final Project Process

Each week we developed skills torwards a final project. Check of the windy and indecisive road to my final project here. See the actual final project on the Final Project page.

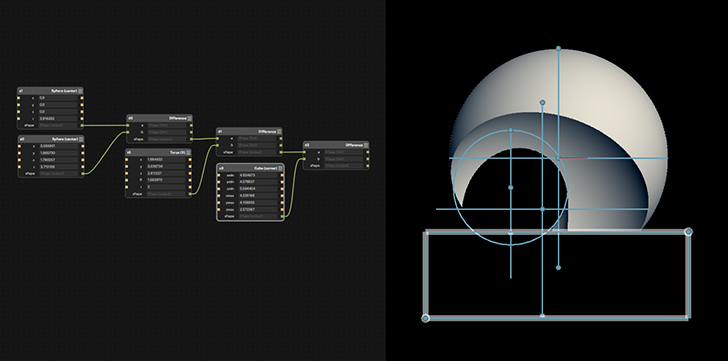

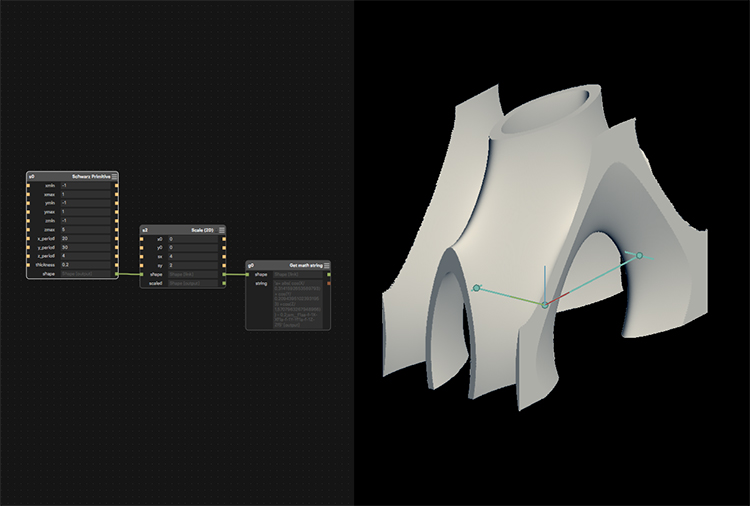

First I used new-to-me software Antimony by Matt Ketter. i Was particularly interested in it's 'fRep' modeling environment which allowed you to extract the mathmatical function of intersected and subtracted shapes. after Playing around and generating forms that could be vaugly interpreted as 'shelter' i dedicated time to decoding the 'get math string' node.

update 01

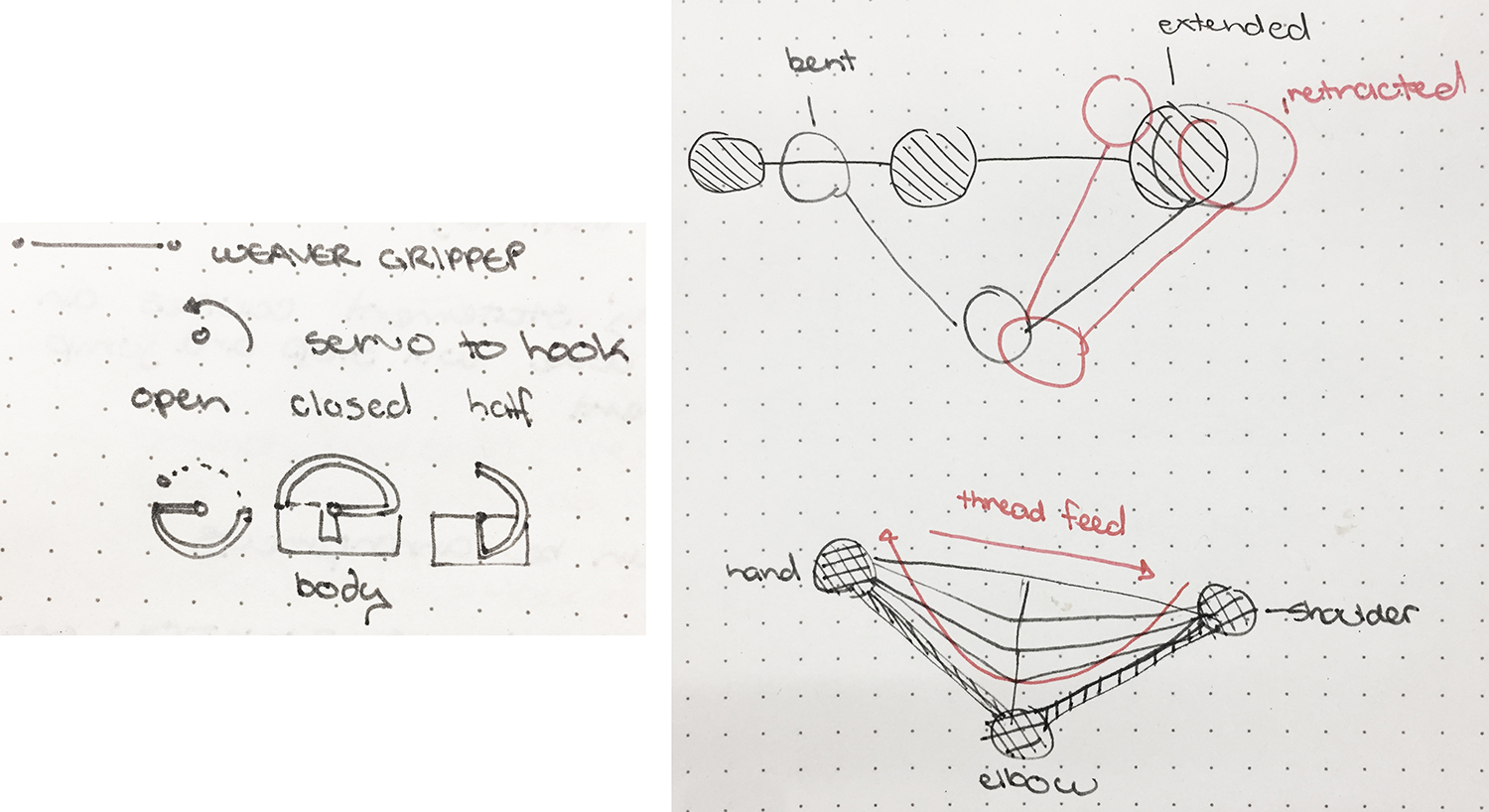

A few weeks later...it Is time to get on track. but First i needed to set it. guided By my background and interest i decided to both complicate and simplify the project. my End goal is two part. the Part i complicated is the method, which starts with creating sets of autonomous robotic end effectors used for weaving. here The word autonomous describes the relationship with the robotic manipulator. using Electronic sensors embedded into a gripper, the actions will react to the material, rather than be controlled by the standard I/Os. the Area i simplified is the output. to Prototype the end effectors, i going to create a simple woven shade structure rather than an enclosed tent. these Are the goals i am setting for this course, although i suspect the project will continue to develop long after the class.

update 02

The final project has been changing every week, but I think it is finally finalized (maybe). It was really important to get the servo running and to be able to send it input to control the movement this week. More details in week8 and week10.

The current plan is to make 2 servo seperate motors boards (on suction cups that are worn as jewelry) that relay with a master board. Each servo will have special attachments for it to hold and release string. I hoping with this i can create a system that can turn a machine (like a robotic manupulator) or a room a person into a weaving/knitting/crocheting contraption.

update 03

I couldn't find anything to exactly show what I want to do but it seems like a combonation of a CNC knitting machine and arm knitting.

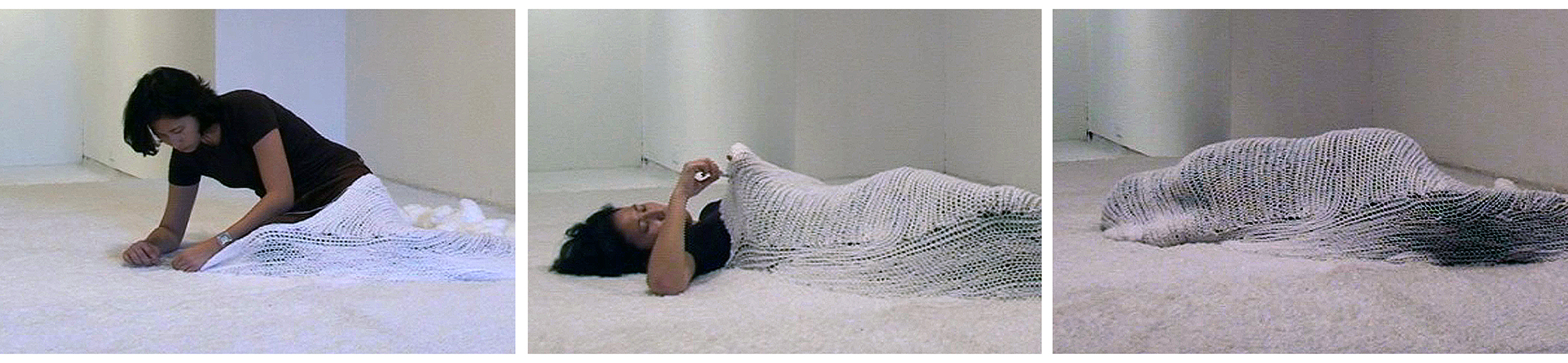

I also found some previous students that have done knitting related machines like a knitting machine, a weaving loom , and a sewing machine . These are great references for the machine half, but I am imagining a wearable verson. Of course the knit will be much less dense for time sake, and technically closer to a weave. I am also drawing a lot of visual (and mood) inspiration from artist Bea Camacho who is pictured below knitting herself into the floor. Just in time for winter finals.

The first sketches...

update 04

During networkiing week, I tried integrating a bluetooth chip to get the two servo boards to communicate.

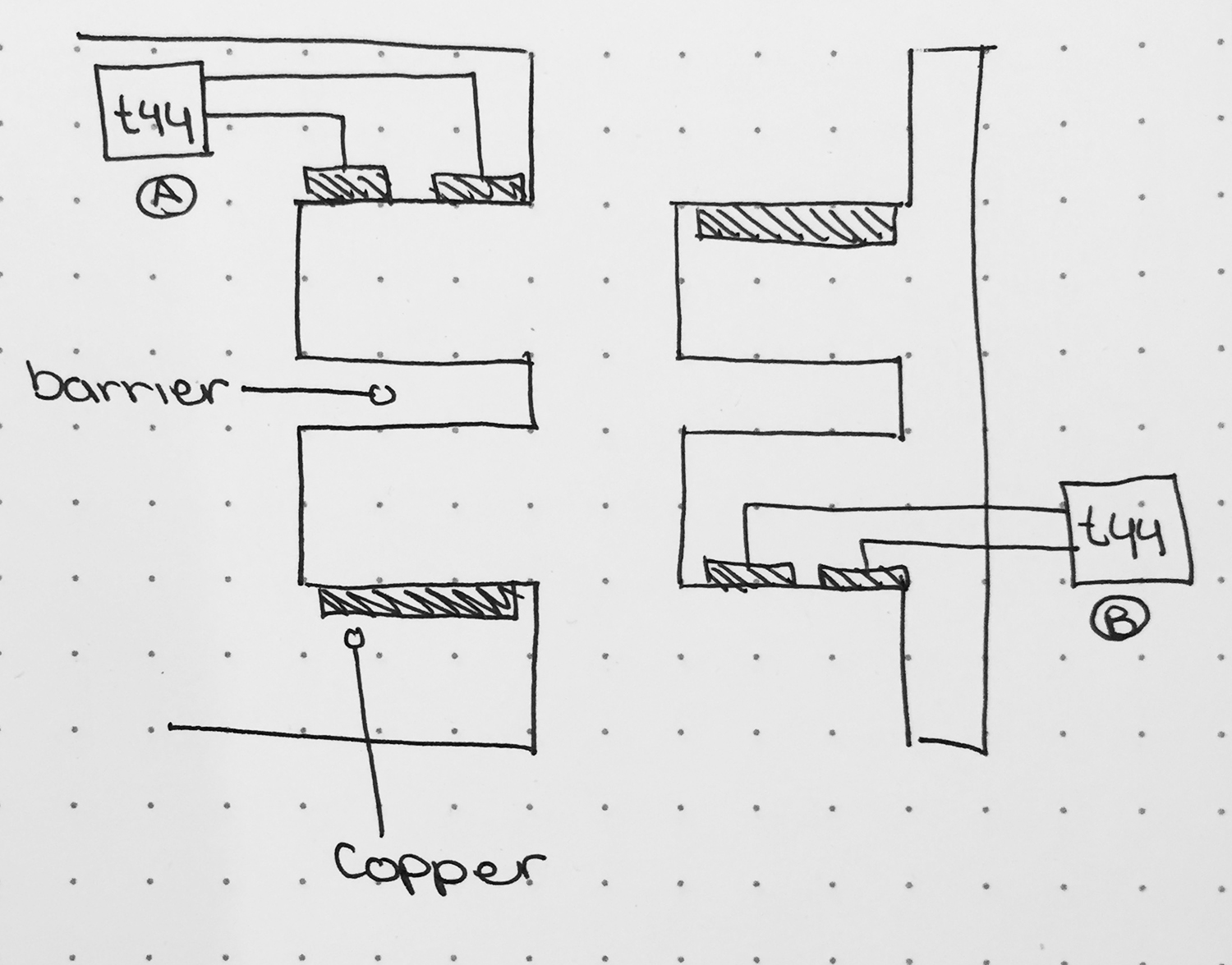

But before I finished the bluetooth setup, I had the idea of using the servo and transmit-recieve step response as the communication between the two boards. Here is the first sketch of that...

This inspired a final project change of plans. So here is my final final project idea: Two pieces of jewelry that can change appereance. One piece of jewelry likes to be distinct, while the other likes to match. When they are in proximity to each other, it uses step response to read the form of the other and react accordingly. If they are in the same form, the "distinctive" piece will activate it's servo to change form. If they are in different forms, the "matcher" piece will activate it's servo to match. Below is the first test if this was even possible. More details are in the week12 page.

update 05

Surprise! I changed my final project again. The problem with a class called "How to Make (Almost) Anything" is that I want to make (almost) everything. My final still uses transmit-recieve step response like the last idea, everything else is new and pulls from casting week. I ended up making a cement lamp, that is turned on and off by capacitence sensors hidden in the cast. See that project on my Final Project page.