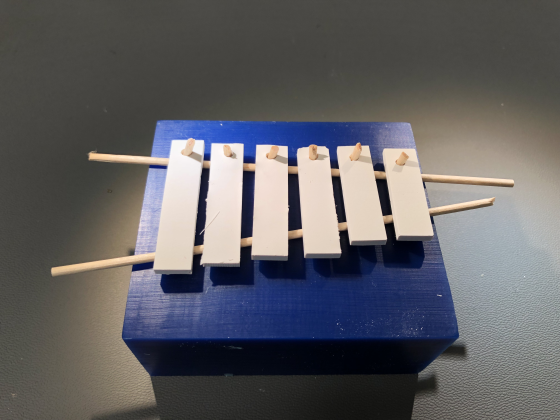

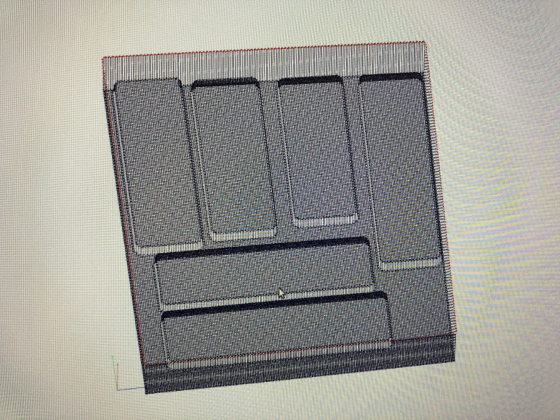

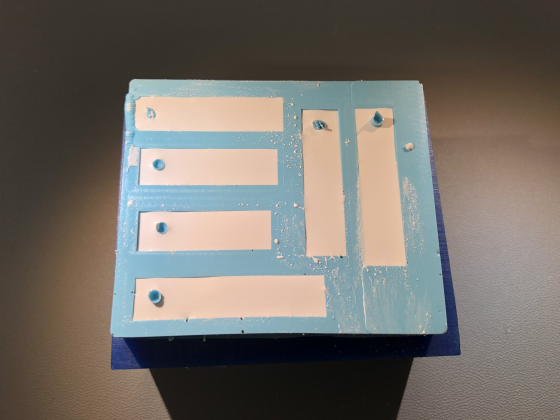

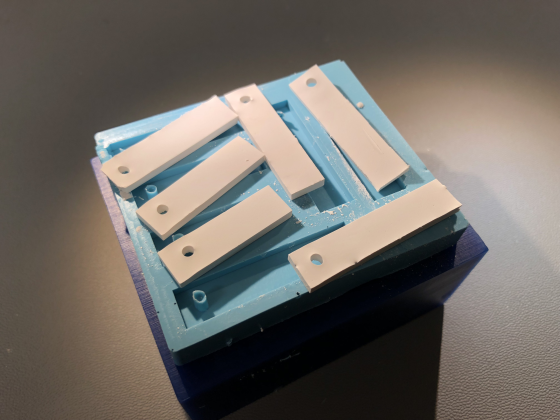

This week I made tiny xylophone/idiophone. My intention is to cast a set of resonant metal bars that can be struck by a microcontroller triggered hammer for my final project. For my first step I decided to make a miniature set with only drystone and then later this week I am going to try to build a bigger mold and try to cast and tune the cerrotru. I am not sure how resonant this will be but I am exicted to try.

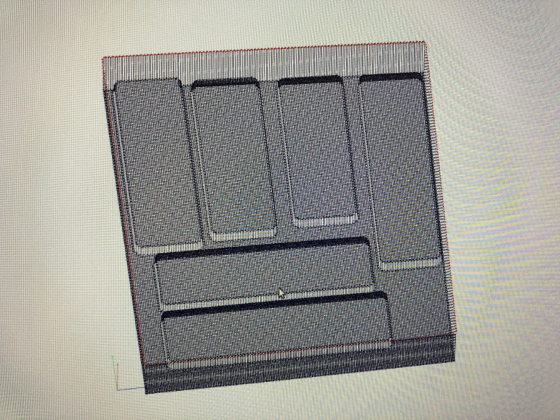

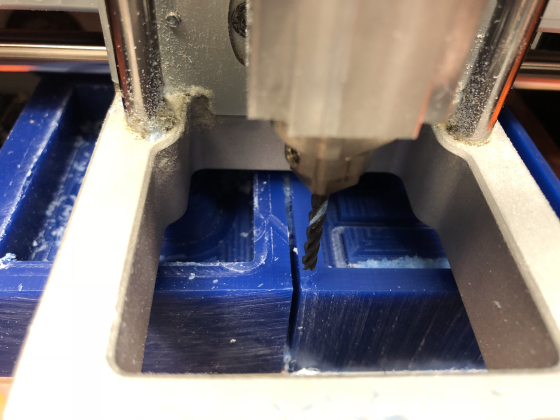

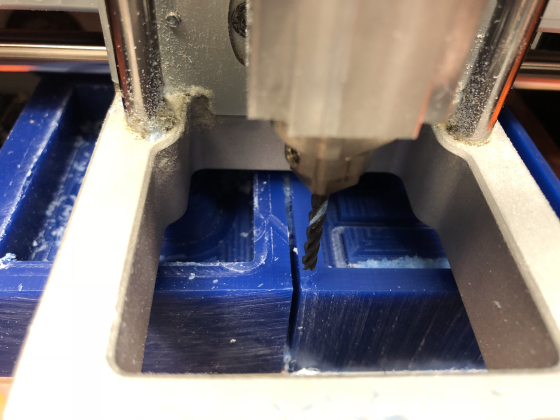

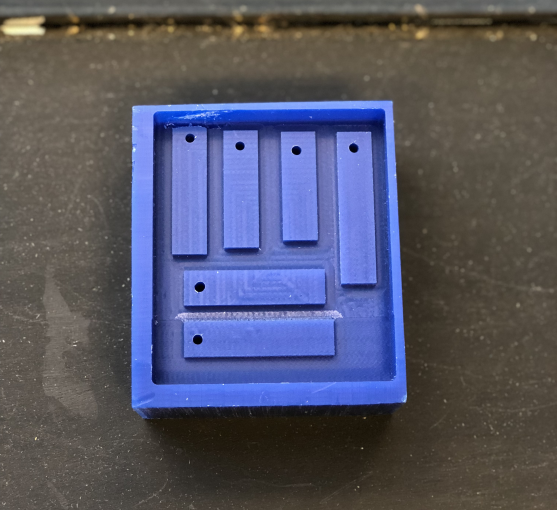

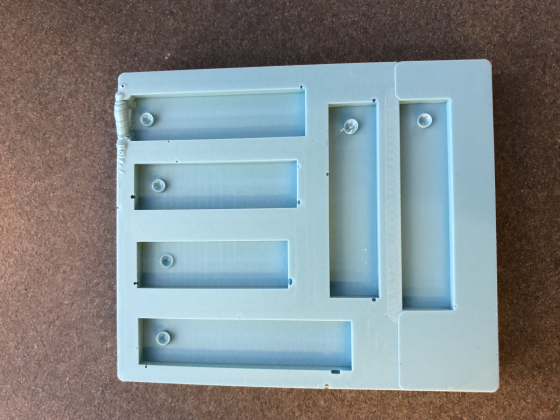

My design this week was relatively simple so I was hoping to get to cast metal but a few problems with the CNC machines put me off that goal. I initially had a hard time getting mods to send any commands to the roland src20 in EDS. This turned out to be because there is a particular order that you need to click through the mods interface to result in the fields autopopulating correctly (at least in the older version of Mods that we needed to use). THis resulted in some confusion on my part as the send field which should have read \bin\lib\lc1 ';' was empty and I didn't immediately see this. Once I either clicked through in the correct sequence or manually filled in the field I had no problem jogging the endmill around etc. Next I had some significant problems finding a dpi value that allowed my smallest features (holes in each bar) to get into the tool path without creating an insanely long mill time. In the end I used a drill to make the holes more uniform.

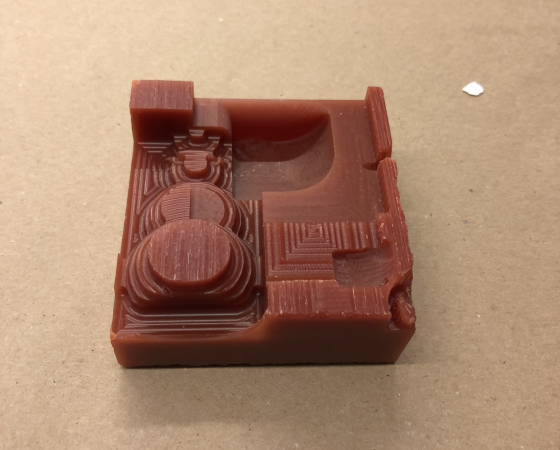

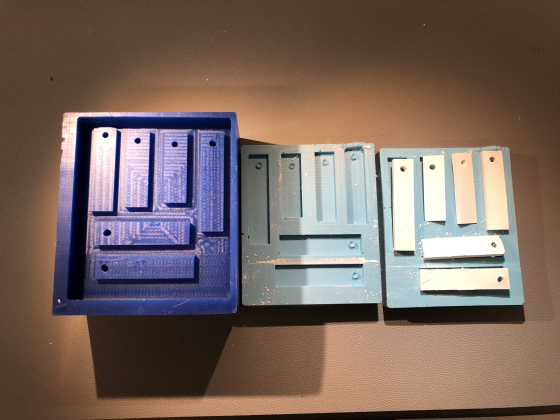

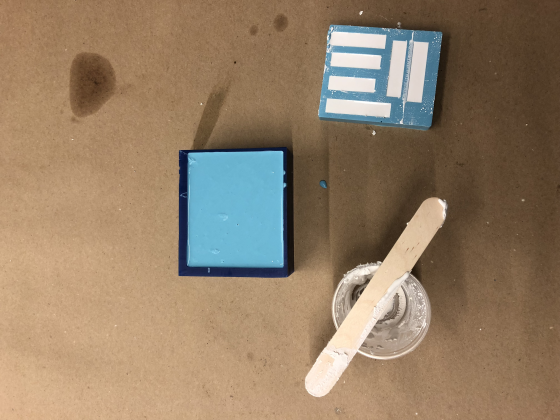

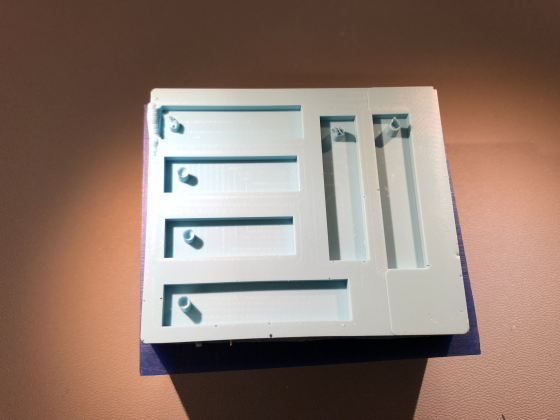

The next problem I had was the Oomoo is difficult to get into very tight spaces. Thus my first oomoo mold did not have the protrusions necessary to get holes in my bars. To get the oomoo to set right I had to push it into the holes using a broken q-tip. Then everything went smoothly. I have to think about how I should scale the dimensions of my molds for my larger metal bars. Perhaps I need to test several sizes to see if I can get any resonance and tune the bars.