m o l d i n g - C a s t i n g

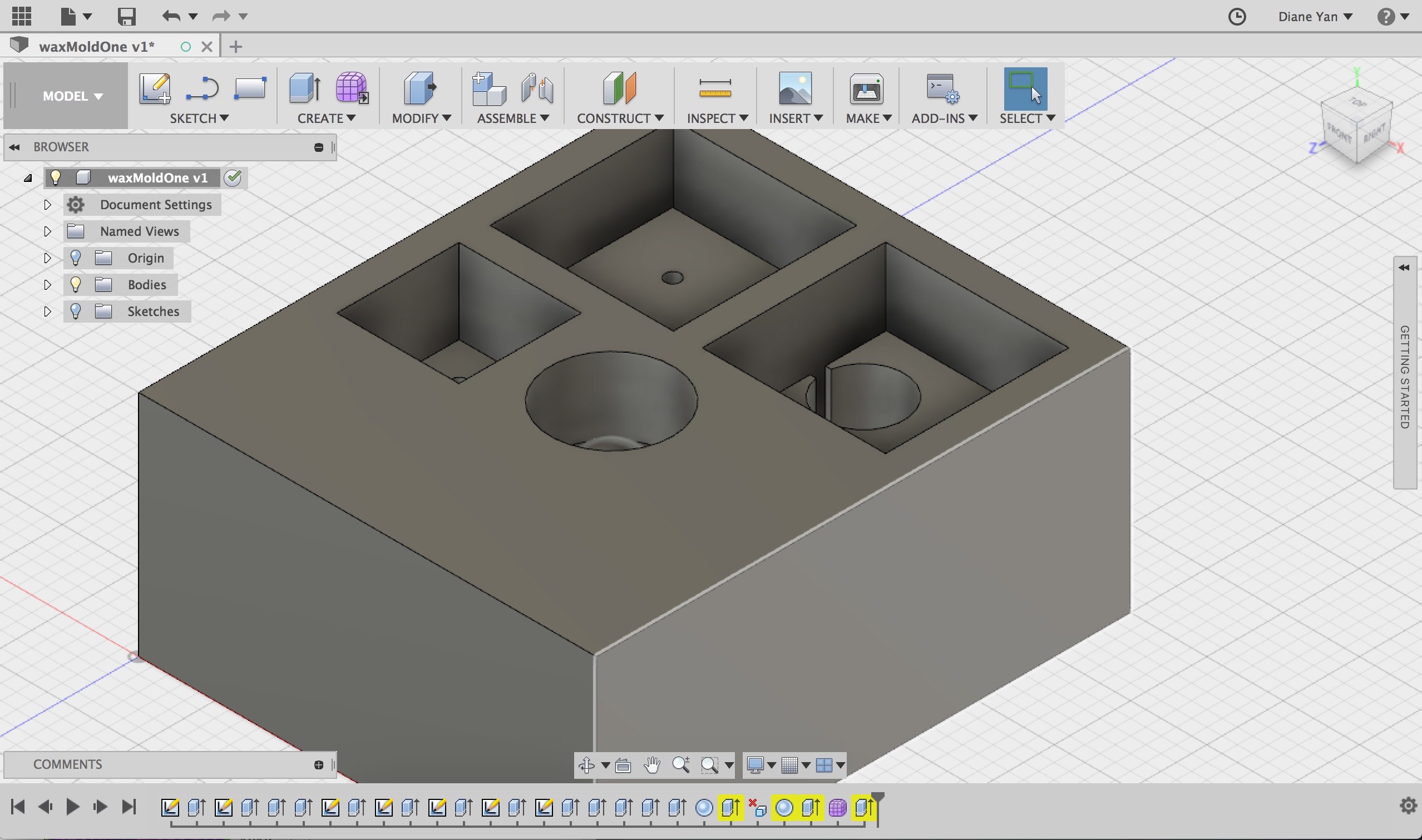

for Molding and casting week, i cast some marble. well Actually, i cast a bithium and tin alloy with gypsum to get the marble appearance. the process began with modeling the positive in (new to me software) Fushion 360.

next, The model was exported to an STL file and imported into VCarve to mill on the Shopbot out of machinable wax. other Than typical issues one runs into when using new software, the makor issue was the end mill melting the wax, causing it to gunk up the bit. this, As i learned, was a result of the too high spindel rate.

next Came the best part, the casting experimentation. i Did one small metal cast and forgot to add the talc. this Produced a very bubbly "volcanic stone" appearance which led me to the idea of "marble casting". i remelted the metal, poured it back into the mold half way up and tilted around while it was still molten, then dumped out the excess in a process that i can only describe as... very-cautious-reckless-abandon. after The metal cooled (about 10 minutes) i mixed up a small batch of gypsum and fill the rest of the mold, making sure to vibrate so it reached all the nooks in the metal.

some Of the final sanded casts below. i Wonder if there is a skin safe top coat finish i can give them before making them into necklaces for friends?