Zach Cohen / How to Make (almost) Anything

3D Scanning & Printing / Nozzles and Blobs

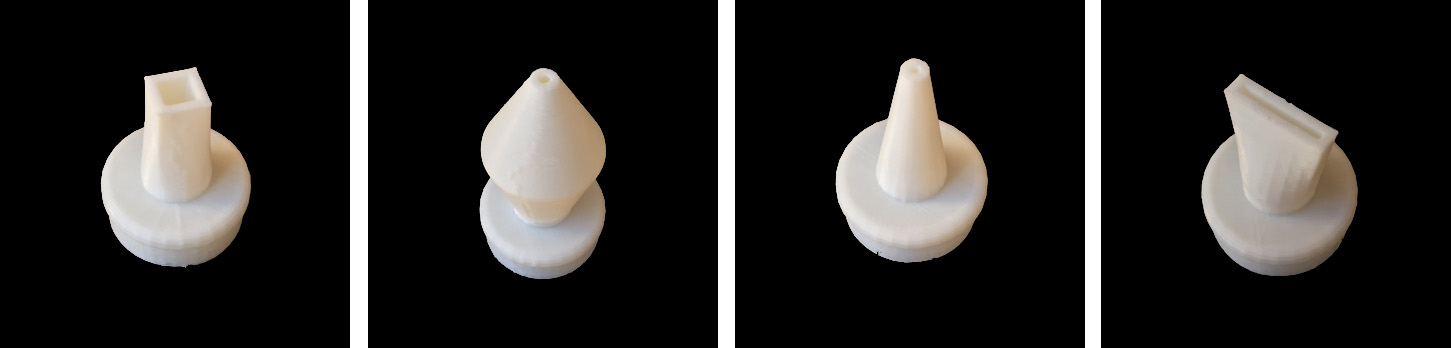

For the 3D printing portion of the assignment, I used the printer to prototype several different kinds of nozzles for my extruder end effector.

My first round of prints was done on the Sindoh, but the attachment to the caulk tube that I had retrofitted to be my hopper was not dimensionally accurate, so I had to redesign.

I then printed another round on both the Sindoh and the Ultimaker. The Ultimaker was having difficulty extruding so I put the temperature up and the speed down, which caused me to lose resolution. The Sindoh had no problem but required a filament reload and changing out the roll was a little tricky.

I tested extruding with each nozzle and found that the "broad-tipped" nozzle had the best flow control for my application. The "torpedo-shaped" nozzle was also interesting because it resulted in a delayed start to the extrusion which can be seen in the exaggerated taper of the beads.

I also printed a couple of extruder body prototypes, which I will use to test my pneumatic bladder extrusion concept.

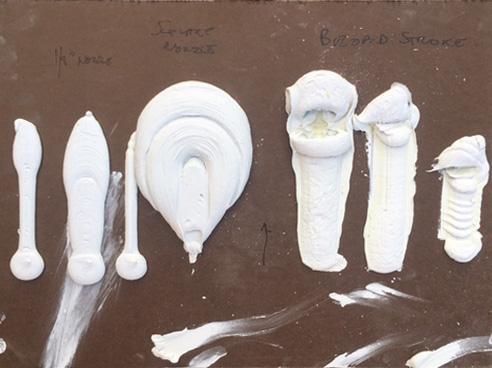

For the 3D scanning portion of the assignment, I scanned a small test I made with my concrete 3D printer.

This proved to be difficult because of the size and amorphousness of the object. Initially, I thought it had to do with the color of the object and the background, or the combination of the two, so I spraypainted the object and made a stand for it. However, it turned out that the issue was that the color of the background needed to be kept constant. So I put it on a swivel stool with a neutral color and swiveled the seat as I scanned.

I printed out the scan, which showed the problems in capturing the resolution of the object. However, the overall form was pretty good.

I then attempted to print another concrete test on top of my print of the scan of my other concrete test...

...but it collapsed because the mix was not right and the points did not form to size.