Zach Cohen / How to Make (almost) Anything

Computer-controlled Machining / Robostation

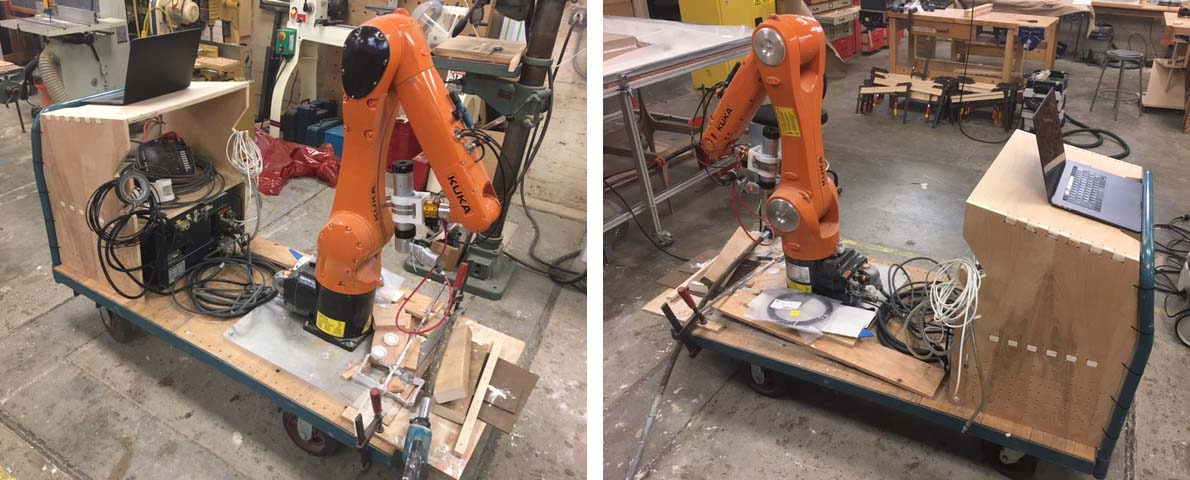

The work area of the robotic arm in N51 was a mess. There was no dedicated storage or table space for students to use while working with the arm, and the trolley that the arm sits on was a mess of wires and leftover materials...so I decided to make a CAD station.

The CAD station design consists of several elements: ventilation for the robot compupter, integrated hooks for wires and tubing, shelf storage, and, of course, a working surface. I also aimed to integrate the design with the existing trolley by forming the profile of the station to fit the contour of the metal railing.

The milling process went smoothly with the exception of two small details that needed to be touched up. First, the drill holes didn't go all the way through the sheet, which was in part purposeful so as to not drill through the spoilboard, but meant that I had to quickly finish each hole by hand. Second, because of the depth of the cuts being too high, there was a lot of chip-out and a lot of sanding that had to be done.

After a lot of sanding, the pieces were ready for assembly. I made the joints loose deliberately to allow some wiggle room, but I took away too much material and had to use glue to keep everything together.

I used finger-joints to join pieces together and zip ties to fasten the work station to the trolley. My trace of the railing wasn't that accurate, but close enough for the piece to look somewhat integrated.