Zach Cohen / How to Make (almost) Anything

Machine Design / VanGo

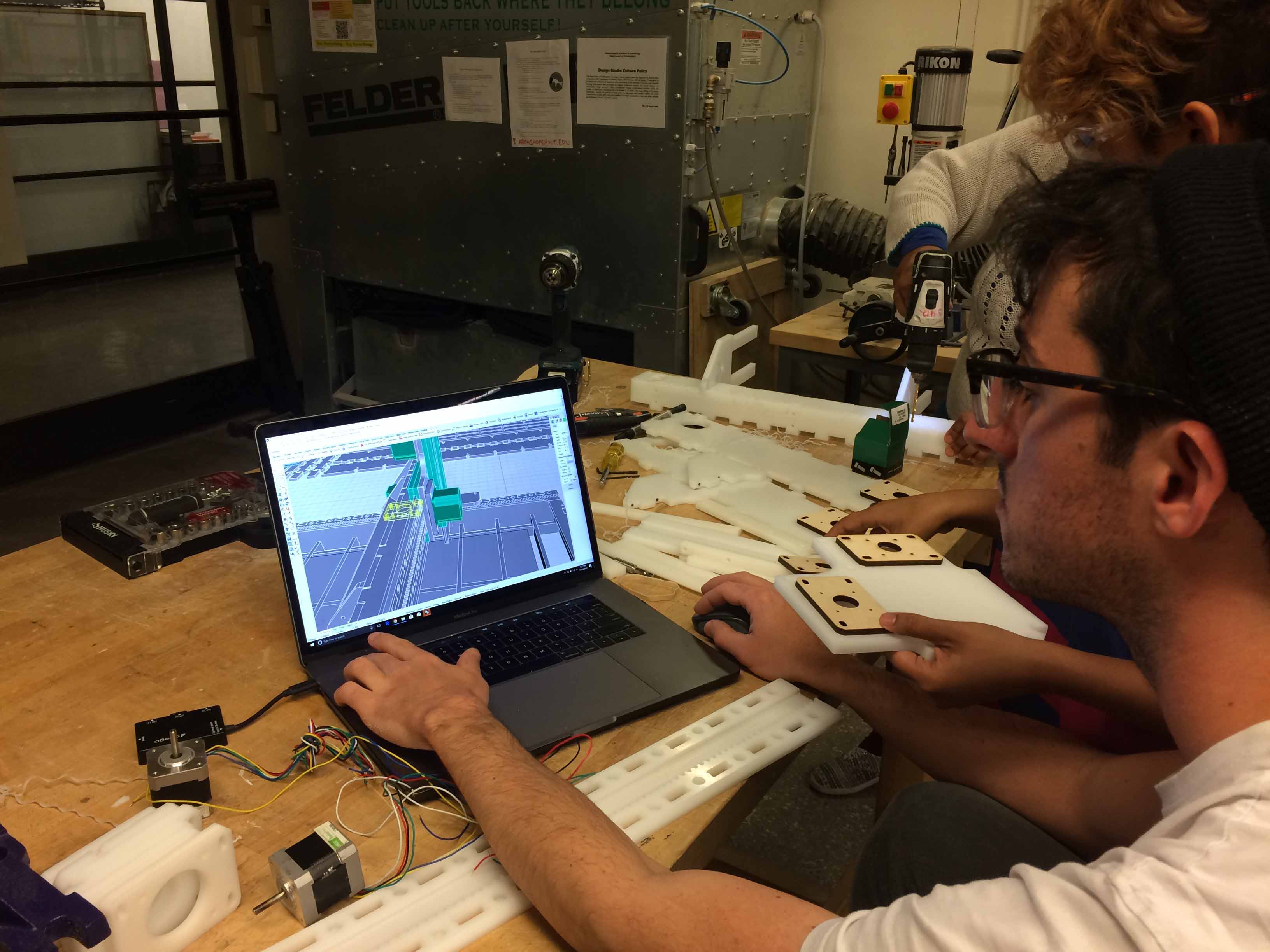

For the Machine Design assignment, I was on the Electrical and Assembly Team. We had made a schematic of our wiring layout in Rhino, but when we received the pieces, we found a lot of surprises and wiring was the most straightforward part.

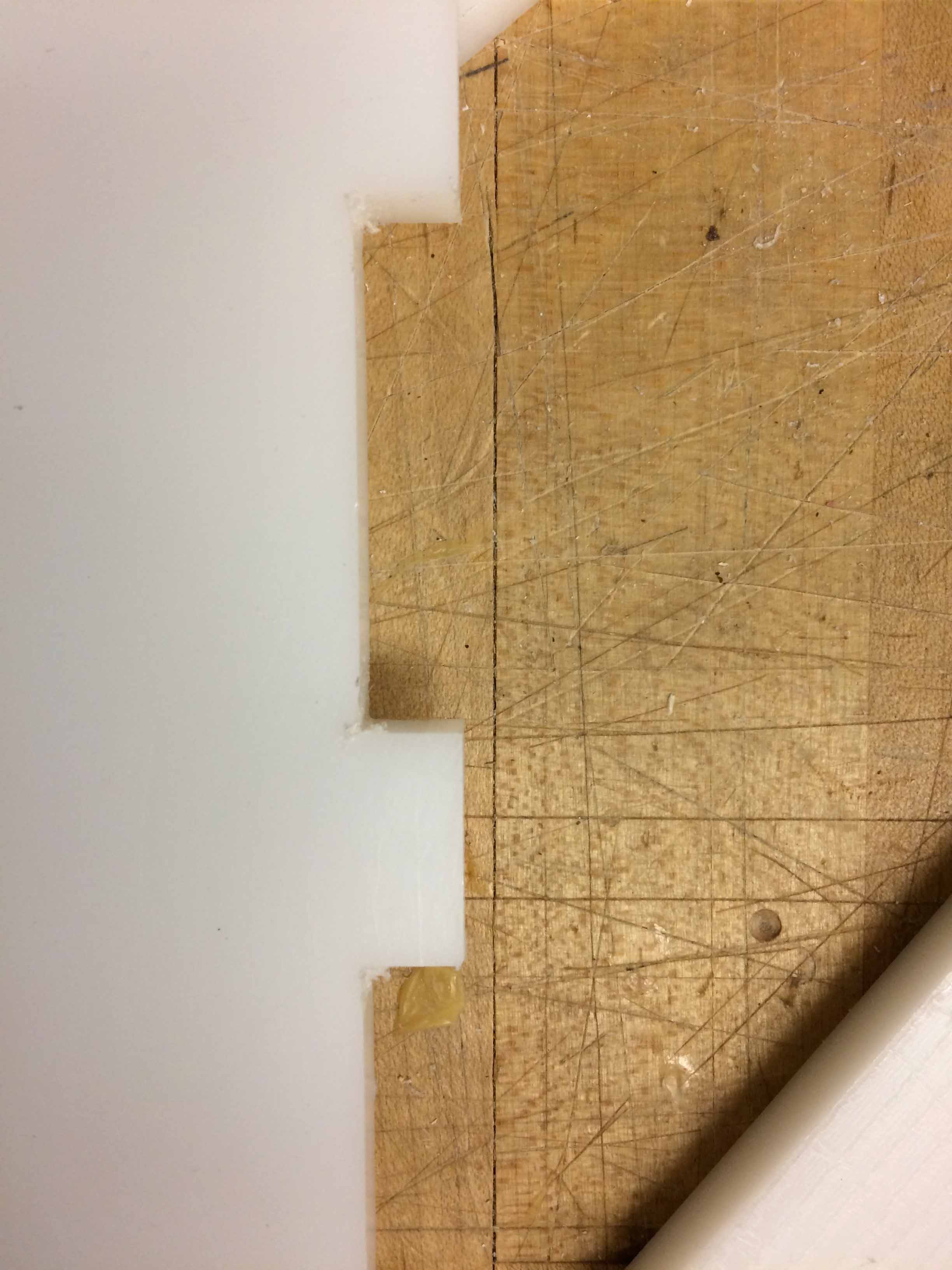

First, we discovered that all of the press-fit joints had rounded edges so none of them would fit together. This means we had to go back in and bandsaw all of the joints to remove the excess material left by the router.

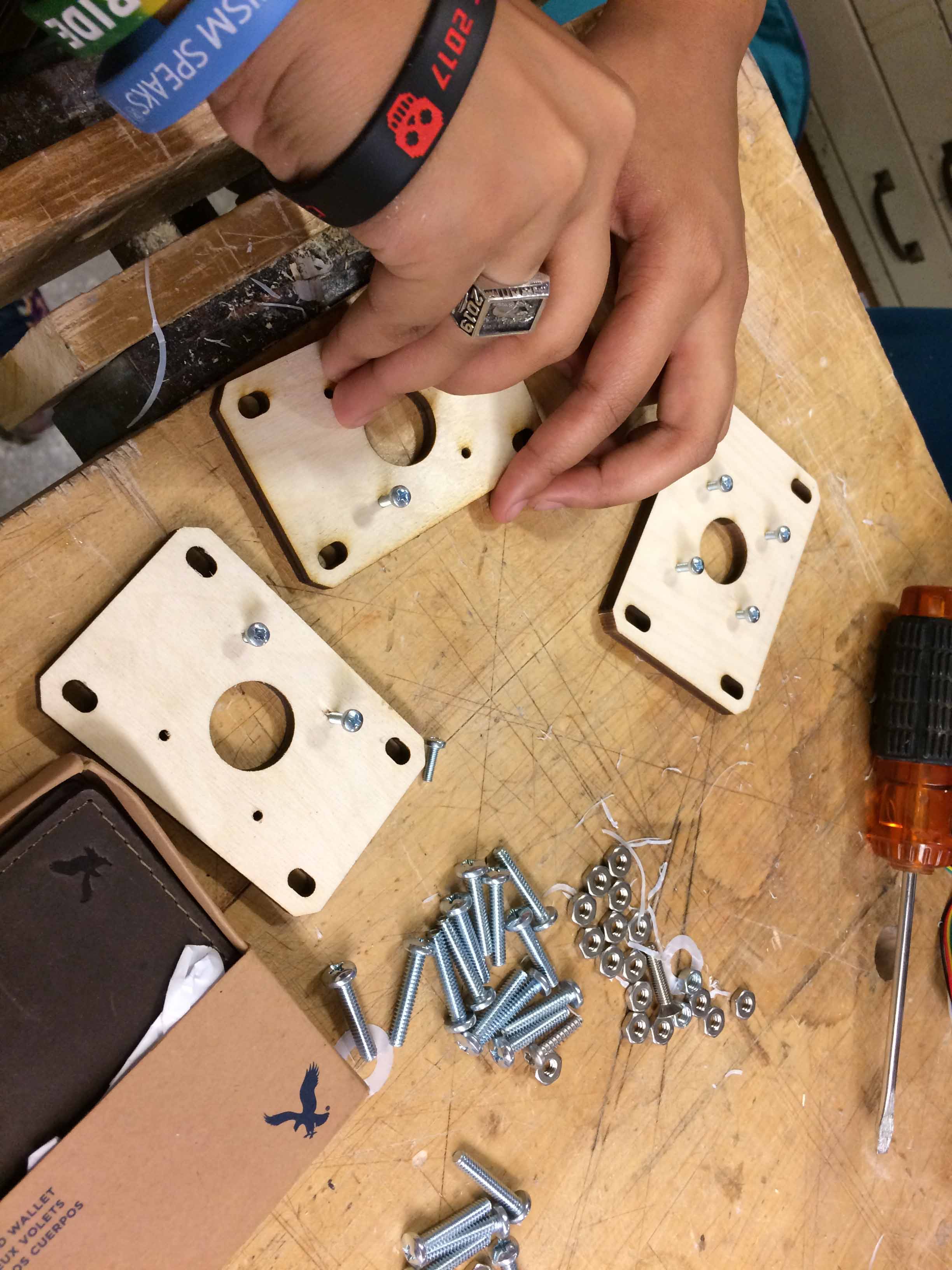

All of the mounting plates made for the motor were made for a different model of stepper motor so we had to remodel the plates and lasercut them out of scrap wood in the shop.

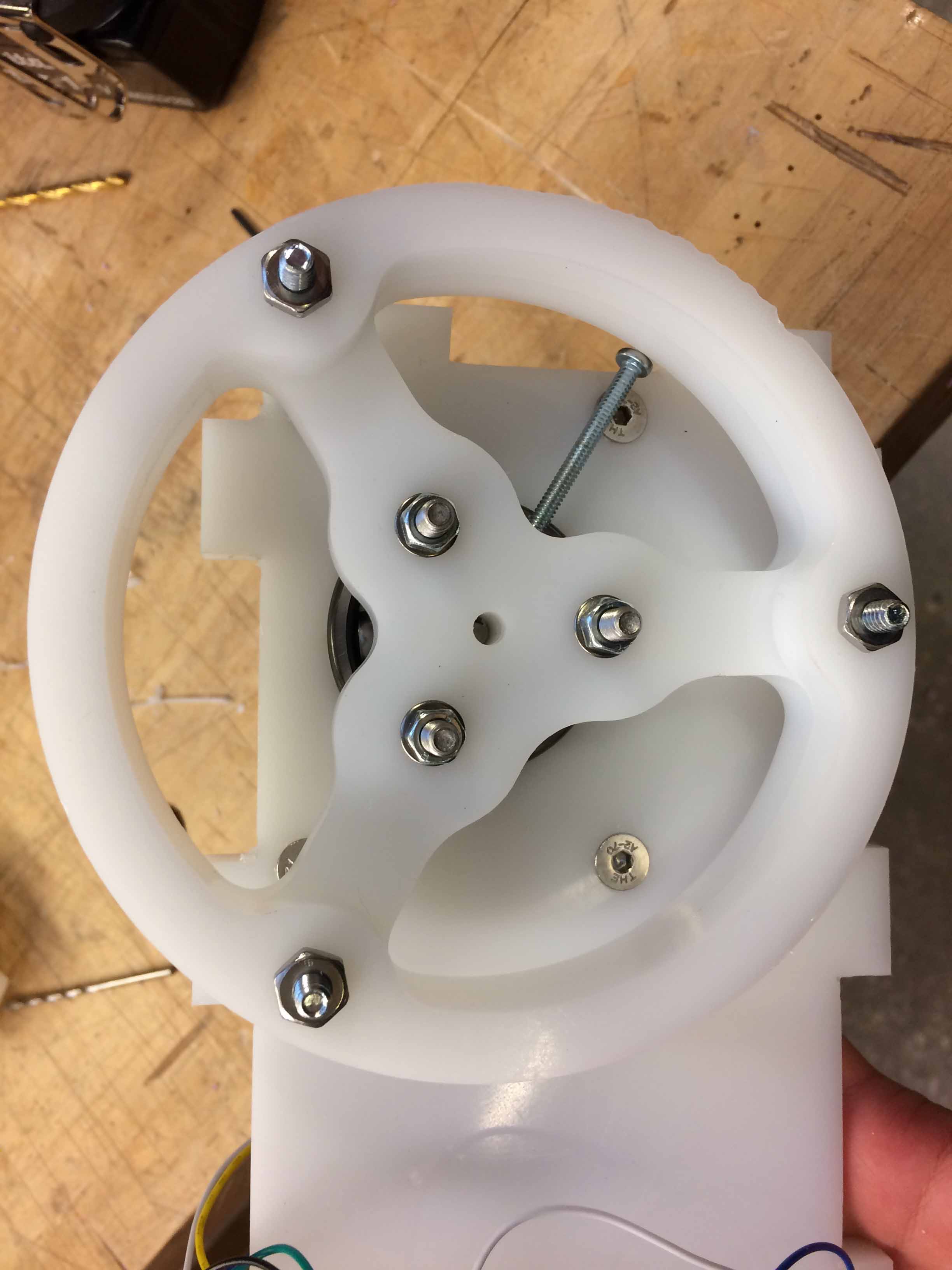

There were lots of fasteners that required nuts, but no nuts included in our set so we had to scavenge different shops to find the right hardware.

We had to improvise some set screws for our wheel hubs.

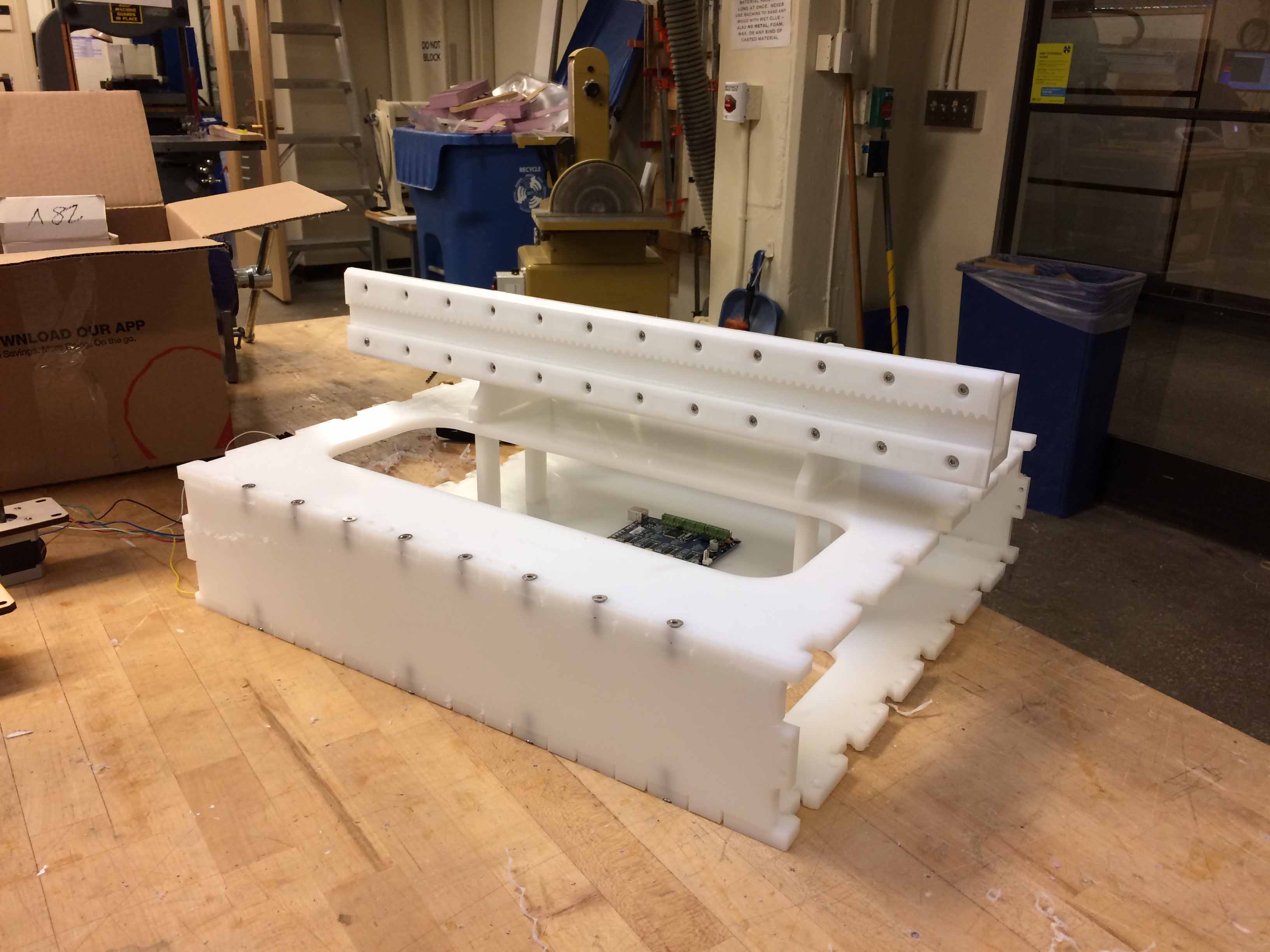

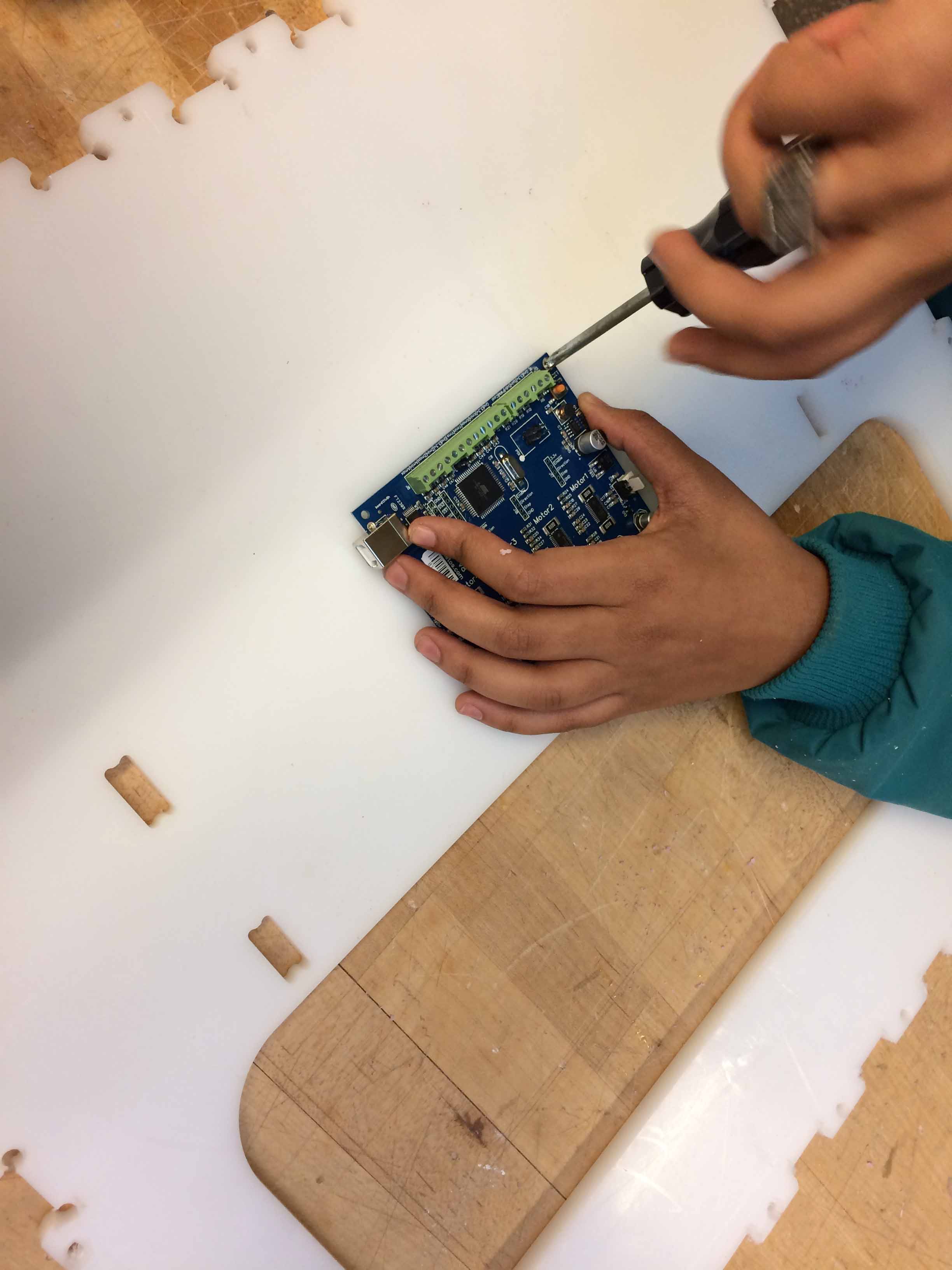

Mounting the TinyG was perhaps the simplest part of the whole operation. We located it in the center of the chassis to make easy connections to the various motors.

With several small modifications and finessing of different parts, the VanGo tooks shape.