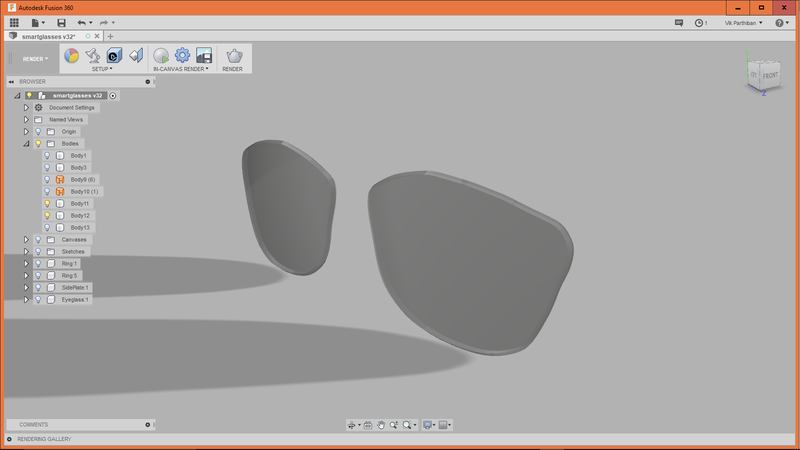

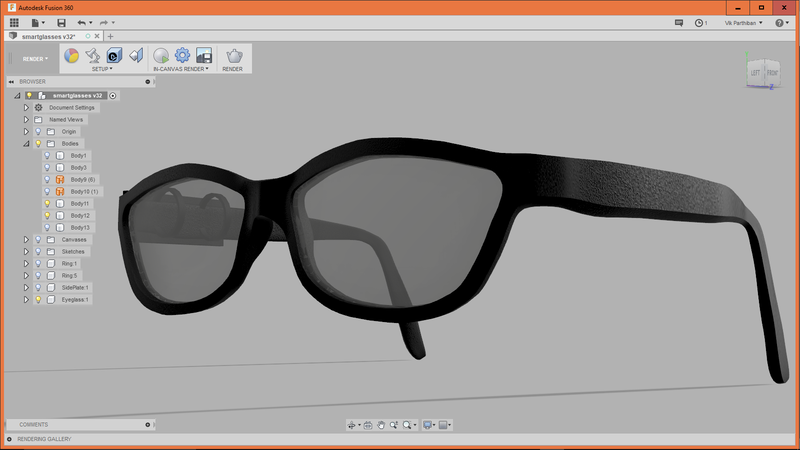

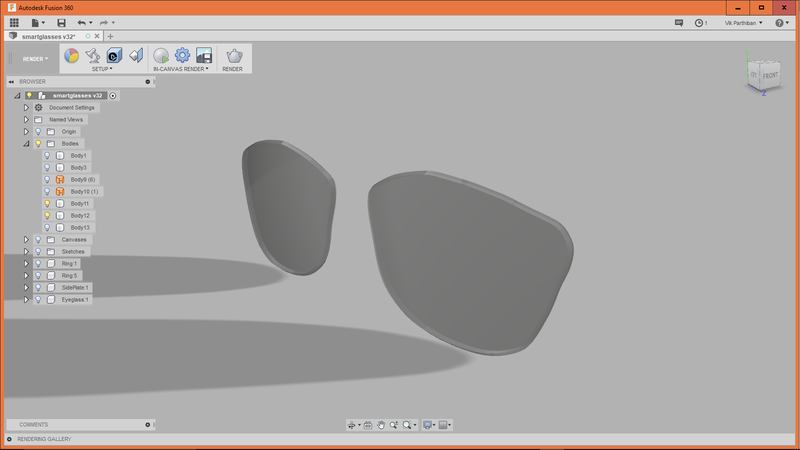

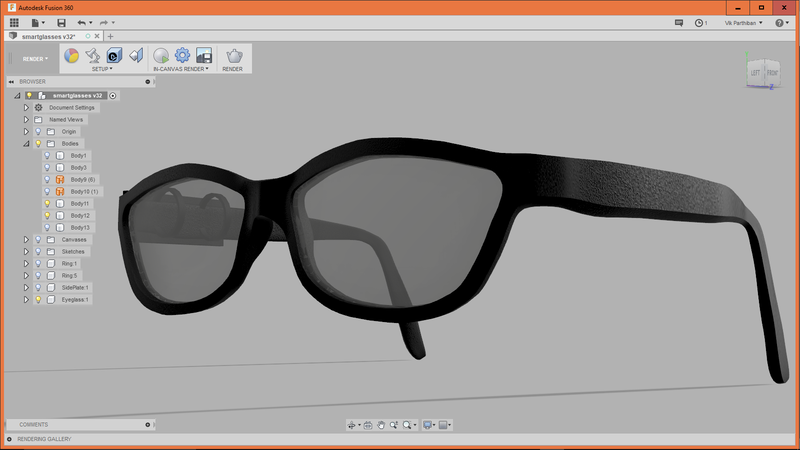

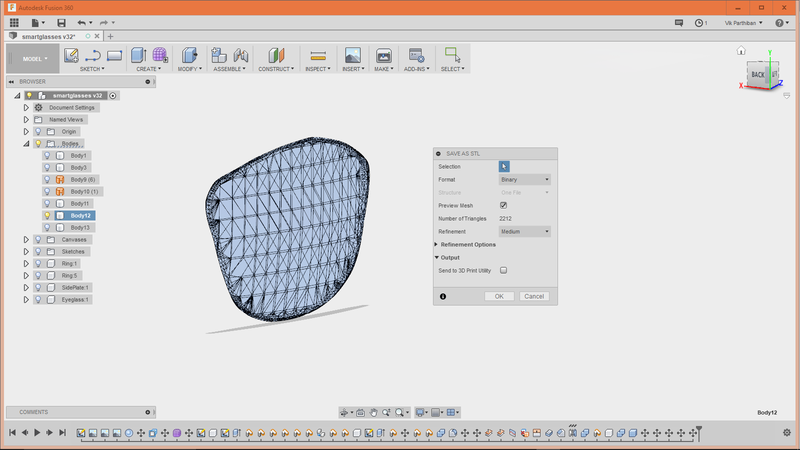

For this week, I attempted cast a transparent lens for my wearable display. First I designed the lens in Fusion 360 following the tutorials from Week01.

Save lens as STL to be 3D milled at Shopbot.

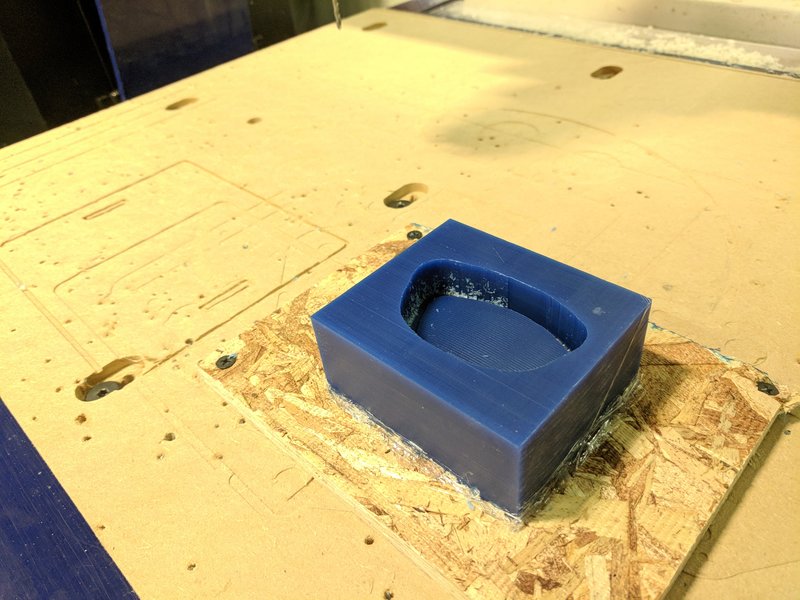

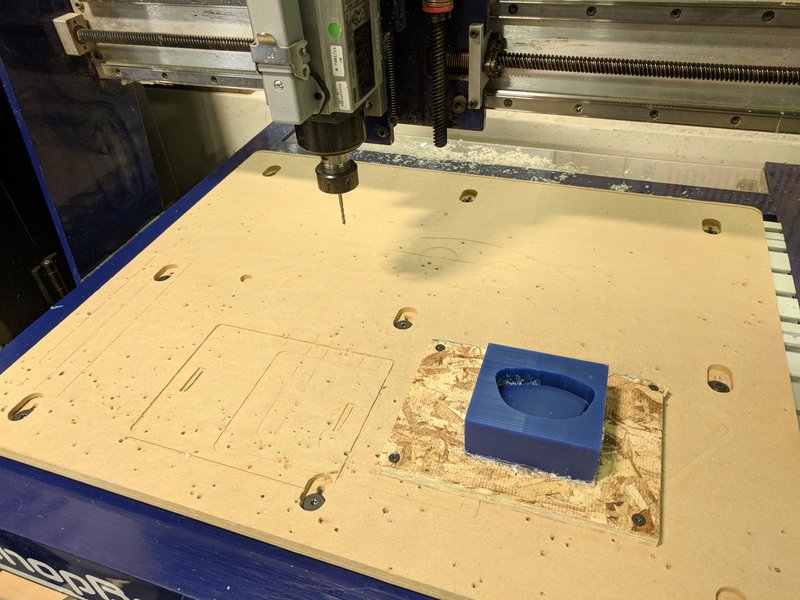

Mill the lens mold (positive mold). Shopbot Toolpaths must be configured correctly here.

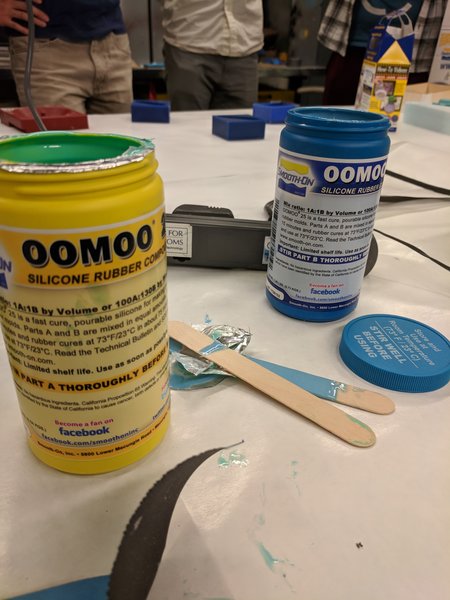

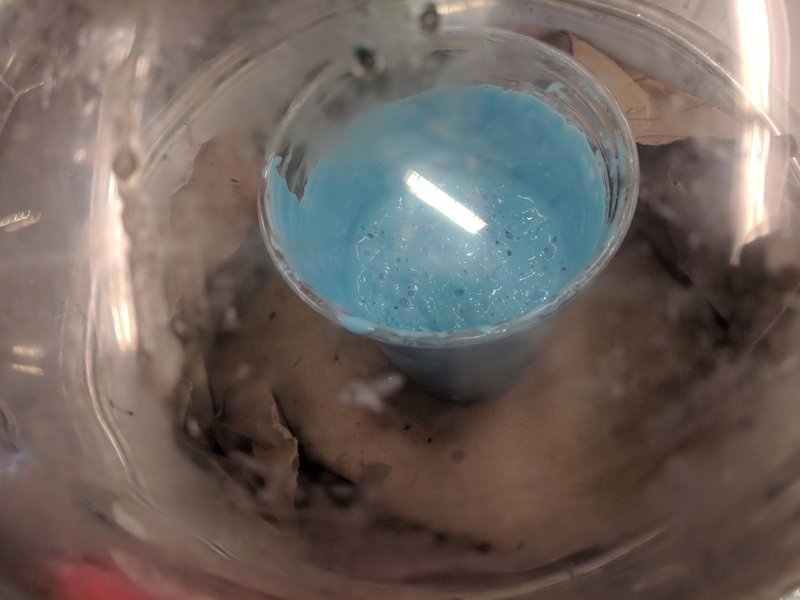

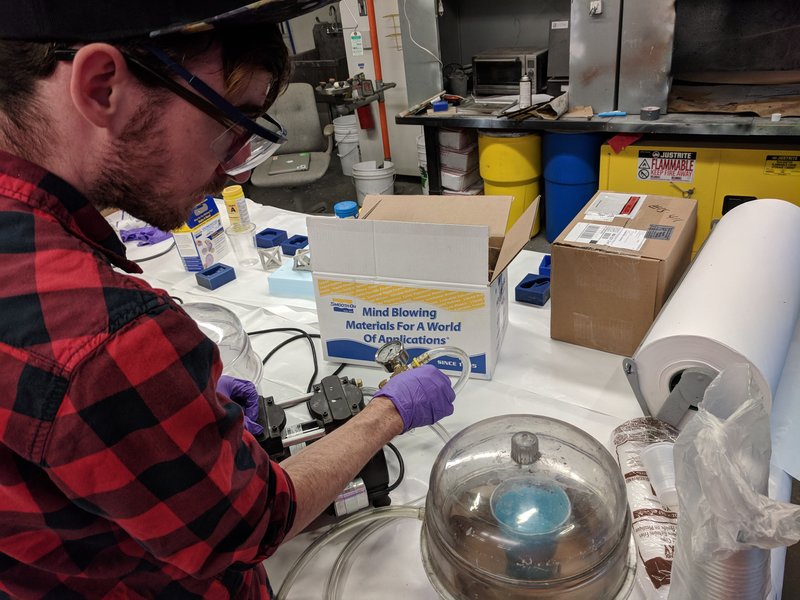

Add Oomoo Smooth-On 15g:100g to the milled mold (to make negative mold) remove bubbles using vacuum pump.

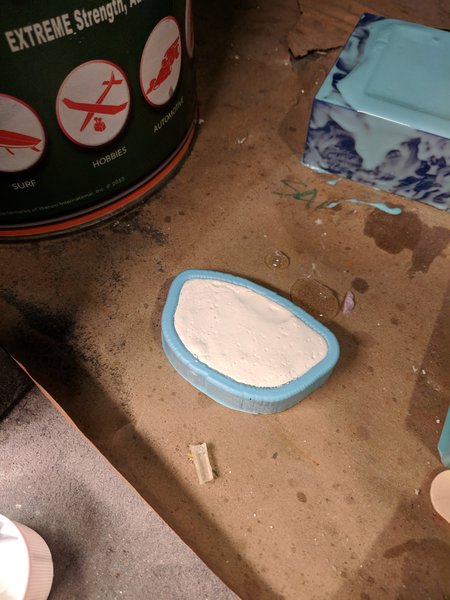

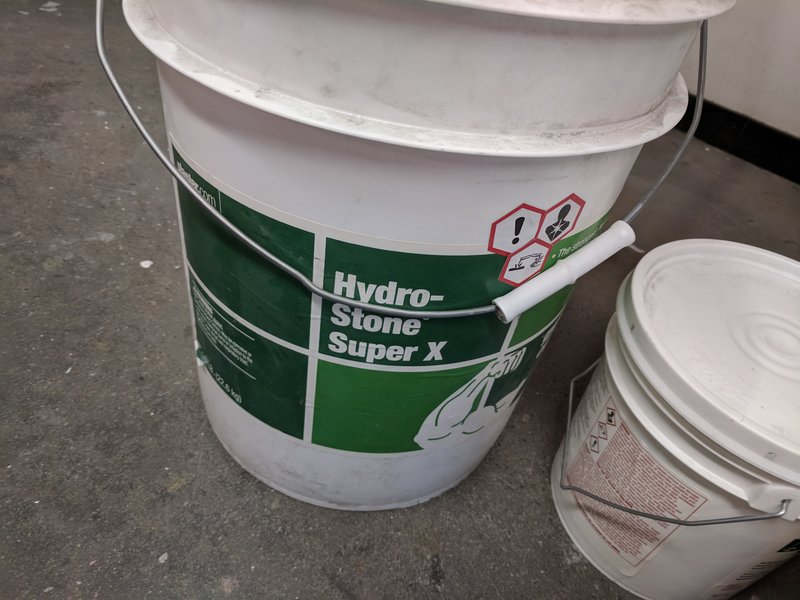

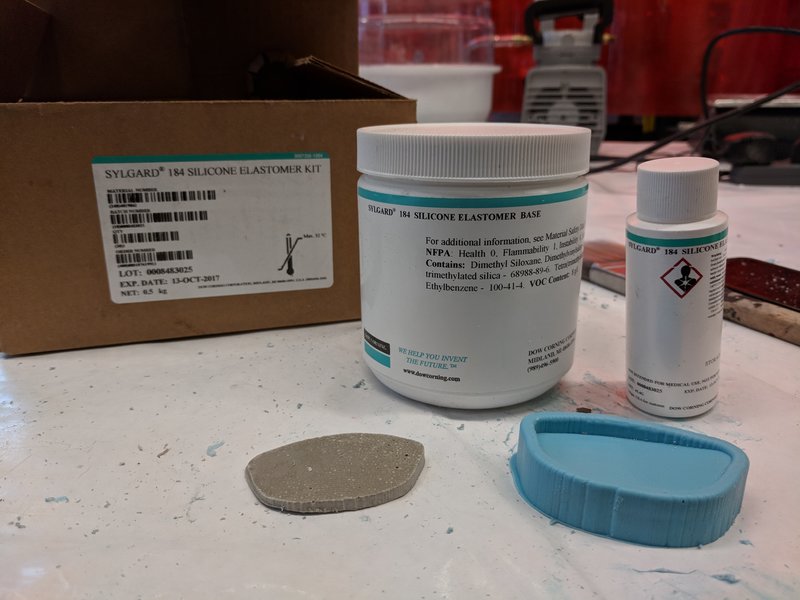

After a few hours, remove the negative mold from the positive mold. Next, I'll put Hydrostone SuperX 20g(water):100g into the negative mold (light blue substrate) to make a test lens.

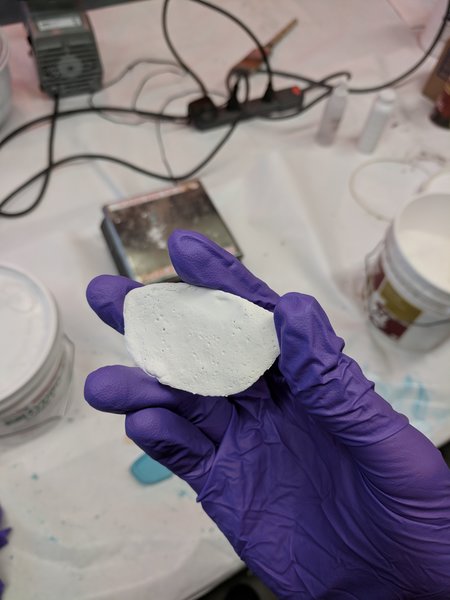

Here's a "lens" made with Hydrostone. Obviously not the right transparent material, but making sure I understand the procedures.

Then, I tried PDMS Sylgard 184 (transparent polymer) to make a transparent lens. Then put it in in oven at 65C to harden the material.

Special thanks and credit to Sean Hickey, Emily Salvador, and Tomas Vega for helping me with many steps of these processes.