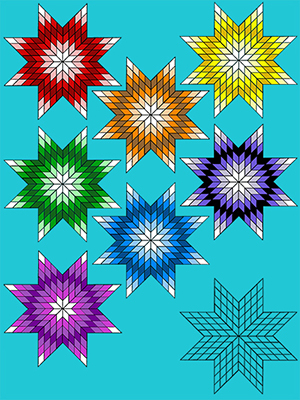

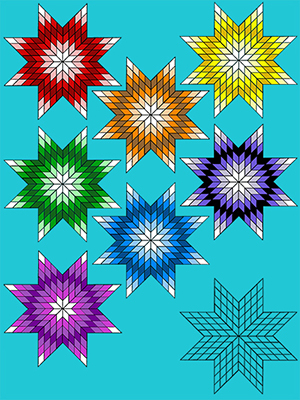

As a creator of Morningstar-patterned artwork in textiles and other media, I have found a color visualization and selection to be a challenge. It's time consuming to draw and color paper templates in order to configure a successful color scheme for a design. I would like to create an app that would allow the user to choose from an array of colors to help guide creative decisions, such as how to arrange the colors in the starburst design, how many diamonds are needed and how to create perfect geometric forms. An accompanying LED projection unit, programmed from the app, could project color choices to help the user get a sense of scale. It would also be a beautiful ambient light source.

Week 1 thoughts: I have faced significant struggles this week with setting up my webpage. This may mean writing an app at this stage is out of reach. Perhaps creating a remote control would be a more viable route and would achieve a similar result.

Week 2: In using the epilog to cut out my diamond shapes, I have realized there is a limitation on what kind of materials can be cut in the machine. If I am looking for a clear plastic substrate, I must use an approved plastic substance. I ran into some difficulty with creating the notches which joined my pieces together, and I realized that I will have to do several test runs of the diamond shape in order to arrive at a final design which will match the specifications to make the unit work.

Week 3: I'm thinking about an appropriate design for a circuitboard for my project.

Week 4: This week had me again re-evaluating my proposed final project. I am becoming interested in creating a robot-like structure with unique, sculptural three-dimensional parts. Still if I choose to move forward with the Morningstar light projection unit, I will need to lay out the design and decide where the 3D printed elements will be located, and what need 3D printed parts would serve.

Week 5: Electronics design is challenging and had me thinking about how I would combine components to do the tasks I hope to accomplish in my final project. Without kowing how to program the boards, it's still a bit of a mystery to me how it will all come together, but I do have the skills now to design and produce the circuit board that will be needed. One of the components I would like to try working with is a photodiode. I think it would be exciting to power the object with light, the way solar panels do.

Week 6: This week I have considered how my final project can benefit from the use of the shopbot and I can see creating a stand, perhaps on wheels for the projector.

Week7: I have begun to narrow down what my final project will be. I had done work and research on creating a box where people could speak the names of the missing and murdered indigenous women into a microphone inside the box, and there would be unit inside the box that would record it and store it and then the user could access a button panel to playback a single name, all the names, on demand, amplifying the name on the speaker. The box would be made beautifully, using the CNC cutter to cut out an image of a woman in wood, where the speaker's sound would come out. This project also seems very daunting, and I wonder if it would be possible for me. I spoke with TA Prashad about this and he said from a programming standpoint, it would be fairly easy to write the program for this. This is good to know, and I am still trying to decide if I want to go in this direction. It's a very difficult project to do emotionally, and might be too heavy of subject matter to use when learning new technology. If I can learn the technology, this is a project I can do at a later time when I am more proficient.

After further reflection on the flexibility of the Morningstar form, I continued to consider the possibility of creating a Morningstar projector, in a format altered from the original vision. Instead of a color chooser, it would use a kaleidoscope rotating inside of the unit with light shining through it to project the Morningstar image onto a wall or surface. My son Sam inspired me to do this by shining a flashlight through a clear flat box of colored glass beads. As he rotated the box, the light projected beautiful colors and shapes to the wall. With this project, the programming would have to turn on the light and rotate the interior cartridge containing glass beads of differing shapes and colors. The programming could be written to include different speeds of rotation, low medium and high. Perhaps the cartridge could be opened to add different materials that would have a different effect on the projection. I am leaning towards doing this, since it is in better alignment with my initial goals for this class.

Week 8: Creating the four diamond morningstar form in Fusion was very helpful. It will serve as a template for the final project parametric image. I also considered the possibility of casting a lens for the projector.

Week 9:This week I attempted to create the board that I will need for my project. I will need two outputs, and LED array or RBG and a DC Motor.This week has really helped to to solidify what I will need to do to accomplish my final project.

Week 10: This week has taugh me about the many streams of workflow that must occur in order to successfully create a machine.

Week 11: This week I did research on light/ optics. As an artist I have much experience working with color, but only with paints and pigments, which are merely light reflective. It's a whole new world to me to study color through light emission. Optics is fascinating and I began looking at the work of early scientists who studied light, including Thomas Young. I want to learn more and I'm excited for this project, which will give me the opportunity to experiment with light.

This week (week 12), I made a lot of progress. I created two models, one of the outer packaging of the projector, because I would like to use the water jet to cut it out of a piece of aluminum, and one of the interior light/ mirror chamber.

I learned about RBG and the light spectrum, inlcuding what is perceptible to the human eye and brain.

I began to research RGB components. I found two possible products to use in the final piece:

Planning

The rotating morning star kaleidoscope projector consists of a rotating slide filled with translucent beads with an LED array illuminating it. The light shines down an eight sided mirror tube and is projected through an epoxy cast lens onto a wall or other surface.

I would like to program it to rotate at different speeds, maybe slow, medium and fast.The DC motor will drive the rotation, and I will have to design a gear that is specific to the slide and casing dimensions. The ligh source will be from an LED array or RGB, and it will be programmed to shine at least 2-3 different configurations of light. The unit will be powered by a 9V battery and will have an on/off switch.

I will make an epoxy resin cast series of lenses that will project the image at a distance.

The shape of the light will be in a morningstar form and this will need to be machined with the shopbot. The final piece will project a unique light sculpture.

With the second model, I created the chamber in the actual shape of a Morningstar to see how light would be reflected and refracted through a lens. I calculated the focal point of a couple of different lenses to determine which would work well for my intended purpose.

I look forward to further testing. I also received the special RGB LED that I ordered, a MaxM from BlinkM that will provide the light source. This week I learned about the RGB spectrum and how to use code to arrive at different rgb light combinations that result in different colors.

Final Weeks update to my process: Many things came together this week which bode well for the final stretch of creating the Morningstar Projector. I completed development and design of the projector and finished purchasing all the parts.

I also used the 3D printer to print a gear for the motor whose specs I downloaded from the Traceparts.com website.

There was an issue with the interior of the gear. It was not solid so I worked with Seth who helped me source a belt and gear for my motor from the Mars lab.

I also began creating the parametric files for the pieces to be laser cut from the 1/8th inch plywood.

I have kep a tally of the parts needed to produce my projector:

I have also begun experimenting with the GUI available with the MaxM RGB LED board.but ultimately decided not to use it

The Project:

"Morningstar Lightchamber" is an LED projection unit that transmits RGB colors, programmable in all colors of the rainbow up to 8 meters. The unit can be projected straight ahead or at an angle of up to 60 degrees. Light from the RGB LED travels through a mirrored-morningstar chamber and through a lens 100mm lens with a 200mm focal point, to display a kaleidoscopic image on the wall or other surface. The unit has a programmable stepper motor and belt attached to a 4" PVC pipe which rotates the chamber. It can go slow, medium, accelerates and decelerates and rotate the opposite way.

Rotating rgb leds for the holidays can be bought very cheap, but I wanted to learn the processes so I can continue to make rgb light objects for my artwork. I've been using the Morningstar design to learn the various processes this semester, and wanted produce a final piece that would be an expression of the skills I've learned this semester as well as an example of Dakota cultural expression.

What did I design? I designed the Morningstar Lightchamber to work with the focal point of the lens to create kaleidoscopic reflections when projected. I designed the rotating unit and body of the unit. I designed the base to be heavy enough to keep the unit from tipping over when projecting at a range of angles between 0-60 degrees. I designed the motherboard with a switch and H-bridge and the ability to network with the MaxM LED unit, even though it did not work in the end and I had to find an alternative to make the unit work, an Arduino.

Final Implementation:

What questions were answered? I wanted to figure out how to create a projection unit and use light as a medium. As an artist, I used light's reflective qualities, and am starting to use it as a source. This is the first opportunity I have had to integrate light's colors in the spectrum of RBG, and I look forward to learning more about how to produce color combinations. I also had to determine the length of the chamber to produce a clear projected image of the Morningstar so did may tests to figure out the best size for a distance of 6 to 8 meters.

This project was both a success and a failure. The projector eventually worked, but I was not successful in actually making a networked circuit using I2C. My goal was to create a motherboard with nodes for the MaxM unit and the H-bridge for a DC motor. I spent many hours designing and creating boards, testing them, working with several TAs to debug and even got a tutor to help me.

I was ultimately not successful in making my boards do what I set out to do. My progress in programming was stymied because I was not able to make my board(s) function. I did have a few small successes, but the timeline needed to create the final project demanded alternatives, so it was suggested that I use an Arduino board. I was able to do this successfully and to combine two types of code: one for the LED unit and one for the stepper motor on it to make it function at the most basic level. The stepper motor and belt needs some tuning to function continually, so that is not fully successful either.

Overall, I am thrilled I was actually able to make a projector, even though it is primitive. It's not something I ever thought I would be able to do. I have become fascinated with optics and plan to continue studying it through the creative process. I also plan to continue to learn and refine my skills in all areas of what I learned this semester so that I can make better light projection units. It's a goal to pass along what I have learned to other Native artists once I graduate and begin teaching. I think "Morningstar Lightchamber" has been a great jumping-off point.

Process:

I began with questions: how would I get the light to focus and form the shape of a Morningstar? How would I get the unit to rotate? How far would I need to project in order for this unit to be useful in an art installation?

After creating lots of drawings working out the various questions with a pencil, I began translating the process into the digital realm using Fusion to develop the components.

I use the loft function to create reflective area to surround the LED and focus the light towards the end of the chamber. I decided to use a PVC pipe, 4 inches in diameter to house the chamber and easily rotate it.

I created all the components of the body of the chamber and pvc housing in fusion in order to laser cut them on quarter inch wood board.

I ran into a problem when laser cutting when the laser cut out the pieces at 33% of the size I needed. There was an issue translating the .svg files from Illustrator into Corel. I was unfamiliar with Corel, which the Epilog laser cutter was connected to, so I didn't check the ultimate size. Unfortunately, I had only purchased a limited amount of board, so I had to make do with what I had. I was able to stop the job and cut only the most important pieces: the pvc housing and the lens carrier.

I was able to salvage some of the other pieces to at least provide some packaging.

I also used the composite week assignment as a base for the unit and I filled the bottom with rockite and let it set in order to make it heavy.

I installed ball-joint hardware to give the projector range of motion from 0 to 60 degrees so that I can project on a ceiling as well.

I created the mirrored inner light chamber in the Morningstar form after much testing and mistakes, ultimately using mat board and mylar tape to create the form.

I inserted in into the pipe and began assembly.

I installed the stepper motor and used thermomorph plastic to create a track around the pvc pipe for the belt to grip.

I sewed the belt to size. There is an issue with the tension of the belt, so I need to take another look at it to make sure it will do a full rotation without any issues.

I had initially planned to use a DC motor, connecting the H-bridge board from Neil's design (which I built twice and neither worked) to the mother board, which I also designed and created multiple times without success. Since it didn't work, I ran over to Microcenter and they only had a stepper motor with board in stock. I also got an Arduino Uno at that stage, since I was having issues with making my own boards respond.

Here is the code I used in the Arduino IDE for the stepper motor, using the AccelStepper library.

I followed the instructions on the datasheet for the MaxM, which I knew at the outset could either be networked using I2C to any board or to an Arduino.

The datasheet provided several examples of code to input for Arduino to create different light experiences, and I chose to modify the timing of a basic singular blue, red, green and then all three combined to create my first light show with the projector.

Here is the final form, and it was later painted purple.

I'm really excited that it works! I'm grateful for the opportunity to learn these skills and feel this is the beginning of something really unique.