f i n a l P r o j e c t

Le Gropius is a cement lamp that is turned on and off with capacitance sensors under the cast form. There are multiple hidden sensor pairs and the ATTiny 85 processor inside switches which sensors trigger the on and off everytime it is used.

h a r d w a r e

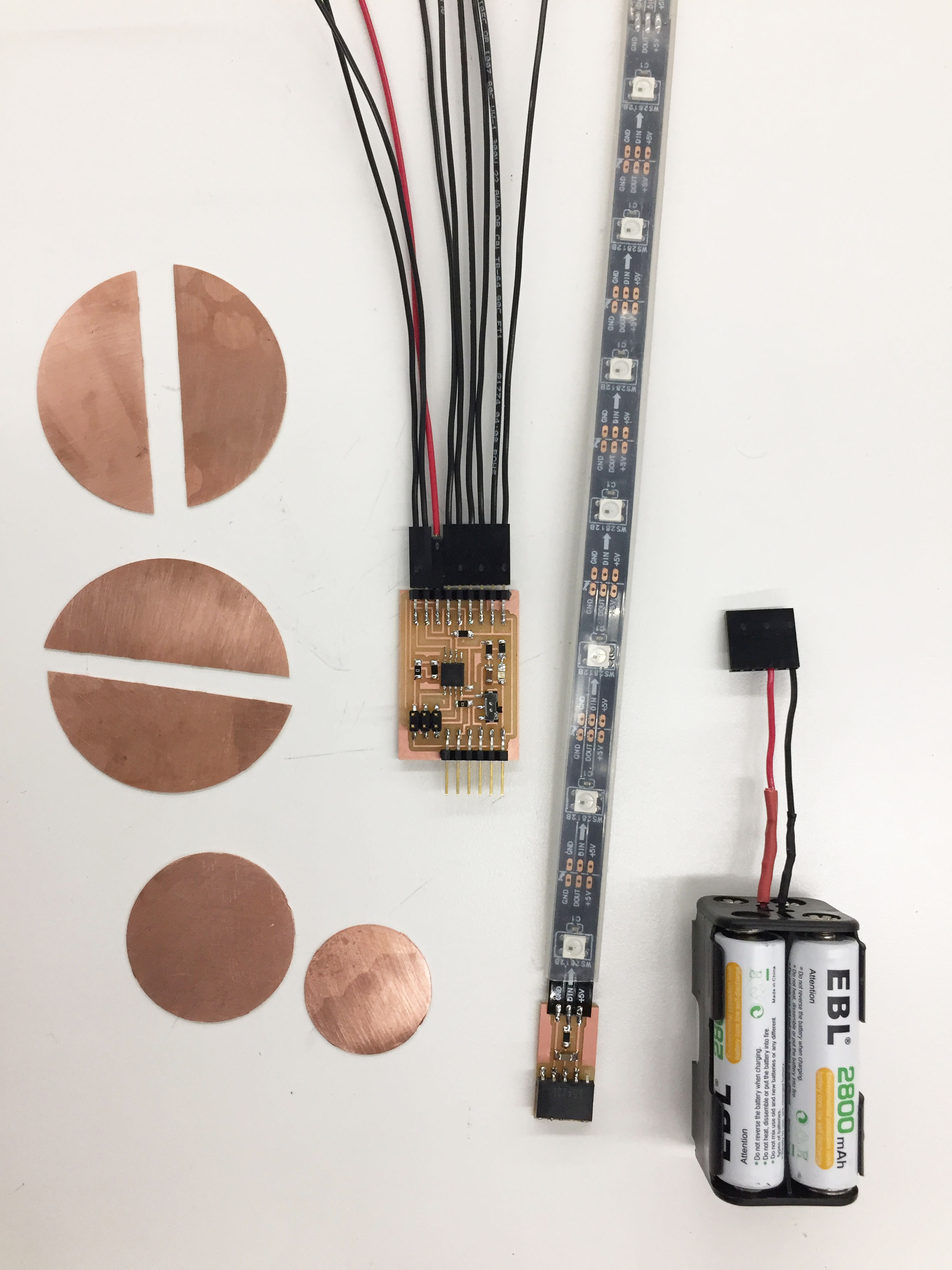

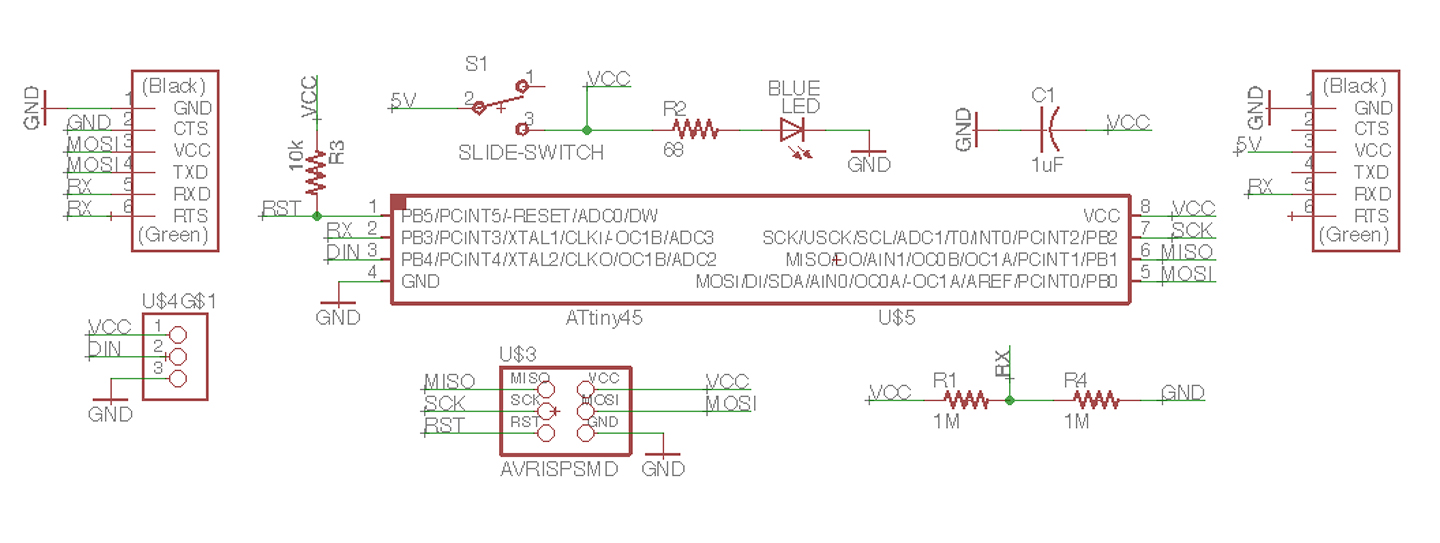

First was the design of the electical components. The board has an ATTiny 85 processor($0.95/single), four resitors($0.10/single), a ceramic capacitor($0.10/single), a LED($0.34/single), a switch($1.00/single), an ISP header($0.43/single), and FTDI header, and 3 headers to connect to the NeoPixel LEDS($16.95), and 6 headers to connect to copper pads. The NeoPixels are connected to a board that has a capacitor, a resistor, and a header for connections.

s o f t w a r e

I used some NeoPixels that I had, from before I learned how to make my own in this class. The hardware was convenient but the setup required more work because they are meant to be plug and play with and Arduino board rather than an ATTing. I found this this tutorial very helpful. The hardest part was calibrating the transmit-recieve step response. It seemed to change values everyting I put the chip back into the block. Looking back I should have figured out a way to sesnse relative change rather than absolute value because the baseline was so volatile.

m o l d i n g

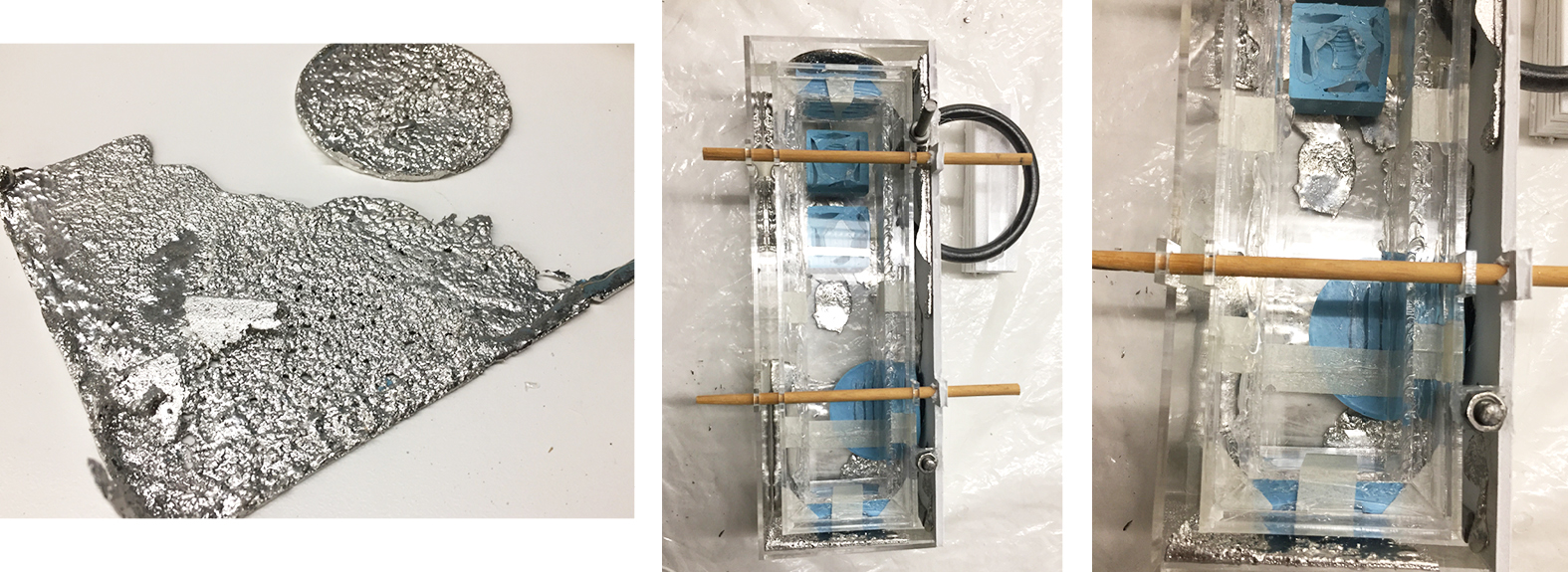

The materiality was inspired by the metal and hydrastone cast I did in the molding and casting week.

The frankenstein mold might be the ugliest thing I have ever made. However, each piece serves a different function. It is made of plexiglass (laser cut and put in locations I needed clarity), foam core (hand cut and put in locations I needed sacrificial material), and Oomu (cast and put in places I needed flexibily and easy demolding). The dowels as the top register and hold the two parts of the mold together. I also made a partial cast of Oomu to do the metal casting. I did some test slab tests and found a 1 square inch of copper can still sense capacitive change through 1/4" of rockite. So some parts had to be super thin to get the sensing.

c a s t i n g

The secret to a good composite cast like this is to do a really bad job on one material and then a really good job on the second material. I first cast metal into the Oomu mold. I didn't use talc and also shook it while it cooled to get a volcanic stone look. I then glued these into the 'frankenstein's monster' mold. Next I carefully weighed and mixed rockite, then poured through the whole mold. Because it's an expanding cement, you do have to top off after the first cast. I learned this during the marterial test. I also cast a steel ring I rolled on a 3-in-1 sheet metal machine into it because rockite is an "anchoring cement" so I wanted to anchor something in there. The GSD just got a Zund so I was able to do an introductory tutorial and cut some copper on it.

Then I added in all the parts. The deep pockets were for the copper pads and the ledges was for the LED strip. Here is is with some lights...