Week 5: Make Something Big

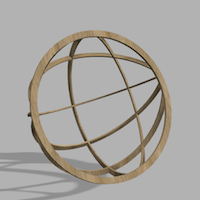

Some of my initial inspiration:

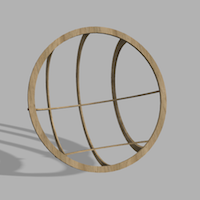

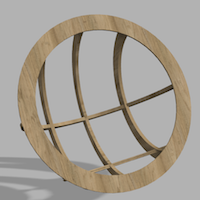

I decided to build the spherical chair because it was the one that had an interesting function and form.

My design was based around the average sitting height of a person scaled by 25% (43 in inner diameter).

After many struggles in Mastercam, I began to cut on the Onsrud. It has an automatic tool change function.

My something big (at 5:06 AM on Tuesday)!

Appendix of Checklists:

Some Helpful Commands to Know in Rhino for Making 2-D Paths:

Basic commands:

Join - Makes closed curves

Explode - Cuts curves into constituent pieces

Fillet (radius 0) - Joins and trims two intersecting points

Trim - Trims stray lines

Things to check if your curves are not closed:

Project to CPlane - Check to make sure your DXFs from Fusion are in the same plane

Sel closed curves - See which curves are not closed

Intersect - Puts a point on each corner to see if any are not connected

Show edges (and choose naked edges) - Show where your shape is not closed (especially helpful for 3D Printing)

A generic checklist for the Onsrud Router and Mastercam:

1. Make sure there are 3 layers:

-Stock

-Drill points

-Lines to cut

2. Make sure you set your stock dimensions in stock setup

3. Mastercam calls import "merge" - opening is reserved for mastercam files

4. Do your drill path first - choose your "level" or layer and make sure you choose the correct drill size. To select points you must right click the window.

5. If you are doing 4-axis routing, make sure you create a check surface to not drill into the bed.

6. Turn on "rapid retract"; turn off "lead in/lead off".

7. Avoid cutting small parts near the vacuum edge; if you need to cut a lot of parts consider doing it in parts.

8. Use simluations to do a sanity check. To check if you are doing depth well use "verify". Make sure that all of your lines are chained together and not separate lines.

So much thanks to Justin, Jen, Sam S. and all the woodshop TAs for giving me so much feedback!! Esp. Justin for giving me so much advice and feedback about my design and helping me with my Rhino and Mastercam files!