Vinyl Cutting

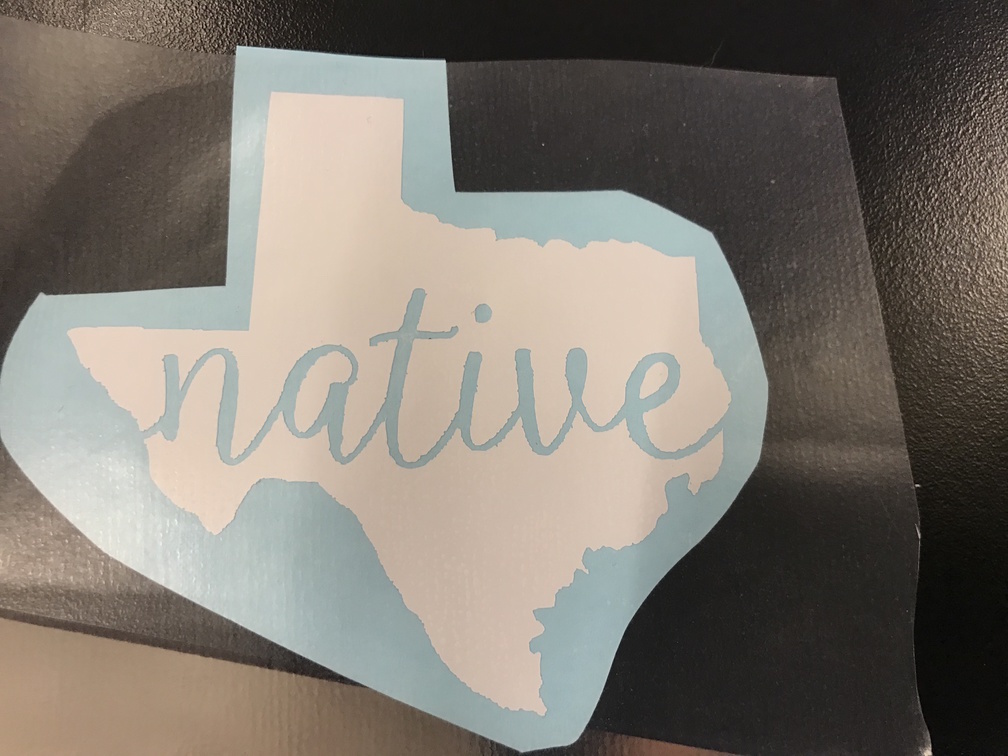

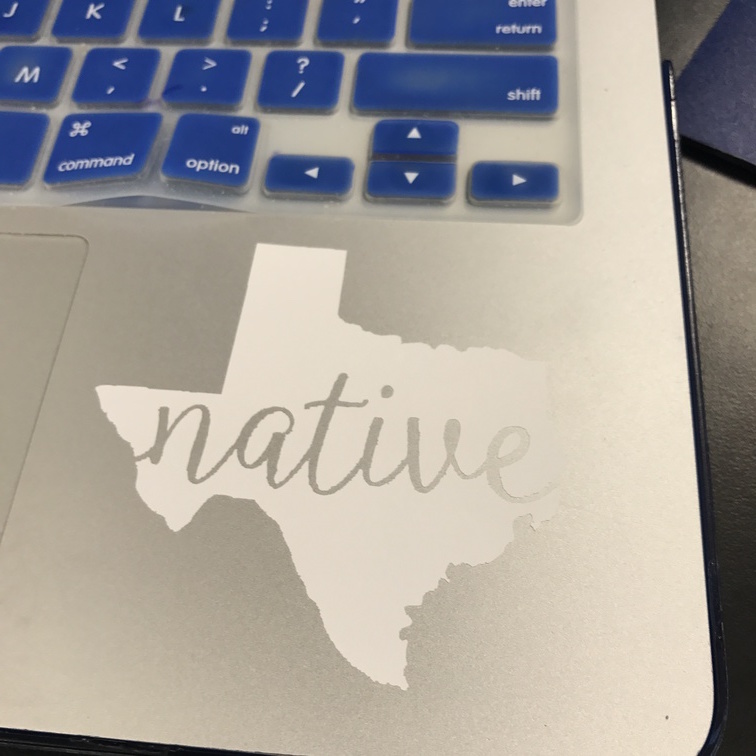

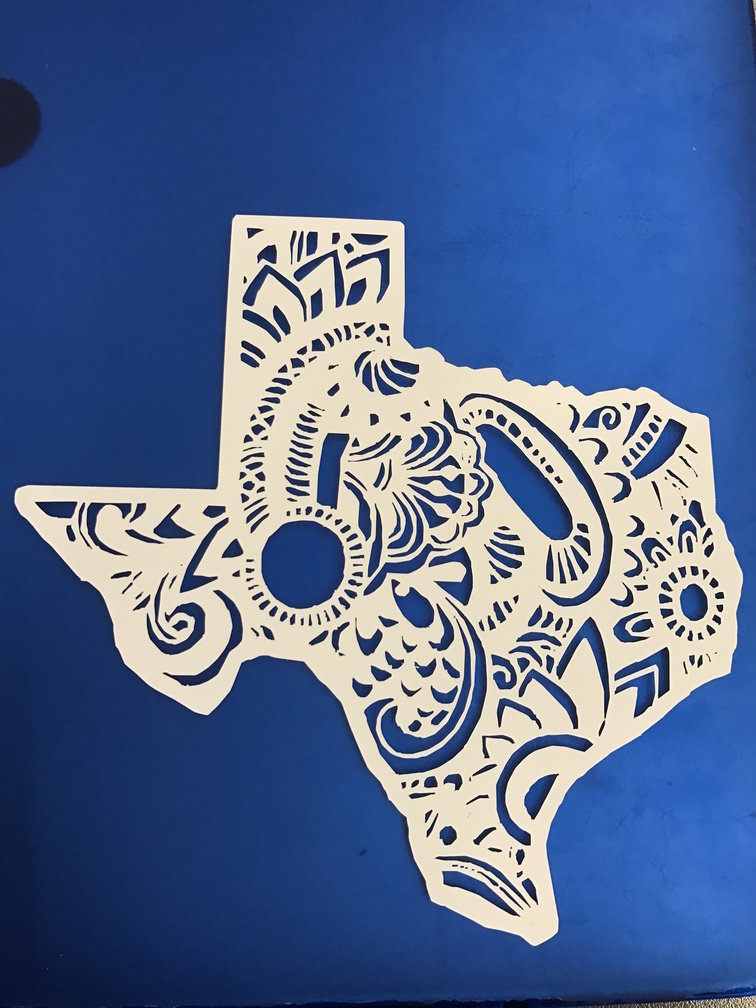

For the vinyl cutting assignment I decided to make laptop stickers inspired by my hometown Austin, Texas. After looking to Pinterst and Etsy for inspiration, I designed two different Texas laptop stickers in Illustrator and converted them to png files.

When first attempting to cut out the stickers, I did not check the setting on the computer. Unfortunately the force was set too low and the blade did not completely cut through the vinyl. After increasing the force after a series of prebuilt test cuts, the stickers were successfully cut.

The "native" Texas sticker was less intricate than the tribal design. The native sticker was weeded straight from the vinyl cutout using needlenose pilers and a poky stick. Afterwards transfer paper was used to move it to my laptop.

The tribal design Texas sticker was significantly more intricate. This time I first transfered the entire sticker to my laptop case before weeding the inside of the Texas shape with the poky stick. Unfortunately some of the intricacies of the design were lost with the increase line weight required by the vinyl cutter.

Laser Cutting

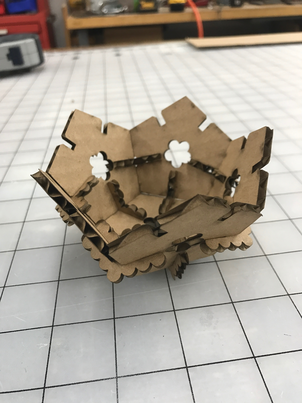

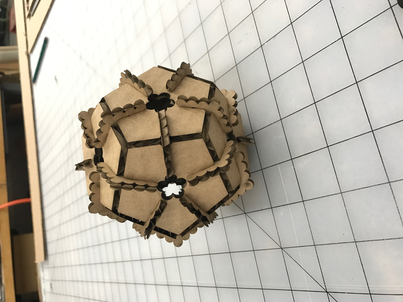

For the laser cutting assignment I decided to make a press fit dodecahedron kit.

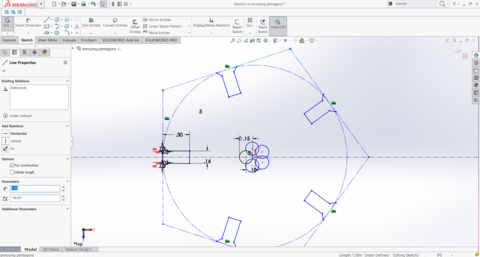

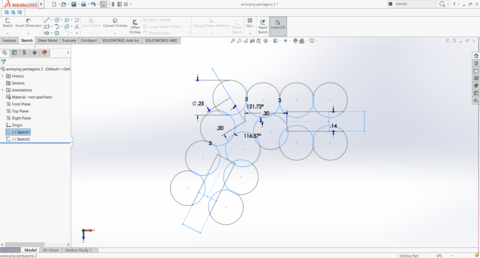

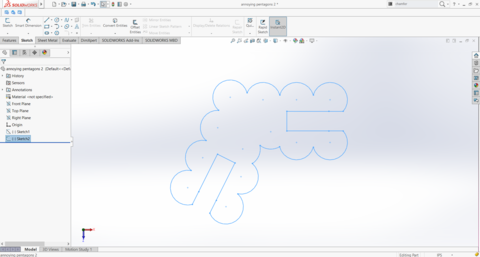

At first I attempted to make the parametric design for this kit in Fusion 360. After several attempts of trying to make edges parallel and setting symmetries, I decided to switch over to SolidWorks as per Dixon's suggestion. In SolidWorks I made the original pentagon shape and locked in the edge size. Then I made the slots for the press fit using the midpoint line to center a rectangle. I used a variable to define the width of this slot, which was changable later, making the design parametric. I added chamfer edges to make the slots easier to put together. I did a circle pattern copy function to make this slot occur on every edge of the pentagon. I also added circles in the middle of the pentagon to give the dodecahedron faces a nice flower pattern. To make the connecting joints, I created a bend at 116 degrees with slots in the same manner. I added scalloped edges for additional flair.

Before cutting the design, I measured the cardboard to be .15 inches thick. I estimated that the kerf on the machine would be .01 inches, so I intially made the press fit slots .14 inches wide. When getting to the laser cutter, I did an intial cut of a pentagon and connector. They fit well together so I did not have to adjust the kerf. Afterwards I cut all the pieces and assembled the dodecahedron.