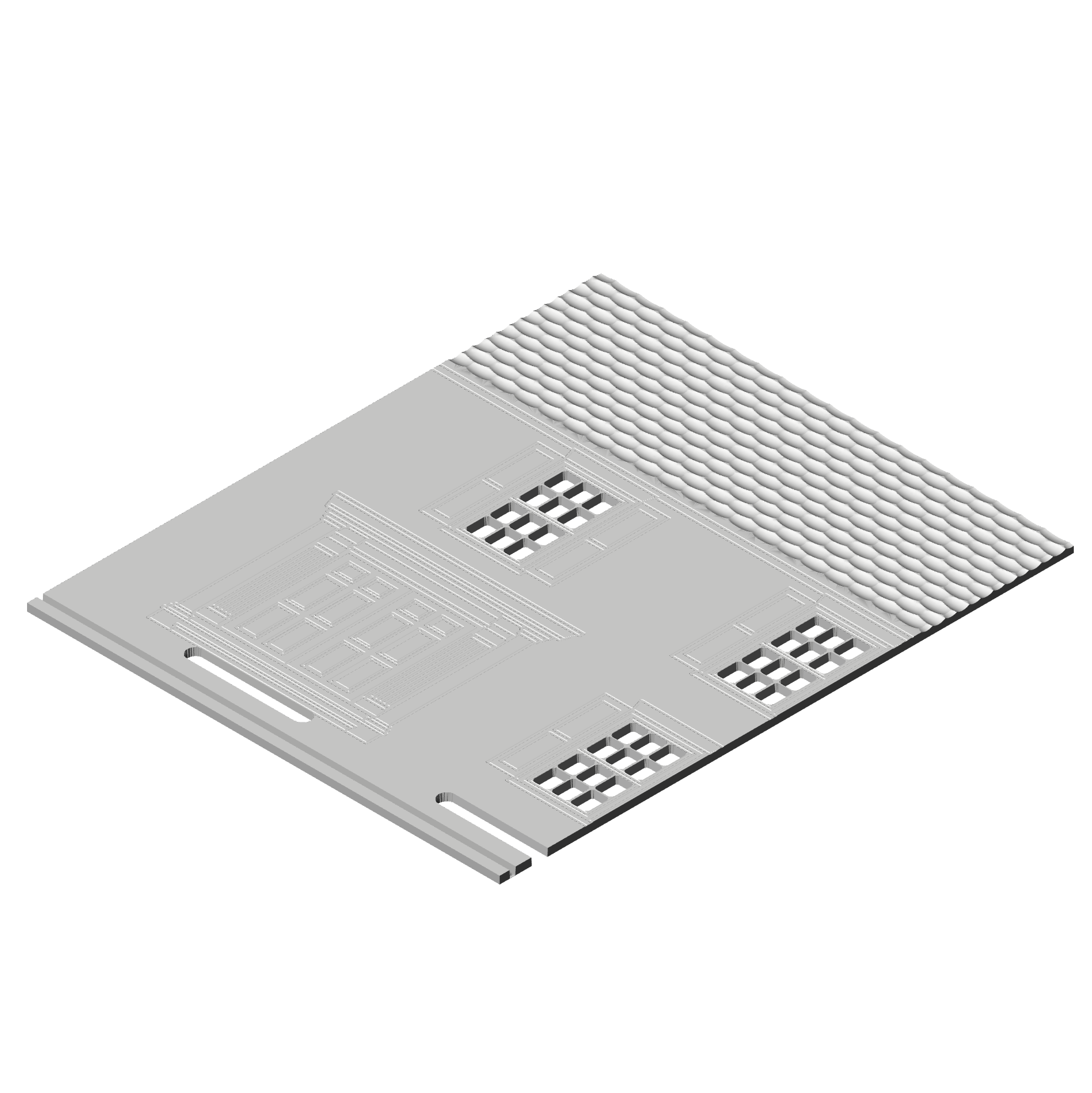

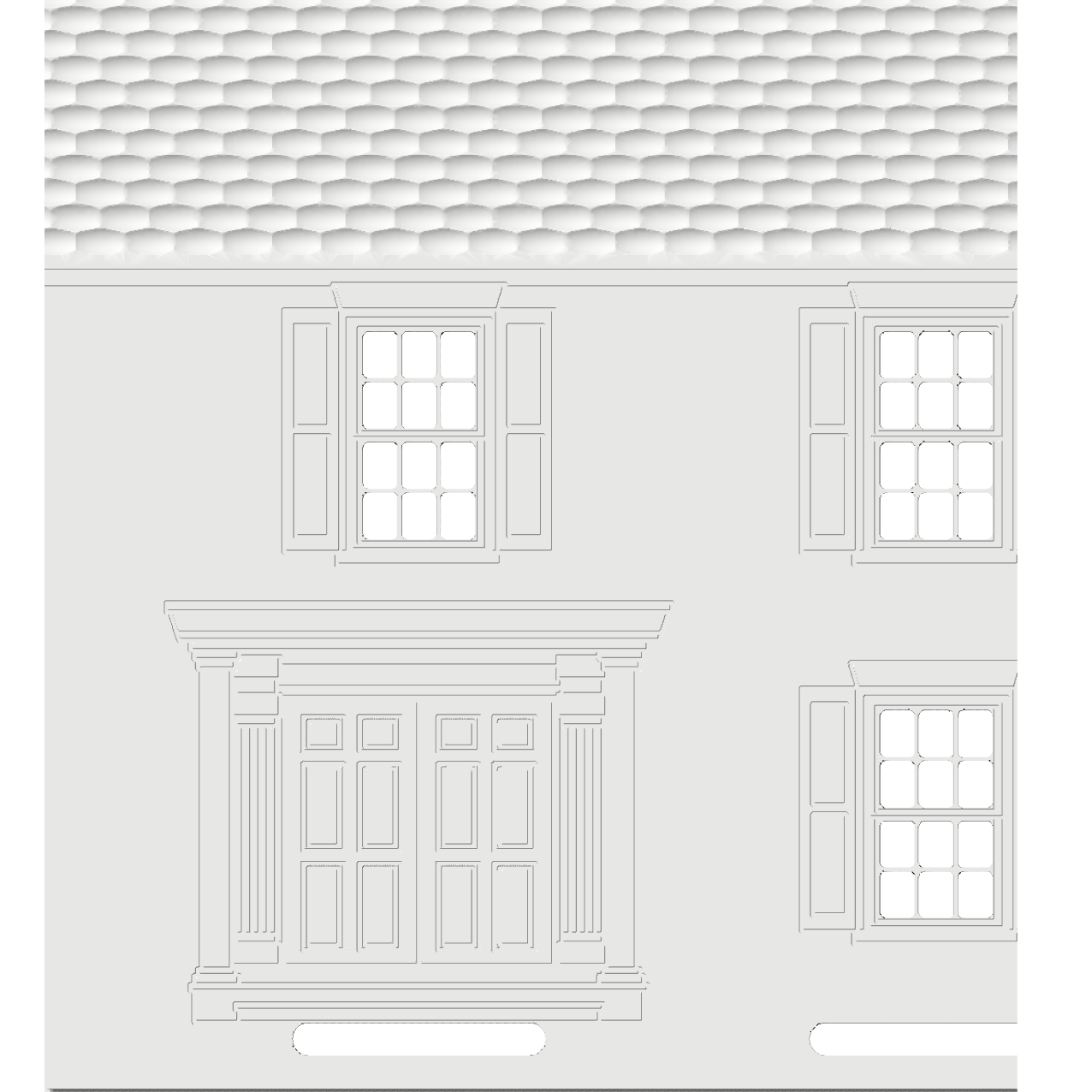

I really need to take better / professional photos of the work done - so much time and the photo's are really garbage. For this week I really wish the architecture department has a proper photo studio - or atleast resources to take proper photos of the work. In the meantime what is on the site will do to represent this week. I was traveling for much of the week with the design studio I am TA'ing for so this week's assignment was a bit rushed. The main goal was the bend the plywood and through a few iterations the plywood did bend by putting the slices on the back of the sheet. At first it was not deep enough or many enough so I had to redo the cutting to double the depth and amount. With help from Egbahl the plywood bent and I was quite happy.

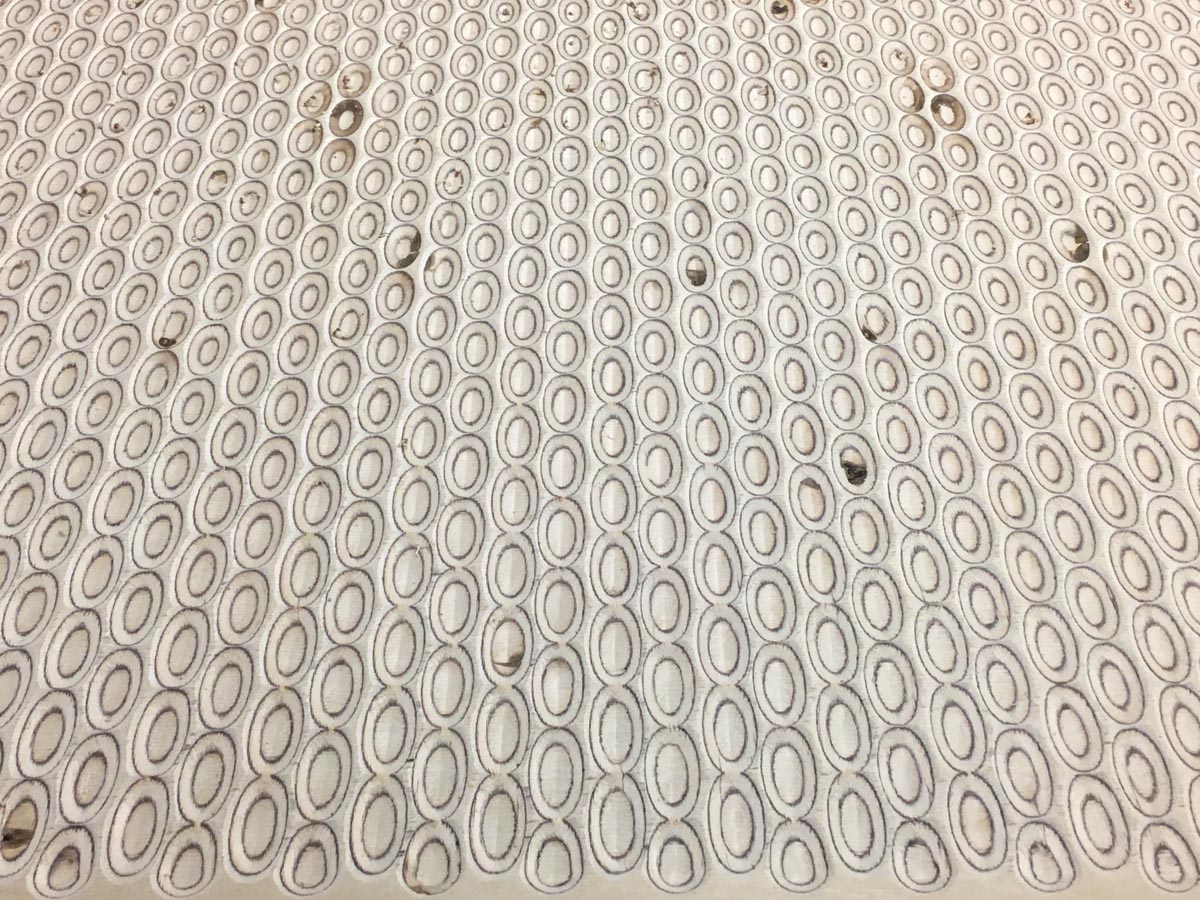

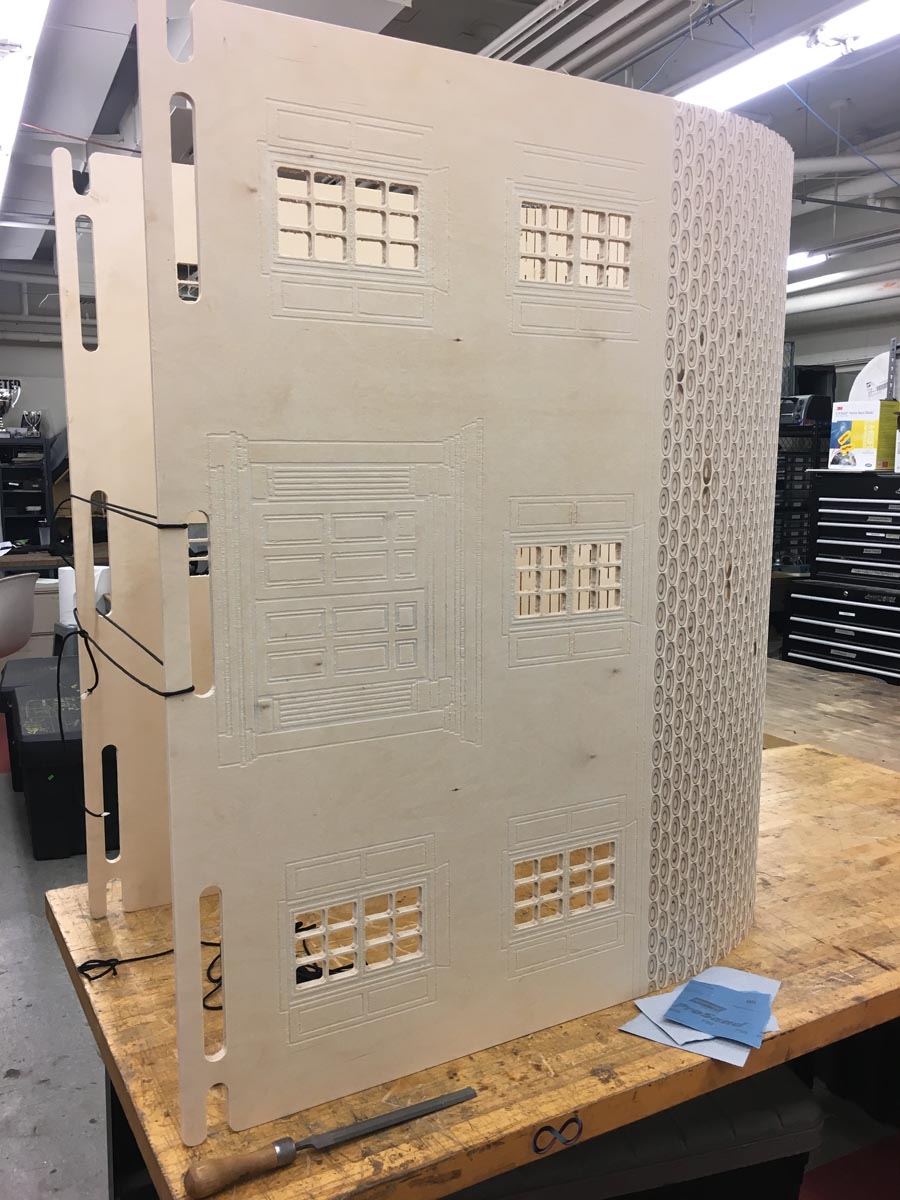

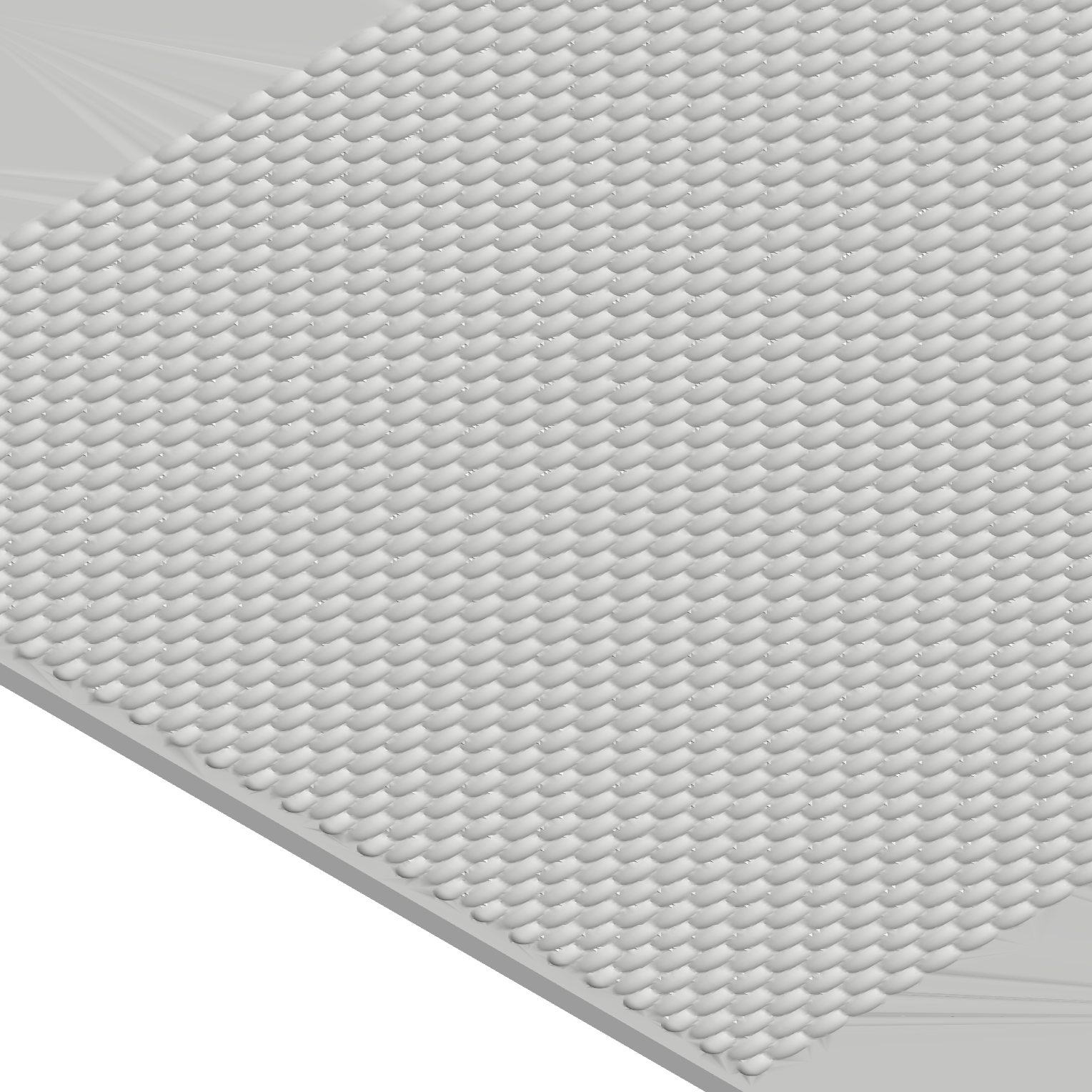

Justin was really vital in this projects success - using a 3" endmill bit I was able to put a patten on the surface of the wood which resembled shingles of a house - the toolpath just raised and lowered over the length o the plywood giving it a pattern. I also quite like the layering of wood and what that allowed to happen.