Week 8: Output Devices

"Priyanka Learns HOW TO MAKE a Programmable RGB LED Board!"

For my eighth assignment for How to Make (Almost) Anything, I decided to take advantage of the time to actually do something useful for my final project. Since I want this shoe to change colors, shapes, and designs, I realized that learning how to work with RGB LEDs would be a good start.

However, I realized that since I am still very new to embedded programming and embedded systems in general, I should start small and focus on one task for now. Due to my current limited knowledge, I chose to recreate Neil's RGB LED array board, and then see how I can use this model to then create a "Flexible" version of this setup using Kapton flex-harness material (that I scavenged from a factory visit for my research work) and copper tape connecting to the board traces.

But first, I started by milling out Neil's RGB LED board, stuffing it, uploading the provided C and MakeFiles and providing commands via Termainal to the Programmer to the board so that the RGB LED can turn on! Here below is the process in pictures:

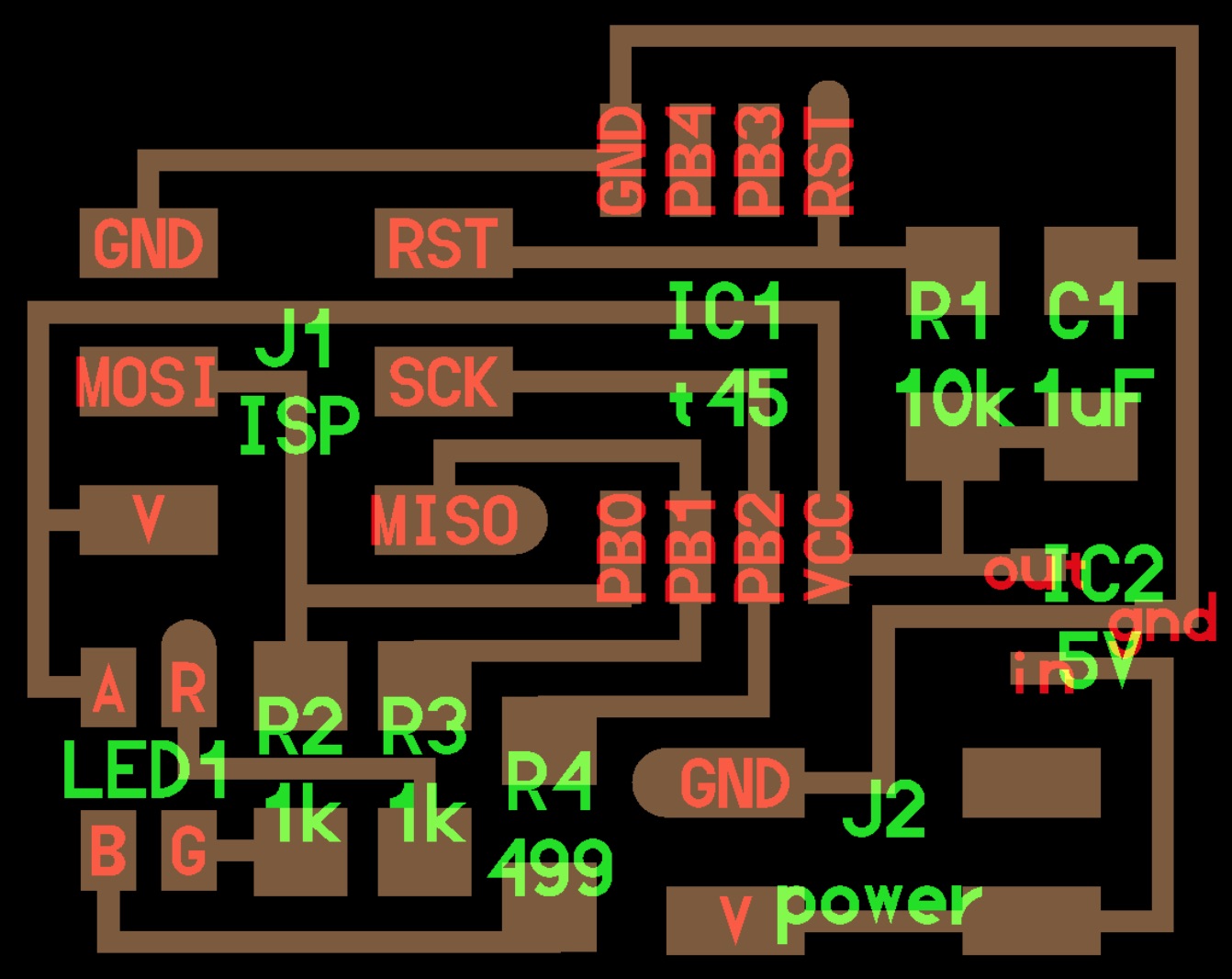

Figure 1: RGB Board Layout on EAGLE

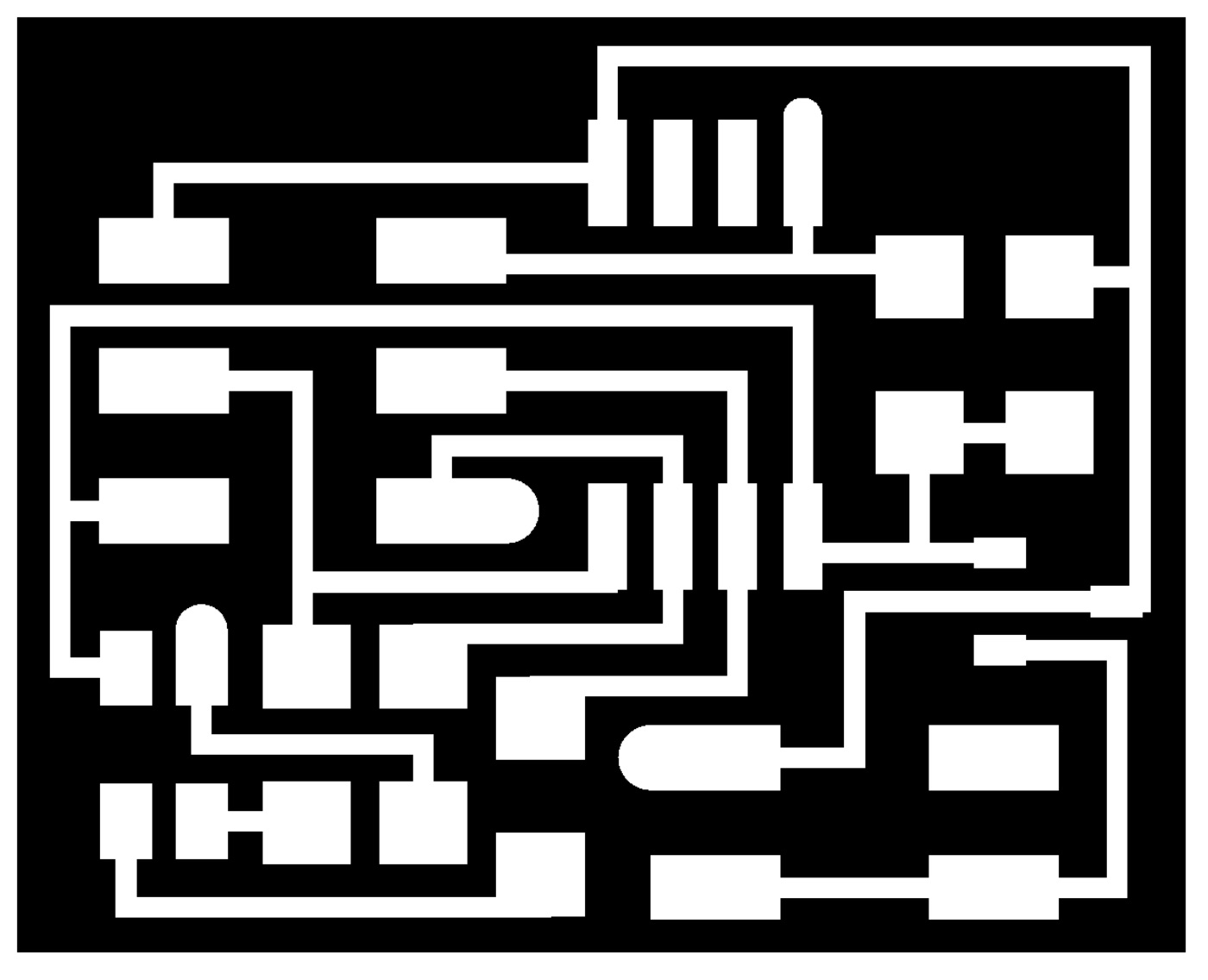

Figure 2: PNG of Trace Layout

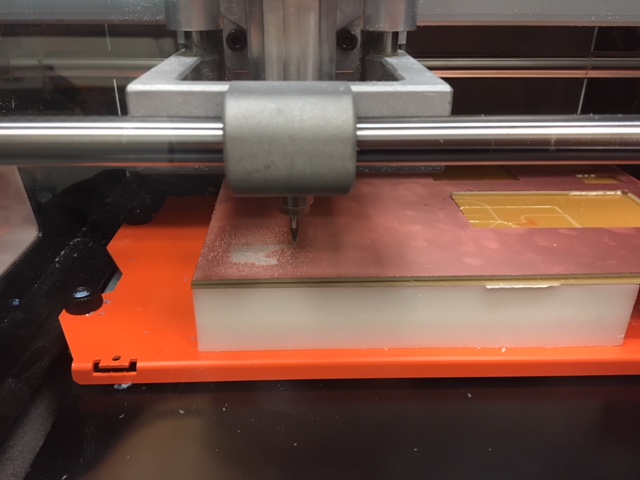

Figure 3: Uploading to Mods and Milling Board on Roland SRM 20

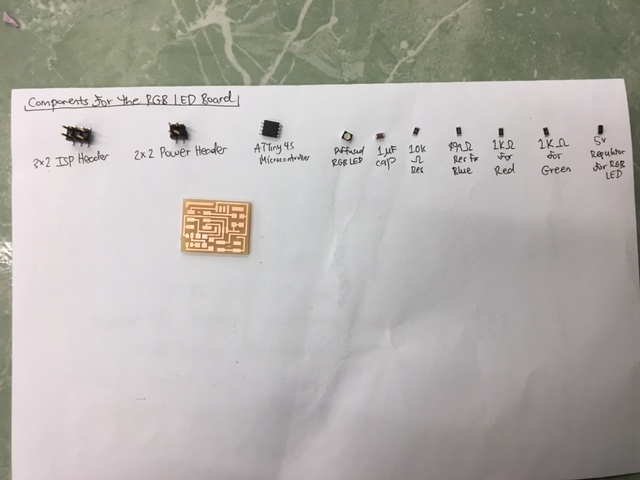

Now it was time for me to get the components from the big components stash in EDS and prepare to have them soldered onto my board!

Figure 5: The Necessary Components Acquired for the Board

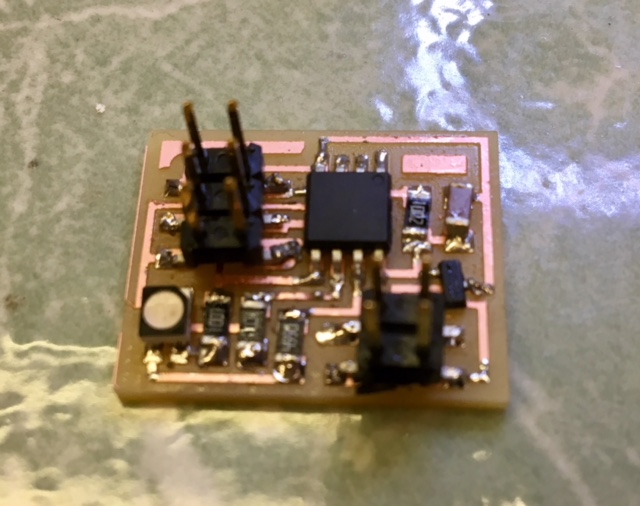

Figure 6: Board Complete and Ready to be Programmed

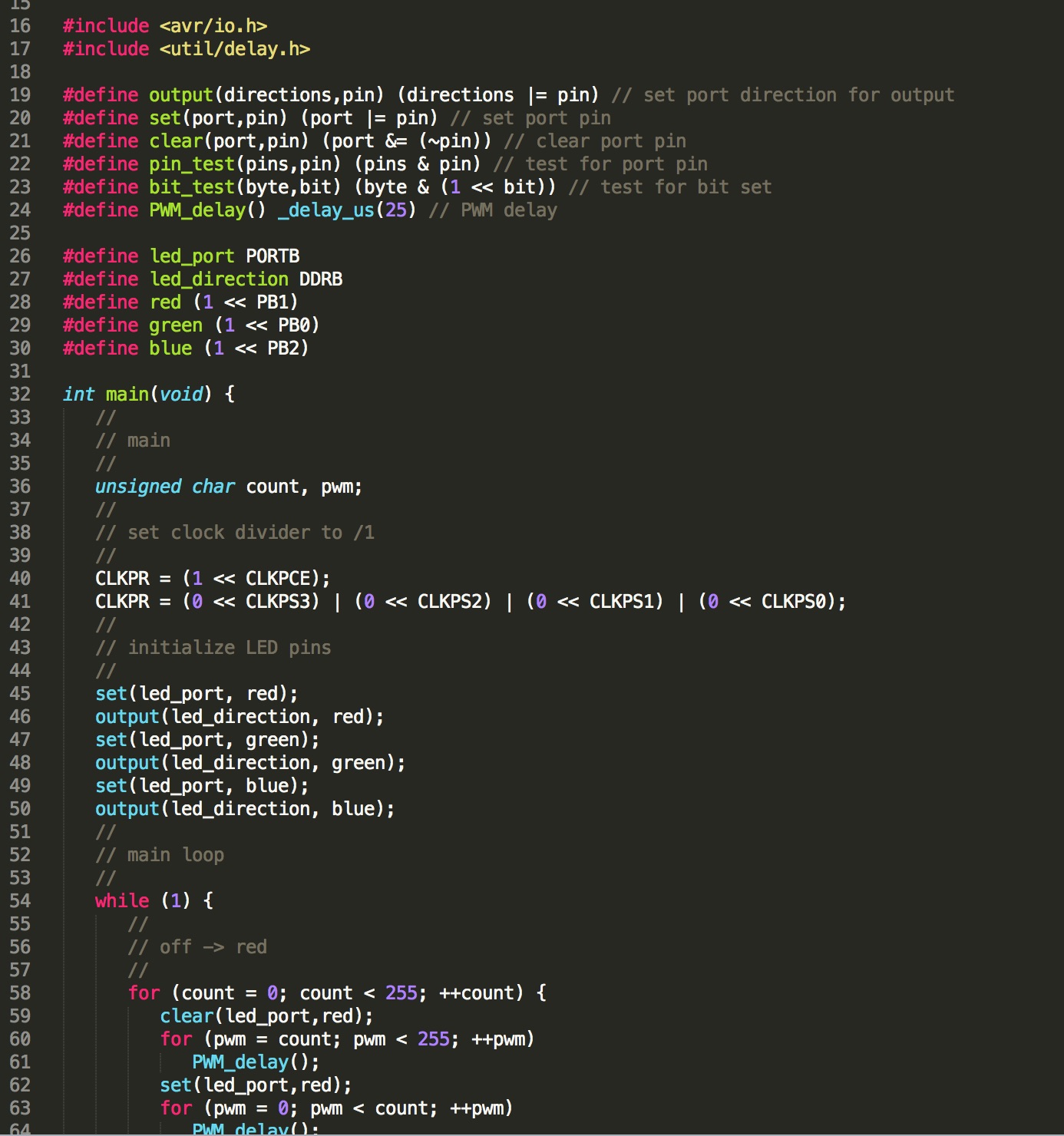

Figure 7: Programming the Board with C and MakeFiles using Terminal Command Line

Figure 8: RGB LED Light is On! (Picture to Come)

Hooray! Here's to my first output device-making experience! Now to continue this work for my final project, so stay tuned!

Update! --> Potential Idea for My Final (or at least an Upcoming) Shoe Project

Near the end of the semester, I went to go talk to Sam Calisch who has worked with inflatable pneumatic bladders with piezoresistive input, and we were able to figure out a potential gameplan for having "comfort sensors" in the sole of the shoe to not only provide the wearer with additional comfort while walking in the shoe, but also information about the gait of the wearer, and thus the ability to then tailor the pneumatic motions of the bladders to ensure continuous use with reduced wear and tear as well as continuous comfort, no matter how long one walks in the shoes. It was quite an exciting conversation, and one that I hope to continue working on after the class ends!