Home

Project 4 - 3D Printing

This week, I did a very basic thing - twice!

Goals

Class Assignment:

- Group Assignment: test the design rules for your 3D printer(s)

- Individual Assignment: design and 3D print an object (small, few cm)

that could not be made subtractively

Things I learned

- How to make something with a weird shape - like a hook

- Iterative design is so important. It's good to start early so that I have enough time to find flaws in and improve on what I've made. Sometimes, things just can't be predicted, and the only way to find out if it works is to try it!

- How to use flip text on onshape

The Process + Pics

- Training and Group Assignment

There are two types of printers that we have in the EDS shop, and I tried printing on each. The first is the Sindoh 3D Wox, and to print, we just load an .stl file, orient it, and hit print. Simple. The second printer is the uPrint SE; this one is unique because support structures are created with a secondary plastic that melts away in a 70 degrees Celcius solution bath (pictures below). For this printer, we Add file > Add to pack > General tab > Print. Again, an .stl file is used, and we have to orient it. Also Simple.

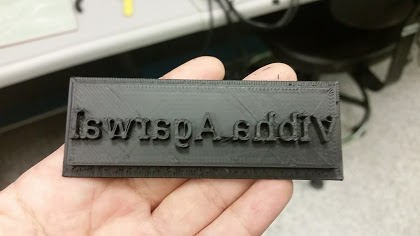

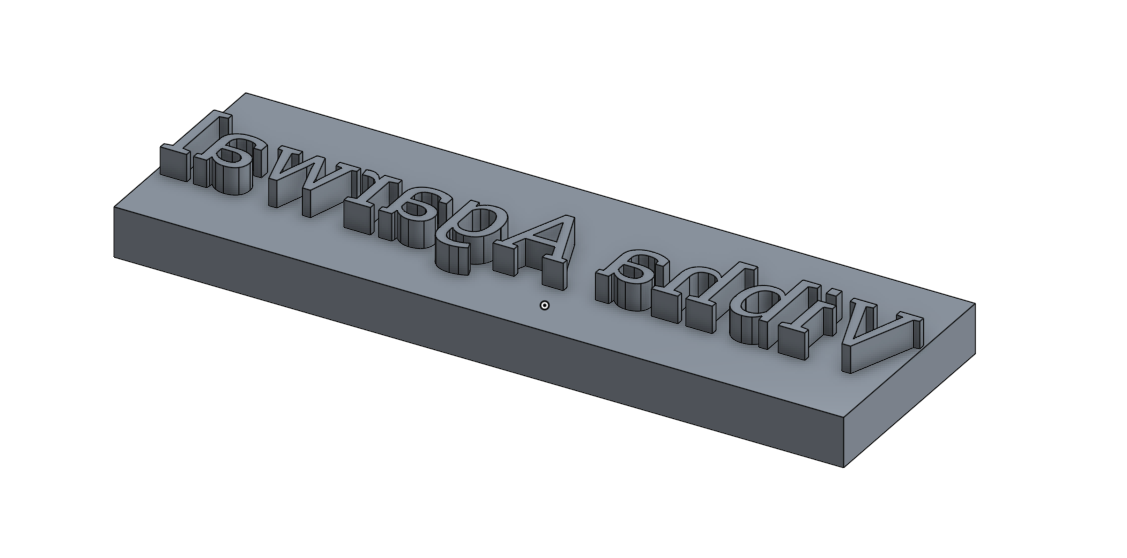

- Making a Stamp

So first I forgot that we had to make something purely additive, and I made a stamp with my name on it (yes, I remembered to make the text backwards). I wanted to find a 3D printer with flex filaments, but couldn't find one in time. Here's what the CAD file looked like, and the finished stamp. I used the Wox to 3D print my stamp. I can't wait to try it out!

- Making a hook

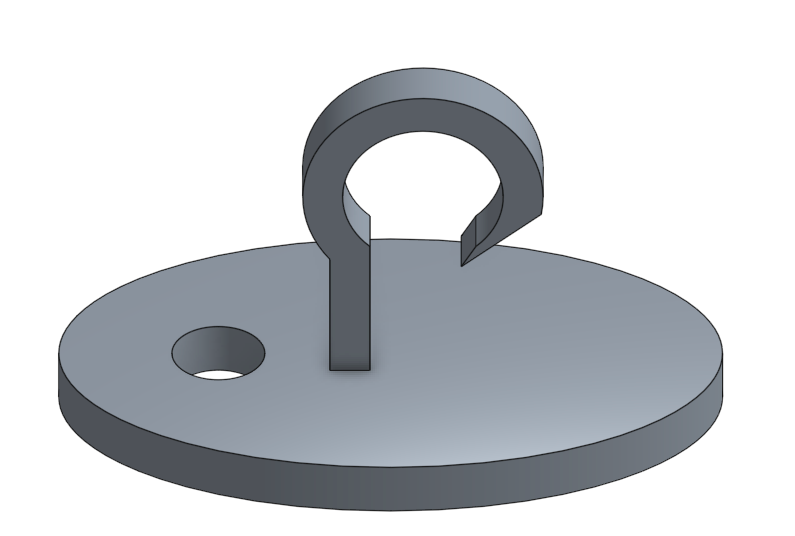

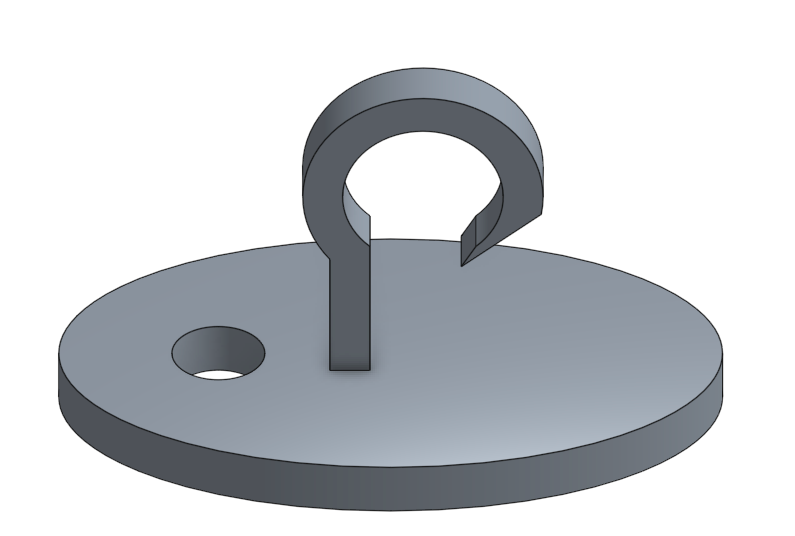

Then, to make something without subtractive processes (the stamp can be made on a CNC machine), I made a hook. It took a while to make the shape on Onshape, because once you make something, you can't modify it much, or move it. This made it hard to combine the base with the hook, and I ended up making an assembly. Here's what the CAD file looked like.

I used the uPrint for this model. I wasn't around when someone moved it to the bath, but I took it out. I had to wear gloves and grab the little metal box that prevented it from getting lost in the bath.

I used the uPrint for this model. I wasn't around when someone moved it to the bath, but I took it out. I had to wear gloves and grab the little metal box that prevented it from getting lost in the bath.

Unfortunately, it was broken. I think the joint between the hook and base just wasn't strong enough.

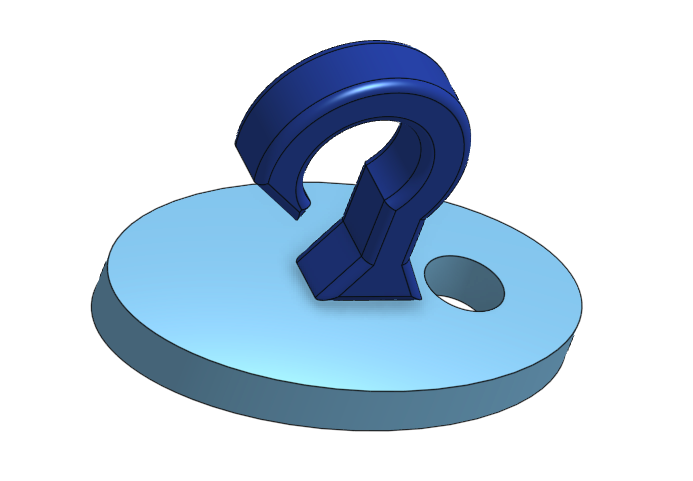

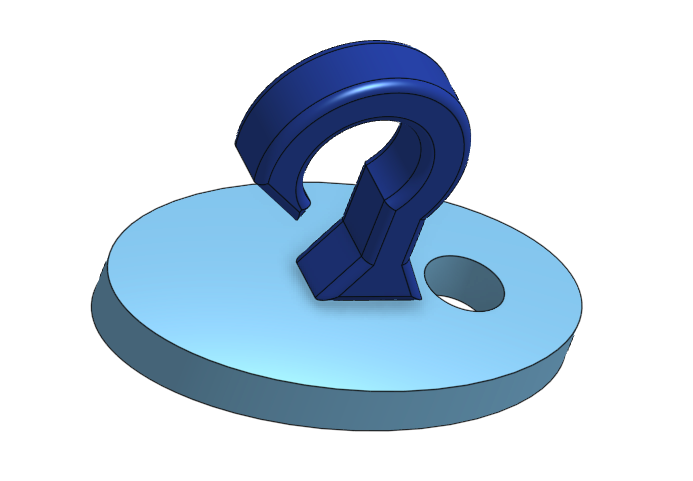

I went back to Onshape to make the hook stronger. Here's the final updated hook.

The shop closed, so I'll have to print it on a later day! But I learned that it's important to iterate on designs.

(EDIT: Overall, I'm not a huge fan of 3D printing, much like Neil. It's a lot of work for something that's usually not that great anyway. Molding and Casting is more fun, and produces better/more consistent results :))

I used the uPrint for this model. I wasn't around when someone moved it to the bath, but I took it out. I had to wear gloves and grab the little metal box that prevented it from getting lost in the bath.

I used the uPrint for this model. I wasn't around when someone moved it to the bath, but I took it out. I had to wear gloves and grab the little metal box that prevented it from getting lost in the bath.

Unfortunately, it was broken. I think the joint between the hook and base just wasn't strong enough.

Unfortunately, it was broken. I think the joint between the hook and base just wasn't strong enough.

I went back to Onshape to make the hook stronger. Here's the final updated hook.

I went back to Onshape to make the hook stronger. Here's the final updated hook.

The shop closed, so I'll have to print it on a later day! But I learned that it's important to iterate on designs.

(EDIT: Overall, I'm not a huge fan of 3D printing, much like Neil. It's a lot of work for something that's usually not that great anyway. Molding and Casting is more fun, and produces better/more consistent results :))

The shop closed, so I'll have to print it on a later day! But I learned that it's important to iterate on designs.

(EDIT: Overall, I'm not a huge fan of 3D printing, much like Neil. It's a lot of work for something that's usually not that great anyway. Molding and Casting is more fun, and produces better/more consistent results :))